Abstract

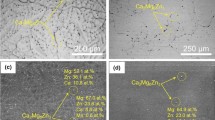

The microstructure, texture, residual stress, and tensile properties of Mg–6Zn–2Y–1La–0.5Zr (wt%) magnesium alloy were investigated before and after extrusion process, which performed at 300 °C and 400 °C. The microstructural characterizations indicated that the as-cast alloy was comprised of α-Mg, Mg–Zn, Mg–Zn–La, and Mg–Zn–Y phases. During homogenization at 400 °C for 24 h, most of the secondary phases exhibited partial dissolution. Extrusion process led to a remarkable grain refinement due to dynamic recrystallization (DRX). The degree of DRX and the DRXed grain size increased with increasing extrusion temperature. The homogenized alloy did not show a preferential crystallographic orientation, whereas the extruded alloys showed strong basal texture. The extrusion process led to a significant improvement on the compressive residual stress and mechanical properties. The alloy extruded at 300 °C exhibited the highest basal texture intensity, the compressive residual stress and hardness, and yield and tensile strengths among the studied alloys.

Similar content being viewed by others

References

M. Kiani, I. Gandikota, M. Rais-Rohani, K. Motoyama, J. Magnes, Alloys 2, 99 (2014)

M. Bamberger, G. Dehm, Annu. Rev. Mater. Res. 38, 505 (2008)

L.L. Rokhlin, Magnesium Alloys Containing Rare Earth Metals: Structure and Properties (CRC Press, Boca Raton, 2003)

Q.S. Yang, B. Jiang, Z.J. Yu, Q.W. Dai, S.Q. Luo, Acta Metall. Sin (Engl. Lett.) 28, 1257 (2015)

T. Tu, X.H. Chen, J. Chen, C.Y. Zhao, F.S. Pan, Acta Metall. Sin. (Engl. Lett.) 32, 23 (2019)

C. Ma, M. Liu, G. Wu, W. Ding, Y. Zhu, Mater. Sci. Eng. A 349, 207 (2003)

H. Yu, Y.M. Kim, B.S. You, H.S. Yu, S.H. Park, Mater. Sci. Eng. A 559, 798 (2013)

H.T. Zhou, Z.D. Zhang, C.M. Liu, Q.W. Wang, Mater. Sci. Eng. A 445–446, 1 (2007)

Z. Zhang, X. Liu, W. Hu, J. Li, Q. Le, L. Bao, Z. Zhu, J. Cui, J. Alloys Compd. 624, 116 (2015)

J.B. Zhang, L.B. Tong, C. Xu, Z.H. Jiang, L.R. Cheng, S. Kamado, H.J. Zhang, Mater. Sci. Eng. A 708, 11 (2017)

X. Fang, S. Lü, J. Wang, X. Yang, S. Wu, Mater. Sci. Eng. A 699, 1 (2017)

S.H. Park, B.S. You, R.K. Mishra, A.K. Sachdev, Mater. Sci. Eng. A 598, 396 (2014)

X. Lu, G. Zhao, J. Zhou, C. Zhang, L. Chen, S. Tang, J. Alloys Compd. 732, 257 (2018)

P.J. Withers, Rep. Prog. Phys. 70, 2211 (2007)

L. Commin, M. Dumont, R. Rotinat, F. Pierron, J.E. Masse, L. Barrallier, Mater. Sci. Eng. A 551, 288 (2012)

T. Hosaka, S. Yoshihara, I. Amanina, B.J. MacDonald, Procedia Eng. 184, 432 (2017)

C. Wang, T. Luo, J. Zhou, Y. Yang, Mater. Sci. Eng. A 722, 14 (2018)

EN ISO 6892-1, Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature (ISO 6892-1:2009) (European Committee for Standardization, n.d.)

