Abstract

We developed a facile method to fabricate highly porous Au-embedded WO3 nanowire structures for efficient sensing of CH4 and H2S gases. Highly porous single-wall carbon nanotubes were used as template to fabricate WO3 nanowire structures with high porosity. Gold nanoparticles were decorated on the tungsten nanowires by dipping in HAuCl4 solution, followed by oxidation. The surface morphology, structure and electrical properties of the fabricated WO3 and Au-embedded WO3 nanowire structures were examined by scanning electron microscopy, transmission electron microscopy, X-ray diffraction, X-ray photoelectron spectroscopy and current–voltage measurements. Formation of a nanowire structure resulted in significant enhancement in sensing response to H2S and CH4 gases. Furthermore, Au embedment into the WO3 nanowire structures remarkably improved the performance of the sensors. The increase in response performance of sensors and adsorption–desorption kinetic processes on the sensing layers were discussed in relation with the role of Au embedment.

Similar content being viewed by others

Introduction

Gas sensors based on semiconducting metal oxides have been reported as indispensable devices that can be used in different daily applications. Compared with many other oxide materials, gas sensors based on tungsten oxide (WO3), which is an n-type semiconductor because of oxygen vacancies1, have attracted much attention because of the inherent electrical resistivity, excellent response and selectivity of WO3 to various gases. Sensing performance, particularly the response of a sensor, can be controlled by modifying the properties of sensing layer, including grain size, porosity, thickness, morphology and impurities, by surface modification with novel metals2. Surface modification with catalytic novel metals particularly showed important advantages. Reactivity of a material surface and solid–gas interactions can be controlled by using various modifiers at different concentrations. For example, the configuration of d electrons of transition metals on the surface of a material can change the surface activity of the oxide semiconductor3,4,5.

Metal nanoparticle decoration and doping of WO3 nanostructures have been widely studied and the modified materials showed desirable properties, thereby improving the performance of devices. Dopants modify the electronic structure by forming impurity levels in bandgaps; dopants are employed to enhance the responses of a sensor to specific gases6,7,8,9. In addition, decoration of metal nanoparticles on WO3 surface may lead to the formation of rectifying Schottky junctions at the interfaces to alter electrical transport behavior of WO3 and/or activate gas molecules that react with WO3 surface. For example, Pt and Pd nanoparticles enhance the dissociation of H2 molecules on WO3 surface via the known spillover effect, thereby improving the performance of H2 gas sensor and gaschromic devices10,11.

In this study, we report a facile method to embed gold catalyst on highly porous WO3 nanowires. The high-porosity nanowire structures of Au-embedded WO3were synthesized by using porous single-wall carbon nanotubes (SWCNTs) as template, followed by tungsten deposition, dip coating in gold salt solution and oxidation. We examined the effects of Au-embedment on structural, electrical and gas sensing properties of the fabricated sensor. Sensors based on nanowire structures of WO3 showed a significant improvement in sensing performance towards CH4 and H2S gases. In particular, WO3-based materials for CH4 sensors have not been reported. However, the additional embedment of Au further enhanced the sensing performance. We found that the Au-embedded WO3 sensor showed high response to CH4. Embedding of Au nanoparticles on WO3 surface also showed interesting response properties toward H2S gas. The adsorption–desorption kinetic processes on the surface of Au nanoparticles and WO3 nanowires surface were also discussed.

Results

Structural Properties

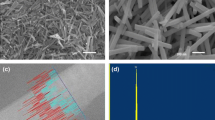

Porous nanowires of tungsten were obtained by sputter deposition of tungsten metal on porous SWCNTs template (Fig. 1a). The characteristic nature of the open spaces of the SWCNT template was stable during the metal sputter deposition and the following oxidation processes, as previously reported12. The morphology was negligibly changed after immersion in Au-containing solution (Fig. 1b and Fig. S3). As seen in Fig. 1c, WO3 nanowire structure was formed by interconnection of WO3 grains during the oxidation process at 700 °C in air. Gold atoms on the surface also agglomerated to Au nanoparticles during the oxidation process. The distribution of Au nanoparticles was non-continuous and scattered on the surface, as revealed by the low-magnification TEM images in Fig. 2a,b. The diameter of the gold nanoparticles ranges from 8 nm to 20 nm and the average diameter of WO3 nanowires is ~120 nm. The HR-TEM images revealed a high crystallinity of the synthesized WO3 nanowires and gold particles. The interplanar spacing of d{202{220} = 0.262 nm in Fig. 2c is consistent with the monoclinic phase of WO3 [JCPDF file no. 43-1035], whereas d{111} = 0.236 nm in Fig. 2d correspond to the cubic phase of Au [JCPDF file no. 04–0784]. The XRD pattern of the WO3 and Au50-WO3 nanowire structures (Fig.3) also confirmed the formation of monoclinic phase WO3 structure [JCPDF file no. 43-1035] and cubic phase of Au structure [JCPDF file no. 04-0784]. The bottom images show elemental mapping for W, O and Au of the Au-embedded WO3 nanowire. The images were obtained by STEM–energy-dispersive X-ray (EDX) spectroscopy, which suggest that gold atoms not only form nanoparticles on the WO3 nanowire surface, but also diffuse inside of the WO3 crystalline lattice.

