Abstract

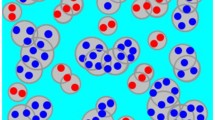

A new statistical model is proposed for the molecular mass distributions (MMD) of polymerized anions in silicate melts. The model is based on the known distribution of Q n species in the MeO-Me2O-SiO2 system. In this model, chain and ring complexes are regarded as a random series of Q n structons with various concentrations of bridging bonds (1 ≤ n ≤ 4, Q 0 corresponds to SiO 4−4 ). This approach makes it possible to estimate the probability of formation of various ensembles of polymer species corresponding to the general formula (Si i O3i+1−j )2(i+1−j)−, where i is the size of the ion, and j is the cyclization number of intrachain bonds. The statistical model is utilized in the STRUCTON computer model, which makes use of the Monte Carlo method and is intended for the calculation of the composition and proportions of polyanions at a specified degree of polymerization of silicate melts (STRUCTON, version 1.2; 2007). Using this program, we simulated 1200 MMD for polyanions in the range of 0.52 ≤ p ≤98, where p is the fraction of nonbridging bonds in the silicon-oxygen matrix. The average number of types of anions in this range was determined to increase from three (SiO 4−4 , Si2O 6−7 , and Si3O 8−10 ) to 153, and their average size increases from 1 to 7.2. A special option of the STRUCTON program combines MMD reconstructions in silicate melts with the formalism of the Toop-Samis model, which enables the calculation of the mole fraction of the O2− ion relative to all anions in melts of specified composition. It is demonstrated that, with regard for the distribution and average size of anion complexes, the concentration of the O2− ion in the MeO-SiO2 system is characterized by two extrema: a minimum at 40–45 mol % SiO2, which corresponds to the initial stages of the gelenization of the polycondensated silicate matrix, and a maximum, which is predicted for the range of 60–80 mol % SiO2.

Similar content being viewed by others

References

M. S. Ghiorso, “Chemical Mass Transfer in Magmatic Processes I. Thermodynamic Relations and Numeric Algorithms,” Contrib. Mineral. Petrol. 90, 107–120 (1985).

M. Ya. Frenkel’ and A. A. Ariskin, “Numeric Algorithm for the Solution of Equilibrium of Crystallizing Basaltic Melt,” Geokhimiya, No. 5, 679–690 (1984).

M. S. Ghiorso and I. S. E. Carmichael, “Modeling Magmatic Systems: Petrologic Applications,” in Thermodynamic Modeling of Geological Materials: Minerals, Fluids and Melts, Rev. Mineral. 17, 467–499 (1987).

M. S. Ghiorso and R. O. Sack, “Chemical Mass Transfer in Magmatic Processes IV. A Revised and Internally Consistent Thermodynamic Model for the Interpolation and Extrapolation of Liquid-Solid Equilibria in Magmatic Systems at Elevated Temperatures and Pressures,” Contrib. Mineral. Petrol. 119, 197–212 (1995).

A. A. Ariskin, G. S. Barmina, M. Ya. Frenkel, and R. L. Nielsen, “COMAGMAT: A Fortran Program to Model Magma Differentiation Processes,” Comput. Geosci. 19, 1155–1170 (1993).

A. A. Ariskin, “Phase Equilibria Modeling in Igneous Petrology: Use of COMAGMAT Model for Simulating Fractionation of Ferro-Basaltic Magmas and the Genesis of High-Alumina Basalt,” J. Volcanol. Geotherm. Res. 90, 115–162 (1999).

A. A. Ariskin and G. S. Barmina, Modeling Phase Equilibria during the Crystallization of Basaltic Magmas (Nauka, Moscow, 2000) [in Russian].

A. A. Ariskin and G. S. Barmina, “COMAGMAT: Development of a Magma Crystallization Model and Its Petrological Applications,” Geochem. Int. 42(Suppl. 1), 1–157 (2004).

M. S. Ghiorso, “Thermodynamic Models of Igneous Processes,” Annu. Rev. Earth Planet. Sci. 25, 221–241 (1997).

R. G. Berman and T. H. Brown, “Development of Models for Multi-Component Melts: Analysis of Synthetic Systems,” in Thermodynamic Modeling of Geological Materials: Minerals, Fluids and Melts, Ed. by I. S. E. Carmichael and H. P. Eugster, Mineral. Soc. Am. Rev. Mineral. 17, 405–442 (1987).

