Abstract

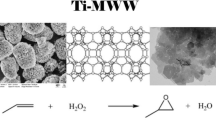

Silylated Ti catalysts based on hexagonal mesoporous silica (Ti-HMS) were prepared by chemical vapor deposition of TiCl4 on HMS silica modified by vapor silylation. The influence of TiCl4 deposition conditions on surface properties and catalytic performance of the catalysts were investigated. Among the methods used to characterize the catalysts were N2-adsorption, Inductively coupled plasma-atomic emission spectrometry (ICP-AES), Ultraviolet-visible spectroscopy (UV-Vis), Raman spectroscopy. Catalytic activity was evaluated in the epoxidation of propylene using cumene hydroperoxide (CHP) as oxidant. Most of Ti ions in HMS mesoporous silica occupy tetrahedral sites and these sites are responsible for the efficient epoxidation activity. The Ti content incorporated in silica decreases with increasing calcination temperature. The experiments indicated 400°C as an appropriate deposition temperature since higher deposition temperatures favor the formation of low active Ti species. A deposition time of 2 h is a sufficient time interval for incorporating Ti into HMS mesoporous silica. A suitable calcination temperature can be estimated as 700°C while higher calcination temperatures promote the formation of low active Ti species. Propylene oxide in high yields (> 95%) can be obtained in the epoxidation of propylene over the catalysts described in the work. The mechanism proposed for the deposition reaction suggests that the incorporation of Ti into HMS is due to silica interaction of Si-OH with TiCl4, chlorination removes Cl-containing Ti species and in this way decreases the Ti content of catalysts at high deposition temperatures.

Similar content being viewed by others

References

Nijhuis, T.A., Makkee, M., Moulijn, J.A., and Weckhuysen, B.M., Ind. Eng. Chem. Res., 2006, vol. 45, p. 3447.

Notari, B., Catal. Today, 1993, vol. 18, p. 163.

Serrano, D.P., Li, H.X., and Davis, M.E., J. Chem. Soc., Chem. Commun., 1992, p. 745.

Camblor, M.A., Corma, A., Martínez, A., and Párez-Pariente, J., J. Chem., Soc. Chem. Commun., 1992, p. 589.

Corma, A., Navarro, M.T., and Pérez-Pariente, J., J. Chem. Soc., Chem. Commun., 1994, p. 147.

Tanev, P.T., Chibwe, M., and Pinnavaia, T.J., Nature, 1994, vol. 368, p. 321.

Mandache, I., Parvulescu, V.I., Popescu, A., Parvulescu, L., Banciu, M.D., Amoros, P., and Beltran, D., Trong On, D., and Kaliaguine S., Microporous Mesoporous Mater., 2005, vol. 81, p. 115.

Wu, P. and Iwamoto, M., J. Chem. Soc., Faraday Trans., 1998, vol. 94, p. 2871.

Wu, P. and Tatsumi, T., Chem. Mater., 2002, vol. 14, p. 1657.

Yonemitsu, M., Tanaka, Y., and Iwamoto, M., Chem. Mater., 1997, vol. 9, p. 2679.

Maschmeyer, T., Rey, F., Sankar, G., and Thomas, J.M., Nature, 1995, vol. 378, p. 159.

Li, K.T. and Lin, C.C., Catal. Today, 2004, vol. 97, p. 257.

Chiker, F., Nogier, J.P., Launay, F., and Bonardet, J.L., Appl. Catal., A, 2003, vol. 243, p. 309.

Pena, M.L., Dellarocca, V., Rey, F., Corma, A., Coluccia, S., and Marchese, L., Microporous Mesoporous Mater., 2001, vols. 44–45, p. 345.

Sever, R.R., Alcala, R.A., Dumesic, J.A., and Root, T.W., Microporous Mesoporous Mater., 2003, vol. 66, p. 53.

Buijink, J.K.F., Van Vlaanderen, J.J.M., Crocker, M., and Niele, F.G.M., Catal. Today, 2004, vols. 93–95, p. 199.

US Patent 6646138, 2003.

Li, X.F., Gao, H.X., Jin, G.J., Chen, L., Ding, L., Yang, H.Y., and Chen, Q.L., J. Mol. Struct., 2008, vol. 872, p. 10.

Yang, Q.H., Wang, S.L., Lu, J.Q., Xiong, G., Feng, Z.C., Xin, Q., and Li, C., Appl. Catal., A, 2000, vols. 194–195, p. 507.

Li, K.T., Lin, P.H., and Lin, S.W., Appl. Catal., A, 2006, vol. 301, p. 59.

Haukka, S., Lakomaa, E.L., and Root, A., J. Phys. Chem., 1993, vol. 97, p. 5085.

Haukka, S., Lakomaa, E.L., Jylhä, O., Vilhunen, J., and Hornytzkyj, S., Langmuir, 1993, vol. 9, p. 3497.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Li, X.F., Wu, C.Z., Gao, H.X. et al. Conditions of deposition of TiCl4 used in preparing the silylated Ti-HMS and their effect on catalytic epoxidation of propylene. Kinet Catal 55, 770–776 (2014). https://doi.org/10.1134/S0023158414060093

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0023158414060093