Abstract

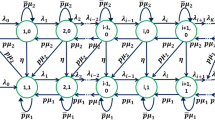

This paper models an unreliable automated manufacturing system (AMS) by a closed queuing network. The AMS consists of a multi-stage network of automated work stations linked by a computer. A closed queuing algorithm is applied to determine the system availability under steady state for the AMS. This algorithm is then integrated into a cost optimization model. By applying the revised genetic algorithm, the optimal (or near-optimal) number of standby units and repair rates for the repair stations are derived by minimizing the total cost. The model is verified by the intuitive results from the sensitivity analysis. A numerical example is used to compare the revised genetic algorithm and the conventional genetic algorithm. The results show that the proposed revised algorithm leads to significant improvement in execution time and lower average total cost.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, C., Ding, JR. & Yeh, JM. A closed queuing maintenance network for automated manufacturing systems. J Oper Res Soc 52, 1121–1129 (2001). https://doi.org/10.1057/palgrave.jors.2601175

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1057/palgrave.jors.2601175