R. G. Berman and T. H. Brown, “A Thermodynamic Model for Multicomponent Melts, with Application to the System CaO-Al2O3-SiO2,” Geochim. Cosmochim. Acta 45, 661–678 (1984).

M. S. Ghiorso, I. S. E. Carmichael, M. L. Rivers, and R. O. Sack, “The Gibbs Free Energy of Mixing of Natural Liquids: An Expanded Regular Solution Approximation for the Calculation of Magmatic Intensive Variables,” Contrib. Mineral. Petrol. 84, 107–145 (1983).

V. A. Solov’ev, E. V. Zhivaeva, and A. O. Kislyuk, “Models of Molecular Associates in the Theories of Thermodynamic Properties of Glass-Forming Melts,” Fiz. Khim. Stekla 24(3), 345–354 (1998).

V. N. Anfilogov, V. N. Bykov, and A. A. Osipov, Silcate Melts (Nauka, Moscow, 2005) [in Russian].

B. A. Shakhmatkin and N. M. Vedishcheva, “Thermodynamic Approach to the Modeling of Physical Properties of Oxide Glasses,” Fiz. Khim. Stekla 24(3), 333–344 (1998).

E. N. Plotnikov and V. L. Stolyarova, “Calculation of Thermodynamic Properties of Melts in the Systems Na2O-SiO2 and B2O-SiO2 Based on the Generalized Lattice Theory of Associated Solutions,” Fiz. Khim. Stekla 31(6), 1048–1086 (2005).

B. Bjorkman, “An Assessment of the System Fe-O-SiO2 Using a Structure Based Model for the Liquid Silicate,” CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 9, 271–282 (1985).

R. L. Nielsen and M. A. Dungan, “Low-Pressure Mineral-Melt Equilibria in Natural Anhydrous Mafic Systems,” Contrib. Mineral. Petrol. 84, 310–326 (1983).

D. Dolejs and D. R. Baker, “Thermodynamic Modeling of Melts in the System Na2O-NaAlO2-SiO2-F2O,” Geochim. Cosmochim. Acta 69, 5537–5556 (2005).

O. A. Esin, “Polymer Model of Molten Silicates,” in Solutions. Melts (Results of Science and Techniques) (VINITI, Moscow, 1975), Vol. 2, pp. 76–107 [in Russian].

D. S. Korzhinskii, “Acid-Base Interaction of Components in the Silicate Melts and Trends of Cotectic Lines,” Dokl. Akad. Nauk SSSR 128(2), 383–386 (1959).

I. B. Bobylev and V. N. Anfilogov, “Features of Crystallization of Silicate Melts and Calculation of Liquidus Lines in Binary Systems,” in Structural Studies of Magmatic Melts (UNO AN SSSR, Sverdlovsk, 1981), pp. 52–61 [in Russian].

R. A. Cruz, S. A. Romero, R. M. Vargas, and L. M. Hallen, “Thermodynamic Analysis of the SiO2-NiO-FeO System,” J. Non-Cryst. Solids 351, 1359–1365 (2005).

G. W. Toop and C. S. Samis, “Activities of Ions in Silicate Melts,” Trans. Metall. Soc. AIME 224, 878–887 (1962).

E. D. Lacy, “A Statistical Model of Polymerisation/Depolymerisation Relationships in Silicate Melts and Glasses,” Phys. Chem. Glasses 6, 171–180 (1965).

D. G. Fraser, “Thermodynamic Properties of Silicate Melts,” in Thermodynamics in Geology (D. Reidel Publ. Company, 1977), pp. 301–325 (1977).

D. G. Fraser, “Acid-Base Properties and Structures: Towards a Structural Model for Predicting the Thermodynamic Properties of Silicate Melts,” Annals Geophysics 48(4/5), 549–559 (2005).