To investigate the surface composition and chemical states of the elements in the sample, XPS spectra of the nanowire structures of WO3 and Au50-WO3 were obtained. The spectrum in Fig. 4a indicates that the surface of the samples is composed of tungsten and oxygen elements with carbon contamination. In addition, Au distribution after annealing of Au-embedded WO3 sample is evident. The peak at 285.7 eV is attributed to CO2, which is commonly adsorbed on the surface of the samples13. The high-resolution spectra of W4f (Fig. 4b) showed peaks at 35.85 and 38.02 eV, which are assigned to W4f7/2 and W4f5/2, respectively. These peaks corresponded to oxidation state +6 of tungsten atoms (WO3)14,15. The shift of these peaks toward lower binding energy in Au50-WO3 can be attributed to photoelectrons emitted from the lower oxidation states of tungsten (sub-stoichiometric WO3−x)14. The Au4f core level spectrum (Fig. 4c) recorded from the Au50-WO3 sample showed peaks at 83.6 and 87.3 eV, which were assigned to Au4f7/2 and Au4f5/2, respectively. These data confirmed that the Au nanoparticles are in metallic state15. The O1s peak in Fig. 4d showed a shift to lower binding energy with Au-embedment suggesting increased defective or incomplete W–O binding via Au addition. The O1s peak could be resolved to two Gaussian function peaks (1) and (2) having binding energies of 531 and 531.8 eV for WO3 nanowire structure and 530.7 and 532.2 eV for Au50-WO3 nanowires, respectively. Peak (1) may be related to oxygen in the lattice and O2− ions and peak (2) might be due to the ions of O2−, O− and OH− in the oxygen-deficient regions16. A shift of the peak (1) to lower binding energy and a shift of the peak (2) to higher binding energy were observed with Au embedment. The shift of the major peak (1) to lower binding energy with Au embedment may be attributed to the defective WO3 or sub-stoichiometry of WO3−x, whereas the shift of peak (2) may suggest an increased binding energy of the ionosorbed oxygen via Au addition. Details of the causes for the latter observation or the stronger binding of the oxygen ions on the surface are unknown, but it is consistent with the delayed surface reaction kinetics in Au50-WO3, which will be discussed.

DC conductivity measurements

The current–voltage (I–V) characteristics of the fabricated nanowires devices, as fundamental properties of electronic materials, were measured with varying temperatures in argon and dry air. Prior to the I–V measurements, the devices were heated to 350 °C in the given ambient conditions to remove the effect of adsorbed water molecules on the surface of the nanowires. The I–V curves of both WO3 and Au50-WO3 are linear, as shown in Fig. 5a-d, indicating the formation of ohmic contacts between the nanowires and Au electrodes. The resistances of nanowires calculated from the I–V measurements for pure WO3, Au10-WO3 and Au50-WO3 nanowire structures are shown in Fig. 5e. The measurements in Ar ambient condition are not affected by oxygen ionosorption effect; results revealed monotonic decrease of the resistance with increasing temperature for all sensors. This relationship indicates a dominant semiconducting behavior. Therefore, the metallic nature of Au did not alter the semiconducting resistance–temperature behavior of the WO3 nanowires probably because of the discreteness of the distribution of Au particles on the surface (Fig. 2). Nevertheless, a finite Au-embedment effect was observed, in which the resistance decreased with increasing content of embedded Au.

The current–voltage characteristics of (a,b) the WO3 nanowire sensor measured in dry air and argon ambient conditions and (c, d) the Au-embedded WO3 nanowire sensor in dry air and argon ambient conditions. (e) Dependence of the resistance of the WO3 and Au-embedded WO3 nanowire sensors on different working temperatures. (f) The relationship between ln(R) and 1/T for the WO3 and Au-embedded WO3 nanowire structures in the argon condition (the straight lines show the fitting).

