Abstract

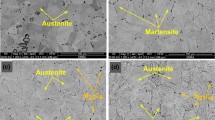

AISI 316H austenitic stainless steel was subjected to equal channel angular pressing (ECAP) at 350°C up to eight passes and the resultant mechanical properties were compared with those obtained after cold rolling as representative for a cold worked state. A high density of thin parallel slip bands was observed inside coarse grains at the beginning of ECAP. Intense micro shear banding took place when pressing was continued by adding more passes. While no martensitic transformation was detected in the microstructure deformation twinning identified to occur at late passes of ECAP. The final microstructure after 8 passes is characterized by a tri-modal grain size distribution with equiaxed ultrafine grains of 176 nm and regions with larger grains of 217–1376 nm surrounded by shear bands containing nano-crystalline grains. Nano twins, 8 nm on average wide, were observed inside the nanocrystalline austenite grains. The observed microstructural features were explained by the stacking fault energy and temperature range for martensitic transformation of the studied material. In terms of mechanical properties, the processed material displayed a combination of very high yield strength exceeding 1550 MPa (close to four times the initial value) and good ductility with deformation εf = 11.6% at failure.

Similar content being viewed by others

REFERENCES

S. Yu. Mushnikova, S. K. Kostin, V. V. Sagaradze, and N. V. Kataev, “Structure, properties, and resistance to stress-corrosion cracking of a nitrogen-containing austenitic steel strengthened by thermomechanical treatment,” Phys. Met. Metallogr. 118, 1155–1166 (2017).

G. G. Yapici, I. Karaman, Z.P. Luo, H.J. Maier, and Y.I. Chumlyakov, “Microstructural refinement and deformation twinning during severe plastic deformation of 316L stainless steel at high temperatures,” J. Mater. Res. 19, 2268–2278 (2004).

R. Z. Valiev, R. K. Islamgaliev, and I. V. Alexandrov, “Bulk nanostructured materials from severe plastic deformation,” Prog. Mater. Sci. 45, 103–189 (2000).

L. S. Vasilev and I.L. Lomaev, “On possible mechanisms of nanostructure evolution upon severe plastic deformation of metals and alloys,” Phys. Met. Metallogr. 101, 386– 392 (2006).

I. G. Brodova, V. I. Zel’dovich, and I. V. Khomskaya, “Structure–Phase Transformations and Properties of Non-Ferrous Metals and Alloys under Extreme Conditions,” Phys. Met. Metallogr. 121, 631– 663 (2020).

A. B. Nayzabekov and I. E. Volokitina, “Effect of the initial structural state of Cr–Mo high-temperature steel on mechanical properties after equal-channel angular pressing,” Phys. Met. Metallogr. 120, 177–183 (2019).

H. Ueno, K. Kakihata, Y. Kaneko, S. Hashimoto, and A. Vinogradov, “Nanostructurization assisted by twinning during equal channel angular pressing of metastable 316L stainless steel,” J. Mater. Sci. 46, 4276–4283 (2011).

S. Scheriau, Z. Zhang, S. Kleber, and R. Pippan, “Deformation mechanisms of a modified 316L austenitic steel subjected to high pressure torsion,” Mater. Sci. Eng., A 528, 2776–2786 (2011).

M. Pisarek, P. Kedzierzawski, M. Janik-Czachor, and K. J. Kurzydlowski, “The effect of hydrostatic extrusion on resistance of 316 austenitic stainless steel to pit nucleation,” Electrochem. Commun. 9, 2463–2466 (2007).

R. Z. Valiev and T. G. Langdon, “Principles of equalchannel angular pressing as a processing tool for grain refinement,” Prog. Mater. Sci. 51, 881–981 (2006).

J. Lu, L. Hultman, E. Holmstrom, K. H. Antonsson, M. Grehk, W. Li, L. Vitos, and A. Golpayegani, “Stacking fault energies in austenitic stainless steels,” Acta Mater. 111, 39–46 (2016).

T. S. Byun, N. Hashimoto, and K. Farrell, “Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels,” Acta. Mater. 52, 3889–3899 (2004).

M. Moallemi, A. Zarei-Hanzaki, and A. Mirzaei, “On the stacking fault energy evaluation and deformation mechanism of sanicro-28 super-austenitic stainless steel,” J. Mater. Eng. Perform. 24, 2335–2340 (2015).

J. Talonen and H. Hanninen, “Formation of shear bands and straininduced martensite during plastic deformation of metastable austenitic stainless steels,” Acta. Mater. 55, 6108–6118 (2007).

S. N. Lezhneva, I. E. Volokitinaa, E. A. Panina, and A. V. Volokitina, “Evolution of the microstructure and mechanical properties of copper during the rolling–ECAP process,” Phys. Met. Metallogr. 121, 689–693 (2020).

Y. T. Zhu and T. G. Langdon, “The fundamentals of nanostructured materials processed by severe plastic deformation,” JOM 56, 58–63 (2004).

R. Z. Valiev, M. Yu. Murashkin, A. V. Ganeev, and N. A. Enikeev, “Superstrength of nanostructured metals and alloys produced by severe plastic deformation,” Phys. Met. Metallogr. 113, 1193–1201 (2012).

ACKNOWLEDGMENTS

The authors would like to thank Warsaw university of technology for their technical support, which made this research possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hajizadeh, K., Kurzydlowski, K.J. Microstructure Evolution and Mechanical Properties of AISI 316H Austenitic Stainless Steel Processed by Warm Multi-Pass ECAP. Phys. Metals Metallogr. 122, 931–938 (2021). https://doi.org/10.1134/S0031918X21300013

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21300013