Abstract

Outsourced carbon mitigation between cities means that some cities benefit from the carbon mitigation efforts of other cities more than their own. This problem conceals the recognition of cities’ mitigation contributions. Here we quantify local and outsourced carbon mitigation levels from 2012 to 2017 and identified ‘outsourced mitigation beneficiaries’ relying on outsourced efforts more than their own among 309 Chinese cities by using a city-level input–output model. It found that the share of outsourced emissions rose from 78.6% to 81.9% during this period. In particular, 240 cities (77.7%) were outsourced mitigation beneficiaries, of which 65 were strong beneficiaries (their local carbon emissions still grew) and 175 cities were weak beneficiaries (with larger outsourced mitigation efforts than local mitigation efforts). Strong beneficiaries were often industrializing cities with more agriculture and light manufacturing, focusing on local economic growth. In contrast, weak beneficiaries were mainly at the downstream of supply chains with services and high-tech manufacturing, which have stronger connections with upstream heavy industry cities. The findings suggest the need for policies to manage outsourced mitigation of supply chains and encourage transformation, improving the fair acknowledgment of cities’ carbon mitigation efforts.

Similar content being viewed by others

Main

As the hubs for economic activities, cities play an important role in generating carbon emissions through production and consumption activities1,2,3. The success of their carbon mitigation largely determines the deliverable of China carbon neutrality commitments and global decarbonization initiative4,5. However, no cities stand alone, where their demands are increasingly outsourced via supply chains6. Interlinked production activity have environmental impacts that transcend city borders7. It is essential to recognize the role of supply-chain and consumption activities within cities in terms of carbon mitigation8,9. Cross-city emissions are a nonnegligible impact, allowing one city’s carbon mitigation effects to transfer to other cities10. Relying on the efforts of other cities rather than their local efforts, causing the outsourced mitigation behaviors, significantly hampers equitable mitigation progression. This challenge underscores the necessity for each city to not only share responsibility in carbon mitigation but also adopt approaches tailored to their regional heterogeneity11,12,13. Overlooking outsourced mitigation behavior threatens coordinated mitigation efforts within China and challenges China’s equitable progression toward carbon neutrality. Considering the mechanisms of environmental impact transmission across cities is of utmost importance to maximize cobenefits and synergies while managing inevitable tradeoffs14.

Free riding is a classic problem where in a group that was providing itself with common goods, each member of the group would have a strong tendency to be an ‘outsourced mitigation beneficiary’—to contribute little or nothing toward the cost of the good, while grabbing its benefits15. Previous studies have been integrating the concept of ‘ outsourced mitigation’ or ‘free riding’ into the discourse on carbon mitigation responsibilities16. This involves using historical data and statistical analysis to examine carbon emission trends across regions17 or assess the impact of policy interventions in mitigating free-riding behavior18. Studies simulate the impacts of outsourced mitigation, adopting numerical models such as general equilibrium19, evolutionary game strategies20,21, simplified scenario22 and urban metabolism23. These studies provide insights into the reasons and drivers of outsourced mitigation for a single individual. Outsourced mitigation calls for a detailed exploration into the complex supply-chain dynamics and the environmental nexus among cities to ascertain its benefits or detriments. Despite many previous studies focused on cross-region carbon emissions24,25,26,27,28,29, there is no clear definition of outsourced mitigation of carbon mitigation, especially at the city level. The lack of systematic methodology to quantify the outsourced mitigation behavior and identify outsourced mitigation beneficiaries is the key barrier30. The gap is particularly true for cities heavily relying on outsourced supply chains. The city-level perspective needs to introduce unique considerations of diversities in resource endowments and industrial configurations4,31. This gap leads to an inadequate understanding of the allocation of mitigation responsibilities between cities, thereby affecting the development of high-resolution emission reduction policies.

To bridge the gap, we investigate outsourced carbon mitigation efforts at the city level by comparing carbon mitigation contributions of both local and outsourced efforts in supply chains. Due to data availability, we chose the period from 2012 to 2017, during which China underwent economic reform, with industrial transformation shifting from a stage of high gross domestic product (GDP) growth30,32. We constructed an environmentally extended multiregional input–output (MRIO) model covering 309 Chinese cities and calculated their carbon footprints over the period. Our analysis aims to identify the outsourced carbon mitigation beneficiaries by attributing the change of city carbon footprints to local and outsourced driving factors, which reveals the mechanism of outsourced mitigation within a city network. By examining the sources of these factors, we can help cities formulate strategies to reduce emissions across cities and facilitate better regional cooperation on carbon mitigation.