The increase in conduction with Au embedment can be explained by the Au-doping effect in the WO3 lattice. This possibility could be postulated based on the EDS data in Fig. 2, which shows a uniform distribution of Au solid through the WO3 nanowire body. Although most of the Au atoms agglomerated on the surface as nano-crystallites, some atoms are incorporated into the WO3 nanowires during the annealing process and might form small Au clusters in theWO3 lattice. If the conductivity of a transition metal oxide is established by hopping of electrons via dopant impurity levels, then the resistance of the oxide can be expressed by the following equation17,18:

where R(T) is the resistance of a semiconductor at the absolute temperature T, ΔEa is the thermal activation energy for hopping and kB is the Boltzmann constant. The temperature-dependent resistances of the pure WO3 and Au-embedded WO3 nanowire structures are shown in Fig. 5f, which were obtained by using the logarithm of equation (1). For pure WO3 nanowires structure, we estimated the activation energies in two temperature ranges because of the slight anomaly observed at 200 °C. The activation energy values were ~0.39 eV for 200–300 °C and ~0.29 eV for 50–150 °C. These values are all greater than the thermal activation energies of 0.27 and 0.25 eV observed for Au10-WO3and Au50-WO3 nanowire structures, respectively. The decrease in activation energies with increasing Au concentration might be due to creation of additional impurities in the lattice. The distribution of Au clusters in the WO3 lattice could somehow increase the oxygen vacancies. Some Au atoms may have occupied the lattice sites to play directly as a dopant. Au atoms can create impurities in the bandgap, but the observation is in agreement with the cases of In-doped CdS19 and Al- and Sb-doped CdTe20, which showed a decrease in activation energy with increasing dopant concentrations. In summary, the increase in conductance with Au embedment was analyzed, but a concrete conclusion cannot be elucidated at present and separate systematic study is necessary.

Interestingly, Fig. 5e shows that the temperature-dependent resistance behaviors of the Au-embedded WO3 nanowires in air deviated from the semiconducting behavior at temperatures >150 °C; the resistances increased with increasing temperature. The increase in resistance is due to an enhanced oxygen ionosorption rate and corresponding increase of surface depletion depth of WO3 nanowires. This phenomenon is the catalytic effect of the embedded Au nanoparticles because the pure WO3 did not show such deviation even in air environment. Activation of oxygen adsorption on the surface of tin oxide decorated with various novel metals has been observed previously21. We found that the catalytic effect of Au critically enhances the dissociation of oxygen molecules at >150 °C, at which the adsorption ionic form of oxygen changes from O2− to O−22.

Gas sensing properties

CH 4 gas sensing

The development of resistive sensors based on metal oxide semiconductors for CH4 detection has been given much research interests in recent years. Among the metal oxides, tin oxide (SnO2) semiconductors have attracted particular attention2, but sensing by WO3 have been seldom reported. The CH4 gas sensing properties of pure WO3 and Au-embedded WO3 nanowire sensors were examined and compared. The sensors exhibited a typical gas-sensing behavior of an n-type semiconductor, as shown by the decrease in sensor resistance with exposure to the reducing gas CH4. The response and recovery behaviours of the Au50-WO3 nanowire sensor upon exposure to 100 ppm CH4 diluted in dry air was measured at different operating temperatures of 200 °C, 250 °C and 300 °C, as shown in Fig. 6a. The response behaviours of WO3, Au10-WO3 and Au50-WO3 sensors measured at the optimum working temperature of 250 °C are compared in Fig. 6b. The trends of temperature dependence of the sensor signal were the same in all the sensors, showing the highest response at 250 °C. The increasing Au content revealed increasing response signals, as shown in Fig. 6c. The response with pure WO3 nanowire sensor was very low, which may be the reason for the limited reports on CH4 gas sensing by WO3-based sensor. The response enhancement was from 3% with pure WO3 to 37% with Au50-WO3 sensor at 100 ppm CH4 and 250 °C. The sensing behaviors of Au50-WO3 sensor for different CH4 gas concentrations measured at 250 °C are shown in Fig. 6d. The concentration dependence of the responses for Au10-WO3 and Au50-WO3 are shown as the inset. Notably, the Au50-WO3 sensor showed a reduced operating temperature in comparison with the SnO2-based methane sensors, as shown in our previous report23.

(a) Gas-sensing properties of Au50-WO3 nanowire sensors upon exposure to 100 ppm CH4 at different working temperatures. (b) Gas-sensing properties of pure WO3 and Au-embedded WO3 nanowire structures at optimal working temperature of 250 °C upon exposure to 100 ppm CH4. (c) The responses of sensors to 100 ppm CH4 at different working temperatures were summarized. (d) The response of Au50-WO3 nanowire sensor to various CH4 gas concentrations at optimal working temperature of 250 °C and its summary showing linearity in sensing CH4 concentration (inset).

