Abstract

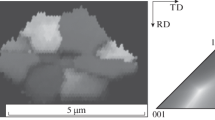

The effect of annealing on the evolution of an ultrafine-grain structure and carbides in a 06MBF steel (Fe–0.1Mo–0.6Mn–0.8Cr–0.2Ni–0.3Si–0.2Cu–0.1V–0.03Ti–0.06Nb–0.09C, wt %) has been studied. The grain–subgrain structure (d = 102 ± 55 nm) formed by high-pressure torsion and stabilized by dispersed (MC, M 3C, d = 3–4 nm) and relatively coarse carbides (M 3C, d = 15–20 nm) is stable up to a temperature of 500°C (1 h) (d = 112 ± 64 nm). Annealing at a temperature of 500°C is accompanied by the formation in regions with a subgrain structure of recrystallized grains, the size of which is close to the size of subgrains formed by high-pressure torsion. The average size and distribution of dispersed particles change weakly. The precipitation hardening and the increase in the fraction of high-angle boundaries in the structure cause an increase in the values of the microhardness to 6.4 ± 0.2 GPa after annealing at 500°C as compared to the deformed state (6.0 ± 0.1 GPa). After 1-h annealing at 600 and 700°C, the microcrystal size (d = 390 ± 270 nm and 1.7 ± 0.7 μm, respectively) increases; the coarse M 3C (≈ 50 nm) and dispersed carbides grow by 5 and 8 nm, respectively. The value of the activation energy for grain growth Q = 516 ± 31 kJ/mol upon annealing of the ultrafine-grained steel 06MBF produced by high-pressure torsion exceeds the values determined in the 06MBF steel with a submicrocrystalline structure formed by equal-channel angular pressing and in the nanocrystalline α iron.

Similar content being viewed by others

References

R. Z. Valiev and I. V. Aleksandrov, Bulk Nanostructured Metallic Materials (Akademkniga, Moscow, 2007) [in Russian].

N. I. Noskova and R. R. Mulyukov, Submicrocrystalline and Nanocrystalline Metals and Alloys (Ural. Otd. Ross. Akad. Nauk, Ekaterinburg, 2003) [in Russian].

A. P. Zhilyaev and T. G. Langdon, “Using high-pressure torsion for metal processing: Fundamentals and applications,” Prog. Mater. Sci. 53, 893–979 (2008).

V. V. Popov, E. N. Popova, D. D. Kuznetsov, A. V. Stolbovskii, and V. P. Pilyugin, “Thermal stability of nickel structure obtained by high-pressure torsion in liquid nitrogen,” Phys. Met. Metallogr. 115, 682–691 (2014).

S. V. Dobatkin, “Severe plastic deformation of steels: Structure, properties and techniques,” in Investigations and Applications of Severe Plastic Deformation, Ed. by T. C. Lowe and R. Z. Valiev, NATO Science Series 3, High Technology. Vol. 80 (Kluwer Academic, Dordrecht, 2000), pp. 13–22.

S. V. Dobatkin and X. Sauvage, “Bulk nanostructured multiphase ferrous and nonferrous alloys,” in Bulk Nanostructured Materials, Ed. by M. J. Zehetbauer and Y. T. Zhu (Wiley-VCH, Weinheim, 2009), pp. 571–603.

A. A. Zakirova, R. G. Zaripova, and V. I. Semenov, “The structure and mechanical properties of carbon steels subjected to severe plastic deformation by torsion,” Vestn. Ufim. Gos. Av.-Tekh. Univ. 11, 123–130 (2008).

S. V. Dobatkin, S. V. Shagalina, O. I. Sleptsov, and N. A. Krasil’nikov, “Effect of the initial state of a lowcarbon steel on nanostructure formation during highpressure torsion at high strains and pressures,” Russ. Metall. (Metally) 2006, 445–452 (2006).

A. V. Korznikov, Yu. V. Ivanisenko, D. V. Laptionok, I. M. Safarov, V. P. Pilyugin, and R. Z. Valiev, “Influence of severe plastic deformation on structure and phase composition of carbon steel” Nanostruct. Mater. 4, 159–167 (1994).

M. V. Degtyarev, T. I. Chashchukhina, L. M. Voronova, A. M. Patselov, and V. P. Pilyugin, “Influence of the relaxation processes on the structure formation in pure metals and alloys under high-pressure torsion,” Acta Mater. 55, 6039–6050 (2007).

A. Etienne, B. Radiguet, C. Genevois, J. M. le Breton, R. Valiev, and P. Pareige, “Thermal stability of ultrafine-grained austenitic steels,” Mater. Sci. Eng., A 527, 5805–5810 (2010).

Y. Ivanisenko, R. K. Wunderlich, R. Z. Valiev, and H. J. Fecht, “Annealing behavior of nanostructured carbon steel produced by severe plastic deformation,” Scr. Mater. 49, 947–952 (2003).

S. S. Gorelik, S. V. Dobatkin, and L. M. Kaputkina, Recrystallization of Metals and Alloys (MISiS, Moscow, 2005) [in Russian].

S. V. Dobatkin, “On the increase of thermal stability of ultrafine grained materials obtained by severe plastic deformation,” Mater. Sci. Forum 426–432, 2699–2704 (2003).

L. M. Voronova, M. V. Degtyarev, and T. I. Chashchukhina, “Thermal stability of submicrocrystalline structure in 4Kh14N14V2M steel,” Phys. Met. Metallogr. 109, 135–141 (2010).

M. V. Karavaeva, S. K. Nurieva, N. G. Zaripov, A. V. Ganeev, and R. Z. Valiev, “Microstructure and mechanical properties of medium-carbon steel subjected to severe plastic deformation,” Metal Sci. Heat Treat. 54, 155–159 (2012).

