Abstract

Terephthalic acid (TPA) is an isomer of ortho-phthalic acid, which is widely used in the chemical industry to produce artificial fibers and plastics, including polyethylene terephthalate; it is a widespread environmental pollutant. The ability of two strains of Glutamicibacter spp. PB8-1 (=ВКМ Ac-2934D) and BO25 (=ВКМ Ac2935D) isolated from the salt mining area (Perm krai, Russia) to grow using terephthalic acid as the only source of carbon and energy was studied. The strains PB8-1 and BO25 could utilize high concentrations of TPA (30 g/L), which was shown for TPA-degrading bacteria for the first time. Strains PB8-1 and BO25 were halotolerant bacteria: they grew in the NaCl-free medium or at NaCl concentrations of up to 90 g/L in a rich medium and up to 60 g/L in a mineral medium supplemented with TPA. No bacteria capable of degrading TPA under saline conditions were previously described. The growth of the strain BO25 using TPA was accompanied by the accumulation and subsequent degradation of protocatechuic acid (PCA), suggesting that the TPA metabolism occurred through PCA, which was previously described for bacteria of different taxa, including actinobacteria. Thus, TPA-degrading strains Glutamicibacter spp. PB8-1 and BO25 are promising for the development of bioremediation methods for saline soils and wastewater contaminated with TPA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Phthalates are salts and esters of ortho-phthalic acid (an isomer of terephthalic and isophthalic acids), which is the simplest of the dibasic aromatic carboxylic acids. Phthalates are widely used in industry as plasticizers in the production of plastics and most types of rubber. Phthalic acid esters (dibutyl phthalate, dimethyl phthalate, and diethyl phthalate) are used for the plasticization of polyvinyl chloride (PVC), in the synthesis of polyester fibers and polyethylene, as well as in the production of building and lubricant materials, varnishes, and cosmetics [1–3]. Terephthalic acid is an isomer of phthalic acid with carboxyl groups at the para positions; it is widely used to obtain saturated polyesters, chemical fibers, plastics, and dyes. TPA is the main initial substance for the production of polyethylene terephthalate (PET), which accounts for 90% of the total amount of saturated polyesters; it is used in the production of artificial fibers, plastic bottles, and plastics. The annual global production of polyethylene terephthalate has exceeded 30 million tons, while the demand for PET is constantly growing [4]. Along with 2-ethylhexanol, TPA is a raw material for the production of dioctyl terephthalate (DOTP), which is a key component in the production of wallpaper, linoleum, flooring and roofing materials, and other building industry products [5].

Due to their wide use in industrial production, phthalates (including TPA) are ubiquitous environmental pollutants, which are currently found in various ecosystems, such as soil, seawater, and bottom sediments [6–8]. The production of 1 ton of TPA usually generates from 3 to 10 tons of wastewater containing high concentrations of this compound. In China, the production capacity for TPA reached 12 million tons per year, while the amount of wastewater is approximately 30 million tons per year, with a concentration of TPA emissions of more than 1000 mg/L [9, 10]. Terephthalic acid possesses hepatotoxic and carcinogenic properties; it is known to adversely affect human and animal cells. Therefore, the disposal of this widespread pollutant is essential [6, 11].

To date, physical and chemical methods for the decomposition of TPA have been developed; however, these methods are complex and costly [12, 13]. Microbial degradation of TPA is an alternative environmentally friendly and low-cost approach [10, 14]. Literature sources have reported the TPA-degrading ability of bacteria belonging to various phylogenetic groups. As an example, the ability of Gram-negative bacteria of the genus Comamonas and Pseudomonas to grow and degrade TPA has been studied [14, 15]. Among Gram-positive bacteria utilizing TPA, several strains of the genera Rhodococcus and Arthrobacter have been described [10, 16, 17]. At the same time, the bacterial destruction of TPA has been studied in less detail than the biodegradation of o-phthalic acid [3, 18]. The decomposition of TPA is known to begin with the dihydroxylation of the aromatic ring to form cis-1,2-dihydroxy-1,2-dihydroterephthalate; during the transformation of the latter, protocatechuic acid (PCA), which is a key metabolite for the utilization of isomers and complex esters of ortho-phthalic acid, is formed [3, 15, 16]. Currently, no papers on the TPA degradation by actinobacteria of the genus Glutamicibacter have been found in the scientific literature.