The enhanced response with Au embedment is ascribed to the catalytic effect of Au on the sensing process. We described the gas adsorption and desorption kinetics in relation to gas sensing of semiconducting WO3 nanowires and found that the response level and the gas selectivity of an oxide sensor is derived from the ratio of the forward (adsorption) reaction rate over the reverse (desorption) reaction rate of the relevant gas species on the oxide surface24,25. The higher response in the Au-embedded structure indicates that the reaction rate of CH4 with ionosorbed oxygen was enhanced with respect to the recovery rate, which is determined by the oxygen adsorption rate in air. We observed that Au has a catalytic effect on oxygen ionosorption and enhances the adsorption rate at >150 °C, which will enhance the recovery rate above. However, given that the enhanced response with Au-embedded sensor dictates far higher enhancement in the reaction CH4+ 4O−→CO2+2H2O+4e−, gold has to further accelerate the CH4 decomposition reaction. For example, for methane dissociated to a methyl group and a hydrogen adatom on Au surface26, the dissociated molecular species can more actively react with the adsorbed atomic oxygen than the covalently bonded CH4 molecules. In conclusion, Au showed catalytic effects on CH4 dissociation and oxygen adsorption, but the rate-enhancement level was greater with CH4 than with O2. The net consequence was the enhanced sensor response for CH4 with Au-embedded WO3 sensor structures.

We also reported that a rush of reducing gas, such as H2 and NH3, on oxygen-ionosorbed oxide surface can produce an instant pile up of H2O molecules on the surface, leading to an overshoot in the response cycle curves24,25. The similar overshoots in the response cycles were observed with CH4 on Au50-WO3sensor at 250–300 °C, as shown in Fig. 6a. We believe the overshoots were also derived from the combined effect of the enhanced reaction rate at high temperature and the high impingement rate of C, H and other fractions of CH4 catalytically dissociated by Au.

H 2 S gas sensing

The operation temperature effect of H2S gas sensing was examined for pure WO3 and Au50-WO3. Fig. 7a shows the response-and-recovery curves of Au50-WO3 nanowire sensor upon exposure to 10 ppm H2S at different operating temperatures (171–362 °C). The response levels are summarized in Fig. 7b. Remarkable improvement in the responses by Au-embedment was observed at all the operation temperatures up to 362 °C. The sudden increase of the response times at 362 °C in both sensors was interesting (Fig. 8a). This phenomenon may be due to the catalytic decomposition of H2S occurring in temperatures between 300 °C and 400 °C27,28. Thus, the species binding on the sensing layer changes at ~300 °C. Therefore, the operating temperature was set at 291 °C for the sensing of H2S to distinguish it from the different sensing mechanisms at >300 °C.

(a) Gas-sensing properties of Au50-WO3 nanowire sensors upon exposure to 10 ppm H2S at different working temperatures. (b) Summary of (a) together with the measurements from WO3 nanowire sensor. The response of (c) Au50-WO3 and (d) pure WO3 nanowire sensors to various H2S gas concentrations at optimal working temperature of 291 °C. Inset shows the summary.

The response behaviors of Au50-WO3 and WO3 nanowire sensors to H2S were measured at various concentrations of 5, 10, 25, 50 and 100 ppm diluted in dry air at operating temperature of 291 °C, as shown in Figs. 7c, d. The responses of these sensors at different gas concentrations were also summarized in Fig. 7d, as shown in the inset. A response of 700 was obtained with the Au50-WO3 nanowire sensor at 100 ppm H2S (Fig. 7c), which is much higher than the response of 100 obtained from the pure WO3 nanowire sensor (Fig. 7d). This result can definitely be explained by the catalytic effect of gold. The catalytically fractionized H2S species could more actively react with ionosorbed oxygen. The WO3 and Au50-WO3 nanowire sensors also showed excellent selectivity to H2S, as is evident from Fig. S4. The response to H2S was more than two orders of magnitude higher than the response to other interfering gases, including H2, NH3, CO and CH4 the same concentration. The selectivity towards H2S was further enhanced by the Au embedding (Fig. S4).

However, the Au50-WO3 nanowires showed much slower response and recovery rates compared with the pure WO3 nanowires through the whole working temperatures <300 °C and the tested H2S gas concentrations, as summarized in Fig. 8. Herein, the response and recovery times were measured assuming exponential rise and decay of the curves based on the first-order surface reaction kinetics for adsorption and desorption24,25. Therefore, they are the characteristic average times of the processes and are the times required for completion of approximately 63% (1-1/e) of the response and recovery processes. The decrease in response and recovery times with increasing working temperatures (Figs. 8a,b) is basically due to the enhanced surface chemical reaction rates in the response and recovery cycles. An exception is the abnormal increase of the response time at 362 °C with both pure WO3 and Au50-WO3 nanowire structures caused by the change in the formula of the species adsorbing on the Au and WO3 surfaces. Its effect on WO3 conductance will be discussed.

