Abstract

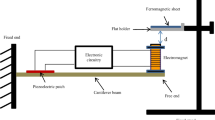

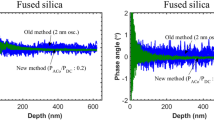

Nanoindenter has been used to directly indent on the cantilever beam to measure Young’s modulus such that the substrate effects can be avoided. However, the deflections of cantilever beam are indirectly extracted from the displacement of nanoindenter and therefore their measurement results are easily influenced by local behaviors around the indentation. In this paper, to the authors’ best knowledge, this is the first time that the nanoindenter is integrated with an optical system to measure Young’s modulus of cantilever beam. The deflection of cantilever beam is directly measured from a specially designed optical system. The influences of substrate effects and local behaviors around indentation are simultaneously avoided from the proposed methodology.

Similar content being viewed by others

References

Mante, P.A., and Robillard, J.F., “Complete Thin Film Mechanical Characterization Using Picosecond Ultrasonics and Nanostructures: Experimental Demonstration on SiO2,” Applied Physics Letters 93:071909.1–091909.3 (2008).

Orthner, P.M.P., Rieth, L.W., and Solzbacher, S., “High Speed Wafer Scale Bulge Testing for the Determination of Thin Film Mechanical Properties,” Review of Scientific Instruments 81:05111.1–05111.7 (2010).

Tong, C.J., Cheng, Y.C., Lin, M.T., Chung, K.J., Hsu, J.S., and Wu, C.L., “Optical Micro-Paddle Beam Deflection Measurement for Electrostatic Mechanical Testing of Nano-Scale Thin Film Application to MEMS,” Microsystem Technologies 15: 1131–1137 (2010).

Tong, L.B., Li, Y.H., Meng, F.L., Tian, H.W., Zheng, W.T., and Wang, Y.M., “Investigation on Mechanical Properties of Suppered TiNi Thin Films,” Journal of Alloys and Compounds 494:166–168 (2010).

Badawi, K.F., Villain, P., Goudeau Ph., and Renault P.O., “Measuring Thin Film and Multilayer Elastic Constants by Coupling in situ Tensile Testing with X-Ray Diffraction,” Applied Physics Letters 80:4705–4707 (2002).

Ye, J., Shimizu, S., Sato, S., Kojima, N., and Noro, J., “Bidirectional Thermal Expansion Measurement for Evaluating Poisson’s Ratio of Thin Films,” Applied Physics Letters 89:031913.1–031913.2 (2006).

Zheng, X.P., Cao, Y.P., Li, B., Feng, X.Q., Jiang, H., and Huang, Y.Y., “Determining the Elastic Modulus of Thin Films Using a Buckling-Based Method: Computational Study,” Journal of Physics D: Applied Physics 42:175506 (7pp) (2009).

Lee, S.J., Han, S.W., Hyun, S.M., Lee, H.J., Kim, J.H., and Kim, Y.I., “Measurement of Young’s Modulus and Poisson’s Ratio for Thin Au Films Using a Visual Image Tracing System,” Current Applied Physics 9:S75–S78 (2009).

Chang, J.Y., Yu, G.P., and Huang, J.H., “Determining of Young’s Modulus and Poisson’s Ratio of Thin Film by Combining sin Ψ X-Ray Diffraction and Laser Curvature Method,” Thin Solid Films 517:6759–6766 (2009).

Zhai, M., Xiang, Y., Xu, J., Ogasawara, N., Chiba, N., and Chen, X., “Determining Mechanical Properties of Thin Films from the Loading Curve of Nanoindentation Testing,” Thin Solid Films 516:7571–7580 (2008).

Roa, J.J., Gilioli, E., Bissoli, F., et al., “Study of the Mechanical Properties of CeO2 Layers with the Nanoindentation Technique,” Thin Solid Films 518:227–232 (2009).

Sasaki, Y., Ciappa, M., Masunaga, T., and Fichtner, W., “Accurate Extraction of the Mechanical Properties of Thin Films by Nanoindentation for the Design of Reliable MEMS,” Microelectronics Reliability 50:1621–1625 (2010).

Breuils, J., Hervé, H., Krier, J., and Vignal, V., “Determination of Elastoplastic Properties of TiO2 Thin Films Deposited on Dual Phase Stainless Steel Using Nanoindentation Tests,” Surface and Coatings Technology 204:2068–2072 (2010).

Yusoh, Y., Jin, J., and Song, M., “Substrate Mechanical Properties of Polyurethane/Organoclay Nanocomposite Thin Films Studied by Nanoindentation,” Progress in Organic Coatings 67:220–224 (2010).

Chawla, V., Jayaganthan, R., and Chandra, R., “A Study of Structural and Mechanical Properties of Sputter Deposited Nanocomposite Ti-Si-N Thin Films,” Surface and Coatings Technology 204:1582–1589 (2010).

Koumoulos, E.P., Charitidis, C.A., Daniolosb, N.M., and Pantelis, D.I., “Nanomechanical Properties of Friction Stir Welded AA6082-T6 Aluminum Alloy,” Materials Science and Engineering B, in press.

Kashani, M.S., and Madhavan, V., “Analysis and Correction of the Effect of Sample Tilt on Results of Nanoindentation,” Acta Materialia 59:883–895 (2011).

Guo, J.J., Wang, K., Fujita, T., McCauley, J.W., Singh, J.P., and Chen, M.W., “Nanoindentation Characterization of Deformation and Failure of Aluminum Oxynitride,” Acta Materialia 59:1671–1679 (2011).

Kaufman, J.D., and Klapperich, C.M., “Surface Detection Errors Cause Overestimation of the Modulus in Nanoindentation on Soft Materials,” Journal of the Mechanical Behavior of Biomedical Materials 2:312–317 (2009).

Nguyen, T.D., Yeager, J.D., Bahr, D.F., Adams, D.P., and Moody, N.R., “Nanoindentation of Compliant Substrate Systems: Effects of Geometry and Compliance,” The Journal of Engineering Materials and Technology 132:021001.1–021001.7 (2010).

Weihs, T.P., Hong, S., Bravman, J.C., and Nix W.D., “Mechanical Deflection of Cantilever Microbeams: A New Technique for Testing the Mechanical Properties of Thin Films,” Journal of Materials Research 3:931–942 (1988).

Ding, J.N., Meng, Y.G., and Wen, S.Z., “Specimen Size Effect on Mechanical Properties of Polysilicon Microcantilever Beams Measured by Deflection Using a Nanoindenter,” Materials Science and Engineering B 83:42–47 (2001).

Hsu, C., Tsou, C., and Fang, W., “Measuring Thin Film Elastic Modulus Using a Micromachined Cantilever Bending Test by Nanoindenter,” Journal of Microlithography Microfabrication and Microsystems 6:033011.1–033011.7 (2007).

Timoshenko, S.P., and Gere, J.M., Mechanics of Materials, Van Nostrand, New York (1972).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, J.S., Chih, Y.K., Chao, L.P. et al. Preliminary investigation on young’s modulus measurement of cantilever beam by integrating nanoindenter with optical system. Exp Tech 38, 11–18 (2014). https://doi.org/10.1111/j.1747-1567.2011.00784.x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1111/j.1747-1567.2011.00784.x