Abstract

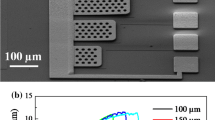

Sample geometry effects on mechanical strengths of gold micro-cantilevers are evaluated by a micro-bending test. Six micro-cantilevers with the same length of 50 μm are prepared, and the width and the thickness are varied to examine individual effects on the yield stress. The yield stress increases from 428 to 519 MPa when the thickness decreases from 11.1 to 6.0 μm. No obvious dependency is observed when varying the width. The results reveal that the thickness and the width each has a different influence on the yield stresses of micro-cantilevers evaluated by the bending test, which is the sample geometry effect.

Similar content being viewed by others

References

M. Lemkin and B.E. Boser: A three-axis micromachined accelerometer with a CMOS position sense interface and digital offset-trim electronics. IEEE J. Solid-State Circ. 34, 456 (1999).

D. Yamane, T. Matsushima, K. Machida, H. Toshiyoshi, and K. Masu: Design of sub-1 g microelectromechanical systems accelerometers. Appl. Phys. Lett. 104, 074102 (2014).

K. Machida, T. Konishi, D. Yamane, H. Toshiyoshi, and K. Masu: Integrated CMOS-MEMS technology and its applications. ECS Trans. 61, 21 (2014).

H.D. Espinosa, B.C. Prorok, and B. Peng: Plasticity size effects in free-standing submicron polycrystalline FCC films subjected to pure tension. J. Mech. Phys. Solids 52, 667 (2004).

C.Y. Chen, M. Yoshiba, T. Nagoshi, T.F.M. Chang, D. Yamane, K. Machida, K. Masu, and M. Sone: Pulse electroplating of ultra-fine grained Au films with high compressive strength. Electrochem. Commun. 67, 51 (2016).

H.C. Tang, T.F.M. Chang, Y.W. Chai, C.Y. Chen, T. Nagoshi, D. Yamane, H. Ito, K. Machida, K. Masu, and M. Sone: Nanoscale hierarchical structure of twins in nanograins embedded with twins and the strengthening effect. Metals 9, 987 (2019).

T. Nagoshi, M. Mutoh, T.F.M. Chang, T. Sato, and M. Sone: Sample size effect of electrodeposited nickel with sub-10 nm grain size. Mater. Lett. 117, 256 (2014).

J.R. Greer, W.C. Oliver, and W.D. Nix: Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821 (2005).

J.R. Greer and J.T.M. De Hosson: Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654 (2011).

D. Kiener, C. Motz, T. Schöberl, M. Jenko, and G. Dehm: Determination of mechanical properties of copper at the micron scale. Adv. Eng. Mater. 8, 119 (2006).

A. Rinaldi, P. Peralta, C. Friesen, and K. Sieradzki: Sample-size effects in the yield behavior of nanocrystalline nickel. Acta Mater. 56, 511 (2008).

E. Demir, D. Raabe, and F. Roters: The mechanical size effect as a mean-field breakdown phenomenon: example of microscale single crystal beam bending. Acta Mater. 58, 1876 (2010).

D. Kiener, W. Grosinger, G. Dehm, and R. Pippan: A further step towards an understanding of size-dependent crystal plasticity: In situ tension experiments of miniaturized single-crystal copper samples. Acta Mater. 56, 580 (2008).

K. Takashima, Y. Higo, S. Sugiura, and M. Shimojo: Fatigue crack growth behavior of micro-sized specimens prepared from an electroless plated Ni-P amorphous alloy thin film. Mater. Trans. 42, 68 (2001).

K. Asano, H.C. Tang, C.Y. Chen, T. Nagoshi, T.F.M. Chang, D. Yamane, T. Konishi, K. Masu, and M. Sone: Promoted bending strength in micro-cantilevers composed of nanograined gold toward MEMS applications. Microelectron. Eng. 196, 20 (2018).

Y. Kihara, T. Nagoshi, T.F.M. Chang, H. Hosoda, T. Sato, and M. Sone: Tensile behavior of micro-sized specimen fabricated from nanocrystalline nickel film. Microelectron. Eng. 141, 17 (2015).

W.F. Hosford: Mechanical Behavior of Materials, 2nd ed. (Cambridge University Press, New York, 2010).

E.O. Hall: The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Lond. B 64, 747 (1951).

N.J. Petch: The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25 (1953).

R.D. Emery and G.L. Povirk: Tensile behavior of free-standing gold films. Part I. Coarse-grained films. Acta Mater. 51, 2067 (2003).

Acknowledgment

This work was supported by JST CREST Grant No. JPMJCR1433, Japan, and the Grant-in-Aid for Scientific Research (S) (JSPS KAKENHI Grant No. 26220907).

Author information

Authors and Affiliations

Supplementary material

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1557/mrc.2020.38.

Rights and permissions

About this article

Cite this article

Suzuki, K., Chang, TF.M., Hashigata, K. et al. Sample geometry effect on mechanical property of gold micro-cantilevers by micro-bending test. MRS Communications 10, 434–438 (2020). https://doi.org/10.1557/mrc.2020.38

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2020.38