Abstract

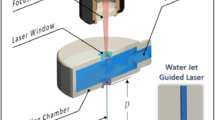

Combined water-jet process and laser machining, the water jet-guided laser processing is suitable in processing a thin and sensitive material with a high degree of precision required. Given that there are many uncertainties of the jet with lower than a 50-μm-diameter nozzle and lower velocities in the stability field of water jet-guided laser machining, a numerical model of a 30-μm water jet, considering the number of grids and the influence of meshes, has been studied to meet the requirements of micrometer order precision machining. Furthermore, the critical Reynolds number and the critical jet exit velocity of the case with a 30-μm-diameter nozzle have been presented to make a comparison between turbulence flow and laminar flow in air with different jet exit velocities from 0.2 to 500 m/s. Hence, the optimal jet exit velocity to achieve the longest stable length of water jet was found. Besides, three cases of 15 m/s jet exit velocity are simulated in different degrees of vacuum, which suggest water jets in vacuum are much more stable than those in atmospheric environment. Finally, a conjecture about water-jet simulation with a smaller diameter of nozzle is proposed as a future work.

Similar content being viewed by others

References

Li CF, Johnson DB, Kovacevic R (2003) Modeling of water-jet guided laser grooving of silicon. Int J Mach Tools Manuf 43(9):925–936

Porter JA, Louhisalmi YA, Karjalainen JA, Fuger S (2007) Cutting thin sheet metal with a water jet guided laser using various cutting distances, feed speeds and angles of incidence. Int J Adv Manuf Technol 33(9–10):961–967

Perrottet, D., Amorosi, S., and Richerzhagen B. (2005) New process for screen cutting: water-jet guided laser, Proceedings of SPIE, the International Society for Optical Engineering. Society of Photo-Optical Instrumentation Engineers: 596105.1-596105.5

Ye R. F. (2009) The key technology and optical system of water-jet guided laser machining. Diss. (Ph.D), Xiamen University

Richerzhagen B (1997) Water guided laser processing. Indust Laser Rev 11:8–10

Zhan C. J., Li C. F., Wang Y. L., Liu T., Pan Y. C. (2010) Numerical study of water-jet guided laser drilling of silicon based on FVM. AIP Conference Proceedings, Vol. 1233

Perrottet D., Green S., and Richerzhagen B. (2006) Clean dicing of compound semiconductors using the water-jet guided laser technology, IEEE/SEMI Advanced Semiconductor Manufacturing Conference: 233–236

Perrottet D., Housh R., Richerzhagen B., and Manley J. (2005) Heat damage-free laser-microjet cutting achieves highest die fracture strength, lasers and applications in science and engineering. Int Soc Optics Photonics: 285–292

Sibailly O. D., Wagner F. R., Mayor L., and Richerzhagen, B. (2003) High precision laser processing of sensitive materials by microjet, Fourth International Symposium on Laser Precision Microfabrication. International Society for Optics and Photonics: 501–504

Perrottet D., Spiegel A., Wagner F. R., Housh R., Richerzhagen B., and Manley J. (2005) Particle-free semiconductor cutting using the water jet guided laser, Lasers and Applications in Science and Engineering. International Society for Optics and Photonics: 240–246

Lee HG, Yoon HS, Ha MY (2008) A numerical investigation on the fluid flow and heat transfer in the confined impinging slot jet in the low Reynolds number region for different channel heights [J]. Int J Heat Mass Transf 51(15):4055–4068

Chen MY, Chalupa R, West AC, Modi V (2000) High Schmidt mass transfer in a laminar impinging slot jet flow [J]. Int J Heat Mass Transf 43(21):3907–3915

Chiriac VA, Ortega A (2002) A numerical study of the unsteady flow and heat transfer in a transitional confined slot jet impinging on an isothermal surface. Int J Heat Mass Transf 45(6):1237–1248

Shanmugam DK, Nguyen T, Wang J (2008) Effect of liquid properties on the stability of an abrasive water-jet. Int J Mach Tools Manufact 48(10):1138–1147

Yan CJ, Xie MZ (2008) Effect of aerodynamic force on the breakup behavior of jets. J Eng Math 25(3):564–566

Söderberg LD, Alfredsson PH (1998) Experimental and theoretical stability investigations of plane liquid jets. Euro J Mech-B/Fluids 17(5):689–737

Lin JZ, Ruan XD, Chen BG (2005) Hydromechanics. Tsinghua University Press, Beijing

Wang HZ (2008) The theory and applications of micro water-jet guided laser machining. Equip Electron Prod Manufact 158:27–31

Su H. X. (1998) The water-jet guided laser machining. Optoelectronic technology & information.11.003: 35–38

Xu R, Du C l, Zeng R, Zhang JJ (2011) Study on jet simulation of nozzles with different contraction angles. J Min Mach 39(2):36–39

Zhang DY, Luo YH, Li X, Chen HW (2011) Numerical simulation and experimental study of drag-reducing surface of a real shark skin. J Hydrodyn 23(2):204–211

Luo YH, Liu YF, Zhang DY, Ng EYK (2014) Influence of morphology for drag reduction effect of sharkskin surface. J Mech Med Biol 14(2):1450029–1–1450029–16

Gong WJ, Wang JM, Gao N (2011) Numerical simulation for abrasive water jet machining based on ALE algorithm. Int J Adv Manuf Technol 53(1–4):247–253

Gohil TB, Saha AK, Muralidhar K (2012) Numerical study of instability mechanisms in a circular jet at low Reynolds numbers. Comput Fluids 64:1–18

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ng, E.YK., Guannan, D. The stability of 30-μm-diameter water jet for jet-guided laser machining. Int J Adv Manuf Technol 78, 939–946 (2015). https://doi.org/10.1007/s00170-014-6692-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6692-8