Abstract

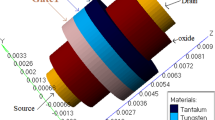

This work implements three fast measurement techniques based on the measure–stress–measure (MSM) method. These techniques, namely, measuring–around–\({{V}_{{{\text{th}}}}}\), one–point on–the–fly (OTF), and pulsed current-voltage (PIV), were used to characterize three different technologies of metal–oxide–semiconductor field-effect transistors (MOSFETs) with same gate dielectric silicon–dioxide (SiO2) and various thicknesses \({{t}_{{{\text{ox}}}}}\) = 20 nm, 4 nm, 2.3 nm. Moreover, well–configured electrical stress biasing has been performed to discuss the dielectric degradation of these devices using those characterization techniques. The pros and cons of the used techniques are well discussed based on our results. Furthermore, experimental results showed that threshold voltage shift (\(\Delta {{V}_{{{\text{th}}}}}\)) follows a power law time dependence with time exponent (n) being 0.16 for molecular hydrogen (H2) diffusing species and 0.25 for hydrogen atoms (H) diffusing species. We have found that the thicker the SiO2 dielectric the more the oxide traps (\({{N}_{{{\text{ot}}}}}\)) contribute to the resulting degradation. However, the dependency between SiO2 dielectric thickness and oxide traps could not be necessarily linear.

Similar content being viewed by others

DATA AVAILABILITY

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

REFERENCES

Bauza, D. and Ghibaudo, G., Microelectronics, 1994, vol. 25, p. 41. https://doi.org/10.1016/0026-2692(94)90158-9

Mahapatra, S., Huard, V., Kerber, A., Reddy, V., Kalpat, S., and Haggag, A., Proc. 2014 IEEE Int. Reliability Physics Symposium, Waikoloa, HI, 2014. https://doi.org/10.1109/IRPS.2014.6860615

Martins, M.T., Medeiros, G.C., Copetti, T., Vargas, F.L., and Bolzani Poehls, L.M., J. Electron. Test.: Theory Appl., 2017, vol. 33, p. 637. https://doi.org/10.1007/S10836-017-5685-6

Taghipour, S. and Niaraki Asli, R., J. Electron. Test.: Theory Appl., 2019, vol. 35, p. 119. https://doi.org/10.1007/S10836-019-05774-3

Miura, Y. and Matukura, Y., Jpn. J. Appl. Phys., Part 1, 1966, vol. 5, p. 180. https://doi.org/10.1143/JJAP.5.180/XML

Kaczer, B., Roussel, P.J., Grasser, T., and Groeseneken, G., IEEE Electron Device Lett., 2010, vol. 31, p. 411. https://doi.org/10.1109/LED.2010.2044014

Djezzar, B., Benabdelmoumene, A., Zatout, B., Messaoud, D., Chenouf, A., Tahi, H., Boubaaya, M., and Timlelt, H., Microelectron. Reliab., 2020, vol. 110, p. 113703. https://doi.org/10.1016/J.MICROREL.2020.113703

Tahi, H., Djezzar, B., Benabdelmoumene, A., Chenouf, A., and Goudjil, M., Microelectron. Reliab., 2014, vol. 54, p. 882. https://doi.org/10.1016/J.MICROREL.2014.01.010

Goel, N., Nanaware, N., and Mahapatra, S., IEEE Electron Device Lett., 2013, vol. 34, p. 1476. https://doi.org/10.1109/LED.2013.2284668

Rangan, S., Mielke, N., and Yeh, E.C.C., Proc. IEEE Int. Electron Devices Meeting 2003, Washington, DC, 2003, p. 14.3.1. https://doi.org/10.1109/IEDM.2003.1269294.

Denais, M., Bravaix, A., Huard, V., Parthasarathy, C., Ribes, G., Perrier, F., Rey-Tauriac, Y., and Revil, N., Proc. IEEE Int. Electron Devices Meeting, San Francisco, CA, 2004, IEDM 109–112. https://doi.org/10.1109/iedm.2004.1419080.