The response and recovery times measured with varying H2S concentrations are shown in Figs. 8c,d. The decreasing response time with increasing gas concentrations observed with the pure WO3 nanowires is the general trend in the sensing of reducing gases when the sensing behavior is based on a simple chemical reaction on the surface24,25. However, interestingly, the response time abnormally changes with H2S concentration for the Au-embedded sample, as shown in Fig. 8c. The result reveals a difference in H2S gas-sensing mechanism between pure WO3 and Au-embedded WO3 structures.

Generally, the response levels were enhanced but the response-recovery kinetics slowed down with Au-embedment. The improved gas-sensing response levels were definitely assisted by the Au nanoparticles. As we systematically examined in Refs. 25 and 29, the response and recovery processes of the WO3 sensing layer towards reducing gases are the results of thermally activated chemical reaction processes on the surface. H2S gas molecules continuously react with the pre-absorbed oxygen ions (say O−)22 via

to form H2O and SO2. Meanwhile, oxygen molecules from the air environment continuously adsorb on the empty adsorption sites on the surface in the air atmosphere. Therefore, the response level to H2S reflects the steady-state distribution of oxygen ionosorption on the WO3 nanowire surface under continuous impingement of H2S and O2molecules. In addition, creation of additional surface oxygen vacancies29 due to

sequent reduction of W6+ to W4+to release electrons into the WO3 nanowires was also proposed to be the reason for the response. However, a study of the detailed chemical route for sensing is beyond the scope of the present research.

Therefore, the enhanced response in Au50-WO3 nanowire sensor with respect to the pure WO3 (Fig. 7b) can be attributed to the highly catalytic dissociation of H2S by Au nanoparticles. As can be recall from Fig. 5c, the Au nanoparticles also enhanced the dissociation rate for oxygen adsorption. Therefore, the higher response observed with Au nanoparticles than with the pure WO3 could be derived from the increase in desorption rate of the adsorbed oxygen ions in equation (2), which was propelled by both of the enhanced dissociation reactions of H2S and O2.

A probable explanation for the enhanced catalytic role of Au in increasing the response of the sensor may be derived from the literature. H2S is known to adsorb strongly onto Au because of the high chemical affinity of S on Au30. Leavitt and Beebe31 found that H2S decomposes to SH via

to chemisorb onto the Au surface and the formed H2 is released in the temperature range of 165–520 K. At >520 K, the adsorbed SH undergoes disproportionation to form gaseous H2S and S-adsorption on the Au surface via

The binding of S on Au can lower the surface work function of Au as much as 1 eV32, so this lowering of Au work function would decrease the band bending at the interface of Au and WO3 nanowires, leading to a further resistance decrease and an improved response in the Au-embedded WO3 sensor. Both effects enhance the sensor response and explain the Au catalytic effect.

Now, the issues that need to be addressed are as follows: (i) the longer response and recovery times of Au-embedded WO3 than WO3 (Fig. 8), (ii) the abnormal increase of the response time at 362 °C(Fig. 8a) and (iii) the sudden rise of response time for higher H2S concentration in Au-embedded WO3 (Fig. 8c). The slower response and recovery kinetics with Au-embedment should be caused by some delayed reactions in relation to Au nanoparticles. A simple reaction of (2) may explain the sensing with pure WO3. The decreasing response time as the H2S concentration increased in Fig. 8c for WO3 reflects the concentration-dependent surface reaction rate (or 1/τ∝ CH2S), which is observed when the surface reaction kinetics controls the sensing24,25. By contrast, additional reactions, such as

may occur with Au at relatively low temperatures. The locally generated H2 gas molecules are added to the WO3 surface for additional reactions. While this added surface reaction increased the sensor response level, the dissociation reaction on Au and/or the successive reaction on WO3 surfaces delayed the overall response and recovery processes. As the H2S concentration increased, further delayed responses were observed due to the absolute increase of the reactions, but the contribution of the reactions occurring directly on the WO3 surface [or equation (2)] became relatively dominant at far higher H2S concentrations, resulting in reduced response time (Fig. 8c).

For the recoveries, the simple re-adsorption of oxygen atoms on the WO3 surface explains the recovery cycle for WO3. However, for Au-embedded WO3, the surfaces not only of WO3, but also of Au particles, need to be recovered to the standby condition. In other words, chemical reactions, such as 2SH(ads)+O2→H2S(g)+SO2(g) and/or S(ads)+O2→SO2(g), are required to recover to the original Au surface condition. The reactions themselves require time and may be slow and also can influence the processes occurring on nearby WO3 surface and finally determine the response time. For example, the produced H2S gas from the Au surface can impinge on the WO3 surface to play the role of analyte gas molecule and hinder the oxygen ionosorption. The delayed response and recovery rates are clear for different working temperatures and H2S gas concentrations, as shown in Fig. 8.

