Abstract

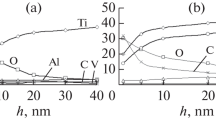

The N+ ion implantation effect on the surface morphology, nitrogen accumulation, formation of chemical compounds, and structural and phase state of 03Kh17N12M2T steel and VT6 titanium alloy surface layers has been investigated. Irradiation with N+ ions results in nitrogen accumulation up to 17 at % in stainless steel, and the formation of chemical compounds, such as CrN, Cr2N, MoN, TiN, and Fe4N, in the form of small clusters with the crater-shaped surface. Nitrogen in the titanium alloy is accumulated up to 32 at % to form titanium nitrides, in particular, TiN, in the form of phase inclusions, distributed over the entire surface. The surface morphology of stainless steel is shown to depend on sputtering processes, while that of titanium alloy is shown to depend on the formation of numerous titanium nitride inclusions.

Similar content being viewed by others

REFERENCES

D. A. Kozlov, B. A. Krit, V. V. Stolyarov, and V. V. Ovchinnikov, “Ion-beam modification of tribological properties of chromium steel,” Fiz. Khim. Obr. Mater., No. 1, 50–53 (2010).

A. R. Sungatulin, V. P. Sergeev, M. V. Fedorishcheva, and O. V. Sergeev, “Influence of treatment with ion beams (Cr + B) of the surface layer of steel 38KhN3MFA on wear resistance,” Izv. Tomskogo Politekhnicheskogo Un-Ta 315, No. 2, 134–137 (2009).

S. N. Bratushka and L. V. Malikov, “Ion-plasma modification of titanium alloys,” Vopr. At. Nauki Tekh., No. 6, 126–140 (2011).

V. V. Ovchinnikov, E. V. Makarov, and N. V. Gushchina, “Austenite formation in α-phase Fe–Mn alloy after cold plastic working and fast heating by an Ar+ ion beam to 299°C,” Phys. Met. Metallogr. 120, No. 12, 1207–1212 (2019).

A, Gulyaev, Metal Science, 7th ed. (Metallurgiya, Moscow, 2015) [in Russian].

E. V. Shelekhov and T. A. Sviridova, “Programs for X‑ray analysis of polycrystals,” Met. Sci. Heat Treat., No. 8, 309–313 (2000).

R. Berish, Sputtering of Solids Using Ion Bombardement (Mir, Moscow, 1984) [in Russian].

https://srdata.nist.gov/xps/EnergyTypeValSrch.aspx.

Y. Shi, Siyuan Long, L. Fang, F. Pan, and H. Liao, “Effects of N2 content and thickness on CrNx coatings on Mg alloy by the planar DC reactive magnetron sputtering,” Appl. Surf. Sci. 255, 6515–6524 (2009).

H. Dong, S. He, X. Wang, C. Zhang, and D. Sun, “Study on conductivity and corrosion resistance of N‑doped and Cr/N co-doped DLC films on bipolar plates for PEMFC,” Diamond Relat. Mater. 110, 108156 (2020).

Z. N. Jaf, Z.-T. Jiang, H. A. Miran, M. Altarawneh, J.‑P. Veder, M. Minakshi, Z-f. Zhou, H. N. Lim, N. M. Huang, and Z. Bogdan, “Dlugogorski Physico-chemical properties of CrMoN coatings—combined experimental and computational studies,” Thin Solid Films, 137671 (2020).

Y. Jiang, X. Zhang, A. Al Mehedi, M. Yang and J.‑P. Wang, “A method to evaluate α"-Fe16N2 volume ratio in FeN bulk material by XPS,” Mater. Res. Express 2, 1–8 (2015).

S. M. Reshetnikov, O. R. Bakieva, E. M. Borisova, V. L. Vorob’ev, F. Z. Gil’mutdinov, T. S. Kartapova, and V. Ya. Bayankin, “Effect of nitrogen ion implantation on corrosion-electrochemical and other properties of Armco-iron. Part II. Corrosion-electrochemical behavior of Armco-iron samples implanted with nitrogen ions,” Korroziya: Mater., Zashch., No. 4, 1–8 (2017).

ACKNOWLEDGMENTS

The research was carried out at the “Center for Physical and Physicochemical Methods of Analysis, Research of Properties and Characteristics of Surfaces, Nanostructures, Materials, and Products,” Udmurt Federal Research Center of the Ural Branch of the Russian Academy of Sciences.

Funding

This work was performed within the scope of a State Task of the Ministry of Education and Science of the Russian Federation (task no. 121030100002-0).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Vorob’ev, V.L., Bykov, P.V., Kolotov, A.A. et al. Formation of Surface Layers of Stainless Steel and Titanium Alloy by N+ Ion Implantation. Phys. Metals Metallogr. 122, 1213–1219 (2021). https://doi.org/10.1134/S0031918X21120139

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21120139