The goal of this research was to characterize two bacteria of the genus Glutamicibacter, which were isolated from the salt mining site and were able to degrade terephthalic acid.

EXPERIMENTAL

Objects of research. The bacterial strains BO25 and PB8-1, obtained from the collection of the Laboratory of Microbiology of Technogenic Ecosystems (Institute of Ecology and Genetics of Microorganisms, Ural Branch, Russian Academy of Sciences) and identified as members of the genus Glutamicibacter, were used in this study [19].

Strains BO25 and PB8-1 were isolated from the samples collected at the industrial salt mining site (Berezniki, Russia). The strain BO25 was isolated from a sample of technogenic mineral formations of potash production BKPRU-1 by direct plating onto the rich agar Raymond medium (RRM) [19] supplemented with NaCl (50 g/L). The strain PB8-1 was isolated from a rhizosphere soil sample collected near the BKPRU-3 salt dump by the method of enrichment cultivation in the Raymond mineral medium containing ortho-phthalic acid (1 g/L) as a substrate and supplemented with NaCl (30 g/L) [19].

Media and cultivation conditions. Bacteria were grown in the Raymond mineral medium (RMM) of the following composition (g/L): NH4NO3, 2.0; MgSO4·7H2O, 0.2; K2HPO4, 2.0; Na2HPO4, 3.0; CaCl2·6H2O, 0.01; 1% solution of MnSO4·2H2O; 1 mL/L of 1% solution of FeSO4·7H2O [20]. TPA, ortho-phthalic acid (OPA), dibutyl phthalate (DBP), dimethyl phthalate (DMP), protocatechuic acid (PCA), benzoate, and naphthalene at a concentration of 1.0 g/L were used as substrates. The growth characteristics of the strains were studied in the liquid Raymond medium supplemented with NaCl (30–100 g/L). To prepare the rich Raymond Medium (RRM), tryptone (5 g/L) and yeast extract (2.5 g/L) were added to the Raymond mineral medium as substrates. The cultivation of microorganisms in the liquid media was carried out on a thermostatically controlled shaker (100 rpm) at 28°С. To obtain agar media, agar-agar (15 g/L; Helicon, Russia) was added. The cultivation of microorganisms was carried out in a thermostat at 28°C.

Characteristics of bacterial growth. The growth of bacteria at different concentrations of sodium chloride was studied during batch culture in the liquid RMM containing TPA (1.0 g/L) in the presence of NaCl (30, 60, or 70 g/L) or in the salt-free medium. Exponential cultures grown on the NaCl-free RMM containing TPA as a substrate were used as inoculum. Bacterial growth at different concentrations of TPA was evaluated in the K1 liquid mineral medium [22], which was supplemented with the substrate (1, 10, 20, 30, or 40 g/L). Exponential cultures grown on the K1 medium enriched with TPA (1 g/L) as a substrate were used as inoculum. Bacterial cultures were grown in 250-mL Erlenmeyer flasks (volume of the medium, 100 mL) with aeration on a thermal shaker (100 rpm) at 28°C. The optical density (OD600) of the culture liquid was determined using a UV Visible BioSpec-mini spectrophotometer (Shimadzu, Japan) at a wavelength of 600 nm in a cuvette with an optical path length of 1 cm. The specific growth rate (μ, h–1) was calculated according to the standard equation: μ = (lnB2 – lnB1)/(t2 – t1), where В1 and В2 were optical densities of the culture at time moments t1 and t2, respectively [21].

When assessing the growth of bacteria at different pH values, RRM supplemented with 30 g/L of NaCl was used; the strains were cultivated on the agar medium at pH 5.0, 6.0, 7.0, 8.0, and 9.0. The growth was assessed by the presence of bacterial colonies on the seventh day of cultivation [21].

