Abstract

A well-known formula gives the optimum length of a production series by balancing change-over costs against inventory costs. This formula can no longer be considered as optimum in the case of a high breakdown rate of the tools. We can often reduce our costs in such situations by ending the production series when a breakdown occurs. This introduces a variability in the lot-sizes, which in turn causes higher stock levels.

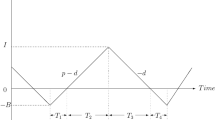

A production policy was developed, based on two limits, Ql and Q2. Production is stopped either at the first break-down after Q1 units have been produced, or at Q2. Optimum values of Q1 and Q2 were derived and can be read off from a set of graphs.

One assumption of this theory is that tools are always available, which theoretically requires an infinite stock of these tools.

A Monte Carlo programme was set up to study the situation, in which the number of tools was limited. The number of tools, and the reorder-level for the products, required for a desired probability of stock-out, can be derived by the programme.

The theoretical values of Q1 and Q2 could be considered optimum for practical purposes in the cases under consideration.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Muyen, A. Optimum Lot-Size Policy if Tools Break Down Frequently. J Oper Res Soc 12, 41–53 (1961). https://doi.org/10.1057/jors.1961.4

Published:

Issue Date:

DOI: https://doi.org/10.1057/jors.1961.4