Abstract

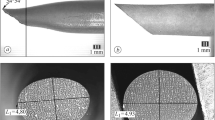

The structure of a turbine blade made of the ChS-70V alloy has been studied after operation in an experimental regime at 880°C. A considerable change in the structural state of the alloy indicates the presence of an extremely high level of stresses in the material. During the operation, the magnetic susceptibility of the alloy increases by two orders of magnitude. The possible structure objects responsible for a change in the magnetic susceptibility are the complexes of superstructure intrinsic stacking faults inside the intermetallic phase.

Similar content being viewed by others

References

Yu. G. Veksler, A. A. Kopylov, and V. V. Bogaevskii, “Structural Stability of Precipitation-Hardening Alloys,” in Heat-Resistant and Refractory Metal Materials. Physicochemical Principles of Production, Ed. by O. A. Bannykh, and K. B. Povarova (Nauka, Moscow, 1987) [in Russian].

N. S. Stoloff, “Physical and Mechanical Metallurgy of Ni3Al and Its Alloys,” Int. Mater. Rev. 34(4), 153–184 (1989).

V. P. Lesnikov and V. P. Kuznetsov, “Corrosion-Resistant ChS70U-VI Alloy and Protective Coatings for Turboprop Engine Blades of Stationary and Ship’s Turboengines,” Gazoturbin. Tekhn., No. 4, 26–27 (2007).

V. A. Skudnov, Yu. P. Tarasenko, and O. B. Berdnik, “Choice of an Optimum Working Temperature of ChS70-VI and ChS88U-VI Nickel Alloys from Sinergy Point of View,” Tekhn. Met., No. 12, 16–20 (2008).

M. B. Rigmant, V. S. Gorkunov, and V. I. Pudov, RF Patent No. 2166191, Byull. Izobret., No. 5, 2000.

M. B. Rigmant, A. P. Nichipuruk, B. A. Khudyakov, V. S. Ponomarev, N. A. Tereshchenko, and M. K. Korkh, “Instruments for Magnetic Phase Analysis of Articles Made of Austenitic Corrosion-Resistant Steels,” Russ. J. Nondestr. Test. 41, 701–709 (2005).

Turbines of Thermal and Atomic Electrical Stations, Ed. by V. V. Frolova and A. G. Kostyuk, (Mosk. Energ. Inst., Moscow, 2002) [in Russian].

F. R. de Boer, C. J. Schinkel, J. Biesterbos, and S. Proost, “Exchange-Enhanced Paramagnetism and Weak Ferromagnetism in the Ni3Al and Ni3Ga Phase,” J. Appl. Phys. 40, 1049–1055 (1969).

S. G. Chowdhury, R. K. Ray, and A. K. Jena, “Structural Transformation in Ni3Al(B) due to Cold Rolling,” Scr. Metall. Mater. 32, 1501–1506 (1995).

N. V. Kazantseva, M. B. Rigmant, and A. N. Pirogov, “Study of Magnetic Structural Phase Transformation upon Nickel Superalloy Deformation,” Fiz. Tekh. Vys. Davl. 17(1), 74–79 (2007).

A. I. Deryagin, V. A. Zavalishin, V. V. Sagaradze, A. R. Kuznetsov, V. A. Ivchenko, N. F. Vil’danova, and B. M. Efros, “Effect of Composition and Temperature on the Redistribution of Alloying Elements in Fe-CrNi Alloys during Cold Deformation,” Phys. Met. Metallogr. 106, 291–301 (2008).

Q. Zeng and I. Baker, “The Effect of Local Versus Bulk Disorder on the Magnetic Behavior of Stoichiometric Ni3Al,” Intermetallics 15, 419–427 (2007).

I. Baker and D. Wu, “Strain-Induced Ferromagnetism in L12 Compounds,” TSM Lett. 2, 57–58 (2005).

Yukichi Umakoshi, Hiroyuki Y. Yasuda, Toshifumi Yanai, “Quantitative Analysis of γ Precipitate in Cyclically Deformed Ni3(Al,Ti) Single Crystals Using Magnetic Technique,” Proc. MRS Fall Meeting-2004, 28 November–3 December 2004, Boston, USA, Vol. 842, 2.3.1–2.3.6 (2004).

Electron Microscopy of Thin Crystals, Ed. by P. B. Hirsch, A. Howie, R. B. Nicholson, D. W. Pashley, and M. J. Whelan (Butterworths, London, 1965; Mir, Moscow, 1968)..

N. V. Kazantseva, N. I. Vinogradova, and N. N. Stepanova, “Electron-Microscopic Study of Planar Defects in Ni3Al Single Crystal after High Temperature Deformation at 1200–1250°C,” Deform. Razrush. Mater., No. 9, 1–6 (2010).

S. N. Grigorov, V. M. Kosevich, S. M. Kosmachev, et al., Electron-Microscopic Images of Dislocations and Stacking Faults (Nauka, Moscow, 1976) [in Russian].

Author information

Authors and Affiliations

Additional information

Original Russian Text © N.N. Stepanova, D.I. Davydov, A.P. Nichipuruk, M.B. Rigmant, N.V. Kazantseva, N.I. Vinogradova, A.N. Pirogov, E.P. Romanov, 2011, published in Fizika Metallov i Metallovedenie, 2011, Vol. 112, No. 3, pp. 328–336.

Rights and permissions

About this article

Cite this article

Stepanova, N.N., Davydov, D.I., Nichipuruk, A.P. et al. The structure and magnetic properties of a heat-resistant nickel-base alloy after a high-temperature deformation. Phys. Metals Metallogr. 112, 309–317 (2011). https://doi.org/10.1134/S0031918X11030288

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X11030288