Abstract

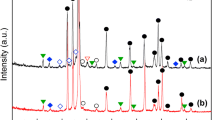

It is widely recognized that subgrain size has significant effect on the strength and ductility of metals. To improve the industrialization of the serve plastic deformations (SPD) technology for magnesium alloys, a new composite extrusion (shortened further as “ES”in this paper) has been employed. The components of ES die have been designed and manufactured and installed to the horizontal extruder for industry. The evolutions of microstructure and texture during the ES process have been studied. The results showed that fine and uniform microstructures can be achieved by Extrusion-Shear (ES) technique and a variety of types of texture can also be found in microstructures, which could weaken the dominant of base texture for (0002). From X-ray diffraction analysis it follows that the (0002) basal plane texture intensity has decreased, and there was found a continuous dynamic recrystallization happening during ES deformation. The research results showed that the ES process can produce a serve plastic deformation and improve the recrystallization of the grain and refine the grains,and weaken the dominant position of the base surface texture.

Similar content being viewed by others

REFERENCES

Hui Zhang, Qiqi Yan, and Luoxing Li, “Microstructures and tensile properties of AZ31 magnesium alloy by continuous extrusion forming process,” Mater. Sci. Eng., A 486, 295–299 (2008).

Liu Tian-mo, Lu Li-wei, and Peng Jian, CH Patent No. 200720124969.5, 20070814.

Liu Tian-mo, Zhang Yu, and Zhang Li, CH Patent No. 200710092779.4, 20070928.

Wenbo Du, Yaling Qin, Zhenjie Yan, and Tieyong Zuo, “Effects of severe plastic deformation on microstructure and property of magnesium alloys, rare metal materials and engineering,” Rare Met. Mater. Engin. 38, 1870–1876 (2009).

K. Matsubara, Y. Miyahara, Z. Horita, and T.G. Langdon, “Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP,” Acta Mater. 51 3073−3084 (2003).

Hu Hongjun, Zhang Dingfei, and Zhang JunPing, “Numerical and physical simulation of new SPD method combining extrusion and equal channel angular pressing for AZ31 magnesium alloy,” Trans. Nonferrous Met. Soc. China 20, 478–483 (2010).

Hu Hongjun, Zhang Dingfei, Yang MingBo, and Deng Ming, “Grain refinement in AZ31 magnesium alloy rod fabricated by an extrusion-shearing severe plastic deformation process”, Trans. Nonferrous Met. Soc. China 21, 243–249 (2011).

Chen Zhenhua, Wrought Magnesium Alloys (Chemical Industry Press, Beijing, 2005) [in Chinese].

Y. Yoshida, H. Yamada, S. Kamado, and Y. Kojima, “Microstructures and tensile properties of ECAE processed Mg–Al–Zn alloys” J. Jpn. Inst. Light Metals 51, 556–562 (2001).

Meng Li, Yang Ping, Cuifeng E. et al., “Analysis on behavior of dynamic recrystallization in magnesium alloy AZ31 by orientation mapping,” J. Univ. Sci. Technol. Beijing 27, 187–192 (2005).

Zhang Dingfei, Liu Jiehui, Hu Hongjun, Shi Guoliang, and Dai Qingwei, “Microstructure and texture evolution of AZ31 magnesium alloy processed by extrusion-shear technique,” J. Mater. Eng. 326 (7), 24–28 (2010).

Hu Hongjun, Zhang Dingfei, Yang MingBo, and Deng Ming, “Research and validation of a new severe plastic deformation technology for magnesium alloys,” Rare Met. Mater. Eng. 39, 2147–2151 (2010)].

Li Yuan-Yuan, Liu Ying, NgaitgiLeo et al., “Effects of the die angle on the microstructures and mechanical properties of AZ31 magnesium alloy processed by equal channel angular pressing,” Trans. Nonferrous Met. Soc. China 14 (1), 53−58 (2004).

Y. H. Chung, J. W. Park, and K. H. Lee, “An analysis of accumulated deformation in the equal channel angular rolling (ECAR) process,” Met. Mater. Int. 12, 289−293 (2006).

H. R. Song, Y. S. Kim, and W. J. Nam, “Mechanical properties of ultrafine grained 5052 Al alloy produced by accumulative roll-bonding and cryogenic rolling”, Met. Mater. Int. 12, 7−13 (2006).

H. Watanabe, H. Tsutsui, and T. Mukai, K. Ishikawa, Y. Okanda, M. Kohzu, and K. Higash, “Grain size control of commercial wrought Mg–Al–Zn alloys utilizing dynamic recrystallization,” Mater. Trans. JIM 42, 1200-1205 (2001).

D. Orlov, G. Raab, T. T. Lamark, M. Popov, and Yu. Estrin, “Improvement of mechanical properties of magnesium alloy ZK60 by integrated extrusion and equal channel angular pressing,” Acta Mater. 59, 375–385 (2011).

ACKNOWLEDGMENTS

This work was supported by the open fund for Key Laboratory of Manufacture and Test Techniques for Automobile Parts (Chongqing University of Technology) Ministry of Education in 2013, and foundation of the post doctorate in Chongqing city and Project Number is Xm201327, and China Postdoctoral Science Foundation funded project, and Chongqing Natural Science Foundation Project of cstc2014jcyjA50004.

Author information

Authors and Affiliations

Corresponding author

Additional information

1The article is published in the original.

Rights and permissions

About this article

Cite this article

Hu, H.J., Sun, Z. Microstructure Evolution during Extrusion-Shear Process of as Cast AZ31 Magnesium Alloy. Phys. Metals Metallogr. 119, 627–633 (2018). https://doi.org/10.1134/S0031918X18040099

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18040099