The possibility of fabricating two-dimensional Si layers on a CaF2/Si(111) film by molecular beam epitaxy is studied. The growth conditions, under which the regions of two-dimensional Si layers are formed, are found. Raman spectroscopy, transmission electron microscopy, photoluminescence, and electron paramagnetic resonance (EPR) studies have shown that regions of two-dimensional Si layers are formed in epitaxial structures prepared by the deposition of one to three biatomic Si layers on the CaF2/Si(111) film surface at a temperature of 550°С. The Raman spectra of these structures exhibit a narrow peak at 418 cm–1, which is due to light scattering on vibrations of Si atoms in the plane of a two-dimensional Si layer intercalated with calcium. The EPR spectra of multilayer structures with regions of two-dimensional Si layers embedded in CaF2 demonstrate an isotropic signal with an asymmetric Dyson shape and the g-factor \(g = 1.9992\) under illumination. Consequently, this signal can be attributed to photoinduced conduction electrons in extended two-dimensional Si islands. These results may be useful for understanding the mechanisms of the formation of two-dimensional materials on CaF2/Si(111) substrates.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Two-dimensional materials with unique electronic and structural properties that differ fundamentally from the properties of bulk materials from which they are fabricated are currently of great worldwide interest [1, 2]. The presence of these properties opens up new possibilities for designing device structures operating on new physical principles, which significantly expand the capabilities of modern micro- and nanoelectronics. Two-dimensional materials are structures with a thickness of one to several atomic layers. The main representative of such materials is graphene. However, there are a number of limitations that prevent the introduction of graphene into nanoelectronics. The key one is the absence of a band gap. Currently, the search for a new, graphene-like two-dimensional material with a band gap and the possibility of its fabrication on an industrial scale is topical. Two-dimensional group IV graphene-like materials based on silicon (silicene) and germanium (germanene) and their solid solutions are considered as the most promising candidates [2, 3]. The currently available data indicate that silicene and germanene have a band gap close to zero [4]. However, it was shown in a number of works [5, 6] that the transition from monolayer silicene to two-layer (bi-silicene) should lead to the appearance of a band gap of \( \sim {\kern 1pt} 1\) eV, which makes this material promising for various optical applications. At present, the most successful attempts to synthesize Si- and Ge‑based two-dimensional materials have been implemented on atomically pure noble metal substrates. In the case of silicene, silver substrates (Ag(111)) are usually used [7], and in the case of germanene, gold or platinum substrates (Au(111) [8], Pt(111) [9]) are used. For further practical applications of two-dimensional materials as active components of devices, it is desirable to obtain these materials on dielectric substrates [2, 10]. It was recently shown in theoretical work [11] that silicene should be stable on a СаF2(111) dielectric layer. The lattice constants of these materials almost coincide (the difference is only 0.5%), and silicene on СаF2(111) retains the Dirac cone in the electron dispersion law with a narrow band gap of about 50 meV. Such prerequisites make it topical to search for ways to prepare silicene on СаF2(111) substrates. One of the promising methods for fabricating two-dimensional structures is molecular beam epitaxy. There are a number of works on the growth of silicon by the molecular beam epitaxy method on the СаF2(111) surface [12–14]. The main problem in this direction is the inappropriate ratio of the surface energies of silicon and calcium fluoride. The former is about three times larger than the latter [13]. As a result, the deposited silicon is collected in three-dimensional islands on the СаF2(111) surface. Several approaches have been proposed to solve this problem. One of them is to use electron irradiation [12] for transforming the CaF2 surface into a Ca-enriched state with a higher surface energy. The second approach is to use surfactants for lowering the surface energy of silicon [13]. The third approach is to use high temperatures, which also leads to the transition of the surface to the Ca-enriched state [14]. However, in the cited works, insufficient attention was paid to the initial stage of silicon growth on СаF2(111), the study of which can provide key information for developing an approach to fabricating silicene (or bi-silicene) on the СаF2(111) surface.

In this work, we study the possibility of the preparation of two-dimensional Si layers embedded in a CaF2 dielectric matrix by the molecular beam epitaxy method. The analysis of the data obtained in the work confirms the formation of the regions of two-dimensional Si layers.

