Abstract—

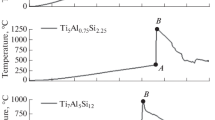

A lightweight intermetallic alloy containing the ternary phase Al18Ti2Mg3 has been prepared for the first time in the Ti–Al–Mg system by self-propagating high-temperature synthesis. In the binary system Ti–Al, synthesis has been carried out in the thermal explosion regime, whereas in the ternary system Ti–Al–Mg layer-by-layer combustion synthesis has been performed. The porosity of the synthesized materials is 43.3%, and its density is 2.4 g/cm3.

Similar content being viewed by others

REFERENCES

Vaidya, W.V., Horstmann, M., Ventzke, V., Petrovski, B., Kocak, M., Kocik, R., and Tempus, G., Structure–property investigations on a laser beam welded dissimilar joint of aluminium AA6056 and titanium Ti6Al4V for aeronautical applications. Part I: local gradients in microstructure, hardness and strength, Materialwissenshaft Werkstofftech., 2009, vol. 40, no. 8, pp. 623–633.https://doi.org/10.1002/mawe.200900366

Manladan, S., Yusof, F., Ramesh, S., and Fadzil, M., A review on resistance spot welding of magnesium alloys, Int. J. Adv. Manuf. Technol., 2016, vol. 86, no. 5, pp. 1805–1825.https://doi.org/10.1007/s00170-015-8258-9

Liu, L., Introduction to welding and joining of magnesium, Welding and Joining of Magnesium Alloys, Liu, L., Ed., Cambridge: Woodhead, 2010, pp. 3–8.https://doi.org/10.1533/9780857090423.1.3

Manladan, S., Yusof, F., Ramesh, S., Fadzil, M., Luo, Z., and Ao, S., A review on resistance spot welding of aluminum alloys, Int. J. Adv. Manuf. Technol., 2017, vol. 90, no. 1, pp. 605–634.https://doi.org/10.1007/s00170-016-9225-9

Han, L., Thornton, M., and Shergold, M., A comparison of the mechanical behaviour of self-piercing riveted and resistance spot welded aluminium sheets for the automotive industry, Mater. Des., 2010, vol. 31, no. 3, pp. 1457–1467.https://doi.org/10.1016/j.matdes.2009.08.031

Ambroziak, A. and Korzeniowski, M., Using resistance spot welding for joining aluminium elements in automotive industry, Arch. Civ. Mech. Eng., 2010, vol. 10, no. 1, pp. 5–13.https://doi.org/10.1016/S1644-9665(12)60126-5

Rodriguez, R., Jordon, J., Allison, P., Rushing, T., and Garcia, L., Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys, Mater. Des., 2015, vol. 83, pp. 60–65.https://doi.org/10.1016/j.matdes.2015.05.074

Han, L., Thornton, M., Boomer, D., and Shergold, M., A correlation study of mechanical strength of resistance spot welding of AA5754 aluminium alloy, J. Mater. Process. Technol., 2011, vol. 211, no. 3, pp. 513–521.https://doi.org/10.1016/j.jmatprotec.2010.11.004

Han, L., Thornton, M., Li, D., and Shergold, M., Effect of governing metal thickness and stack orientation on weld quality and mechanical behaviour of resistance spot welding of AA5754 aluminium, Mater. Des., 2011, vol. 32, no. 4, pp. 2107–2114.https://doi.org/10.1016/j.matdes.2010.11.047

Liu, J., Rao, Z., Liao, S., and Wang, P.-C., Modeling of transport phenomena and solidification cracking in laser spot bead-on-plate welding of AA6063-T6 alloy. Part I. The mathematical model, Int. J. Adv. Manuf. Technol., 2014, vol. 73, nos. 9–12, pp. 1705–1716.https://doi.org/10.1007/s00170-014-5924-2