TPA utilization and PCA determination. TPA and PCA in the growth medium were determined by high-performance liquid chromatography (HPLC) using an LC-20AD Prominence chromatograph (Shimadzu, Japan) with a column (C-18 150 × 4.6 mm; Sigma-Aldrich, United States) and UV-detector SPD-20A (at 205 nm) in the acetonitrile–0.1% H3PO4 system (70 : 30). An 80% acetonitrile solution was used as the mobile phase at a flow rate of 1.0 mL/min at 40°C. Identification was carried out by comparing the peak release times of the extracts to standard solutions of TPA and PCA at concentrations of 50 and 100 mg/L; the retention time (tR) of TPA and PCA was 5.1 and 4.8 min, respectively. The quantitative content was calculated using the LCsolution software package (Shimadzu, Japan). The specific utilization rate (μ, day–1) was calculated using the standard equation: μ = (lnС1 – lnC2)/(t2 – t1), where С1 and С2 were the substrate concentration at the initial and final times t1 and t2, respectively [21].

RESULTS AND DISCUSSION

The general characteristics of the strains. Based on morphophysiological and genetic (16S rRNA gene analysis) characteristics, strains BO25 and PB8-1 were identified as members of the genus Glutamicibacter (family Micrococcaceae). The phylogenetically closest relative to the strain BO25 proved to be the type strain of G. halophytocola, while the strain PB8-1 showed the closest phylogenetic similarity to the type strain of G. arilaitensis [19].

The strains BO25 and PB8-1 were isolated from the samples of sludge and rhizospheric soil collected from the territory of mining and processing of potassium-magnesium salts of the Verkhnekamskoye deposit (Russia). It was previously shown that samples from the area of salt mining were characterized by both an increased salt content and the presence of persistent organic pollutants, including phthalates [23, 24]. Glutamicibacter spp. BO25 and PB8-1 were able to grow using mono- and polyaromatic hydrocarbons when cultivated in the presence of 30 g/L of NaCl. The strain BO25 showed moderate growth with benzoate, OPA, DBP, and DMP, as well as weak growth using naphthalene. The strain PB8-1 was capable of growth on benzoate, OPA, DBP, and naphthalene, as well as weak growth on DMP (Table 1). The literature describes strains of the genus Glutamicibacter growing with phthalates and monoaromatic hydrocarbons as substrates. For instance, the strain G. nicotianae ZM05 is able to utilize OPA and phthalic acid esters: DBP, DMP, diethyl phthalate (DEP), di-n-propyl phthalate, and PCA [25]. The strain G. nicotianae MSSRFPD35 can degrade phenol and its derivatives, as well as catechol [26].

The strains BO25 and PB8-1 grew well at pH from 6.0 to 9.0 with an optimum at 7.0. Similar pH values were previously shown for other species of the genus Glutamicibacter [27].

Growth of the strains BO25 and PB8-1 in the presence of high salt concentrations. The strains BO25 and PB8-1 were able to grow on the agar RRM in both the salt-free cultivation medium and the medium supplemented with up to 90 g/L of sodium chloride. On agar RMM containing TPA (1 g/L) as the sole source of carbon and energy, the strains grew at a NaCl concentration of up to 60 g/L in the medium. The strains BO25 and PB8-1 belonged to moderately halotolerant microorganisms, according to the obtained data and Kushner’s classification [28].

The effect of various NaCl concentrations on the growth and consumption of TPA by the strains PB8-1 and BO25 in the RMM medium containing TPA (1 g/L) as a substrate was studied (Figs. 1 and 2). Active growth of the strains was observed in the presence of up to 60 g/L of NaCl in the medium. The highest growth density (OD600) of the strains was observed during cultivation without the addition of NaCl. High OD600 values and culture growth rates were also observed in the presence of 30 g/L NaCl. An increase in the concentration of NaCl to 60 g/L led to an increase in the growth lag phase and a decrease in the maximum values of OD600 of the strains; however, the specific growth rate decreased insignificantly (Table 2). For the strain BO25, both an increase in the lag phase and a decrease in the maximum value of OD600 were observed, compared to the strain PB8-1. At 70 g/L of NaCl in the medium, no growth of strains with TPA was shown.

