Abstract—

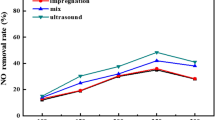

We have studied the catalytic activity of Cu–Ni bimetallic catalysts on yttrium-, tin-, zinc-, and niobium-doped zirconia and ceria supports for methanol steam reforming (MSR), a process for hydrogen production, and examined the effect of the nature of the dopants and annealing temperature on the structure and particle size of the oxide supports and the catalytic activity of the metal oxide composites. In all cases, the addition of heterovalent ions improved the catalytic activity of the materials for the MSR process in comparison with undoped zirconia. The highest hydrogen yield was reached in the case of catalysts doped with niobium and yttrium oxides.

Similar content being viewed by others

REFERENCES

Yaroslavtsev, A.B., Stenina, I.A., Kulova, T.L., Skundin, A.M., and Desyatov, A.V., Nanomaterials for electrical energy storage, Comprehensive Nanoscience and Nanotechnology, Andrews, D.L. et al., Eds., Amsterdam: Academic, 2019, 2nd ed., pp. 165–206.

Shafiei, E., Davidsdottir, B., Leaver, J., Stefansson, H., and Asgeirsson, E.I., Energy, economic, and mitigation cost implications of transition toward a carbon-neutral transport sector: a simulation-based comparison between hydrogen and electricity, J. Clean Prod., 2017, vol. 141, pp. 237–247.

Moliner, R., Lazaro, M.J., and Suelves, I., Analysis of the strategies for bridging the gap towards the hydrogen economy, Int. J. Hydrogen Energy, 2016, vol. 41, pp. 19 500–19 508.

Abe, J.O., Popoola, A.P.I., Ajenifuja, E., and Popoola, O.M., Hydrogen energy, economy and storage: review and recommendation, Int. J. Hydrogen Energy, 2019, vol. 44, pp. 15 072–15 086.

Naruki, E., Shimoda, E., Goshome, K., Yamane, T., Nozu, T., and Maeda, T., Construction and operation of hydrogen energy utilization system for a zero emission building, Int. J. Hydrogen Energy, 2019, vol. 44, pp. 14 596–14 604.

Miranda, P.E., Hydrogen energy, Sustainable and Perennial Science and Engineering of Hydrogen-Based Energy Technologies, Miranda, P.E., Ed., Amsterdam: Academic, 2019, chapter 1, pp. 1–38.

Frusteri, F. and Bonura, G., Hydrogen production by reforming of bio-alcohols, Compendium of Hydrogen Energy. Hydrogen Production and Purification, Subramani, V. et al., Eds., Woodhead Publishing Series in Energy, 2015.

Ghasemzadeh, K., Jalilnejad, E., Mohamad, S., and Tilebon, S., Hydrogen production technologies from ethanol, Ethanol, Basile, A. et al., Eds., Amsterdam: Elsevier, 2019, chapter 12, pp. 307–340.

López-Tenllado, F.J., Hidalgo-Carrillo, J., Montes-Jiménez, V., Sánchez-López, E., Urbano, F.J., and Marinas, A., Photocatalytic production of hydrogen from binary mixtures of C-3 alcohols on Pt/TiO2: influence of alcohol structure, Catal. Today, 2019, vol. 328, pp. 2–7.

Li, Sh., Zheng, H., Zheng, Y., Tian, J., Jing, T., Chang, Jo-Sh., and Ho, Sh.H., Recent advances in hydrogen production by thermo-catalytic conversion of biomass, Int. J. Hydrogen Energy, 2019, vol. 44, pp. 14 266–14 278.

Chiu, Y.J., Chiu, H.C., Hsieh, R.H., Jang, J.H., and Jiang, B.Y., Simulations of hydrogen production by methanol steam reforming, Energy Proc., 2019, vol. 156, pp. 38–42.

Lytkina, A.A., Orekhova, N.V., and Yaroslavtsev, A.B., Catalysts for the steam reforming and electrochemical oxidation of methanol, Inorg. Mater., 2018, vol. 54, no. 13, pp. 1315–1329.