C. Sun, Y. Yang, Y. Liu, K. T. Hartwig, H. Wang, S. A. Maloy, T. R. Allen, and X. Zhang, “Thermal stability of ultrafine-grained Fe–Cr–Ni alloy,” Mater. Sci. Eng., A 542, 64–70 (2012).

O. Renk, A. Hohenwarter, K. Eder, K. S. Kormout, J. M. Cairney, and R. Pippan, “Increasing the strength of nanocrystalline steels by annealing: Is segregation necessary?,” Scr. Mater. 95, 27–30 (2015).

E. G. Astafurova, S. V. Dobatkin, E. V. Naidenkin, S. V. Shagalina, G. G. Zakharova, and Yu. F. Ivanov, “Structural and phase transformations in nanostructured 0.1% C–Mn–V–Ti steel during cold deformation by high pressure torsion and subsequent heating,” Nanothechn. in Russia 4, 109–120 (2009).

S. V. Dobatkin, P. D. Odessky, and S. V. Shagalina, “Ultrafine grained low carbon steels processed by severe plastic deformation,” Mater. Sci. Forum 584–586, 623–630 (2008).

G. G. Maier, E. G. Astafurova, H. J. Maier, E.V. Naydenkin, G. I. Raab, P. D. Odessky, and S. V. Dobatkin, “Annealing behavior of ultrafine grained structure in low-carbon steel produced by equal channel angular pressing,” Mater. Sci. Eng., A 581, 104–107 (2013).

K.-T. Park and D. Shin, “Annealing behavior of submicrometer grained ferrite in low carbon steel fabricated by severe plastic deformation,” Mater. Sci. Eng., A 334, 79–86 (2002).

L. M. Voronova, M. V. Degtyarev, and T. I. Chashchukhina, “Low-temperature recrystallization of submicrocrystalline structure of ARMKO iron and 30G2R steel,” Phys. Met. Metallogr. 98, 83–91 (2004).

L. M. Utevskii, Diffraction Electron Microscopy in Metallography (Metallurgiya, Moscow, 1973) [in Russian].

M. I. Gol’dshtein and V. M. Farber, Precipitation Strengthening of Steel (Metallurgiya, Moscow, 1979) [in Russian].

S. S. Gorelik, Yu. A. Skakov, and L. N. Rastorguev, X-ray Diffraction and Electron-Optical Analysis (MISiS, Moscow, 2002) [in Russian].

G. K. Williamson and R. E. Smallman, “Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye–Scherrer spectrum,” Philos. Mag., 1, 34–46 (1956).

G. G. Maier, E. G. Astafurova, V. S. Koshovkina, E. V. Naidenkin, A. I. Smirnov, V. A. Bataev, A. A. Bataev, P. D. Odesskii, and S. V. Dobatkin, “Formation of ultrafine-grained structure in low-carbon 06MBF steel by cold high-pressure torsion,” Deform. Razrush. Mater., No. 6, 19–24 (2014).

I. I. Gorbachev, V. V. Popov, and A. Yu. Pasynkov, “Thermodynamic calculations of carbonitride formation in low-alloy low-carbon steels containing V, Nb, and Ti,” Phys. Met. Metallogr. 115, 69–76 (2014).

M. V. Degtyarev, L. M. Voronova, and T. I. Chashchukhina, “Grain growth upon annealing of ARMKO iron with various ultra-fine-grained structure produced by high-pressure torsion deformation,” Phys. Met. Metallogr. 99, 276–285 (2005).

Y. Mine, T. Tsumagari, and Z. Horita, “Hydrogen trapping on lattice defects produced by high pressure torsion in Fe–0.01 mass% C alloy,” Scr. Mater. 63, 552–555 (2010).

M. V. Degtyarev, L. M. Voronova, and T. I. Chashchukhina, “Low-temperature recrystallizatin of pure iron deformed by shear under pressure,” Phys. Met. Metallogr. 97, 72–81 (2004).

T. R. Malow and C. C. Koch, “Grain growth in nanocrystalline iron prepared by mechanical attrition,” Acta Mater. 45, 2177–2186 (1997).

G. G. Maier, E. G. Astafurova, E. V. Naidenkin, S. V. Dobatkin, V. S. Koshovkina, “Thermal stability of ultrafine-grained structure produced by equal-channel angular pressing in Fe–Mn–V–Ti–0.1 C and Fe–Mo–Nb–V–0.1 C low-carbon steels with various phase composition, Obrab. Met. (Tekhnol., Oborud., Instrum.), No. 1, 42–47 (2013) [in Russian].

I. I. Novikov, V. S. Zolotorevskii, V. K. Portnoi, N.A. Belov, D. V. Livanov, S. V. Medvedeva, A. A. Aksenov, and Yu. V. Evseev, A Textbook on Metallography, Vol. 2 (MISiS, Moscow, 2009) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.G. Maier, E.G. Astafurova, E.V. Melnikov, A.I. Smirnov, V.A. Bataev, E.V. Naydenkin, P.D. Odessky, S.V. Dobatkin, 2016, published in Fizika Metallov i Metallovedenie, 2016, Vol. 117, No. 11, pp. 1140–1150.

Rights and permissions

About this article

Cite this article

Maier, G.G., Astafurova, E.G., Melnikov, E.V. et al. Evolution of grain–subgrain structure and carbide subsystem upon annealing of a low-carbon low-alloy steel subjected to high-pressure torsion. Phys. Metals Metallogr. 117, 1101–1110 (2016). https://doi.org/10.1134/S0031918X16110090

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X16110090