The structures were synthesized on Si(111) substrates by the molecular beam epitaxy method at a temperature of 550°С. The choice of the synthesis temperature was based on the results of [15], where the optimal temperature range was found for obtaining a planar surface of CaF2/Si(111) films with a thickness of a few tens of nanometers. The conditions for fabricating planar films may differ for thinner CaF2/Si(111) films (see [16]). The epitaxial growth of the CaF2 film was performed at the first stage; the film thickness varied from 10 to 120 nm for different structures. Thin Si layers were successively deposited on the CaF2 film surface at the second stage. The amount of silicon deposited during the formation of two-dimensional layers varied from one atomic bilayer (BL, \(d \approx \) 0.3 nm) to three BLs for different structures. At the chosen substrate temperature, Si desorption from the CaF2 surface cannot be neglected [13, 17]; therefore, the exact thickness of the Si layer could differ from the planned one. Two types of structures were grown: with nine Si layers and with one Si layer. The silicon layers were separated by either 6‑nm- or 2-nm-thick СаF2 interlayers depending on the structure number (see Table 1). At the third stage, the prepared structures were coated with a 3-nm-thick СаF2 protective layer.

The fabricated structures were studied by Raman spectroscopy, transmission electron microscopy (TEM), photoluminescence (PL), and electron paramagnetic resonance (EPR). A description of the experimental methods is given in the supplementary material.

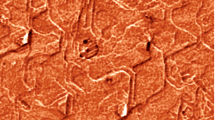

Figure 1 shows a TEM image of a side cross section of multilayer structure 3 (description in Table 1). The planes of the interruption of the epitaxial growth of the CaF2 layers are clearly visible, and the period of their arrangement coincides with the period of deposition of the silicon layers (Fig. 1b). In certain places, the “transitions” from one flat region to another are observed, which is apparently associated with the formation of steps on the surface of the growing CaF2 film. These steps may be due to the introduction of dislocations, which are formed during CaF2 growth at the plastic relaxation of strains caused by the mismatch between CaF2 and Si lattices (≈1.2% at 550°С). This mismatch is provided by the difference in the thermal expansion coefficients of Si and CaF2 [18, 19]. The critical thickness for the introduction of dislocations according to the People–Bean energy balance model [20, 21] was estimated as ≈67 nm. In fact, according to AFM studies for samples with an epitaxial layer thickness of more than 60 nm (Fig. 2b), a network of steps is observed on the surface, which are formed due to the introduction of dislocations caused by plastic relaxation processes, while only growth steps are present on the surface for samples with a thinner epitaxial layer (Fig. 2a) separated by rather wide planar terraces with an rms roughness not exceeding 0.4 nm.

(a) TEM images of a side cross section of a multilayer structure being a 20-nm-thick CaF2 layer on a Si(111) substrate, onto which nine 1-BL-thick Si layers were successively deposited, separated by 6-nm-thick CaF2 interlayers. (b) Magnified TEM images of the same structure. The structure formation temperature was 550°С.

(Color online) AFM scans of the surface of (a) 29‑nm-thick structure 4 and (b) 123-nm-thick structure 5 (see Table 1 for the structure parameters). The rms surface roughness is 1.24 nm for structure 4 and 0.89 nm for structure 5. The rms roughness is 0.32 nm on a 300 × 300 nm flat surface region marked with a white square (panel (a)).

Raman spectroscopy was used as one of the main methods for determining the presence of two-dimensional silicon layers in samples. The results of Raman studies demonstrated that two-dimensional silicon layers (or their regions) embedded in the CaF2 dielectric matrix are formed under the chosen conditions of structure synthesis. The Raman spectra of structures with Si layers exhibit a narrow peak at 418 cm–1 (Fig. 3, lines 1–3 and 5). The position of this peak coincides with the position of one of the three peaks in the Raman spectra (at 418, 388, and 346 cm–1) characteristic of CaSi2 crystal layers [22–24]. The crystal lattice of bulk CaSi2 includes two-dimensional Si layers intercalated with calcium [25, 26]. According to the theoretical consideration in [26], the observed peak at 418 cm–1 can be associated with vibrations of Si atoms in the plane of two-dimensional silicon layers intercalated with calcium (vibration mode \({{E}_{g}}\) (Si)). A slight discrepancy with a theoretical value of 413 cm–1 obtained in [26] for bulk CaSi2may be associated with the strains in the experimental structure or the size effect [23]. Peaks at 388 and 346 cm–1, corresponding to vibrations of Si atoms outside the plane of two-dimensional silicon layers, are not observed in our structures.

