Abstract—

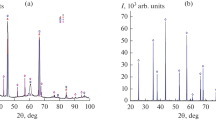

We have studied the effect of heat treatment temperature on dilatometric and densimetric characteristics (geometric dimensions, volume, density, and weight) of plasma-sprayed pure aluminum oxide ceramics using specially prepared samples 46 × 23 × 3 mm in dimensions. Some of the samples were heat-treated at temperatures of 800, 950, 1100, and 1300°C for 1 h in air. Before and after heat treatment, the samples were weighed and we measured their geometric dimensions and calculated their volume and density. In our experiments, we used precision analytical and measuring equipment and thermal analysis methods. The phase composition of the samples was determined by quantitative X-ray diffraction. Their porosity was evaluated using X-ray computed tomography. The results demonstrate that raising the heat treatment temperature leads first to an increase in the length of the samples under study relative to their original length, which is accompanied by a decrease in their thickness (in the range 800–1100°C). The volume and density of the samples also decrease. Further raising the heat treatment temperature (in the range 1100–1300°C) leads to a sharp decrease in all the geometric dimensions and volume of the samples, in combination with a sharp increase in their density, which is accompanied by a decrease in the weight of the samples. This was shown to be due to changes in the phase composition and total porosity of the samples during heating to the above temperatures.

Similar content being viewed by others

REFERENCES

Belyaev, I.V., Stepnov, A.A., and Kireev, A.V., Plazmennonapylnennye pokrytiya i izdeliya iz chistogo oksida alyuminiya (Plasma-Sprayed Coatings and Products from Pure Aluminum Oxide), LAP LAMBERT Academic, 2019.

Kashcheev, I.D., Svoistva i primenenie ogneuporov. Spravochnoe izdanie (Properties and Applications of Refractories: A Handbook), Moscow: Teplotekhnika, 2004.

Belyaev, I.V., Stepnov, A.A., Kireev, A.V., and Pavlov, A.A., Refractory ceramic products from pure oxides with getter coatings, Refract. Ind. Ceram., 2018, vol. 58, no. 6, pp. 615–617.

Stepnov, A.A., Belyaev, I.V., Bazhenov, V.E., Pavlov, A.A., and Kireev, A.V., Control over the porosity of plasma sprayed aluminum oxide parts by heat treatment, Inorg. Mater., 2019, vol. 55, no. 12, pp. 1214–1222.

Fiziko-khimicheskie svoistva okislov (Physicochemical properties of Oxides), Samsonov, G.V., Ed., Moscow: Metallurgiya, 1978.

Kosenko, N.F., Polymorphism of aluminum oxide, Izv. Vyssh. Uchebn. Zaved., Khim. Khim. Tekhnol., 2011, vol. 54, no. 5, pp. 3–16.

Keramika vysokoogneupornykh okislov (Highly Refractory Oxide Ceramics), Poluboyarinov, D.N. and Popilsky, R.Ya., Eds., Moscow: Metallurgiya, 1977.

Belyaev, I., Stepnov, A., Bazhenov, V., Pavlov, A., and Kireev, A., Influence of polymorphic transformations on the porosity of plasma sprayed products from pure aluminum oxide, METAL-2019: 28th Int. Conf. on Metallurgy and Materials (Brno, 2019), Ostrava: TANGER, 2019, pp. 968–972.

Belyaev, I.V., Pavlov, A.A., Bazhenov, V.E., Stepnov, A.A., and Kireev, A.V., Effect of heat treatment temperature on the pore size and density of plasma sprayed aluminum oxide parts, Inorg. Mater., 2021, vol. 57, no. 2, pp. 213–218.

Kudinov, V.V. and Ivanov, V.N., Nanesenie plazmoi tugoplavkikh pokrytii (Plasma Deposition of Refractory Coatings), Moscow: Mashinostroenie, 1981.

Hao Du, Jae Heyg Shin, and Soo Wohn Lee, Study on porosity of plasma-sprayed coatings by digital image analysis method, J. Therm. Spray Technol., 2005, vol. 14, no. 4, pp. 453–461.

Kovarik, L., Bowden, M., Genc, A., Szanyi, J., Charles Peden, H.F., Kwak Ja Hun, Structure of ?-alumina: toward the atomic level understanding of transition alumina phases, J. Phys. Chem., 2014, no. 118, pp. 18051–18058.

Frolov, V.Ya., Klubnikin, V.S., Petrov, G.K., and Yushin, B.A., Tekhnika i tekhnologii naneseniya pokrytii (Coating Processes and Technologies), St. Petersburg: Politekh. Univ., 2008.

Tablitsy fizicheskikh velichin. Spravochnik (Tables of Physical Quantities), Kikoin, I.K., Ed., Moscow: Atomizdat, 2008.

Sokolov, I.N., Chernov, M.S., Kalita, V.I., Komlev, D.I., and Radyuk, A.A., Structure and porosity of plasma coatings, Fiz. Khim. Obrab. Mater., 2020, no. 5, pp. 33–43.

Kudinov, V.V. and Bobrov, G.V., Nanesenie pokrytii napyleniem. Teoriya, tekhnologiya, materialy. Uchebnik dlya vuzov (Growth of Coatings by Sputter Deposition: Theory, Technology, and Materials—Learning Guide for Higher Education Institutions), Moscow: Mashinostroenie, 1992.

Matrenin, S.V. and Slosman, A.I., Tekhnicheskaya keramika (Engineering Ceramics), Tomsk: Tomsk. Politekh. Univ., 2004.

Funding

This work was supported by the RF Ministry of Science and Higher Education (state research target, project no. 0718-2020-0037).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Belyaev, I.V., Stepnov, A.A., Mogil’nikov, P.S. et al. Effect of Heat Treatment Temperature on Dilatometric and Densimetric Characteristics of Plasma-Sprayed Al2O3 Ceramics. Inorg Mater 58, 744–750 (2022). https://doi.org/10.1134/S0020168522070044

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168522070044