Results

The evolution of carbon footprint of China’s cities

From 2012 to 2017, the carbon footprint of 309 cities increased from 7,138.5 Mt to 7,219.8 Mt (Fig. 1a,b), of which the carbon footprint of 157 cities increased (Fig. 1c). The increase was highly disproportionate and concentrated in a few super emitters. The top five cities with the largest carbon footprint increased by 53.6 Mt, accounting for 65.9% of the total increase of 157 cities. These are all high-tech cities and the centers of population and economic activity in China. For example, the carbon footprint of Chongqing (top 1), the largest city in Southwest China, increased from 188.5 Mt to 203.2 Mt over the period.

a,b, Carbon footprint of China’s cities in 2012 (a) and 2017 (b). c, Carbon footprint change. d,e, Outsourced share in 2012 (d) and 2017 (e). f, Outsourced share change from 2012 to 2017. g, Average composition of sectors of carbon footprint in different city types in 2012 and 2017. h, Average contribution of local and outsource to carbon footprint changes in different city types.

The evolution of the carbon footprint was related to China’s economic transition during the period of eliminating backward industries and upgrading industries32. At the national level, the change in carbon footprint was concentrated in the service, construction and energy sectors, which increased by 424.5 Mt, 314.4 Mt and 155.3 Mt, respectively. In contrast, the carbon footprint of other sectors had decreased, especially equipment manufacturing with a decrease of 594.2 Mt. However, there is strong heterogeneity among different types of cities (Fig. 1g and Supplementary Fig. 1). High-tech cities saw the fastest growth in the carbon footprint of the service sector at 6.4%, highlighting their shift toward a service-oriented economy. As a modern metropolis, Shanghai’s service sector carbon footprint increased from 32.0% to 53.7% of the total. However, the carbon footprint of equipment manufacturing decreased the most in high-tech cities (8.0% of the total carbon footprint), which is related to the improvement of production efficiency during industrial upgrading. In light-industry cities, construction is the largest contributor, and its share has increased by 10%, indicating that these cities have improved infrastructure. In contrast, energy has become the key role for heavy-industry cities due to the rapid economic growth and rising energy demand, where the power sector’s share of carbon footprint has increased by 3.9%. For example, Baotou, northern China’s largest heavy-industry city, saw its power sector’s carbon footprint share rise from 4.9% to 13.6% with production expansion.

The carbon footprint of Chinese cities, divided into local and outsourced emissions, shows outsourced share rising from 78.6% in 2012 to 81.9% in 2017. Outsourced emissions surpassed local emissions as the dominant factor in 242 cities (80%) (Fig. 1d–f). This increase is attributed to demands for cleaner and more efficient outsourcing services in agriculture, light-industry and high-tech cities, whereas energy and heavy-industry cities saw a decrease due to stricter environmental regulations (Fig. 1h). Notably, some heavy-industry cities in Northeast China (for example, Changchun and Jinlin) experienced a shift toward higher outsourced emissions as local industries declined. In contrast, energy cities, such as Yulin, reduced outsourced emissions by 12.0%, focusing on local industry supply under environmental policy pressures. The construction sector has upstream supply chains rooted in carbon-intensive industries, such as cement and steel in all types of cities. The impact of these industries stretches goes beyond local boundaries, spilling over to other cities and leading to an increase in outsourced emissions in 50.8% of cities.

Driving factors to the evolution of city-level carbon footprint

To capture the free riders of carbon mitigation among Chinese cities, we first extracted the underlying driving factors of the change in city-level carbon footprints over the period. The evolution of carbon footprints for each city from 2012 to 2017 was decomposed by a combination of two production-side factors (carbon intensity and production structure) and one demand-side factor (final demand). Carbon intensity reflects the energy mix and the adoption of low-carbon technologies, while production structure is associated with the production efficiency and technology level. Final demand indicates the goods and services to meet the needs of household consumption and capital investment. In total, the decrease in carbon intensity and the change of production structure contributed to a decrease in the carbon footprint by −17.2% (−691.9 Mt) and −14.5% (−1,397.1 Mt), respectively, while the rise in final demand lifted up by +34.6% (+2,170.4 Mt).