(Color online) Raman spectra of multilayer structures with nine Si layers having the thickness of one BL (lines 3 and 4), two BLs (line 2), and three BLs (line 1) embedded in CaF2. The spectrum of a structure with one 1-BL-thick Si layer is shown by line 5. For comparison, Raman spectra of the initial Si(111) substrate (line 7) and 40-nm-thick CaF2 film (line 6) grown on the Si(111) substrate at 550°С are also shown. The lines are marked by the numbers of the corresponding structures listed in Table 1.

The comparison of the Raman spectra (Fig. 3) of structures 3 and 5, for which Si layers were formed during the deposition of one silicon BL on CaF2 shows that the intensity of the narrow peak at 418 cm–1 for multilayer structure 3 with nine silicon layers is approximately four times higher than the intensity of the peak for structure 5 with one Si layer. From simple considerations, a ninefold increase in the Raman signal intensity could be expected, but the effect was weaker. This result indicates that the amount of silicon per two-dimensional layer in the multilayer structure 3 is smaller than that in structure 5. We attribute this to a smaller number of steps on the surface of the multilayer structure. According to the literature data, the introduction of dislocations in multilayer heterostructures occurs at higher film thicknesses than in single-layer ones caused by the redistribution and compensation of strains in the structure layers [27, 28]. In addition, the total thickness of structure 3 is smaller than that of structure 5 (see Table 1); therefore, the degree of plastic relaxation for structure 3 is lower. It can be assumed that the nucleation of two-dimensional silicon islands occurs exactly at the steps where fluorine-free calcium atoms, to which silicon atoms can be attached, are present.

This assumption is supported by the comparison of the Raman spectra of multilayer structure 4 and single-layer structure 5. Structure 4 has a thickness not exceeding the critical one for the introduction of dislocations, and the intensity of the Raman signal for it is lower than that for structure 5 with one Si layer, but having a thickness higher than the critical one. The density of steps for plastically relaxed structure 5 is higher (Fig. 2b) than that for unrelaxed structure 4 (Fig. 2a), and, accordingly, the Raman signal from two-dimensional Si for structure 5 is more intense.

A shift of the Raman peak by 2 cm–1 was found for unrelaxed structure 4, which can be associated with elastic strains in the grown film (Fig. 3, line 4). The peak position in this case is 420 cm–1.

When the amount of silicon used to form two-dimensional layers increases from one to three BLs (structures 1–3), a slight increase in the intensity of the Raman signal at 418 cm–1 is observed, which in the case of a structure with three BLs is approximately 25% (Fig. 3). In addition, a small shoulder appears in the Raman peak at 418 cm–1 on the lower energy side (Fig. 3, line 1) for the structure with three BLs, which may indicate that Si layers begin to become nonplanar at such an amount of deposited material.

An additional peak at 445 cm–1 was found in all the Raman spectra of the formed structures, which, as we assume, is associated with the formation of an additional structural phase at the interface between the CaF2 layer and the Si(111) substrate. This interpretation is supported by the observation of this peak in the Raman spectra of structures with CaF2 films (without built-in thin Si layers) grown on Si(111) substrates (Fig. 3, line 6).

