Abstract

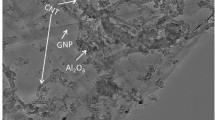

We report the effect of graphene (G) allotropic carbon modification in a content range of 0.5–2.0 wt % on the tribological, strength, and structural characteristics of an Al2O3/G nanocomposite produced by a 10-min plasma spark sintering (at a pressure of 50 MPa and a temperature of 1550°C) of a nanopowder mixture, previously subjected to ultrasonic dispersion in organic solvent. Its lubricant free friction and wear are tested at room temperature on a tribometer under a load of 20 N, at a roundabout motion of a ruby ball penetrator on a disk. The nanohardness and elastic modulus of the nanocomposite are determined via kinetic indentation. The fracture surface structure and friction track are monitored using a scanning electron microscope. The microstructure in the bulk of the nanocomposite was probed via dark- and bright-field transmission electron microscopy scanning of thin foils. The thermal stability of graphene was monitored via Raman spectroscopy. The introduction of graphene is shown to improve micro- and nanohardness, elasticity, and wear resistance by two to three orders of magnitude, as well as to slightly decrease the coefficient of friction. A graphene content of 2 wt % alters the mechanism of wear from brittle fracture to viscous shear owing to stronger coupling of matrix grains and the presence of agglomerates. A lack of degradation and the retention of graphene thermal stability are evidenced as well. The morphology of graphene particles reveals their preferential arrangement inside the corundum grains rather than at the grain boundaries.

Similar content being viewed by others

REFERENCES

Novoselov, K.S. et al., Two-dimensional gas of massless Dirac fermions in graphene, Nature, 2005, vol. 438, pp. 197–200.

Xia, H., Zhang, X., Shi, Z., Zhao, C., et al., Mechanical and thermal properties of reduced graphene oxide reinforced aluminum nitride ceramic composites, Mater. Sci. Eng., A, 2015, vol. 639, pp. 29–36.

Kim, H.J., et al., Unoxidized graphene/alumina nanocomposite: fracture- and wear-resistance effects of graphene on alumina matrix, Sci. Rep., 2014, vol. 4, pp. 5176–5185.

Centeno, A., Rocha, V.G., Alonso, B., Fernández, A., et al., Graphene for tough and electroconductive alumina ceramics, J. Eur. Ceram. Soc., 2013, vol. 333, pp. 201–321.

Borrell, A., Torrecillas, R., Rocha, V.G., Fernández, A., et al., Effect of CNFs content on the tribological behavior of spark plasma sintering ceramic–CNFs composites, Wear, 2012, vol. 274, pp. 94–99.

Stankovich, S. et al., Graphene-based composite materials, Nature, 2006, vol. 442, pp. 282–286.

Zholnin, A.G., Kovaleva, I.V., Yurlova, M.C., Ilina, A.M., et al., Uniaxial magnetic pulsed compaction of α-Al2O3 nanopowders followed by conventional and spark-plasma sintering, Phys. Chem. Mater. Process., 2015, vol. 2, pp. 73–79.

Yu, M., Grasso, S., McKinnon, R., Saunders, T.J., and Reece, M.J., Review of flash sintering: materials, mechanisms and modeling, Adv. Appl. Ceram., 2017, vol. 116, no. 1, pp. 24–60.

Oliver, W.C. and Pharr, G.M., An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, vol. 7, pp. 1564–1583.

Kachala, V.V., Khemchyan, L.L., Kashin, A.S., Orlov, N.V., Grachev, A.A., Zalesskiy, S.S., and Ananikov, V.P., Target-oriented analysis of gaseous, liquid and solid chemical systems by mass spectrometry, nuclear magnetic resonance spectroscopy and electron microscopy, Russ. Chem. Rev., 2013, vol. 82, pp. 648–685.

Kashin, A.S. and Ananikov, V.P., A SEM study of nanosized metal films and metal nanoparticles obtained by magnetron sputtering, Russ. Chem. Bull., 2011, vol. 60, pp. 2602–2607.

ASTM G99-03: Standard Test Method for Wear Testing with a Pin-on-Disc Apparatus, West Conshohocken, PA: ASTM Int., 2003.

Zholnin, A.G., Kovaleva, I.V., Rytenko, V.Yu., Pahilo-Daryal, I.O., et al., Effect of particle size of alumina powder on spark-plasma sintering, Phys. Chem. Mater. Process., 2016, vol. 1, pp. 53–63.

Golovin, Yu.I., Vvedenie v nanotekhnologiyu (Introduction into Nanotechnology), Moscow: Mashinostroenie, 2007.

Klyatskina, E.A., Borrell, A., Grigoriev, E.G., Zholnin, A.G., Salvador, M.D., and Stolyarov, V.V., Structure features and properties of graphene/Al2O3 composite, J. Ceram. Sci. Technol., 2018, vol. 9, no. 3, pp. 215–224.

Benavente, R., Pruna, A., Borrell, A., Salvador, M.D., et al., Fast route to obtain Al2O3-based nanocomposites employing graphene oxide: synthesis and sintering, Mater. Res. Bull., 2015, vol. 64, pp. 245–251.

Inam, F., Vo, T., and Bhat, B.R., Structural stability studies of graphene in sintered ceramic nanocomposites, Ceram. Int., 2014, vol. 40, pp. 16227–16233.

Gupta, A., Chen, G., Joshi, P., Tadigadapa, S., and Eklund, P.C., Raman scattering from high-frequency phonons in supported n-graphene layer films, Nano Lett., 2006, vol. 6, pp. 2667–2673.

Funding

This work was supported within the framework of the Program of Competitiveness by the National Research Nuclear University MEPhI and by the Russian Science Foundation (project no. 16-19-10213).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Maslova

Rights and permissions

About this article

Cite this article

Stolyarov, V.V., Klyatskina, E.A. Friction and Wear of Al2O3 + G Nanocomposite Produced via Spark Plasma Sintering. Inorg Mater 55, 1490–1495 (2019). https://doi.org/10.1134/S0020168519150135

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519150135