Abstract

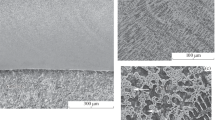

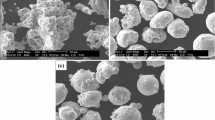

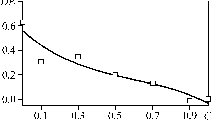

When reconstructing products obtained using additive technologies based on layer-by-layer melting of metal powder by concentrated energy flows, it is advisable to use methods that minimize melting of the initial powder and reduce structural heterogeneity of the material. Cold gas-dynamic spraying with laser-induced intensification of the process (CGDSL) is one of them. The multilayer coatings obtained by the CGDSL method have a homogeneous metal structure, though a significant surface roughness attributed to the particle size of the original powder is observed. The goal of the study is to develop a new method of post-processing of multilayer coatings obtained by CGDSL which can provide a hardened layer on their surface. A hardened layer is formed through introduction of boron carbide powder particles into the laser-molten region formed on the surface of the coating based on 316L stainless steel. An acoustic wave triggered by a “microexplosion” induced by a laser pulse above the surface pushes carbide particles in different directions. Some of them are embedded into the melt pool on the surface of the coating. Thus, the laser microexplosion cartooning of the surface of the CGDSL coating is implemented. Study of the hardened layer revealed a high content of B, C, Cr, Fe, and Ni. Moreover, it is shown that solid carbides of rhombic form are formed in the hardened layer. Chemical and elemental analyses showed that diamond-shaped carbides—carbides of the type (Fe, Cr)xBy—contain a high concentration of Cr and Fe and a relatively small percentage of C. Most likely, the formation of diamond-shaped carbides occurs owing to interaction of chromium which is a part of the initial hardened coating with boron that is released from the surface of BC particles under laser impact. The developed method provides hardening of the surface layer of the coating previously obtained by CGDSL by embedding BC powder particles into the surface. The technology of hardening CGDSL coatings can be implemented using other powder materials.

Similar content being viewed by others

REFERENCES

Bagherifard, S., Monti, S., Zuccoli, M., et al., Cold spray deposition for additive manufacturing of freeform structural components compared to selective laser melting, Mater. Sci. Eng., A, 2018, vol. 721, pp. 339–350.

AL-Mangour, B., Vo, P., Mongrain, R., Irissou, E., and Yue, S., Effect of heat treatment on the microstructure and mechanical properties of stainless steel 316L coatings produced by cold spray for biomedical applications, J. Therm. Spray Technol., 2014, vol. 23, no. 4, p. 641.

Coddet, P., Verdy, C., Coddet, C., Debray, F., and Lecouturier, F., Mechanical properties of thick 304L stainless steel deposits processed by He cold spray, Surf. Coat. Technol., 2015, vol. 277, pp. 74–80.

Gorunov, A.I., Features of coatings obtained by supersonic laser deposition, J. Therm. Spray Technol., 2018, vol. 27, no. 7, pp. 1194–1203.

Yao, J., Li, Z., Li, B., Yang, L., and Yaoet, J., Characteristics and bonding behavior of Stellite 6 alloy coating processed with supersonic laser deposition, J. Alloys Compd., 2016, vol. 661, pp. 526–534.

Lupoi, R., Sparkes, M., Cockburn, A., and O’Neill, W., High speed titanium coatings by supersonic laser deposition, Mater. Lett., 2011, vol. 65, pp. 3205–3207.

Singh, R., Rauwald, K.-H., Wessel, E., et al., Effects of substrate roughness and spray-angle on deposition behavior of cold-sprayed Inconel 718, Surf. Coat. Technol., 2017, vol. 319, pp. 249–259.

Yuan, L.-J., Luo, F., Yao, J.-H., et al., Deposition behavior at different substrate temperatures by using supersonic laser deposition, J. Iron Steel Res. Int., 2013, vol. 20, no. 10, pp. 87–93.

Yao, J., Yang, L., Li, B., et al., Characteristics and performance of hard Ni60 alloy coating produced with supersonic laser deposition technique, Mater. Des., 2015, vol. 83, pp. 26–35.

Li, B., Jin, Y., Yao, J., et al., Solid-state fabrication of WCp-reinforced Stellite-6 composite coatings with supersonic laser deposition, Surf. Coat. Technol., 2017, vol. 321, pp. 386–396.

Li, B., Jin, Y., Yao, J., Li, Z., et al., Influence of laser irradiation on deposition characteristics of cold sprayed Stellite-6 coatings, Opt. Laser Technol., 2018, vol. 100, pp. 27–39.

Gorunov, A.I., Formation of wear-resistant coatings based on nickel by supersonic laser surfacing, Fiz. Khim. Obrab. Mater., 2016, no. 5, pp. 59–64.

Sova, A., Grigoriev, S., Okunkova, A., and Smurov, I., Cold spray deposition of 316L stainless steel coatings on an aluminum surface with the following laser post-treatment, Surf. Coat. Technol., 2013, vol. 235, pp. 283–289.

Ivannikov, A.Yu., Kalita, V.I., Komlev, D.I., et al., Investigation into improving microstructure and properties of plasma sprayed Ni coating via electromechanical treatment, J. Mater. Process. Technol., 2019, vol. 266, pp. 442–449.

Gorunov, A.I., The structure and mechanical properties of corrosion-resistant steel coating formed by gas-dynamic sputtering method with process activation by laser emission, Deform. Razrushenie Mater., 2016, no. 9, pp. 2–7.

Makarov, A.V., Sobolev, N.N., Malygina, I.Yu., and Osintseva, A.L., Formation of wear-resistant chromium-nickel coating with extra high thermal stability by combined laser-and-heat treatment, Met. Sci. Heat Treat., 2015, vol. 57, nos. 3–4, pp. 161–168.

Kalita, V.I., Yarkin, V.V., Bagmutov, V.P., et al., Formation of coatings with nanostructures and amorphous structures, Russ. Metall. (Engl. Transl.), 2007, vol. 2007, no. 6, pp. 534–539.

Gorunov, A.I., Investigation microstructure of carbon fibers reinforced composite on Fe and Ni-based obtained by laser metal deposition, Surf. Coat. Technol., 2019, vol. 364, pp. 279–288.

Funding

This work was supported by the Russian Science Foundation, project no. 19-79-00039 (development of the method of hardening of a multilayer CGDSL coating by means of acoustic effects created by a laser, investigation of the structure and chemical composition of the hardened layer) and the grant of the President of the Russian Federation, no. MK-3745.2019.8 (obtaining of multilayer coatings by CGDSL method).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Gumerov

Rights and permissions

About this article

Cite this article

Gorunov, A.I. Study of a Hardened Multilayer Coating Obtained by Cold Gas-Dynamic Spraying with Laser Intensification. Inorg Mater 57, 1463–1467 (2021). https://doi.org/10.1134/S0020168521150085

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521150085