Abstract

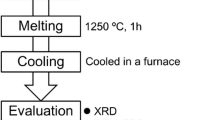

Vanadium slag samples, which are taken at various stages of the converter devanadation of lowsilicon (0.05–0.15% Si) cast iron and after cooling in converter pans, are studied by electron-probe microanalysis and X-ray diffraction. The evolution of the compositions of spinelide, silicate, and metallic phases is investigated. The experimental results are compared with the well-known formation mechanism and the phase composition of the slags of the devanadation of silicon cast irons during oxygen or air blowing. It is shown that, despite the differences in the compositions and the grain sizes of a spinelide phase, the mechanism of its formation at the initial stages of oxidation of cast iron elements with different silicon contents is the same. The spinelide composition and the element distribution over a grain depend on the cast iron composition and the quantity and composition of the silicate phases that form during devanadation in a converter and upon cooling of a slag ingot

Similar content being viewed by others

References

L. A. Smirnov and A. V. Kushnarev, “State of the art and the prospects of processing of the titanomagnetite vanadium-containing raw materials in Russia,” in Ferrous Metallurgy: State and Prospects (OAO Chermetin formatsiya, Moscow, 2013).

A. V. Polyakov, Fundamentals of the Metallurgy of Vanadium (Metallurgizdat, Moscow, 1959).

N. P. SlotvinskiiSidak and V. I. Kolpakova, “Structure of vanadium slags and vanadium extraction,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 8, 37–42 (1961).

N. A. Vatolin, N. G. Moleva, P. I. Volkova, and T. V. Sapozhnikova, Oxidation of Vanadium Slags (Nauka, Moscow, 1978).

L. A. Smirnov, B. A. Abramov, B. I. Topychkanov, and L. P. Kulikova, “Mineralogical composition and component distribution over the phases in the vanadium slags of the basic oxygen process,” in Steelmaking (UralNIIChM, Sverdlovsk, 1972), Vol. 16, pp. 43–55.

L. A. Smirnov, B. I. Topychkanov, Yu. A. Deryabin, and V. F. Rybalko, “Electron-probe microanalysis of oxygen-converter slags,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 4, 14–18 (1980).

V. G. Vinokurov, S. V. Mikhailikov, E. I. Zaitseva, et al., “Properties of converter vanadium slags,” in Metallurgical Processing of Titanomagnetite Ores (Metallurgiya, Moscow, 1969), Vol. 17, pp. 70–79.

G. K. Tarabrin, V. A. Biryukova, V. A. Nasekin, and A. G. Rusakova, “Effect of the mineralogical and chemical compositions of converter vanadium-containing slag on the technological indices during the production of V2O5,” Kompleks. Ispol’z. Miner. Syr’ya, No. 11, 38–42 (1979).

L. A. Smirnov, S. V. Filatov, V. A. Rovnushkin, et al., “Devanadation of lowsilicon cast iron,” Stal’, No. 5, 35–42 (2010).

V. A. Rovnushkin, A. L. Smirnov, and M. S. Fomichev, “Mechanism of skull formation in mixers during the processing of vanadium cast iron,” Stal’, No. 5, 49–52 (2010).

L. A. Smirnov, V. A. Rovnushkin, A. L. Smirnov, and S. P. Burmasov, “Vanadium slags of the oxygen–converter devanadation of lowsilicon cast iron,” Stal’, No. 5, 60–65 (2010).

S. V. Neugonikov, S. V. Vinogradov, P. V. Ekkert, and E. V. Shekhovtsev, “Method for decreasing skull formation in mixers during operation with vanadium cast iron,” Stal’, No. 6, 40–43 (2004).

V. V. Filippov, V. S. Rudin, and A. Yu. Chernavin, “Study of the conditions of grainal formation during the melting of the titanomagnetites of the Kachkanar ore-dressing and processing enterprise,” Stal’, No. 5, 15–18 (2000).

O. A. Esin and P. V. Gel’d, Physical Chemistry of Metallurgical Processes (Gos. Tekh. Izdvo., Sverdlovsk, 1962).

N. A. Vatolin, L. A. Smirnov, P. I. Volkova, et al., “Effect of the conditions of cooling of vanadium slag on its chemical treatability,” in Combined Metallurgical Processing of Iron Ores (Tr. Ural NIIChM, 1977), Vol. 31, pp. 96–104 (1977).

L. A. Smirnov, V. A. Rovnushkin, and A. L. Smirnov, “Phase-mineralogical composition of vanadium slags,” in New Technologies and Materials in Metallurgy (UrO RAN, Yekaterinburg, 2010), pp. 70–91.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.A. Smirnov, V.A. Rovnushkin, A.L. Smirnov, 2015, published in Metally, 2015, No. 2, pp. 26–34.

Rights and permissions

About this article

Cite this article

Smirnov, L.A., Rovnushkin, V.A. & Smirnov, A.L. Formation and phase-mineralogical composition of converter slags. Russ. Metall. 2015, 191–198 (2015). https://doi.org/10.1134/S0036029515030088

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029515030088