Abstract

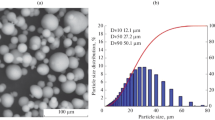

Results of a series of experiments aimed at studying laser cladding of individual tracks with the use of the B4C–Ti–6Al–4V cermet powder mixture are reported. The influence of laser cladding parameters (radiation power, beam motion velocity, and focus position) on the characteristics of tracks being formed (geometric sizes, microhardness, and elemental composition) is studied. It is shown that an increase in the concentration of reinforcing particles in the initial powder mixture alters the character of mass transfer inside the melt pool, leading to changes in the shape of the single track. It is found that a complex heterogeneous structure is formed in the melt pool, including secondary phase compounds formed in chemical reactions due to in-situ synthesis. The microhardness values at various points of the single track are observed to differ by more than a factor of 2 (in the interval HV0.3 = 548–1415).

Similar content being viewed by others

REFERENCES

T. Moges, G. Ameta, and P. Witherell, “A Review of Model Inaccuracy and Parameter Uncertainty in Laser Powder bed Fusion Models and Simulations," Trans. ASME. J. Manufactur. Sci. Engng. 141, 040801 (2019).

C. Kenel, D. Grolimun, X. Li, et al., “In situ Investigation of Phase Transformations in Ti–6Al–4V under Additive Manufacturing Conditions Combining Laser Melting and High-Speed Micro-X-ray Diffraction," Sci. Rep. 7, 16358 (2017). DOI: 10.1038/s41598-017-16760-0.

L. E. Murr, E. Martinez, X. M. Pan, et al., “Microstructures of Rene 142 Nickel-Based Superalloy Fabricated by Electron Beam Melting," Acta Materialia 61, 4289–4296 (2013). DOI: 10.1016/j.actamat.2013.04.002.

A. Bandyopadhyay and K. D. Traxel, “Invited Review Article: Metal-Additive Manufacturing. Modeling Strategies for Application-Optimized Designs," Addit. Manufactur. 22, 758–774 (2018).

P. K. Gokuldoss, S. Kolla, and J. Eckert, “Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting-Selection Guidelines," Materials 10, 672–684 (2017).

Y. Li, M. Zaloznik, J. Zollinger, et al., “Effects of the Powder, Laser Parameters and Surface Conditions on the Molten Pool Formation in the Selective Laser Melting of IN718," J. Materials Process. Technol. 289, 116930 (2021). DOI: 10.1016/j.jmatprotec.2020.116930.

X. Wu, “In situ Formation by Laser Cladding of a TiC Composite Coating with a Gradient Distribution," Surf. Coatings Technol. 115, 111–115 (1999). DOI: 10.1016/S0257-8972(99)00045-6.

H. Y. Wang, Q. C. Jiang, X. L. Li, and J. G. Wang, “In situ Synthesis of TiC/Mg Composites in Molten Magnesium," Scripta Materialia. 48, 1349–1354 (2003). DOI: 10.1016/S1359-6462(03)00014-9.

C. Cui, Z. Guo, H. Wang, and J. Hu, “In situ TiC Particles Reinforced Grey Cast Iron Composite Fabricated by Laser Cladding of Ni-Ti-C System," J. Materials Process. Technol. 183, 380–385 (2007). DOI: 10.1016/j.jmatprotec.2006.10.031.

M. Masanta, P. Ganesh, R. Kaul, et al., “Development of a Hard Nano-Structured Multi-Component Ceramic Coating by Laser Cladding," Materials Sci. Engng. A 508, 134–140 (2009). DOI: 10.1016/j.msea.2008.12.031.

A. Golyshev and A. Orishich, “Microstructure and Mechanical Characterization of Ti6Al4V-B4C Metal Ceramic Alloy, Produced by Laser Powder-Bed Fusion Additive Manufacturing," Intern. J. Adv. Manufactur. Technol. 109, 579–588 (2020). DOI: 10.1007/s00170-020-05509-1.

A. Emamian, S. F. Corbin, and A. Khajepour, “The Influence of Combined Laser Parameters on in-situ Formed TiC Morphology during Laser Cladding," Surf. Coatings Technol. 206, 124–131 (2011). DOI: 10.1016/j.surfcoat.2011.06.062.

A. Emamian, S. F. Corbin, and A. Khajepour, “Effect of Laser Cladding Process Parameters on Clad Quality and in-situ Formed Microstructure of Fe–TiC Composite Coatings," Surf. Coatings Technol. 205, 2007–2015 (2010). DOI: 10.1016/j.surfcoat.2010.08.087.

A. A. Golyshev and A. A. Filippov, “Comparative Investigation of Nickel-Based Metal-Ceramic Structures with Ceramic Particles of Tungsten and Boron Carbides Made by the Selective Laser Melting Method," Nanosci. Technol. 11, 247–257 (2020). DOI: 10.1615/NanoSciTechnolIntJ.2020033784.

B. Das, M. Gopinath, A. K. Nath, and P. P. Bandyopadhyay, “Online Monitoring of Thermo Cycles during Laser Remelting of Flame Sprayed Chromia Coating in Pulsed Mode and Coating Properties," Optik. 227, 166030 (2020). DOI: 10.1016/j.ijleo.2020.166030.