A correlation between the growth parameters of the strains and a decrease in the concentration of TPA in the cultivation medium was noted. It was shown that the terephthalate degradation by the strains PB8-1 and BO25 in the NaCl-free medium and the medium supplemented with 30 g/L of NaCl was more than 84%. With an increase in the content of NaCl in the medium to 60 g/L, a decrease in the level of substrate degradation to 69.7 and 62.8% for the strains PB8-1 and BO25, respectively, was observed (Table 2).

Bacteria of the genus Glutamicibacter growing on the media containing high salt content are known. For instance, G. halophytocola KLBMP5180T and Glutamicibacter sp. YD01, as shown by the authors, are able to grow on a rich medium in the presence of up to 130 and 100 g/L NaCl, respectively [27, 29]. However, strains of the genus Glutamicibacter capable of degrading phthalates (in particular, TPA) under conditions of increased salinity have not been previously described.

Growth of the strains BO25 and PB8-1 on media with high concentrations of TPA. It was found that the strains PB8-1 and BO25, when cultivated in the NaCl-free K1 medium [22], can use TPA as the sole source of carbon and energy at concentrations of up to 30 g/L (Fig. 3). At a TPA concentration of 1 g/L, the maximum OD600 values of the medium were 0.8 and 0.94 by 78–102 h of cultivating the PB8-1 and BO25 strains, respectively. For both strains, an increase in the concentration of TPA in the medium resulted in an increase in the duration of the lag phase, accumulation of biomass, and a decrease in the specific growth rate (Table 3). At the same time, the maximum OD600 values of the strains were observed at 10 g/L of TPA. They were 1.43 and 1.6 for the strains PB8-1 and BO25, respectively. With an increase in the concentration of TPA up to 40 g/L in the medium, the growth of the studied strains was not observed.

The highest level of TPA utilization was noted when growing the strains PB8-1 and BO25 in the K1 medium at a substrate concentration of 1.0 g/L: 79% after 99 h and 87.5% after 118 h, respectively. The maximum specific rate of TPA consumption by these strains was also observed at a TPA content of 1.0 g/L in the medium (Table 3).

As shown for the members of various taxonomic groups, high concentrations of terephthalic acid can inhibit the growth of bacteria and their ability to degrade this compound. As an example, 10 g/L and higher concentrations of TPA suppress the ability of Arthrobacter sp. 0574 to decompose TPA [10], while the growth of bacteria of the genus Pseudomonas is inhibited by concentrations of more than 1 g/L [14]. The strain Rhodococcus sp. N2, which utilizes 10 g/L of TPA within 5 days has been described [30]. The studied strains Glutamicibacter spp. PB8-1 and BO25 could grow efficiently at higher concentrations of TPA, up to 30 g/L. Thus, the studied strains were not only able to withstand critically high concentrations of TPA; they also used this compound as a source of carbon and energy, which is of undoubted interest for further study.

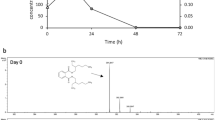

Degradation of TPA by the PB8-1 and BO25 strains. The degradation of terephthalic acid by aerobic bacteria is known to occur through the step of formation of cis-1,2-dihydroxy-1,2-dihydroterephthalate. The latter is converted to PCA, which is further decomposed to the main products of vital activity of a microbial cell (Fig. 4) [3, 16, 31]. The ability of the studied strains BO25 and PB8-1 to grow in the RMM containing 30 g/L of NaCl and PCA as a substrate was shown (Fig. 5). The strain BO25 had higher maximum values of OD600 and a specific growth rate using PCA, as compared to the strain PB8-1 (Table 2). HPLC analysis of the TPA utilization products in the culture medium during cultivation of the strain BO25 with this substrate showed the presence of PCA (0.3 and 0.1 g/L) after 48 and 70 h of cultivation, respectively. Based on the presence of the metabolite in the medium containing TPA and the ability of the studied strains to grow using PCA (Fig. 5), it was proposed that the destruction of TPA by the strain Glutamicibacter sp. BO25 was carried out via the PCA formation, with its subsequent decomposition (Fig. 4). The PCA utilization by actinobacteria is known to proceed predominantly through the ortho-pathway [32]. At the same time, there are data on the possibility of PCA degradation by strains of the Micrococcaciae family (genera Arthrobacter and Pseudarthrobacter) via the ortho- and/or meta-pathway [18, 33]. Studies of the metabolic pathway of degradation of TPA and PCA by the strains Glutamicibacter spp. BO25 and PB8-1 will be continued.