Kim, D.H., Kim, J.H., Jang, Y.S., and Kim, J.C., Hydrogen production by oxidative steam reforming of methanol over anodic aluminum oxide-supported Cu–Zn catalyst, Int. J. Hydrogen Energy, 2019, vol. 44, pp. 9873–9882.

Tahay, P., Khani, Y., Jabari, M., Bahadoran, F., and Safari, N., Highly porous monolith/TiO2 supported Cu, Cu–Ni, Ru, and Pt catalysts in methanol steam reforming process for H2 generation, Appl. Catal., A, 2018, vol. 554, pp. 44–53.

Khzouz, M., Gkanas, E.I., Du, S., and Wood, J., Catalytic performance of Ni–Cu/Al2O3 for effective syngas production by methanol steam reforming, Fuel, 2018, vol. 232, pp. 672–683.

Kuo, M.T., Chen, Y.Y., Hung, W.Y., Lin, S.F., Lin, H.P., Hsu, C.H., Shih, H.Y., Xie, W.A., and Li, S.N., Synthesis of mesoporous CuFe/silicates catalyst for methanol steam reforming, Int. J. Hydrogen Energy, 2019, vol. 44, pp. 14 416–14 423.

Sa, S., Silva, H., Brandao, L., Sousa, J.M., and Mendes, A., Catalysts for methanol steam reforming—a review, Appl. Catal., B, 2010, vol. 99, pp. 43–57.

Azenha, C.S.R., Mateos-Pedrero, C., Queirós, S., Concepción, P., and Mendes, A., Innovative ZrO2-supported CuPd catalysts for the selective production of hydrogen from methanol steam reforming, Appl. Catal., B, 2017, vol. 203, pp. 400–404.

Sarafraz, M.M., Safaei, M.R., Goodarzi, M., and Ajomandi, M., Reforming of methanol with steam in a micro-reactor with Cu–SiO2 porous catalyst, Int. J. Hydrogen Energy, 2019 (in press). https://doi.org/10.1016/j.ijhydene.2019.05.215

Hwang, B.Y., Sakthinathan, S., and Chiu, T.W., Production of hydrogen from steam reforming of methanol carried out by self-combusted CuCr1 –xFexO2 (x = 0–1) nanopowders catalyst, Int. J. Hydrogen Energy, 2019, vol. 44, pp. 2848–2856.

Thyssen, V.V., Sartore, D.M., and Assaf, E.M., Effect of preparation method on the performance of Ni/MgOSiO2 catalysts for glycerol steam reforming, J. Energy Inst., 2019, vol. 92, pp. 947–958.

Liu, X., Men, Y., Wang, J., He, R., and Wang, Y., Remarkable support effect on the reactivity of Pt/In2O3/MOx catalysts for methanol steam reforming, J. Power Sources, 2017, vol. 364, pp. 341–350.

Wang, S., Niu, H., Guo, M., Wang, J., Chen, T., and Wang, G., Effect of zirconia polymorph on the synthesis of diphenyl carbonate over supported lead catalysts, Mol. Catal., 2019, vol. 468, pp. 117–124.

Lytkina, A.A., Zhilyaeva, N.A., Ermilova, M.M., Orekhova, N.V., and Yaroslavtsev, A.B., Influence of the support structure and composition of Ni–Cu-based catalysts on hydrogen production by methanol steam reforming, Int. J. Hydrogen Energy, 2015, vol. 40, pp. 9677–9684.

Liu, X., Toyir, J., Piscina, P.R., and Homs, N., Hydrogen production from methanol steam reforming over Al2O3- and ZrO2-modified CuOZnOGa2O3 catalysts, Int. J. Hydrogen Energy, 2017, vol. 42, pp. 13 704–13 711.

Guangwei, X., Laitao, L., Changquan, L., and Xiaomao, Y., Synthesis of mesoporous ZnO (m-ZnO) and catalytic performance of the Pd/m-ZnO catalyst for methanol steam reforming, Energy Fuels, 2009, vol. 23, pp. 1342–1346.