Humpenöder, F., Popp, A., Stevanovic, M., Müller, C., Bodirsky, B.L., Bonsch, M., Dietrich, J.P., Lotze-Campen, H., Weindl, I., and Biewald, A., Land-use and carbon cycle responses to moderate climate change: implications for land-based mitigation?, Environ. Sci. Technol., 2015, vol. 49, no. 11, pp. 6731–6739. https://doi.org/10.1021/es506201r

Manladan, S., Yusof, F., Ramesh, S., and Fadzil, M., A review on resistance spot welding of magnesium alloys, Int. J. Adv. Manuf. Technol., 2016, vol. 86, no. 5, pp. 1805–1825.https://doi.org/10.1007/s00170-015-8258-9

Kim, H.C. and Wallington, T.J., Life-cycle energy and greenhouse gas emission benefits of lightweighting in automobiles: review and harmonization, Environ. Sci. Technol., 2013, vol. 47, no. 12, pp. 6089–6097.https://doi.org/10.1021/es3042115

Modaresi, R., Pauliuk, S., Løvik, A.N., and Müller, D.B., Global carbon benefits of material substitution in passenger cars until 2050 and the impact on the steel and aluminum industries, Environ. Sci. Technol., 2014, vol. 48, no. 18, pp. 10776–10784.https://doi.org/10.1021/es502930w

Zhang, F.Y., Yan, M.F., You, Y., Zhang, C.S., and Chen., H.T., Prediction of elastic and electronic properties of cubic Al18Ti2Mg3 phase coexisting with Al3Ti in Al–Ti–Mg system, Phys. B (Amsterdam, Neth.), 2013, vol. 408, pp. 68–72.https://doi.org/10.1016/j.physb.2012.09.039

Huashun Yu., Kim, J.D., and Kang, S.B., The formation of AlN and TiN particles during nitrogen bearing gas injection into Al–Mg–Ti melt, Mater. Sci. Eng., A, 2004, vol. 386, nos. 1–2, pp. 318–325.https://doi.org/10.1016/j.msea.2004.07.049

Zhang, X.P., Yang, T.H., Castagne, S., and Wang, J.T., Microstructure, bonding strength and thickness ratio of Al/Mg/Al alloy laminated composites prepared by hot rolling, Mater. Sci. Eng., A, 2011, vol. 528, nos. 4–5, pp. 1954–1960.https://doi.org/10.1016/j.msea.2010.10.105

Parisa, D.M. and Beitallah, E., Microstructure and mechanical properties of tri-metal Al/Ti/Mg laminated composite processed by accumulative roll bonding, Mater. Sci. Eng., A, 2015, vol. 628, pp. 135–142.https://doi.org/10.1016/j.msea.2014.12.067

Merzhanov, A.G., The chemistry of self-propagating high-temperature synthesis, Mater. Chem., 2004, vol. 14, pp. 1779–1791.https://doi.org/10.1039/B401358C

Boyarchenko, O.D., Kamynina, O.K., Sytschev, A.E., Vadchenko, S.G., Gotman, I., and Umarov, L.M., Synthesis of Ti–Al based materials by thermal explosion, Int. J. Self-Propag. High-Temp. Synth., 2010, vol. 19, pp. 285–291.https://doi.org/10.3103/S1061386210040084

Kochetov, N.A. and Sytschev, A.E., Effects of magnesium on initial temperature and mechanical activation on combustion synthesis in Ti–Al–Mg system, Mater. Chem. Phys., 2021, vol. 257, no. 1, paper 12372.https://doi.org/10.1016/j.matchemphys.2020.123727

Murray, J.L., The Mg–Ti (magnesium–titanium) system, Bull. Alloy Phase Diagrams, 1986, vol. 7, pp. 245–248.https://doi.org/10.1007/BF02868999

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Lazarev, P.A., Sychev, A.E., Kochetov, N.A. et al. Preparation of an Al–Ti–Mg Composite by Self-Propagating High-Temperature Synthesis. Inorg Mater 57, 324–329 (2021). https://doi.org/10.1134/S0020168521030079

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521030079