Another observation is that the further slowing down of the response rate at higher temperature of 362 °C was observed in both pure WO3 and Au-WO3 sensor structures (Fig. 8a). Therefore, it is a temperature-related reaction kinetics that occurs on WO3. A new reaction causing the apparently slower kinetics suddenly emerged at the above-mentioned temperature. The new reaction could be caused by the sudden change in (i) the formula of analyte gas provided and/or (ii) the ionosorbed oxygen formulas, resulting in a change in the reaction equation on the WO3 surface. If the impinging H2S gas molecules directly decompose to S and H2 and adsorb on the WO3 surface via equation (3), the high temperature further accelerates the decomposition reaction. The delayed escape of the highly increased product gas of H2O out of the surface could increase the apparent response time. Otherwise, the direct decomposition of H2S on the WO3 surface via

can be accelerated at the high temperature, thereby producing higher H2. The increased impingement of H2 on the surface could increase the apparent response time. The third possibility is due to the ionic form of adsorbed oxygen that may change from O− to O2– at such a high temperature [O2+4e→2O2−(ads)]22. The binding energy of O2− is expected to be greater than that of O–; thus, the desorption of the former is more difficult. This situation led to the longer response time.

Conclusions

Highly porous Au-embedded WO3 nanowire structures with diameters of ~120 nm were fabricated by tungsten deposition on porous SWCNT template, followed by dipping in HAuCl4 solution and oxidation. The Au atoms coated on the W nanowire surface agglomerated to form Au crystallites on the surface and in the WO3 lattice. The effects of Au, particularly of the embedded Au crystallites on the surface, on the gas-sensing properties were investigated based on the surface reactions. A comparison of the foregoing findings with the results obtained from pure WO3 nanowires is useful to discuss the Au embedment effect. For CH4 gas-sensing performance, the WO3 nanowire structure showed a significant lowering of working temperature with respect to SnO2 structure, whereas the Au-embedded structure demonstrated enhanced gas-sensing response because of improved dissociation of CH4 gas molecules. A different sensing performance of Au-embedded WO3 nanowires was observed for H2S gas. Although the gas-sensing signals were similarly improved, the response and recovery kinetics were slowed down by Au. Such complication seems to have originated from the diverse reaction routes of H2S gas on the Au and WO3 surfaces. The intermediate gas products on the surface may be impinged on the surface and play the role of analyte gas (such as H2) and/or temporarily adsorbed on the surface and show delayed detachment (such as H2O). The Au particles embedded on the surface catalyzed the dissociation reactions of O2, CH4 and H2S gases, thereby enhancing the oxygen ionosorption reaction and the gas-sensing reactions.

Methods

Fabrication of sensor structures

The Au patterned substrates were installed on the inside wall of the arc-discharge chamber; the substrate were then coated with SWCNTs, as described in Ref. 12 and 35.

Synthesis was performed at an arc current density of 40 A/cm2 in H2 gas at 400 Torr for 4 min. The carbon source used was a graphite rod that contained catalyst wires of iron, nickel and molybdenum12,33,34. The SWCNT template substrates were heat-treated at 400 °C in air for 2 h to remove amorphous carbon. The SWCNT bundles seated on the substrate revealed large open spaces among the SWCNTs because of steric hindrance12. Tungsten metal layers were deposited on the SWCNT templates using a DC magnetron sputtering system. The deposition was performed at room temperature under a constant Ar pressure of 3.8 × 10−2 Torr and input power of 100 W for 120 s. During deposition, the substrates were rotated to attain uniform thickness. The conformal deposition of W along the porous SWCNT bundles also revealed highly porous W/SWCNT composite nanowires. Gold salt solutions were prepared by dissolving different amounts of HAuCl4 salt in the mixture of distilled water and ethanol at 1:3 ratio. The W/SWCNT samples were dip-coated with Au by immersing in gold salt solutions of 0, 10 and 50 mM of HAuCl4; the samples were identified as WO3, Au10-WO3 and Au50-WO3, respectively. Oxidation of the samples at 700 °C for 2 h resulted in conversion of W to WO3 and formation of Au nanoparticles while burning out the SWCNTs, leaving a highly porous tungsten oxide nanowire network. Fig.S1 shows the flowchart of the fabrication process for open-space ensemble Au-embedded WO3 nanowires structure using a highly porous SWCNT template.

Characterization

Surface morphology of the nanowire structures was investigated by field emission scanning electron microscopy (FESEM; JEOL, JSM-700F) and transmission electron microscopy (TEM), scanning TEM (STEM) and high-resolution TEM (HR-TEM). The structural properties were investigated by X-ray diffraction (XRD; Rigaku D/MAX-RC) using Cu Kα radiation with a Ni filter. The electronic structure of the surface of samples was elucidated by X-ray photoelectron spectroscopy (XPS; VGMultilab 2000; Thermo VG Scientific, UK).