Thus, halotolerant TPA-degrading members of the genus Glutamicibacter were characterized for the first time. The strains BO25 and PB8-1 were capable of growth and efficient degradation of TPA, in the case of the high-salinity medium (up to 60 g/L of NaCl) and at high concentrations of this compound in the cultivation medium (up to 30 g/L), in particular. These characteristics of bacterial cultures were reported for the first time. The described bacterial cultures are promising for the development of efficient biotechnologies for the treatment of polluted/saline soils and industrial wastewater.

REFERENCES

Jin, D.-C., Liang, R.-X., Dai, Q.-Y., Zhang, R.-Y., Wu, X.-L., and Chao, W.-L., J. Microbiol. Biotechnol., 2010, vol. 20, no. 10, pp. 1440–1445.

Keyser, P., Pujar, B.G., Eaton, R.W., and Ribbons, D.W., Environ. Health Perspect., 1976, vol. 18, p. 159.

Liang, D.W., Zhang, T., and Fang, H., Appl. Microbiol. Biotechnol., 2008, vol. 80, pp. 183–198.

Delle, ChiaieK.R., McMahon, F.R., Williams, E.J., Price, M.J., and Dove, A.P., Polym. Chem., 2020, vol. 11, pp. 1450–1453.

Medvedev, A.N. and Cherezova, E.N., Vestn. Tekhnol. Univ., 2015, vol. 18, no. 15, pp. 44–46.

Przybylinka, P.A. and Wyszkowski, E., Ecol. Chem. Eng., 2016, vol. 23, no. 2, pp. 347–356.

Staples, C.A., Parkerton, T.F., and Peterson, D.R., Chemosphere, 2000, vol. 40, pp. 885–891.

Gao, D. and Wen, Z., Sci. Total Environ., 2016, vol. 541, pp. 986–1001.

Zhang, X., Wan, Y., Cheng, S., Sun, S., Zhu, C., Li, W., Zhang, X., Wang, G., Lu, J., and Luo, X., J. Environ. Sci. (China), 2005, vol. 17, no. 5, pp. 876–880.

Zhang, Y.-M., Sun, Y.-Q., Wang, Z.-J., and Zhang, J., South Afr. J. Sci., 2013, vol. 109, nos. 7/8, article ID 0019. https://doi.org/10.1590/sajs.2013/20120019

Zhang, Z., Ma, L., Zhang, X.X., Li, W., Zhang, Y., Wu, B., Yang, L., and Cheng, S., J. Hazard. Mater., 2010, vol. 181, pp. 1121–1126.

Park, T., Lim, J., Lee, Y., and Kim, S., J. Supercrit. Fluids, 2013, vol. 26 P, pp. 201–213.

Shafaei, A., Nikazar, M., and Arami, M., Desalination, 2010, vol. 252, pp. 8–16.

Wang, Z.J., Teng, L.H., and Zhang, J.F., Afr. J. Biotechnol., 2011, vol. 10, no. 16, pp. 3143–3148.

Kasai, D., Kitajima, M., Fukuda, M., and Masai, E., Appl. Environ. Microbiol., 2010, vol. 76, no. 18, pp. 6047–6055.

Hara, H., Eltis, L.D., Davies, J.E., and Mohn, W.W., J. Bacteriol., 2007, vol. 189, no. 5, pp. 1641–1647.

