Abstract—

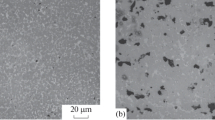

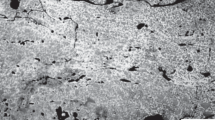

The results of obtaining by plasma processing of spherical, including hollow, particles of cermet powder with high content of carbide inclusions have been presented. The phase composition of particles has been determined, their morphology and internal structure has been studied. An explanation of formation of a hollow particle has been proposed.

Similar content being viewed by others

REFERENCES

Berger, L.M., Thiele, S., Börner, T., Janka, L., and Rodriguez Ripoll, M., Influence of Cr3C2–NiCr feedstock powder characteristics on the deposition efficiency, coating microstructures and abrasion wear resistance, Thermal Spray 2014: Proc. Int. Thermal Spray Conf., 2014, pp. 806–812.

Melnyk, C., Gansert, R., Lajun, D., Weinstein, B., Grant D., and Watson, M., Investigation of mechanical properties of coatings and bulk components of various grain sized tungsten-carbide–cobalt based materials, Thermal Spray 2011: Proc. Int. Thermal Spray Conf., 2011, pp. 157–161.

Żórawski, W., Skrzypek, S., and Trpčevska, J., Tribological properties of hypersonically sprayed carbide coatings, FME Trans., 2008, vol. 36, pp. 81–86.

Zimakov, S., Kulu, P., Goljandin, D., et al., Microstructured cermet powders for HVOF spraying, Welding Powder Metall., 2005, vol. 1, pp. 1–8.

Balamurugan, G.M. and Duraiselvam, M., Influence of temperature on the wear behaviour of WC–Co plasma sprayed AISI 304 austenitic stainless steel, Comput. Modelling New Technol., 2010, vol. 14, no. 3, pp. 30–40.

Fincke, J.R., Swank, W.D., and Haggard, D.C., Comparison of the characteristics of HVOF and plasma thermal spray, Proc. Thermal Spray Industrial Applications Conf., Boston, 1994, pp. 325–330.

Vereshchaka, A.S., Rabotosposobnost’ rezhushchego instrumenta s iznosostoikimi pokrytiyami (Performance of Cutting Tools with Wear-Resistant Coatings), Moscow: Mashinostroenie, 1993.

Tkachenko, Yu.G., Ordan’yan, S.S., and Yulyugin, V.K., Characterization of friction and deformation in the contact zone of titanium carbide in the homogeneity range, Poroshk. Metall. (Kiev), 1979, vol. 6, pp. 45–51.

Merzhanov, A.G., Tverdoplamennoe gorenie (Solid-Flame Combustion), Chernogolovka: Inst. Strukturnoi Makrokinetiki Ross. Akad. Nauk, 2000.

Lyakhov, N.Z., Talako, T.L., and Grigor’eva, T.F., Vliyanie mekhanoaktivatsii na protsessy fazo- i strukturoobrazovaniya pri SVS, (Effect of Mechanical Activation on Phase and Structure Formation Processes during Self-Propagating High-Temperature Synthesis), Novosibirsk: Parallel’, 2008.

Solonenko, O.P., Ovcharenko, V.E., Ulianitsky, V.Y., Chesnokov, A.E., and Batraev, I.S., Effect of the microstructure of SHS powders of titanium carbide–nichrome on the properties of detonation coatings, J. Surf. Invest., 2016, vol. 10, no. 5, pp. 1040–1047.

Solonenko, O.P., Criterion conditions for the formation of hollow microspheres from plasma-treated agglomerated particles, Thermophys. Aeromech., 2014, vol. 21, no. 6, pp. 735–746.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chesnokov, A.E., Smirnov, A.V. Peculiarities of the Formation of the Internal Structure of Cermet Particles during Plasma Processing. Inorg Mater 55, 395–400 (2019). https://doi.org/10.1134/S0020168519040058

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519040058