Abstract

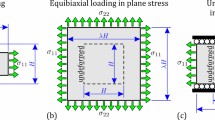

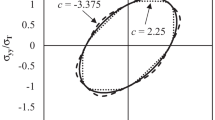

Multilevel (mainly two-level) crystal plasticity models have been widely used for studying processes of inelastic deformation of polycrystalline materials over the last 15–20 years. Anisotropy of plastic strain in crystallites is usually taken into account at the mesoscale, while their elastic properties are often considered as isotropic. The purpose of this study is to assess the differences in the stress–strain characteristics (especially residual mesoscopic stress) by taking into account the anisotropy of elastic properties of materials calculated for the isothermal deformation of polycrystals with various types of crystallite lattice symmetry within a representative macroscopic volume. To this end, our results are compared with the data obtained for a material with isotropic elastic properties using the Voigt–Reuss–Hill averaging procedures. The results of the analysis for the stress–strain state of polycrystalline samples with fcc, bcc, and hcp lattices obtained in a simple shear test (up to the accumulated strain of 50%) are presented. The statistical two-level constitutive model, constructed within the geometrically nonlinear elasto-viscoplasticity theory, is used for calculations. In such constitutive models, the main fundamental relation is the law of elasticity written in the rate relaxation form in terms of the measures of the stress and strain rates, being independent of the chosen reference frame (or of the superimposed rigid motion). It is shown that the analysis of the anisotropy effect has a noticeable impact on the characteristic macroscopic volume stress–strain state only in the initial deformation stage. Subsequently, for deformations exceeding 1–1.5%, the difference becomes insignificant. At the same time, the results of calculating the residual mesoscopic stress (i.e., the stress after unloading the representative macroscopic volume), which has a significant effect on the strength characteristics of materials, with allowance for the crystal anisotropy turned out to be significantly different from those obtained under the hypothesis of isotropy.

Similar content being viewed by others

REFERENCES

Fizicheskaya mezomekhanika i komp’yuternoe konstruirovanie materialov (Physical Mesomechanics and Computer-Aided Design of Materials), Panin, V.E., Ed., Novosibirsk: Nauka, 1995.

Panin, V.E., Physical foundations of mesomechanics of a medium with a structure, Russ. Phys. J., 1992, vol. 35, pp. 305–315. https://doi.org/10.1007/BF00560066

Trusov, P.V. and Shveykin, A.I., Mnogourovnevye modeli mono- i polikristallicheskikh materialov: teoriya, algoritmy, primery primeneniya (Multilevel Models of Mono- and Polycrystalline Materials: Theory, Algorithms, Application Examples), Novosibirsk: Sib. Otdel. Akad. Nauk, 2019. https://doi.org/10.15372/MULTILEVEL2019TPV

McDowell, D.L., A perspective on trends in multiscale plasticity, Int. J. Plast., 2010, vol. 26, pp. 1280–1309. https://doi.org/10.1016/j.ijplas.2010.02.008

Horstemeyer, M.F., Multiscale modeling: A review, in Practical Aspects of Computational Chemistry, Leszczynski, J. and Shukla, M.K., Eds., Netherlands: Springer, 2009, pp. 87–135. https://doi.org/10.1007/978-90-481-2687-3_4

Roters, F., Eisenlohr, P., Hantcherli, L., Tjahjanto, D.D., Bieler, T.R., and Raabe, D., Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications, Acta Mater., 2010, vol. 58, pp. 1152–1211. https://doi.org/10.1016/j.actamat.2009.10.058

Trusov, P.V. and Shveykin, A.I., Teoriya plastichnosti (Plasticity Theory), Perm: Perm. Gos. Tekhn. Univ., 2011.

