Abstract

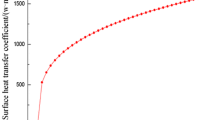

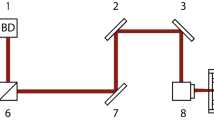

The effects of the water-jet velocity and its angle on the laser–water-jet processing results are studied. It is found that the depth of laser–water-jet processing gradually increases with an increase in the water-jet angle; however, this increasing trend becomes less pronounced as the water-jet angle increases from 60 to 75°. As the water-jet velocity increases, the depth of laser–water-jet processing gradually increases.

Similar content being viewed by others

REFERENCES

W. C. Yu, X. B. Hu, Y. X. Cui, et al., “Laser Ablation of 6H–SiC Single Crystals and Spectral Characterization," Spectroscopy Spectral Anal. 36 (4), 1255–1260 (2016).

S. Feng, C. Huang, J. Wang, et al., “Investigation and Modelling of Hybrid Laser–Water Jet Micromachining of Single Crystal SiC Wafers Using Response Surface Methodology," Materials Sci. Semicon. Proc. 68, 199–212 (2017).

R. Maboudian, C. Carraro, D. G. Senesky, et al., “Advances in Silicon Carbide Science and Technology at the Micro- and Nanoscales," J. Vacuum Sci. Technol. A 31 (5), 050805 (2013).

T. Lee, D. Jang, D. Ahn, et al., “Effect of Liquid Environment on Laser-Induced Backside Wet Etching of Fused Silica," J. Appl. Phys. 107 (3), 033112 (2010).

Y. K. Madhukar, S. Mutlick, and A. K. Nath, “An Investigation on Co-Axial Water-Jet Assisted Fiber Laser Cutting of Metal Sheets," Optics Lasers Eng. 77, 203–218 (2016).

Y. K. Ng and D. Guannan, “The Stability of 30 \(\mu\)m-diameter Water Jet for Jet-Guided Laser Machining," Int. J. Adv. Manufactur. Technol. 78 (5–8), 939–946 (2015).

C. Yang, T. Jiang, Y. Yu, et al., “Study on Surface Quality of Wood Processed by Water-Jet Assisted Nanosecond Laser," BioResources 13 (2), 3125–3134 (2018).

Y. Chang, “Mathematically Modeling of Water Jet-Assisted Ultraviolet-Laser Machining of Thermal Barrier Coatings," IOP Conf. Ser. Mater. Sci. Eng. 439 (3), 032001 (2018).

S. Feng, C. Huang, J. Wang, et al., “An Analytical Model for the Prediction of Temperature Distribution and Evolution in Hybrid Laser–Waterjet Micro-Machining," Precision Eng. 47, 33–45 (2017).

B. Webb and C.-F. Ma, “Single-Phase Liquid Jet Impingement Heat Transfer," Adv. Heat Transfer 26, 105–217 (1995).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, 2021, Vol. 63, No. 1, pp. 16-22. https://doi.org/10.15372/PMTF20220103.

Rights and permissions

About this article

Cite this article

Chen, Y., Li, X., Chen, X. et al. EFFECTS OF THE LASER–WATER-JET PROCESSING OF SILICON CARBIDE. J Appl Mech Tech Phy 63, 11–16 (2022). https://doi.org/10.1134/S0021894422010035

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894422010035