A. Khalili, M. Goodarzi, M. Mojtahedi, and M. J. Torkamany, “Solidification Microstructure of in-situ Laser-Synthesized Fe–TiC Hard Coating," Surf. Coatings Technol. 307, 747–752 (2016). DOI: 10.1016/j.surfcoat.2016.09.051.

B. AlMangour, D. Grzesiak, and J. M. Yang, “In-situ Formation of Novel TiC-Particle-Reinforced 316L Stainless Steel Bulk-Form Composites by Selective Laser Melting," J. Alloys Compounds. 706, 409–418 (2017). DOI: 10.1016/j.jallcom.2017.01.149.

X. H. Wang, S. L. Song, S. Y. Qu, and Z. D. Zou, “Characterization of in situ Synthesized TiC Particle Reinforced Fe-Based Composite Coatings Produced by Multi-Pass Overlapping GTAW Melting Process," Surf. Coatings Technol. 201, 5899–5905 (2007). DOI: 10.1016/j.surfcoat.2006.10.042.

S. Saedi, N. Shayesteh Moghaddam, A. Amerinatanzi, et al., “On the Effects of Selective Laser Melting Process Parameters on Microstructure and Thermomechanical Response of Ni-rich NiTi," Acta Materialia 144, 552–560 (2018). DOI: 10.1016/j.actamat.2017.10.072.

A. A. Golyshev, A. M. Orishich, and A. A. Filippov, “Similarity Laws in Laser Cladding of Cermet Coatings," Prikl. Mekh. Tekh, Fiz. 60 (4), 194–205 (2019) [J. Appl. Mech. Tech. Phys. 60 (4), 758–767 (2019)].

R. Fabbro, “Melt Pool and Keyhole Behaviour Analysis for Deep Penetration Laser Welding," J. Phys. D. Appl. Phys. 43, 445501 (2010). DOI: 10.1088/0022-3727/43/44/445501.

B. Fotovvati, S. F. Wayne, G. Lewis, and E. Asadi, “A Review on Melt-Pool Characteristics in Laser Welding of Metals," Adv. Materials Sci. Engng. 11, 4–18 (2018). DOI: 10.1155/2018/4920718.

J. J. S. Dilip, S. Zhang, C. Teng, et al., “Influence of Processing Parameters on the Evolution of Melt Pool, Porosity, and Microstructures in Ti–6Al–4V Alloy Parts Fabricated by Selective Laser Melting," Progr. Addit. Manufactur. 2, 157–167 (2017). DOI: 10.1007/s40964-017-0030-2.

S. Ghosh, L. Ma, L. E. Levine, et al., “Single-Track Melt-Pool Measurements and Microstructures in Inconel 625," JOM. 70, 1011–1016 (2018). DOI: 10.1007/s11837-018-2771-x.

L. Scime and J. Beuth, “Melt Pool Geometry and Morphology Variability for the Inconel 718 Alloy in a Laser Powder Bed Fusion Additive Manufacturing Process," Addit. Manufactur. 29, 100830 (2019). DOI: 10.1016/j.addma.2019.100830.

C. Kusuma, S. H. Ahmed, A. Mian, and R. Srinivasan, “Effect of Laser Power and Scan Speed on Melt Pool Characteristics of Commercially Pure Titanium (CP-Ti)," J. Materials Engng Perform. 26, 3560–3568 (2017). DOI: 10.1007/s11665-017-2768-6.

A. A. Golyshev, A. G. Malikov, A. M. Orishich, and V. B. Shulyatyev, “Experimental Study of Laser-Oxygen Cutting of Low-Carbon Steel using Fibre and CO2-Lasers under Conditions of Minimal Roughness," Quantum Electron. 44, 970–974 (2014). DOI: 10.1070/qe2014v044n10abeh015412.

V. M. Fomin, A. A. Golyshev, A. G. Malikov, et al., “Creation of a Functionally Gradient Material by the Selective Laser Melting Method," Prikl. Mekh. Tekh, Fiz. 61 (5), 224–234 (2020) [J. Appl. Mech. Tech. Phys. 61 (5), 878–887 (2020)].

A. A. Golyshev, A. G. Malikov, A. M. Orishich, and V. B. Shulyat’ev, “High-Quality Laser Cutting of Stainless Steel in Inert Gas Atmosphere by Ytterbium Fibre and CO2 Lasers," Quantum Electron. 44, 233–238 (2014). DOI: 10.1070/qe2014v044n03abeh015320.

A. M. Rubenchik, W. E. King, and S. S. Wu, “Scaling Laws for the Additive Manufacturing," J. Materials Process. Technol. 257, 234–243 (2018). DOI: 10.1016/j.jmatprotec.2018.02.034.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, 2021, Vol. 63, No. 2, pp. 104-116. https://doi.org/10.15372/PMTF20220210.

Rights and permissions

About this article

Cite this article

Golyshev, A.A., Orishich, A.M. EFFECT OF LASER IMPACT PARAMETERS ON THE FORMATION OF A POOL OF THE MOLTEN B4C — Ti–6Al–4V CERMET MIXTURE. J Appl Mech Tech Phy 63, 268–278 (2022). https://doi.org/10.1134/S0021894422020109

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894422020109