Trusov, P.V. and Shveykin, A.I., Multilevel crystal plasticity models of single- and polycrystals. Statistical models, Phys. Mesomech., 2013, vol. 16, pp. 23–33. https://doi.org/10.1134/S1029959913010037

Trusov, P.V. and Shveykin, A.I., Multilevel crystal plasticity models of single- and polycrystals. Direct models, Phys. Mesomech., 2013, vol. 16, pp. 99–124. https://doi.org/10.1134/S1029959913020021

Kroner, E., Allgemeine Kontinuumstheorie der Versetzungen und Eigenspannungen, Arch. Rational Mech. Anal., 1959, vol. 4, pp. 273–334. https://doi.org/10.1007/BF00281393

Lee, E.H. and Liu, D.T., Finite-strain elastic-plastic theory with application to plane-wave analysis, J. Appl. Phys., 1967, vol. 38, pp. 19–27. https://doi.org/10.1063/1.1708953

Lee, E.H., Elastic-plastic deformation at finite strain, J. Appl. Mech., 1969, vol. 36, pp. 1–6. https://doi.org/10.1115/1.3564580

Green, A.E. and Adkins, J.E., Large Elastic Deformations and Non-Linear Continuum Mechanics, Oxford: Clarendon, 1960.

Trusov, P.V., Kondratev, N.S., and Shveikin, A.I., About geometricaly nonlinear constitutive relations for elastic material, Vestn. PNIPU, Mekh., 2015, no. 3, pp. 182–200. https://doi.org/10.15593/perm.mech/2015.3.13

Taylor, G.I., Plastic strain in metals, J. Inst. Met., 1938, vol. 62, pp. 307–324.

Lin, T.H., Analysis of elastic and plastic strains of a face-centered cubic crystal, J. Mech. Phys. Solid., 1957, vol. 5, pp. 143–149. https://doi.org/10.1016/0022-5096(57)90058-3

Truesdell, C.A., Hypo-elasticity, J. Ration. Mech. Anal., 1955, vol. 4, pp. 83–133.

Truesdell, C., The simplest rate theory of pure elasticity, Commun. Pure Appl. Math., 1955, vol. 8, pp. 123–132. https://doi.org/10.1002/cpa.3160080109

Truesdell, C., Hypo-elastic shear, J. Appl. Phys., 1956, vol. 27, pp. 441–447. https://doi.org/10.1063/1.1722399

Xiao, H., Bruhns, O.T., and Meyers, A., Hypo-elasticity model based upon the logarithmic stress rate, J. Elasticity, 1997, vol. 47, pp. 51–68. https://doi.org/10.1023/A:1007356925912

Xiao, H., Bruhns, O.T., and Meyers, A., Objective corotational rates and unified work-conjugacy relation between Eulerian and Lagrangean strain and stress measures, Arch. Mech., 1988, vol. 50, no. 6, pp. 1015–1045. https://am.ippt.pan.pl/index.php/am/article/view/v50p1015/631

Xiao, H., Bruhns, O.T., and Meyers, A., The choice of objective rates in finite elastoplasticity: general results on the uniqueness of the logarithmic rate, Proc. R. Soc. London, Ser. A, 2000, vol. 456, pp. 1865–1882. https://doi.org/10.1098/rspa.2000.0591

Xiao, H., Bruhns, O.T., and Meyers, A., Objective stress rates, path-dependence properties and non-integrability problems, Acta Mech., 2005, vol. 176, pp. 135–151. https://doi.org/10.1007/s00707-005-0218-2

Hill, R., Constitutive inequalitites for isotropic elastic solids under finite strain, Proc. R. Soc. London, Ser. A, 1970, vol. 314, pp. 457–472. https://doi.org/10.1098/rspa.1970.0018

Seth, B.R., Generalized strain and transition concepts for elastic-plastic deformation-creep and relaxation, in Applied Mechanics, Görtler, H., Ed., Berlin: Springer, 1966, pp. 383–389. https://doi.org/10.1007/978-3-662-29364-5_51

Lurie, A.I., Nonlinear Theory of Elasticity, Amsterdam: Elsevier, 1990.