Gas sensing property measurement

Gas sensing properties were also measured using 6487 Keithley in a chamber with controls for temperature and gas flow12,35. The response of a sensor, S, was defined by Ri/Rf or (Ri-Rf)/Rf for reducing gases, where Ri is the standby resistance in air and Rf is the resistance upon exposure to reducing gas. We used 1000 ppm CH4 and H2S gases diluted in nitrogen as the source gas, which was further diluted in dry air at varying concentrations in the ppm range. The structure of gas sensor is shown in Figs. S2a–c. The setup for the gas sensing measurements is shown in Fig. S2d.

Additional Information

How to cite this article: Minh Vuong, N. et al. Porous Au-embedded WO3 Nanowire Structure for Efficient Detection of CH4 and H2S. Sci. Rep. 5, 11040; doi: 10.1038/srep11040 (2015).

References

Gillet, M., Lemire, C., Gillet, E. & Aguir, K. The role of surface oxygen vacancies upon WO3 conductivity. Surf Sci 532–535, 519–525 (2003).

Basu, S. & Basu, P. K. Nanocrystalline Metal Oxides for Methane Sensors: Role of Noble Metals. Journal of Sensors 2009 (2009).

Drozdov, V. A. et al. Comparative study of the activity of Al−Pd and Al−Pt catalysts in deep oxidation of hydrocarbons. React Kinet Catal Lett 27, 425–427 (1985).

Zhu, B. L., Xie, C. S., Zeng, D. W., Song, W. L. & Wang, A. H. Investigation of gas sensitivity of Sb-doped ZnO nanoparticles. Mater Chem Phys 89, 148–153 (2005).

Rumyantseva, M. N., Kovalenko, V. V., Gas’kov, A. M. & Pagnier, T. Metal-oxide based nanocomposites as materials for gas sensors. Russ J Gen Chem 78, 1081–1092 (2008).

Chen, L. & Tsang, S. C. Ag doped WO3-based powder sensor for the detection of NO gas in air. Sensor Actuat B: Chem 89, 68–75 (2003).

Zhu, S. et al. Synthesis of Cu-doped WO3 materials with photonic structures for high performance sensors. J Mater Chem 20, 9126–9132 (2010).

Tao, W.-H. & Tsai, C.-H. H2S sensing properties of noble metal doped WO3 thin film sensor fabricated by micromachining. Sensor Actuat B: Chem 81, 237–247 (2002).

Kawasaki, H., Ueda, T., Suda, Y. & Ohshima, T. Properties of metal doped tungsten oxide thin films for NOx gas sensors grown by PLD method combined with sputtering process. Sensor Actuat B: Chem 100, 266–269 (2004).

Wittwer, V. et al. Gasochromic windows. Sol Energ Mat Sol C 84, 305–314 (2004).

Xiang, Q. et al. Au Nanoparticle Modified WO3 Nanorods with Their Enhanced Properties for Photocatalysis and Gas Sensing. J Phys Chem C 114, 2049–2055 (2010).

Vuong, N. M., Jung, H., Kim, D., Kim, H. & Hong, S.-K. Realization of an open space ensemble for nanowires: a strategy for the maximum response in resistive sensors. J Mater Chem 22, 6716–6725 (2012).

Zhang, Y.-W. et al. Facile Alcohothermal Synthesis, Size-Dependent Ultraviolet Absorption and Enhanced CO Conversion Activity of Ceria Nanocrystals. J Phys Chem B 107, 10159–10167 (2003).

Navío, C. et al. Gold clusters on WO3 nanoneedles grown via AACVD: XPS and TEM studies. Mater Chem Phys 134, 809–813 (2012).

Moulder, J F, Stickle, W F, Sobol, P E & Bomben, K D. Handbook of X-ray Photoelectron Spectroscopy. (Eden Prairie: Perkin Elmer) (1992).

Nagasawa, Y. et al. Photoemission study of the interaction of a reduced thin film SnO2 with oxygen. Surf Sci 433–435, 226–229 (1999).

Mrooz, O. et al. Thermoelectrical degradation processes in NTC thermistors for in-rush current protection of electronic circuits. Microelectron Reliab 41, 773–777 (2001).

Wang, X. et al. Gas sensors, thermistor and photodetector based on ZnS nanowires. J Mater Chem 22, 6845–6850 (2012).

Megahid, N. M., Wakkad, M. M., Shokr, E. K. & Abass, N. M. Microstructure and electrical conductivity of In-doped CdS thin films. Physica B 353, 150–163 (2004).