Messaoud, D., Djezzar, B., Benabdelmoumene, A., Zatout, B., and Zitouni, A., Proc. 2020 Int. Conference on Electrical Engineering (ICEE), Istanbul, 2020. https://doi.org/10.1109/ICEE49691.2020.9249809

Messaoud, D., Djezzar, B., Benabdelmoumene, A., Boubaaya, M., Zatout, B., and Zitouni, A., Alger. J. Signals Syst., 2021, vol. 6, p. 24. https://doi.org/10.51485/ajss.v6i1.3

Zafar, S., Lee, B.H., and Stathis, J., IEEE Electron Device Lett., 2004, vol. 25, p. 153. https://doi.org/10.1109/LED.2004.824244

Chakravarthi, S., Krishnan, A.T., Reddy, V., Machala, C.F., and Krishnan, S., Proc. 2004 IEEE Int. Reliability Physics Symposium, Phoenix, AZ, 2004, p. 273. https://doi.org/10.1109/RELPHY.2004.1315337

Grasser, T., Bias Temperature Instability for Devices and Circuits, Springer, 2014. https://doi.org/10.1007/978-1-4614-7909-3

Benabdelmoumene, A., Djezzar, B., Chenouf, A., Zatout, B., and Kechouane, M., IEEE Trans. Device Mater. Reliab., 2018, vol. 18, p. 583. https://doi.org/10.1109/TDMR.2018.2874359

Kerber, A., Cartier, E., Pantisano, L., Rosmeulen, M., Degraeve, R., Kauerauf, T., Groeseneken, G., Maes, H.E., and Schwalke, U., Proc. 2003 IEEE Int. Reliability Physics Symposium, Dallas, TX, 2003, p. 41. https://doi.org/10.1109/RELPHY.2003.1197718

Shen, C., Li, M.F., Wang, X.P., Yeo, Y.C., and Kwong, D.L., IEEE Electron Device Lett., 2006, vol. 27, p. 55. https://doi.org/10.1109/LED.2005.861025

Li, M.F., Huang, D., Shen, C., Yang, T., Liu, W.J., and Liu, Z., IEEE Trans. Device Mater. Reliab., 2008, vol. 8, p. 62. https://doi.org/10.1109/TDMR.2007.912273

Paulsen, R. and White, H.M., IEEE Trans. Electron Devices, 1994, vol. 41, p. 1213. https://doi.org/10.1109/16.293349

Shen, C., Li, M.F., Foo, C.E., Yang, T., Huang, D.M., Yaps, A., Samudra, G.S., and Yeo, Y.C., Proc. Int. Electron Devices Meeting, IEDM, Washington, DC, 2006.

McWhorter, P.J. and Winokur, P.S., Appl. Phys. Lett., 1998, vol. 48, p. 133. https://doi.org/10.1063/1.96974

Heh, D., Young, C.D., and Bersuker, G., IEEE Electron Device Lett., 2008, vol. 29, p. 180. https://doi.org/10.1109/LED.2007.914088

Velamala, J.B., Reddy, V., Zheng, R., Krishnan, S., and Cao, Y., Proc. 2010 IEEE Int. Reliability Physics Symposium, Anaheim, CA, 2010, p. 650. https://doi.org/10.1109/IRPS.2010.5488754

Alam, M.A. and Mahapatra, S., Microelectron. Reliab., 2005, vol. 45, p. 71. https://doi.org/10.1016/J.MICROREL.2004.03.019

Wang, W., Reddy, V., Krishnan, A.T., Vattikonda, R., Krishnan, S., and Cao, Y., IEEE Trans. Device Mater. Reliab., 2007, vol. 7, p. 509. https://doi.org/10.1109/TDMR.2007.910130

Stathis, J.H., Mahapatra, S., and Grasser, T., Microelectron. Reliab., 2018, vol. 81, p. 244. https://doi.org/10.1016/J.MICROREL.2017.12.035

ACKNOWLEDGMENTS

This work was supported by Directorate General for Scientific Research and Technological Development/Ministry of High Education and Scientific Research of Algeria (DGRSDT/MESRS) under the National Funding of Research (FNR) contract Νo. 05-4/FCS/DMN/ CDTA/PT 19-21.

In addition, this research work would not have been possible without the contribution of FCS team members, Microelectronics and Nanotechnology Division of CDTA, so they are gratefully acknowledged for their precious helps and discussions. This work is also done in collaboration with LSS team of IGEE (ex: INELEC), many thanks for their counsels.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis, and manuscript writing were performed by DhiaElhak Messaoud. Measurements were taken with the help of Mohamed Boubaaya and Boumediene Zatout. Samples study and preparation were done by Amel Chenouf. Data analysis and results discussion were achieved with the help of Boualem Djezzar and Abdelmadjid Benabdelmoumene. Abdelkader Zitouni has commented on the manuscript.

Corresponding author

Ethics declarations

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

CONSENT FOR PUBLICATION

The authors agree for publication.

CONSENT TO PARTICIPATE

The authors agree to participate.

Rights and permissions

About this article

Cite this article

Messaoud, D.E., Djezzar, B., Boubaaya, M. et al. Fast Methods for Studying the Effect of Electrical Stress on SiO2 Dielectrics in Metal-Oxide-Semiconductor Field-Effect Transistors. Instrum Exp Tech 66, 1095–1105 (2023). https://doi.org/10.1134/S0020441223060106

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441223060106