Figure 2 shows that spatial heterogeneity across factors of intensity, production structure and final demand driving the carbon footprint change. The decrease in carbon intensity in 231 cities (74.7% of the total) drove emissions down, exemplified by Wuhan’s 67.6 Mt reduction due to a 35.0% decrease in carbon intensity. However, some northern cities saw increases in carbon footprint due to their power sectors and heavy manufacturing sectors. Improved production structure led to lower emissions in 278 cities (90.0%), showing a shift toward more efficient technologies, especially in coastal eastern cities focusing on industrial modernization (for example, the upgrading of industrial structure in the Shandong Peninsula). In contrast, except for some cities in North China and Northeast China, the increase in final demand in the 242 cities (78.3%) led to an increase in emissions. Final demand significantly promoted the increase of carbon footprint in high-tech cities because these cities have stronger consumption potential (for example, the increase in final demand caused the carbon footprint in Beijing to increase by 68.2 Mt).

Contributions of driving factors (carbon intensity, production structure and final demand) to the carbon footprint change in Chinese cities from 2012 to 2017 and local and outsourced contributions of their factors.

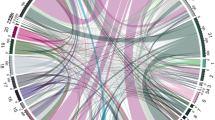

The impact of the driving factors on a city’s carbon footprint can be further decomposed to capture the impact of supply chains. We divided these three factors into local and outsourced contributions. As the supply chain is increasingly outsourced, the outsourced impact mainly dominates the three factors. In 195 cities (63% of the total), the contribution of carbon intensity change in upstream cities was greater than the local mitigation. The carbon footprint of upstream cities in southern cities has decreased more significantly, such as Wuhan, where upstream contribution was 9.3 times that of local. Similarly, 241 cities (78%) have a higher mitigation effect brought by production upgrade in upstream cities rather than the local efforts. Eastern coastal cities benefited more from the industrial upgrading of upstream cities. For example, due to Shandong Peninsula’s industrial upgrading, outsourced production structure was more contributed by neighboring cities, because the industrial upgrading of one city can prioritize the surrounding cities. Moreover, 272 cities (88%) found that their carbon emissions are more affected by imports from other cities than the local demand. As a result, more developed cities import more products from other regions. For example, in Beijing, imports increased carbon footprint was 6.2 times than local demand.

Key cities benefit from outsourced carbon mitigation effects through the supply chain

By comparing the mitigation contribution of local and outsourced efforts for each city, we identified 240 outsourced beneficiaries (almost 78% of all cities in the study). The identification is based on the criteria that the mitigation contribution of outsourced efforts in upstream cities is greater than that of local efforts. Final demand promoted carbon emission in most cities (Fig. 2) as it cannot adequately reflect mitigation efforts, but rather reflects the trade pattern and market. As outsourced carbon mitigation is about what extent the mitigation efforts in upstream cities lead to the mitigation in downstream cities, we only focus on production-side factors (carbon intensity and production structure) reflecting technical progress. However, when technical progress on carbon mitigation in both local and outsourced, mitigation contribution of the party can be amplified by final demands (that is, cities in zone 3 and zone 4 are easily confused with comparison of local and outsourced efforts). Therefore, we have considered the final demand and removed the effect to compare local and outsourced mitigation efforts by the change in emissions per final demand.

Figure 3a shows the quadrant classification of cities in terms of local and outsourced mitigation efforts. All the cities are divided into five zones based on the relationship between mitigation contribution of local and outsourced efforts, namely bad performers (zone 1), strong beneficiaries (zone 2), weak beneficiaries (zone 3), role models (zone 4) and hard workers (zone 5). All beneficiaries show the significance of declining effect of mitigation efforts in other cities; however, the local performance varies. Therefore, the beneficiaries can be divided into 65 strong beneficiaries and 175 weak beneficiaries in terms of their difference in outsourced mitigation degree. The former sees the lack of local mitigation efforts with growing local carbon emissions. In contrast, the latter shows the local mitigation efforts with declining local emissions but still smaller than the outsourced mitigation efforts from other cities. In contrast to these beneficiaries, other cities can be divided into 56 role models, 15 hard workers and 4 bad performers. Role models show that local mitigation efforts were greater than the outsourced mitigation from other cities. Hard workers and bad performers found their carbon footprint was dominantly increased by outsourced impacts, instead of declining carbon footprints from the supply chain as beneficiaries. However, the difference between them is about local mitigation efforts. Hard workers saw the local mitigation efforts with declined local emissions, but the bad performers still found the increased local emissions due to the lack of local mitigation efforts.

a, Quadrants classification of cities in terms of changes in emission per final demand (RMB, Chinese currency) caused by local (x axis) and outsourced (y axis) mitigation efforts. b, Geographic distribution of city classification.