Al-Douri, A. J., Al-Shakily, F. Y., Alnajjar, A. A. & Alias, M. F. A. The Role of Dopant Concentration on Conductivity and Mobility of CdTe Thin Films. Advances in Condensed Matter Physics 2011 (2011).

Haridas, D. & Gupta, V. Enhanced response characteristics of SnO2 thin film based sensors loaded with Pd clusters for methane detection. Sensor Actuat B: Chem 166–167, 156–164 (2012).

Barsan, N. & Weimar, U. Conduction model of metal oxide gas sensors. J Electroceram 7, 143–167 (2001).

Vuong, N. M. et al. Ni2O3-decorated SnO2 particulate films for methane gas sensors. Sensor Actuat B: Chem 192, 327–333 (2014).

Manno, D., Micocci, G., Serra, A. & Tepore, A. Thermal deposition and characterization of Se-Sn mixed oxide thin films for NO gas sensing applications. J Appl Phys 83, 3541–3546 (1998).

Tepore, A. et al. Kinetic behavior analysis of porphyrin Langmuir–Blodgett films for conductive gas sensors. J Appl Phys 84, 1416–1420 (1998).

Papadopoulos, C. A., Vlachos, D. S. & Avaritsiotis, J. N. Comparative study of various metal-oxide-based gas-sensor architectures. Sensor Actuat B: Chem 32, 61–69 (1996).

R.B. Slimane, F.S. Lau, R.J. Dihu & Khinkis, M. Production of hydrogen by superadiabatic decomposition of hydrogen sulfide. Proceedings of the 2002 US DOE Hydrogen Program Review, NREL/CP-610–32405 (2002).

Ramgir, N. S. et al. Selective H2S sensing characteristics of CuO modified WO3 thin films. Sensor Actuat B: Chem 188, 525–532 (2013).

Frühberger, B., Grunze, M. & Dwyer, D. J. Surface chemistry of H2S-sensitive tungsten oxide films. Sensor Actuat B: Chem 31, 167–174 (1996).

Geng, J., Thomas, M. D. R., Shephard, D. S. & Johnson, B. F. G. Suppressed electron hopping in a Au nanoparticle/H2S system: development towards a H2S nanosensor. Chem Commun 1895–1897 (2005).

Leavitt, A. J. & Beebe Jr, T. P. Chemical reactivity studies of hydrogen sulfide on Au(111). Surf Sci 314, 23–33 (1994).

Mubeen, S. et al. Sensitive Detection of H2S Using Gold Nanoparticle Decorated Single-Walled Carbon Nanotubes. Anal Chem 82, 250–257 (2009).

Hoa, N. D., Van Quy, N., Cho, Y. & Kim, D. Porous single-wall carbon nanotube films formed by in Situ arc-discharge deposition for gas sensors application. Sensor Actuat B: Chem 135, 656–663 (2009).

Vuong, N. M., Hieu, H. N. & Kim, D. An edge-contacted pn-heterojunction of a p-SWCNT/n-WO3 thin film. J Mater Chem C 1, 5153–5160 (2013).

Hoa, N. D., Van Quy, N. & Kim, D. Nanowire structured SnOx–SWNT composites: High performance sensor for NOx detection. Sensor Actuat B: Chem 142, 253–259 (2009).

Acknowledgements

This work was supported by the National Research Lab and Basic Research Lab(No. NRF-2013R1A4A1069528) programs of National Research Foundation of Korea (NRF).

Author information

Authors and Affiliations

Contributions

N.M.V. conducted all experimental work. N.M.V. and D.K. wrote the main manuscript text. H.K. involved in discusion of XPS, gas sensing data, etc. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Minh Vuong, N., Kim, D. & Kim, H. Porous Au-embedded WO3 Nanowire Structure for Efficient Detection of CH4 and H2S. Sci Rep 5, 11040 (2015). https://doi.org/10.1038/srep11040

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep11040

- Springer Nature Limited

This article is cited by

-

Self-heated WO3 nanowires for selective and sensitive detection of NO2 gas at room temperature

Journal of Materials Science: Materials in Electronics (2024)

-

Fast response and recovery polyaniline montmorillonite reduce graphene oxide polymer nanocomposite material for detection of hydrogen cyanide gas

Scientific Reports (2023)

-

Investigation on the microstructural, optical, electrical, and photocatalytic properties of WO3 nanoparticles: an effect of Ce doping concentrations

Journal of Materials Science: Materials in Electronics (2023)

-

Synergistic Effect of Nickel on Tungsten Oxide Hydrate (WO3·H2O) As a Photoanode for Dye-Sensitized Solar Cells

Journal of Electronic Materials (2022)

-

Investigation of H2S gas sensing performance of Ni:WO3 films at room temperature: nickel precursor effect

Journal of Materials Science: Materials in Electronics (2022)