Abstract

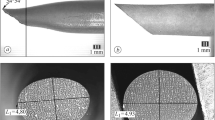

The irreversible structural changes of the single-crystal ZhS32-VI nickel superalloy blades of a high-pressure turbine that occur during life tests of a gas turbine engine are studied. The main operation damages in the hottest section of the blade airfoil are found to be the fracture of the heat-resistant coating in the leading edge and the formation of thermomechanical fatigue cracks. The possibility of reconditioning repair of the blades is considered.

Similar content being viewed by others

References

E. N. Kablov, “Strategic trends in the development of materials and technologies of their processing up to 2030,” Aviats. Materialy i Tekhnologii, No. 8, 7–17 (2012).

O. G. Ospennikova, “Strategy of development of special high-temperature alloys and steels and protective and heat-resistant coatings,” Aviats. Materialy i Tekhnologii, No. 8, 19–36 (2012).

E. N. Kablov, N. V. Petrushin, I. L. Svetlov, and I. M. Demonis, “Nickel cast next-generation superalloys,” Aviats. Materialy i Tekhnologii, No. 8, 36–52 (2012).

E. N. Kablov, Cast Gas Turbine Engine Blades. Alloys, Technologies, Coatings (MISiS, Moscow, 2001).

E. N. Kablov, Yu. A. Bondarenko, A. B. Echin, and V. A. Suvorova, “Development of directional solidification of GTE blades made of superalloys with a singlecrystal and composition structures,” Aviats. Materialy i Tekhnologii, No. 1, 3–8 (2012).

S. A. Budinovskii, S. A. Muboyadzhyan, A. S. Gayamov, and S. V. Stepanova, “Ion-plasma heat-resistant coatings with a composition barrier layer for oxidation protection of ZhS36-VI alloy,” Metalloved. Term. Obrab. Met., No. 1, 34–40 (2011).

E. N. Kablov and S. A. Muboyadzhyan, “High-temperature and heat-resistant coatings for the high-pressure turbine blades of promising GTE,” Aviats. Materialy i Tekhnologii, No. 8, 60–70 (2012).

S. A. Muboyadzhyan, “Protective coatings for the parts of the hot conduit of GTE,” in All Materials. Encyclopedic Handbook (2011), Vol. 3, 26–30; Vol. 4, 13–20.

M. R. Orlov, O. G. Ospennikova, and V. V. Avtaev, “Deformation and fracture of nickel superalloy single crystals during short- and long-term static loading,” Deformatsiya i Razrushenie Materialov, No. 3, 17–23 (2014).

O. G. Ospennikova, M. R. Orlov, and V. V. Avtaev, “Anisotropy of the elastoplastic characteristics of nickel superalloys-basis for designing single-crystal turbine blades,” Deformatsiya i Razrushenie Materialov, No. 11, 12–19 (2013).

Yu. S. Eliseev, V. A. Poklad, O. G. Ospennikova, and M. R. Orlov, “Method for the production of a single-crystal casting for a gas turbine engine blade with given axial and azimuthal alloy orientations,” RF Patent 2329120, Byull. Izobret., No. 20 (2008).

R. E. Shalin, I. L. Svetlov, and E. B. Kachanov, Nickel Superalloy Single Crystals (Mashinostroenie, Moscow, 1977).

P. D. Zhemanyuk, O. V. Rubel’, V. K. Yatsenko, and M. R. Orlov, “Simulation of the crystallographic anisotropy of the long-term strength of nickel superalloy single crystals,” Aviatsionno-Kosmicheskaya Tekhnika i Tekhnologiya, No. 9, 346–350 (1999).

P. D. Zhemanyuk, V. K. Yatsenko, O. V. Rubel’, and M. R. Orlov, “Choice of CO of the turbine blades produced by directional solidification,” Tehnologicheskie Sistemy, No. 3(9), 46–50 (2001).

M. R. Orlov and O. G. Ospennikova, “Operation damage and repair of cast turbine blades made of nickel superalloys,” Liteinoe Proizvodstvo, No. 8, 48–52 (2007).

M. R. Orlov, “Physicochemical features of the formation of thermal pores and the operating ability of single-crystal turbine blades,” Deformatsiya i Razrushenie Materialov, No. 6, 43–48 (2008).

M. R. Orlov, “Analytical estimation of the kinetics of pore removal in cast turbine blades during hot isostatic pressing,” Metalloved. Term. Obrab. Met., No. 2, 17–20 (2009).

E. N. Kablov, M. R. Orlov, and O. G. Ospennikova, “Pore formation mechanisms in single-crystal turbine blades and the pore removal kinetics by hot isostatic pressing,” Aviats. Materialy i Tekhnologii, No. 8, 117–129 (2012).

M. R. Orlov and S. A. Golynets, “Creep kinetics of nickel superalloys under tension conditions,” Liteishchik Rossii, No. 7, 38–41 (2013).

Yu. P. Shkretov, M. R. Orlov, V. A. Poklad, A. I. Mina- kov, O. G. Ospennikova, and A. M. Terekhin, “Method for repairing the turbine blades in a gas turbine engine,” RF Patent 2367554, Byull. Izobret., No. 26 (2009).

V. A. Poklad, O. G. Ospennikova, M. R. Orlov, Yu. P. Shkretov, A. M. Terekhin, and A. I. Minakov, “Method for cleaning the parts of a gas turbine engine made of nickel-based superalloys from the products of high-temperature oxidation and sulfide corrosion,” RF Patent 2357010, Byull. Izobret., No. 15 (2007).

M. R. Orlov and F. N. Karachevtsev, “Removal of the products of oxidation and corrosion from turbine blade channels,” Metallurgiya Mashinostroeniya, No. 2, 30–33 (2012).

M. R. Orlov, O. G. Ospennikova, and L. I. Rassokhina, “Preparation of the surface of turbine blades for nondestructive control by liquid penetrant inspection,” Zavod. Lab., No. 8, 35–39 (2013).

M. R. Orlov, O. G. Ospennikova, and F. N. Karachevtsev, “Quality assurance for the surface of turbine blades during the deposition of protective diffusion coatings,” Metallurg, No. 2, 77–84 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © O.G. Ospennikova, M.R. Orlov, V.G. Kolodochkina, R.M. Nazarkin, 2014, published in Deformatsiya i Razrushenie Materialov, 2014, No. 8, pp. 22–29.

Rights and permissions

About this article

Cite this article

Ospennikova, O.G., Orlov, M.R., Kolodochkina, V.G. et al. Structural changes and damage of single-crystal turbine blades during life tests of an aviation gas turbine engine. Russ. Metall. 2015, 324–331 (2015). https://doi.org/10.1134/S0036029515040114

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029515040114