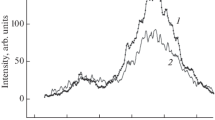

The EPR spectra of multilayer structures 1 and 2 (see Table 1) exhibited an isotropic EPR signal with a g-factor of \(g = 1.9992\) and a linewidth of \(\Delta H \approx \) 0.7 G. The signal was manifested upon illumination with white light (Fig. 4) in the temperature range of 4.5–20 K. As the temperature increased, the signal intensity decreased and the signal disappeared above 20 K. An aftereffect is an interesting result. At sufficiently low temperatures <10 K, the signal appeared in the spectrum after turning off illumination, but its magnitude dropped by several times. The signal had an asymmetric Dyson shape, which, together with the g‑factor value, suggests that this signal belongs to photoinduced conduction electrons in the Si layers. The observed aftereffect can be explained by the spatial separation of electrons and holes in the heterosystem under study, which hinders the recombination process. However, this issue requires further studies. The comparison of the EPR results with microscopic studies makes it possible to conclude that the signal originates from extended two-dimensional silicon islands formed in the structures under study. The formation of continuous planar two-dimensional silicon layers is not confirmed. A narrower EPR signal with an EPR linewidth on the order of 0.1–0.2 G and less would be observed during the formation of continuous two-dimensional silicon layers. The isotropy of the signal indicates the absence of additional spin relaxation mechanisms (isotropy of the EPR linewidth) associated with the asymmetry of quantum wells with respect to the growth plane (caused by the Bychkov–Rashba interaction). For the structures prepared by deposition of one Si BL (structures 3–5, see Table 1), the above EPR signal was not observed, which can be explained by the insufficient sensitivity of the method at small amounts of deposited silicon. It should be noted that all samples, in which the EPR signal was observed, according to the AFM data, have a characteristic grid of steps on the surface, which indicates a relation between the steps on the surface and the extended two-dimensional silicon islands that give an EPR signal when illuminated.

(Color online) EPR spectra of structure 2 (see Table 1) measured under illumination with white light (red line) and in the dark after turning off the light (blue line). The magnetic field is applied along the [111] direction. The microwave power was \(P = 0.063{\kern 1pt} \) mW and the temperature was \(T = 6{\kern 1pt} \) K.

The comparison of the Raman, EPR, and microscopic results indicates that the growth of Si layers occurs mainly from steps on the СаF2 surface. Silicon atoms can bind to the calcium-terminated edges of the steps. The larger the number of steps, the more probable the nucleation and further growth of a two-dimensional silicon layer. This assumption is consistent with an increase in the intensity of the Raman signal at 418 cm–1 in structures with thicker СаF2 layers. Here, the density of steps is much higher and, accordingly, the probability of the nucleation of two-dimensional Si layers is higher.

The formation of regions of two-dimensional Si layers is also confirmed by the photoluminescence studies. Figure 5 demonstrates the PL spectrum from structure 4, which clearly shows two broad peaks P2 at ≈480 nm (2.6 eV) and P1 at ≈685 nm (1.8 eV). We attribute the first peak to defects in CaF2 [29], and the second one can be associated with regions of two-dimensional Si layers. According to the literature data for bi-silicene, optical transitions should be observed in this spectral range. It was shown in [5] that bi-layer silicene is an indirect-gap material with a band gap of 1.08 eV. Upon passivation of bi-silicene with fluorine (e.g., upon incorporation into CaF2), the band gap increases to 1.78 eV, which exactly corresponds to the observed P1 peak.

(Color online) Photoluminescence spectrum of structure 4 (see Table 1) measured at 78 K. A diode laser module operating at a wavelength of 405 nm was used to excite luminescence.

To summarize, we have demonstrated that regions of two-dimensional silicon layers can be formed on CaF2 by molecular-beam epitaxy. The results obtained can be used in the future for developing approaches to the fabrication of two-dimensional silicon-based materials.