C. R. Masson, “Ionic Equilibria in Liquid Silicates,” J. Am. Ceram. Soc. 51, 134–143 (1968).

C. R. Masson, I. B. Smith, and S. G. Whiteway, “Activities and Ionic Distributions in Liquid Silicates: Application of Polymer Theory,” Can. J. Chem. 48, 1456–1464 (1970).

S. C. Whiteway, I. B. Smith, and C. R. Masson, “Theory of Molecular Size Distribution in Multichain Polymers,” Can. J. Chem. 48, 33–45 (1970).

V. B. Pretnar, “Beitrag zur Ionentheorie der Silikatmelzen,” Ber. Bunsen Ges. Phys. Chem. 72, 773–778 (1968).

C. F. Baes, Jr. “A Polymer Model for BeF2 and SiO2 Melts,” J. Solid State Chem. 1, 159–170 (1970).

O. A. Esin, “Comparison of Estimation Methods of the Degree of Polymerization of Silicate Melts,” in Physical Chemistry of Metallurgical Melts Tr. Inst. Metallurg., Vyp. 28, 76–90 (1972).

O. A. Esin, “On Complex Anions in the Melted Cinder,” in Structure and Properties of Metallurgical Melts, Tr. Inst. Metallurg., Vyp. 28, 76–90 (1974).

“Encyclopedia of Polymers,” Ed. by V. A. Kabanova, in Soviet Encyclopedia (Moscow, 1974), Vol. 2, pp. 286–300 [in Russian].

C. R. Masson, “Anionic Composition of Glass-Forming Melts,” J. Non-Cryst. Solids 25, 3–41 (1977).

P. C. Hess, “Structure of Silicate Melts,” Can. Mineral. 15, 162–178 (1977).

B. O. Mysen, “Experimental, in Situ, High-Temperature Studies of Properties and Structure of Silicate Melts Relevant to Magmatic Processes,” Eur. J. Mineral. 7, 745–766 (1995).

B. O. Mysen, “Structure and Properties of Magmatic Liquids: From Haplobasalt to Haploandesite,” Geochim. Cosmochim. Acta 63, 95–112 (1999).

V. N. Bykov, V. N. Anfilogov, and A. A. Osipov, Spectroscopy and Structure of Silicate Melts and Glasses (IM URO RAN, Miass, 2001) [in Russian].

G. S. Henderson, “The Structure of Silicate Melts: A Glass Perspective,” Can. Mineral. 43, 1921–1958 (2005).

V. G. Konakov, “Study of Oxygen Ion Activity in the Sodium-Silicate Melts,” Fiz. Khim. Stekla 16(5), 753–758 (1990).

V. G. Konakov and M. M. Shul’ts, Studies of Relative Basicities (Oxygen Indicator) of Melts in the Systems M 2 O-SiO 2 (m= Li, Na, K), Fiz. Khim. Stekla 22(6), 715–723 (1996).

G. Ottonello, “Thermodynamic Constraints Arising from the Polymeric Approach to Silicate Slags,” J. Non-Cryst. Solids 282, 72–85 (2001).

J-H. Park and C.-H. Rhee, “Ionic Properties of Oxygen in Slag,” J. Non-Cryst. Solids 282, 7–14 (2001).

G. Ottonello, R. Moretti, L. Marini, and M. V. Zuccolini, “Oxidation State of Iron in Silicate Glasses and Melts: A Thermochemical Model,” Chem. Geol. 174, 159–179 (2001).

R. Moretti and G. Ottonello, “Polymerization and Disproportionation of Iron and Sulfur in Silicate Melts: Insights from an Optical Basicity-Based Approach,” J. Non-Cryst. Solids 323, 111–119 (2003).

R. Moretti and G. Ottonello, “Solubility and Speciation of Sulfur in Silicate Melts: The Conjugated Toop-Samis-Flood-Grjotheim (CTSFG) Model,” Geochim. Cosmochim. Acta 69, 801–823 (2005).

K. W. Semkow and L. A. Haskin, “Concentrations and Behavior of Oxygen and Oxide Ion in Melts of Composition CaO-MgO-xSiO2,” Geochim. Cosmochim. Acta 49, 1897–1908 (1985).

R. O. Colson, C. R. Keedy, and L. A. Haskin, “Diffusion and Activity of NiO in CaO-MgO-Al2O3-SiO2 Melts Considering Effects of a O 2− and γNi 2+,” Geochim. Cosmochim. Acta 59, 909–925 (1995).

