Abstract

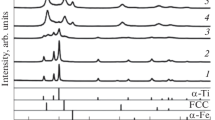

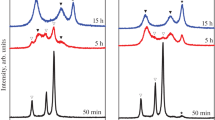

It has been shown using X-ray diffraction, scanning electron microscopy, and chemical analysis that, upon ball milling of α-titanium in liquid organic media (toluene and n-heptane), a nanocrystalline fcc phase is formed that is a metastable carbohydride Ti(C,H) deficient in hydrogen and carbon compared to stable carbohydrides. The dimensions of powder particles after milling in toluene and n-heptane differ substantially (are 5–10 and 20–30 μm, respectively. It has been shown that the kinetics of the formation of Ti(C,H) is independent of the milling medium. The atomic ratios H/C in the products of mechanosynthesis agree well with those corresponding to the employed organic media, i.e., H/C = 1.1 for toluene and 2.3 for n-heptane. A solid-liquid mechanism of mechanosynthesis is suggested, which includes repeated processes of particle fracturing with the formation of fresh surfaces, adsorption of liquid hydrocarbons on these surfaces, and subsequent cold welding of the newly formed particles. It is assumed that the formation of the fcc phase in the process of milling is connected with the generation of stacking faults in α-Ti. Upon annealing at 550°C, the fcc phase decomposes with the formation of stable titanium carbide TiC (annealing in a vacuum) or stable titanium carbohydride and a β-Ti(H) solid solution (annealing in argon) with a partial reverse transformation Ti(C,H) → α-Ti in both cases.

Similar content being viewed by others

References

C. Suryanarayana, Mechanical Alloying and Milling (Marcel Dekker, New York, 2004).

T. F. Grigor’eva, A. P. Barinova, and N. Z. Lyakhov, Mechanochemical Synthesis in Metallic Systems (Parallel’, Novosibirsk, 2008) [in Russian].

G. A. Dorofeev, V. I. Lad’yanov, A. N. Lubnin, F. Z. Gil’mutdinov, E. V. Kuz’minykh, and S. M. Ivanov, “Initial stage of mechanochemical synthesis in the Ti-C exothermic system,” Bull. Russ. Acad. Sci.: Phys. 74, 1427–1434 (2011).

Z. H. Cheng, G. R. MacKay, D. A. Small, and R. A. Dunlap, “Phase development in titanium by mechanical alloying under hydrogen atmosphere,” J. Phys. D: Appl. Phys. 32, 1934–1937 (1999).

E. P. Yelsukov, V. A. Barinov, and L. V. Ovetchkin, “Synthesis of disordered Fe3C alloy by mechanical alloying of iron powder with liquid hydrocarbon (toluene),” J. Mater. Sci. Lett. 11, 662–663 (1992).

S. F. Lomayeva, E. P. Yelsukov, G. N. Konygin, G. A. Dorofeev, V. I. Povstugar, S. S. Mikhailova, and A. H. Kadikova, “Structure, phase composition and magnetic characteristic of the nanocrystalline iron powders obtained by mechanical milling in heptane,” Nanostruct. Mater. 12, 483–486 (1999).

T. Suzuki and M. Nagumo, “Mechanochemical reaction of Ti-Al with hydrocarbon during mechanical alloying,” Scr. Metall. Mater. 27, 1413–1418 (1992).

S. F. Lomaeva, A. N. Maratkanova, V. A. Volkov, O. M. Nemtsova, D. V. Surnin, and E. P. Elsukov, “Mechanosynthesis of Fe-TiC nanocomposites in presence of organic liquids,” Khim. Fiz. Mezoskop. 12, 120–126 (2010).

S. F. Lomaeva, I. V. Povstugar, V. A. Volkov, A. N. Maratkanova, E. P. Elsukov, “Mechanochemical synthesis of nanocomposites in Fe-Th-C system from different precursors,” Khim. Interesah Ustoich. Razvit. 17, 629–639 (2009).

T. S. Suzuki and M. Nagumo, “Metastable intermediate phase formation at reaction milling of titanium and n-heptane,” Scr. Metall. Mater. 32, 1215–1220 (1995).

M. Nagumo, T. S. Suzuki, and K. Tsuchida, “Metastable states during reaction milling of hcp transition metals with hydrocarbon,” Mater. Sci. Forum 225–227, 581–586 (1996).

I. Manna, P. P. Chattopadhyay, P. Nandi, F. Banhart, and H.-J. Fecht, “Formation of face-centered-cubic titanium by mechanical attrition,” J. Appl. Phys. 93, 1520–1524 (2003).

P. Chatterjee and S. P. S. Gupta, “An X-ray diffraction study of strain localization and anisotropic dislocation contrast in nanocrystalline titanium,” Philos. Mag. 81, 49–60 (2001).