Figure 3b shows the geographical distribution of outsourced beneficiaries. Strong beneficiaries were located in the northeast of China. Strong beneificiaries were composed of 23.1% agriculture cities, 21.5% energy cities, 7.7% high-tech cities, 21.5% heavy-industry cities and 26.5% light-industry cities (Table 1). These cities are heavily dependent on fossil fuels, indicating higher local emissions. Strong beneificiaries increased their local emissions by 131.8 Mt, as their local carbon intensity increased by 27.9% on average over the period. In contrast, their outsourced emissions were decreased by 166.8 Mt, largely due to mitigation efforts along the supply chain. For example, the outsourced carbon intensity declined by 36.5% on average. On the downstream beneficiary side, high-tech cities benefited from the highest average outsourced mitigation contribution of 9.7 Mt from upstream cities. On the upstream mitigation side, heavy-industry cities provided the highest mitigation contribution of 49.4 Mt to strong beneficiaries, accounting for 31.1% of total outsourced mitigation. The local efforts of strong beneficiaries did not reduce the carbon footprint because these cities were in the industrialization stage, and the development of industries led to an increase in emissions. According to local performance, energy cities are heavily dependent on fossil fuel extraction and processing, and their infrastructure was carbon locked in33. Their local production-related factors increased the most, by 5.7 Mt on average. In contrast to heavy-industry cities, the contribution of local production-related factors to the carbon footprint of agriculture and light-industry cities was the lowest with an average of 0.7 Mt, indicating a large potential to transform them into weak beneficiaries. They should be provided with financial and technical support to maintain their local production-related factors to promote emission reductions.

Weak beneficiaries, spread across coastal and developed inland regions, include 21.1% agriculture cities, 6.3% energy cities, 30.2% high-tech cities, 13.7% heavy-industry cities and 28.6% light-industry cities. The mitigation force is derived from both local and outsourced sources. The economic status of weak beneficiaries is relatively prosperous, with an average GDP 29.9% above the national average, and they are transitioning to a low-carbon economy. They reduced local emissions by 403.5 Mt due to declines in local intensity (223.5 Mt) and production technology upgrades (180.1 Mt). Their outsourced emissions were reduced by 1,302.7 Mt due to decreases in outsourced intensity (462.2 Mt) and improvements in production technologies (840.5 Mt). Given their downstream position of the supply chain, the mitigation efforts of their upstream cities are more likely to be realized. On the downstream side, high-tech cities have benefited the highest average outsourced mitigation contribution of 14.6 Mt from upstream cities. On the upstream mitigation side, heavy-industry cities provided the most mitigation contributions of 401.2 Mt to weak beneficiaries, accounting for 32.1% of total outsourced mitigation. Compared to strong beneficiaries, the outsourced mitigation from upstream cities’ efforts to weak beneficiaries were more dispersed. Thus, the share of mitigation contributions from efforts in the top ten largest cities was 18.3% of the total mitigation contribution from upstream cities for weak beneficiaries (Supplementary Table 1). This was 20.2% less than for strong beneficiaries. The energy cities that rely on outsourced mitigation weakly demonstrate a minimal disparity of 1.3 Mt between their average local and outsourced efforts in mitigating contributions. This suggests a significant opportunity to transform them into role models. These cities should enhance their technological research and development efforts to enhance production efficiency and further increasing their low-carbon industry share.

Role models, predominantly heavy-industry cities (30.8%) located in central China, are mid-supply chain and rely less on upstream cities for emissions reduction. They reduced local emissions by 206.6 Mt and outsourced emissions by 124.4 Mt, with improvements due to both intensity reductions (62.1 Mt) and production technology upgrades (62.3 Mt). Hard workers were mainly composed of 33.3% agriculture cities and 44.4% heavy-industry cities. Located in northern China, their remoteness from major cities hinders benefits from the outsourced mitigation of cities advancing in low-carbon transitions. Hard workers have reduced local emissions by 37.4 Mt, while their outsourced emissions were increased by 13.7 Mt. They are suggested to receive subsidies. Bad performers, including two energy cities and one each from light and heavy industry in northern China, focused on resource-based economic growth, increasing emissions by 5.8 Mt locally and 0.9 Mt from outsourced activities. They should prioritize green trade to lower emissions and aim to become strong beneficiaries.