REFERENCES

S. Z. Butler, S. M. Hollen, L. Cao, et al., ACS Nano 7, 2898 (2013).

M. Galbiati, N. Motta, M. de Crescenzi, and L. Camilli, Appl. Phys. Lett. 6, 041310 (2019).

G. Vogg, A. J.-P. Meyer, C. Miesner, M. S. Brandt, and M. Stutzmann, Appl. Phys. Lett. 78, 3956 (2001).

Z. Ni, Q. Liu, K. Tang, J. Zheng, J. Zhou, R. Qin, Z. Gao, D. Yu, and J. Lu, Nano Lett. 12, 113 (2012).

R. Yaokawa, T. Ohsuna, T. Morishita, Y. Hayasaka, M. J. S. Spencer, and H. Nakano, Nat. Commun. 7, 10657 (2016).

X. Wang and Z. Wu, Phys. Chem. Phys. 19, 2148 (2017).

J. Sone, T. Yamagami, Y. Aoki, K. Nakatsuji, and H. Hirayama, New J. Phys. 16, 095004 (2014).

M. E. Davila, L. Xian, S. Cahangirov, A. Rubio, and G. L. Lay, New J. Phys. 16, 095002 (2014).

L. Li, S. Lu, J. Pan, Z. Qin, Y. Wang, Y. Wang, G. Cao, S. Du, and H. Gao, Adv. Mater. 26, 4820 (2014).

Yu. Yu. Illarionov, A. G. Banshchikov, D. K. Polyushkin, S. Wachter, T. Knobloch, M. Thesberg, L. Mennel, M. Paur, M. Stöger-Pollach, A. Steiger-Thirsfeld, M. I. Vexler, M. Waltl, N. S. Sokolov, T. Mueller, and T. Grasser, Nat. Electron. 2, 230 (2019).

S. Kokott, P. Pflugradt, L. Matthes, and F. Bechstedt, J. Phys.: Condens. Matter 26, 185002 (2014).

P. O. Pettersson, R. J. Miles, and T. C. McGill, J. Appl. Phys. 76, 7328 (1994).

C. R. Wang, B. H. Muller, E. Bugiel, and K. R. Hofmann, Appl. Surf. Sci. 211, 203 (2003).

A. Klust, M. Grimsehl, and J. Wollschlager, Appl. Phys. Lett. 82, 4483 (2003).

J. Suela, E. Abramof, P. H. O. Rappl, F. E. Freitas, H. Closs, and C. Boschetti, J. Phys. D: Appl. Phys. 44, 185405 (2011).

Yu. Yu. Illarionov, M. I. Vexler, V. V. Fedorov, S. M. Suturin, and N. S. Sokolov, J. Appl. Phys. 115, 223706 (2014).

A. P. Taylor, B. M. Kim, P. D. Persans, and L. J. Schowalter, MRS Online Proc. Libr. 298, 103 (1993).

Y. Okada and Y. Tokumaru, J. Appl. Phys. 56, 314 (1984).

R. B. Roberts and G. K. White, J. Phys. C: Solid State Phys. 19, 7167 (1986).

R. People and J. C. Bean, Appl. Phys. Lett. 47, 322 (1985).

R. People and J. C. Bean, Appl. Phys. Lett. 49, 229 (1986).

A. V. Kacyuba, A. V. Dvurechenskii, G. N. Kamaev, V. A. Volodin, and A. Y. Krupin, Mater. Lett. 268, 127554 (2020).

A. Kacyuba, A. Dvurechenskii, G. Kamaev, V. Volodin, and A. Krupin, J. Cryst. Growth 562, 126080 (2021).

A. V. Dvurechenskii, A. V. Kacyuba, G. N. Kamaev, V. A. Volodin, and Zh. V. Smagina, Nanomaterials 12, 1407 (2022).

G. Vogg, M. S. Brandt, M. Stutzmann, and M. Albrecht, J. Cryst. Growth 203, 570 (1999).

S. M. Castillo, Z. Tang, A. P. Litvinchuk, and A. M. Guloy, Inorg. Chem. 55, 10203 (2016).

J. W. Matthews and A. E. Blakeslee, J. Cryst. Growth 27, 118 (1974).

S. M. Hu, J. Appl. Phys. 69, 7901 (1991).

N. Salah, N. D. Alharbi, S. S. Habib, and S. P. Lochab, J. Nanomater. 2015, 136402 (2015).

ACKNOWLEDGMENTS

We are grateful to the Center for Collective Use VTAN, Novosibirsk State University and the Center for Collective Use Nanostructures, Rzhanov Institute of Semiconductor Physics, Siberian Branch, Russian Academy of Sciences for providing the measuring equipment.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation, project no. 075-15-2020-797 (13.1902.21.0024).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by L. Mosina

Supplementary Information

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zinovyev, V.A., Zinovieva, A.F., Volodin, V.A. et al. Synthesis of Epitaxial Structures with Two-Dimensional Si Layers Embedded in a CaF2 Dielectric Matrix. Jetp Lett. 116, 628–633 (2022). https://doi.org/10.1134/S0021364022602159

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021364022602159