Z. P. Chen, Z. Wen, and Q. Jiang, “Phase stabilities of fcc Ti nanocrystals,” Solid State Commun. 132, 747–750 (2004).

S. Xiong, W. Qi, B. Huang, M. Wang, Z. Li, and S. Liang, “Size-temperature phase diagram of titanium nanosolids,” J. Phys. Chem. C 116, 237–241 (2012).

M. R. Seelam, G. Barkhordarian, and C. Suryanarayana, “Is there a hexagonal-close-packed (hcp) facecentered-cubic (fcc) allotropic transformation in mechanically milled Group IVB elements?” J. Mater. Res. 24, 3454–3461 (2009).

H. Goldschmidt, Interstitial Alloys (Butterworths, London, 1967; Mir, Moscow, 1971).

L. V. Zueva and A. I. Gusev, “Effect of nonstoichiometry and ordering on the period of the basis structure of cubic titanium carbide,” Phys. Solid State 41, 1032–1038 (1999).

C. S. Barret and T.B. Massalski, Structure of Metals (McGraw-Hill, New York, 1966; Metallurgiya, Moscow, 1984).

R. A. Young, Introduction to the Rietveld method (Oxford University Press, Oxford, 1993).

DifracPlus Topas: Topas 4.2 Technical Reference (Bruker AXS, Karlsruhe, 2009).

D. Balzar, “Voigt-Function Model in Diffraction Line-Broadening Analysis,” in Microstructure Analysis from Diffraction, Ed. by R. L. Snyder, H. J. Bunge, and J. Fiala, International Union of Crystallography Monographs No. 10 (Oxford University Press, New York, 1999), pp. 94–126.

S. Pratapa and B. O’ Connor, “Development of MgO ceramic standards for X-ray and neutron line broadening assessments,” Adv. X-ray Analys. 45, 41–47 (2001).

A. I. Savvatimskii, “Melting point of graphite and liquid carbon.” Phys.-Usp. 46, 1295–1303 (2003).

Z. Guo, A. P. Miodownik, N. Saunders, and J. Schille, “Influence of stacking-fault energy on high temperature creep of alpha titanium alloys,” Scr. Mater. 54, 2175–2178 (2006).

X. Z. Liao, S. G. Srinivasan, Y. H. Zhao, M. I. Baskes, Y. T. Zhu, F. Zhou, E. J. Lavernia, and H. F. Xu, “Formation mechanism of wide stacking faults in nanocrystalline Al,” Appl. Phys. Lett. 84, 3564–3566 (2004).

S. V. Bobylev, M. Yu. Gutkin, and I. A. Ovid’ko, “Generation of glide split-dislocation half-loops by grain boundaries in nanocrystalline Al,” Phys. Solid State 48, 1495–1505 (2006).

J. P. Hirth and J. Lothe, Theory of Dislocations (McGraw-Hill, New York, 1968; Atomizdat, Moscow, 1972).

I. G. Khidirov, S. Kh. Sultanova, B. B. Mirzaev, N. N. Mukhtarova, and V. V. Getmanskiy, “Phase transformations and neutron diffraction study of antiphase domains ordering in cubic titanium carbohydrides at the lower limit of homogeneity range,” Int. J. Altern. Energ. Ecolog., No. 11. 8–14 (2004).

I. G. Khidirov, B. B. Mirzaev, N. N. Mukhtarova, V. V. Getmanskjy, B. T. Serikbaev, Kh. M. Kholmedov, S. Yu. Zaginaichenko, D. V. Shchur, V. K. Pishchuk, L. V. Kuzmenko, V. V. Garbuz, S. V. Nuzhda, and O. V. Pishchuk, “Determination of Ti2C1 − x H2 − y solid solution homogeneity range by neutron diffraction method,” Int. J. Altern. Ener. Ecolog., No. 5, 49–55 (2007).

S. K. Dolukhanyan, “SHS-method of production of hydrogen accumulators,” Int. J. Altern. Ener. Ecolog., No. 11, 13–16 (2005).

W. B. Pearson, A Handbook of Lattice Spacings and Structures of Metals and Alloys (Pergamon, Oxford, 1967).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.A. Dorofeev, A.N. Lubnin, V.I. Lad’yanov, V.V. Mukhgalin, B.E. Puskkarev, 2014, published in Fizika Metallov i Metallovedenie, 2014, Vol. 115, No. 2, pp. 167–178.

Rights and permissions

About this article

Cite this article

Dorofeev, G.A., Lubnin, A.N., Lad’yanov, V.I. et al. Structural and phase transformations during ball milling of titanium in medium of liquid hydrocarbons. Phys. Metals Metallogr. 115, 157–168 (2014). https://doi.org/10.1134/S0031918X14020057

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X14020057