A. Lan, L. Huo, Mater. Sci. Eng. A 651, 646 (2016)

J.Y. Lee, D.H. Kim, H.K. Lim, D.H. Kim, Mater. Lett. 59, 3801 (2005)

S. Luo, A. Tang, F. Pan, K. Song, W. Wang, Trans. Nonferrous Met. Soc. China 21, 795 (2011)

M. Mezbahul-Islam, A.O. Mostafa, M. Medraj, J. Mater. 2014, e704283 (2014)

H. Zengin, Y. Turen, H. Ahlatci, Y. Sun, J. Mater. Eng. Perform. 27, 389 (2018)

L. Liu, X. Chen, F. Pan, Z. Wang, W. Liu, P. Cao, T. Yan, X. Xu, Mater. Sci. Eng. A 644, 247 (2015)

Z.C. Hildebrand, M. Qian, D.H. StJohn, M.T. Frost, in (Minerals, Metals & Materials Society (TMS), 2004)

J.D. Robson, C. Paa-Rai, Acta Mater. 95, 10 (2015)

H. Zengin, Y. Turen, H. Ahlatci, Y. Sun, I.H. Kara, Key Eng. Mater. 750, 118 (2017)

Y. Du, M. Zheng, X. Qiao, W. Peng, B. Jiang, Mater. Sci. Eng. A 673, 47 (2016)

M.L. Huang, H.X. Li, H. Ding, J.W. Zhao, S.M. Hao, J. Alloys Compd. 612, 479 (2014)

N.G. Ross, M.R. Barnett, A.G. Beer, Mater. Sci. Eng. A 619, 238 (2014)

M. Shahzad, L. Wagner, Mater. Sci. Eng. A 506, 141 (2009)

A.H. Ammouri, G. Kridli, G. Ayoub, R.F. Hamade, J. Mater. Process. Technol. 222, 301 (2015)

C.I. Chang, C.J. Lee, J.C. Huang, Scr. Mater. 51, 509 (2004)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena (Elsevier, Amsterdam, 2012)

J.D. Robson, D.T. Henry, B. Davis, Acta Mater. 57, 2739 (2009)

Y.N. Wang, J.C. Huang, Mater. Chem. Phys. 81, 11 (2003)

N. Stanford, M.R. Barnett, Mater. Sci. Eng. A 496, 399 (2008)

G. Shayegan, H. Mahmoudi, R. Ghelichi, J. Villafuerte, J. Wang, M. Guagliano, H. Jahed, Mater. Des. 60, 72 (2014)

N.J. Petch, J. Iron Steel Inst. 174, 25 (1953)

C.H. Caceres, G.E. Mann, J.R. Griffiths, Metall. Mater. Trans. A 42, 1950 (2011)

S.H. Park, H. Yu, J.H. Bae, C.D. Yim, B.S. You, J. Alloys Compd. 545, 139 (2012)

H. Zengin, Y. Turen, Mater. Chem. Phys. 214, 421 (2018)

M.R. Barnett, Mater. Sci. Eng. A 464, 8 (2007)

A. Chapuis, J.H. Driver, Acta Mater. 59, 1986 (2011)

S. Kleiner, P.J. Uggowitzer, Mater. Sci. Eng. A 379, 258 (2004)

J. Bohlen, M.R. Nürnberg, J.W. Senn, D. Letzig, S.R. Agnew, Acta Mater. 55, 2101 (2007)

H. Yu, C. Li, Y. Xin, A. Chapuis, X. Huang, Q. Liu, Acta Mater. 128, 313 (2017)

M.E. Turan, S. Ozcelik, F. Husem, H. Ahlatci, Y. Sun, I. Tozlu, Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 232, 589 (2018)

Acknowledgements

This study is financially supported by the Scientific Research Projects of Karabuk University (KBU-BAP-16/1-DR-075).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Zengin, H., Turen, Y., Turan, M.E. et al. Evolution of Microstructure, Residual Stress, and Tensile Properties of Mg–Zn–Y–La–Zr Magnesium Alloy Processed by Extrusion. Acta Metall. Sin. (Engl. Lett.) 32, 1309–1319 (2019). https://doi.org/10.1007/s40195-019-00901-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00901-7