Lehmann, T., Anisotrope plastische Formänderungen, Rheol. Acta, 1964, vol. 3, pp. 281–285. https://doi.org/10.1007/BF02096162

Dienes, J.K., On the analysis of rotation and stress rate in deforming bodies, Acta Mech., 1979, vol. 32, pp. 217–232. https://doi.org/10.1007/BF01379008

Pozdeev, A.A., Trusov, P.V., and Nyashin, Yu.I., Bol’shie uprugoplasticheskie deformatsii: teoriya, algoritmy, prilozheniya (Lagre Elastic-Plastic Deformations: Theory, Algorithms, Applications), Moscow: Nauka, 1986.

Trusov, P.V., Shveykin, A.I., and Yanz, A.Yu., Motion decomposition, frame-indifferent derivatives, and constitutive relations at large displacement gradients from the viewpoint of multilevel modeling, Phys. Mesomech., 2017, vol. 20, pp. 357–376. https://doi.org/10.1134/S1029959917040014

Trusov, P.V. and Shveykin, A.I., On motion decomposition and constitutive relations in geometrically nonlinear elastoviscoplasticity of crystallites, Phys. Mesomech., 2016, vol. 19, pp. 377–391. https://doi.org/10.1134/S1029959917040026

Krivosheina, M.N., Tuch, E.V., and Khon, Yu.A., Applying the Mises-Hill criterion to modeling the dynamic loading of highly anisotropic materials, Bull. Russ. Acad. Sci.: Phys., 2012, vol. 76, pp. 80–84. https://doi.org/10.3103/S1062873812010169

Newnham, R.E., Properties of Materials. Anisotropy, Symmetry, Structure, Oxford: Oxford Univ. Press, 2005.

Shermergor, T.D., Teoriya uprugosti mikroneodnorodnykh tel (The Theory of Elasticity of Micro-Inhomogeneous Bodies), Moscow: Nauka, 1977.

Birger, I.A., Ostatochnye napryazheniya (Residual Stresses), Moscow: Mashgiz, 1963.

Fridman, Ya.B., Mekhanicheskie svoistva metallov. Ch. 1. Deformatsiya i razrushenie (Mechanical Properties of Metals. Part 1. Deformation and Destruction), Moscow: Mashinostroenie, 1974.

Pozdeev, A.A., Nyashin, Yu.I., and Trusov, P.V., Ostatochnye napryazheniya: teoriya i prilozheniya (Residual Stresses: Theory and Applications), Moscow: Nauka, 1974.

Radchenko, V.P. and Saushkin, M.N., Polzuchest’ i relaksatsiya ostatochnykh napryazhenii v uprochnennykh konstruktsiyakh (Creep and Relaxation of Residual Stresses in Reinforced Structures), Moscow: Mashinostroenie, 2005.

Kachanov, L.M., Osnovy mekhaniki razrusheniya (Fundamentals of Fracture Mechanics), Moscow: Nauka, 1974.

Collins, J.A., Failure of Materials in Mechanical Design: Analysis, Prediction, Prevention, New York: Wiley, 1981.

Rabotnov, Yu.N., Vvedenie v mekhaniku razrusheniya (Introduction to Fracture Mechanics), Moscow: Nauka, 1987.

Besson, J., Continuum models of ductile fracture: A review, Int. J. Damage Mech., 2010, vol. 19, pp. 3–52. https://doi.org/10.1177%2F1056789509103482

Volegov, P.S., Gribov, D.S., and Trusov, P.V., Damage and fracture: Review of experimental studies, Phys. Mesomech., 2016, vol. 19, pp. 319–331. https://doi.org/10.1134/S1029959916030103

Funding

This study was supported by the Ministry of Science and Higher Education of the Russian Federation (basic part of a State assignment for the Perm National Research Polytechnic University, project no. FSNM-020-0027) and the Russian Foundation for Basic Research and Perm Territory (project no. 20-41-596002).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Sin’kov

Rights and permissions

About this article

Cite this article

Sokolov, A.S., Trusov, P.V. A Two-Level Elasto-Viscoplastic Model: Application to the Analysis of the Crystal Anisotropy Influence. J Appl Mech Tech Phy 62, 1145–1155 (2021). https://doi.org/10.1134/S0021894421070178

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894421070178