Abstract

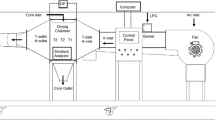

An experimental study of a novel dryer is performed. In this current study, paddy drying is carried out using a vertical dryer. The paddy mass is varied as 10, 20, and 30 kg at the air temperature and velocity of 60°C and 5 m/s, respectively. The results indicate that an increase in the paddy mass raises the drying rate and efficiency. However, the large masses of paddy need a long time to reach the required 14% moisture content. The highest efficiency achieved is 3.27% at the paddy mass of 30 kg.

Similar content being viewed by others

REFERENCES

A. A. Adebowale, G. O. Fetuga, C. B. Apata, and L. O. Sanni, “Effect of Variety and Initial Moisture Content on Physical Properties of Improved Millet Grains," Nigerian Food J. 30 (1), 5–10 (2012).

S. Syahrul, M. Mirmanto, Y. Hartawan, and S. Sukmawaty, “Effect of Air Intake Temperature on Drying Time of Unhulled Rice Using a Fluidized Bed Dryer," Heat Mass Transfer 55 (2), 293–298 (2019).

S. Rahayoe, Teknik Pengeringan (Univ. Gadjah Mada, Yogyakarta, 2017).

M. A. Graciafernandy, R. Ratnawati, and L. Buchori, “Pengaruh Suhu Udara Pengering dan Komposisi Zeolit 3a Terhadap Lama Waktu Pengeringan Gabah Pada Fluidized Bed Dryer," J. Ilmiah Momentum.8 (2), 6–10 (2012).

R. Rhomdani, Pengaruh Variasi Kecepatan Udara dan Massa Bahan Terhadap Waktu Pengeringan Jagung Pada Alat Fluidized Bed (Teknik Univ., Mataram, 2016).

M. Djaeni, N. Aishah, H. Nissaulfasha, and L. Buchori, “Corn Drying with Zeolite in the Fluidized bed Dryer under Medium Temperature," J. Technol. Sci. 24 (2), 1–6 (2013).

V. Palled, S. R. Desai, and M. Anantachar, “Performance Evaluation of Solar Tunnel Dryer for Chilly Drying," Karnataka J. Agricultural Sci. 25 (4), 472–474 (2012).

M. Mirmanto, E. D. Sulistyowati, and I. D. K. Okariawan, “Effect of Radiator Type on Dryer Room Temperature Distribution and Heat Transfer Rate," JP J. Heat Mass Transfer. 13 (4), 512–532 (2016).

M. Mirmanto, S. Syahrul, E. D. Sulistyowati, and I. D. K. Okariawan, “Effect of Inlet Temperature and Ventilation on Heat Transfer Rate and Water Content Removal of Red Chili," J. Mech. Sci. Technol. 31 (3), 1531–1537 (2017).

S. Syahrul, M. Mirmanto, S. Ramdoni, and S. Sukmawaty, “Pengaruh Kecepatan Udara dan Massa Gabah Terhadap Kecepatan Pengeringan Gabah Menggunakan Pengering Terfluidisasi," J. Dinamika Teknik Mesin.7 (1), 54–59 (2017).

C. C. E. Margana and S. Sukmawaty, Karakterisasi dan Simulasi Mesin Pengering Gabah Tipe Vertikal Kontinyu Dengan Aliran Udara Panas Berlawanan Mataram (Univ. Mataram, 2010); https://www. academia.edu/2946895.

S. Syahrul, A. D. Cahyono, M. Mirmanto, et al., “The Effect of Grain Mass Variations on Drying Time by Adding a Pipe Heat Exchanger to a Fluidized Bed Dryer," AIP Conf. Proc. 2199, 040011-1–040011-6 (2019).

J. P. Holman, Heat Transfer (McGraw-Hill, 2002).

F. Incropera, D. P. DeWitt, T. L. Bergman, and A. S. Lavine (eds.)Fundamentals of Heat and Mass Transfer (John Wiley and Sons, Hoboken, 2006).

Y. A. Cengel, Heat Transfer a Practical Approach(McGraw-Hill, New York, 2003).

S. Sukmawaty, Y. Astuti, R. Sabani, et al., “Measurement and Comparison with the Existing Published Model of Minimum Air Velocity and Pressure Drop of a Fluidized Bed Dryer for Drying Corn," Int. J. Mech. Eng. Technol. 9 (11), 1501–1510 (2018).

A. Kumar, V. Kumar, K. Khan, and A. Kumar, “Experimental Investigation on Drying of Mint Leaves (m. pulegium) in a Solar Tunnel Dryer," Int. J. Pure Appl. Biosci 5 (2), 682–689 (2017).

M. Yahya, “Performance Analysis of Solar-Assisted Fluidized Bed Dryer Integrated Biomass Furnace with and without Heat Pump for Drying of Paddy," Int. J. Photoenergy, No. 2. 1–17 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, 2021, Vol. 62, No. 2, pp. 61–69.https://doi.org/10.15372/PMTF20210206.

Rights and permissions

About this article

Cite this article

Syahrul, S., Mirmanto, M., Sukmawaty, S. et al. EFFECT OF PADDY MASS VARIATIONS ON THE DRYING RATE AND EFFICIENCY OF A CONTINUOUS VERTICAL DRYER. J Appl Mech Tech Phy 62, 230–237 (2021). https://doi.org/10.1134/S0021894421020061

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894421020061