R. O. Colson, A. M. Floden, T. R. Haugen, et al., “Activities of NiO, FeO, and O2− in Silicate Melts,” Geochim. Cosmochim. Acta 69, 3061–3073 (2005).

N. V. Borisova, V. G. Konakov, T. G. Kostyreva, and M. M. Shul’ts, “Possibilities of Complex Formation with the Participation of O2− Ions in the Melts and Glasses in the System Na2O-SiO2-CuO2-CuO,” Fiz. Khim. Stekla 29(1), 44–53 (2003).

G. Ottonello, “Chemical Interactions and Configurational Disorder in Silicate Melts,” Annals Geophysics 48(4/5), 561–581 (2005).

R. Moretti, “Polymerization, Basicity, Oxidation State and Their Role in Ionic Modeling of Silicate Melts,” Annals Geophysics 48(4/5), 583–608 (2005).

V. B. Polyakov and A. A. Ariskin, “Simulation of the Composition and Proportions of Anions in Polymerized Silicate Melts,” Glass Phys. Chem., 34, 50–62 (2008).

M. Temkin, “Mixture of Melted Salts as Ionic Solutions,” Zh. Fiz. Khim. 20(1), 105–110 (1946).

R. S. Bradley, “Thermodynamic Calculations on Phase Equilibria Involving Fused Salts, Part II, Solid Solutions and Applications to the Olivines,” Am. J. Sci. 260, 550–554 (1962).

C. T. Herzberg, “The Solubility of Olivine in Basaltic Liquids: An Ionic Model,” Geochim. Cosmochim. Acta 43, 1241–1251 (1979).

O. A. Esin, “Polymerization of Anions in Molten Silicates,” Dokl. Akad. Nauk SSSR 211(2), 341–342 (1973).

O. A. Esin, “Isomeric Species of Anions and Estimation of Activities in Molten Silicates,” Zh. Fiz. Khim. 50(7), 1858–1860 (1976).

O. A. Esin, “Formation Constants and the Structure of Silicate Polymers,” Zh. Fiz. Khim. 52(4), 1073–1074 (1978).

M. Falk and R. E. Thomas, “Molecular Size Distribution in Random Polyfunctional Condensation with or without Ring Formation: Computer Simulation,” Can. J. Chem. 52, 3285–3295 (1974).

J. R. Van Wezer, Phosphorous and Its Compounds (Inostrannaya Literatura, Moscow, 1962) [in Russian].

H. Maekawa, T. Maekawa, K. Kawamura, and T. Yokokawa, “The Structural Groups of Alkali Silicate Glasses Determined from 29Si MAS-NMR,” J. Non-Cryst. Solids 127, 53 (1991).

M. L. Huggins, “The Structure of Amorphous Materials,” J. Phys. Chem. 58, 1141–1146 (1954).

H. St. C. O’Neill and A. J. Berry, “Activity Coefficients at Low Dilution of CrO, NiO and CoO in Melts in the System CaO-MgO-Al2O3-SiO2 at 1400°C: Using the Thermodynamic Behavior of Transition Metal Oxides in Silicate Melts to Probe Their Structure,” Chem. Geol. 231, 77–89 (2006).

A. A. Borisov, “Experimental Study of the Effect of SiO2 on Ni Solubility in Silicate Melts,” Petrologiya 14(6), 564–575 (2006) [Petrology 14, 530–539 (2006)].

A. A. Borisov, “Experimental Study of the Influence of SiO2 on the Solubility of Cobalt and Iron in Silicate Melts,” Petrologiya 15(6), 564–575 (2007) [Petrology 15, 523–529 (2007)].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Ariskin, V.B. Polyakov, 2008, published in Geokhimiya, 2008, No. 5, pp. 467–486.

Rights and permissions

About this article

Cite this article

Ariskin, A.A., Polyakov, V.B. Simulation of molecular mass distributions and evaluation of O2− concentrations in polymerized silicate melts. Geochem. Int. 46, 429–447 (2008). https://doi.org/10.1134/S0016702908050017

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0016702908050017