Sanches, S.G., Huertas Flores, J., and Pais da Silva, M.I., Cu/ZnO and Cu/ZnO/ZrO2 catalysts used for methanol steam reforming, Mol. Catal., 2018, vol. 454, pp. 55–62.

Stenina, I.A., Voropaeva, E.Yu., Brueva, T.R., Sinel’nikov, A.A., Drozdova, N.A., Ievlev, V.M., and Yaroslavtsev, A.B., Heat-treatment induced evolution of the morphology and microstructure of zirconia prepared from chloride solutions during, Russ. J. Inorg. Chem., 2008, vol. 53, no. 6, pp. 842–848.

Borik, M.A., Volkova, T.V., Kuritsyna, I.E., Lomonova, E.E., Myzina, V.A., Ryabochkina, P.A., and Tabachkova, N.Yu., Features of the local structure and transport properties of ZrO2–Y2O3–Eu2O3 solid solutions, J. Alloys Compd., 2019, vol. 770, pp. 320–326.

Shukla, V., Balani, K., Subramaniam, A., and Omar, S., Phase stability and conductivity in the pseudo ternary system of xYb2O3–(12 – x)Sc2O3–88ZrO2 (0 ≤ x ≤ 5), Solid State Ionics, 2019, vol. 332, pp. 93–101.

Lytkina, A.A., Orekhova, N.V., Ermilova, M.M., and Yaroslavtsev, A.B., The influence of the support composition and structure (MxZr1 –xO2 –d) of bimetallic catalysts on the activity in methanol steam reforming, Int. J. Hydrogen Energy, 2018, vol. 43, pp. 198–207.

Trovarelli, A., Catalysis by Ceria and Related Materials, London: Imperial College, 2002, p. 508.

Zhao, Q., Lorenz, H., Turner, S., Lebedev, O.I., Tendeloo, G.V., Rameshan, C., Klotzer, B., Konzett, J., and Penner, S., Catalytic characterization of pure SnO2 and GeO2 in methanol steam reforming, Appl. Catal., A, 2010, vol. 375, pp. 188–195.

Guarido, C.E.M., Cesar, D.V., Souza, M.M.V.M., and Schmal, M., Ethanol reforming and partial oxidation with Cu/Nb2O5 catalyst, Catal. Today, 2009, vol. 142, pp. 252–257.

Dancini-Pontes, I., De Souza, M., Silva, F.A., Scaliante, M.H.N.O., Alonso, C.G., Bianchi, G.S., Neto, A.M., Pereira, G.M., and Fernandes-Machado, N.R.C., Influence of the CeO2 and Nb2O5 supports and the inert gas in ethanol steam reforming for H2 production, Chem. Eng. J., 2015, vol. 273, pp. 66–74.

Bejugama, S. and Pandey, A.K., Effect of Nb2O5 on sintering and mechanical properties of ceria stabilized zirconia, J. Alloys Compd., 2018, vol. 765, pp. 1049–1054.

Cai, F., Lu, P., Ibrahim, J.J., Fu, Y., Zhang, J., and Sun, Y., Investigation of the role of Nb on Pd–Zr–Zn catalyst in methanol steam reforming for hydrogen production, Int. Hydrogen Energy, 2019, vol. 44, pp. 11 717–11 733.

Stenina, I.A., Voropaeva, E.Yu., Veresov, A.G., Kapustin, G.I., and Yaroslavtsev, A.B., Effect of precipitation pH and heat treatment on the properties of hydrous zirconium dioxide, Russ. J. Inorg. Chem., 2008, vol. 53, no. 3, pp. 350–356.

Funding

This work was supported by the Russian Federation Ministry of Science and Higher Education (agreement no. RFMEFI58617X0053) and CNRS, France (project no. 38200SF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Lytkina, A.A., Bakuleva, N.A., Orekhova, N.V. et al. Effects of Support Structure and Composition on the Activity of Cu–Ni Catalysts for Methanol Steam Reforming. Inorg Mater 55, 1230–1236 (2019). https://doi.org/10.1134/S0020168519120100

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519120100