Abstract

Although material requirements planning (M.R.P.) allows managers to better plan hierarchical production and inventory systems, much is still left to the planner's intuition and experience in devising realistic master production schedules, selecting appropriate lot sizes for components, and changing capacity levels. Decisions are made sequentially, rather than simultaneously, with no real assurance of satisfactory performance.

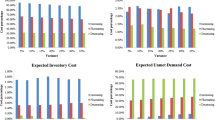

This research proposes an integrated model for facilitating these decisions. A mixed-integer nonlinear programming model is formulated such that it can be solved by a heuristic procedure. Several versions of this procedure are tested in a research design controlling for nine variables on shop and cost structure. Preliminary research results show that the procedure gives good solutions to the situations represented by the experimental variables. Computational results are also encouraging.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bahl, H., Ritzman, L. An Integrated Model for Master Scheduling, Lot Sizing and Capacity Requirements Planning. J Oper Res Soc 35, 389–399 (1984). https://doi.org/10.1057/jors.1984.79

Published:

Issue Date:

DOI: https://doi.org/10.1057/jors.1984.79