Choi, K.Y., Kim, D., Sul, W.J., Chae, J.C., Zylstra, G.J., Kim, Y.M., and Kim, E., FEMS Microbiol. Lett., 2005, vol. 252, pp. 207–213.

Eaton, R.W., J. Bacteriol., 2001, vol. 183, no. 12, pp. 3689–3703.

Yastrebova, O.V. and Plotnikova, E.G., Vestn. Perm. Univ., Ser. Biol., 2020, no. 4, pp. 321–333.

Raymond, R.L., Dev. Industr. Microbiol., 1961, vol. 2, no. 1, pp. 23–32.

Netrusov, A.I., Praktikum po mikrobiologii (A Practical Course in Microbiology), Moscow: Akademiya, 2005.

Zaitsev, G.M. and Karasevich, Yu.N., Mikrobiologiya, 1981, vol. 50, pp. 35–40.

Bachurin, B.A. and Odintsova, T.A., Sovremennye ekologicheskie problemy Severa (Modern Environmental Problems of the North), vol. 2: Stoikie organicheskie zagryazniteli v otkhodakh gornogo proizvodstva. (Persistent Organic Pollutants in Mining Waste), Apatity: Nauchn. Tsentr Ross. Akad. Nauk, 2006.

Korsakova, E.S., Shestakova, E.A., Khairulina, E.A., and Nazarov, A.V., Ross. Immunol. Zh., 2015, vol. 9 (18), no. 2 (1), pp. 591–593.

Wang, X., Shen, S., Wu, H., Wang, H., and Wang, L., Microorganisms, 2021, vol. 30, no. 9(7), pp. 1417–1428.

Purushothaman, D., Jegan, S., Anu, D.A., and Prabavathy, V.R., Front. Microbiol., 2020, vol. 11, article ID 1573. https://doi.org/10.3389/fmicb.2020.01573

Feng, W.-W., Wang, T.-T., Bai, J.-L., Ding, P., Xing, K., Jiang, J.-H., Peng, X., and Qin, S., Int. J. Syst. Evol. Microbiol., 2017, vol. 67, pp. 1120–1125.

Kushner, D.J., in Life in High Salt and Solute Concentrations: Halophilic Bacteria, in Microbial Life in Extreme Environments, Kushner, D.J., Ed., London: Academic Press, 1978, pp. 317–368.

Ji, J., Yuan, D., Jin, C., Wang, G., and Li, X., Acta Physiol. Plant., 2020, vol. 42, no. 42. https://doi.org/10.1007/s11738-020-3034-3

Suwanawat, N., Parakulsuksatid, P., Nitayapat, N., and Sanpamongkolchai, W., Int. J. Environ. Sci. Dev., 2019, vol. 10, no. 1, pp. 30–33.

Benjamin, S., Pradeep, S., Josh, M.S., Kumar, S., and Masai, E., J. Hazard. Mater., 2015, vol. 298, pp. 58–72.

Bugg, T.D., Ahmad, M., Hardiman, E.M., and Singh, R., Curr. Opin. Biotechnol., 2011, vol. 22, pp. 394–400.

Tsagogiannis, E., Vandera, E., Primikyri, A., Asimakoula, S., Tzakos, A.G., Gerothanassis, I.P., and Koukkou, A.-I., Int. J. Mol. Sci., 2021, vol. 22, p. 9647. https://doi.org/10.3390/ijms22179647

Funding

This study was carried out within the framework of the state task (topic state registration no. АААА-А19-119112290008-4). This research was also supported by the Russian Foundation for Basic Research and the Ministry of Education and Science of the Perm krai (project no. 19-44-590011r_a).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Additional information

Translated by A. Panyushkina

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yastrebova, O.V., Malysheva, A.A. & Plotnikova, E.G. Halotolerant Terephthalic Acid-Degrading Bacteria of the Genus Glutamicibacter. Appl Biochem Microbiol 58, 590–597 (2022). https://doi.org/10.1134/S0003683822050167

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0003683822050167