Discussion

This study reveals a widespread trend among Chinese cities leveraging supply-chain networks for carbon mitigation, indicating a prevalent outsourced carbon mitigation behavior when cities benefit from the mitigation efforts of upstream cities without comparable local efforts. A comprehensive analysis of different types of cities provides insights into the different determinants and consequences of carbon mitigation in interregional contexts. Cities downstream of supply chains, such as high-tech cities, can effectively reduce emissions through technology and supply-chain management34. It is vigilant that they transfer their carbon-intensive industries causing emission increasing in other cities. Those who take over these industries were mainly agriculture or light industry. Insufficient technical and financial reserves for green and low-carbon development hardly supported their low transformation and industrial upgrading. Some major emitters can effectively reduce emissions, such as heavy-industry cities, through industrial upgrading, providing huge benefit to other cities’ carbon footprint decreasing. However, some major emitters, such as energy cities, face the challenge of slower economic growth and increased competitive pressure, need to embrace technological progress, fuel switching and cleaner substitutes. Outsourced carbon mitigation is normal behavior. In the early stages of industrialization, cities tend to focus on industrial development and cannot rely on their own emission reductions. Outsourced carbon mitigation by the supply chain provides a potential opportunity to reduce carbon emissions by actively promoting industrial upgrading and improving emissions performance.

Targeted policy initiatives are essential to promote equitable, proactive mitigation across heterogeneous cities by addressing their different barriers and motivations. It is necessary to systematically assess the mitigation potential and mitigation costs of the dominated industries based on socioeconomic conditions and developmental levels35. For cities with limited mitigation potential, bad performers should be encouraged to strengthen their trade with role models to facilitate the reduction of their outsourced emissions and turn them into strong beneficiaries (Fig. 3a). Strong beneficiaries are found in energy cities and heavy-industry cities, with agriculture and power as the dominant industries and lower marginal mitigation costs. Such cities should be supported through financial and technical support to transform outdated production capacity, such as retrofitting and upgrading of coal power units, and transform them into weak beneficiaries. Conversely, weak beneficiaries, characterized by their high-tech and service-oriented industries with higher mitigation costs, should amplify their investment in technological innovation and research to enhance industrial efficiency, such as intelligent management of power plants using digital twin technology, and transform them into role models. In addition, the establishment of a carbon compensation mechanism is critical, whereby cities facing irreversible outsourced mitigation due to high marginal mitigation costs require subsidies to support hard workers for their more proactive mitigation efforts. Effectively reducing emissions and acknowledging cities’ role in climate change mitigation require policies that are specifically designed to address the distinct challenges and opportunities of each city.

Demand has a significant impact on the correlation between different cities in the supply chain. Outsourced demands can serve as an important factor that determines free-riding behaviors to carbon mitigation along the supply chain. A total of 57% of beneficiaries outsourced their final demands from upstream cities, which amplifies outsourced mitigation efforts, due to economic specialization and the industrial distribution (Supplementary Fig. 2). These cities, often concentrated in heavy or energy industries, either lack the capacity for local sustainable development or are inherently resource intensive, requiring the import of cleaner, more efficiently produced goods and services from upstream cities. This dynamic not only reflects the economic interdependencies that shape regional trade patterns, but also underlines the importance of collaborative efforts across cities to improve overall carbon mitigation strategies. Facilitating the incorporation of emission reduction strategies into the supply-chain management of cities is a commendable measure36. The demand-side solution has played a crucial role in driving mitigation efforts and is expected to have even greater mitigation potential in the future. To address emission reduction challenges, cities should consider enhancing trade partnerships with low-carbon cities. This would enable them to procure clean energy and low-carbon products, thereby minimizing their carbon footprint. It is important to recognize that a city’s demand is determined by its socioeconomic situation over a long period of time, and addressing the demand side of the issue necessitates a long-term strategy to avoid the loss of local industry. It is crucial to consider the rebound effects of demand-side emission reductions. These consequences can include the establishment of high-carbon assets and the risks associated with policy instability or reversal.

As the latest provincial input–output table and the city statistical yearbook are not publicly available, the key data used in this study is from the latest year of the city MRIO table, which can only be compiled up to 2017. Thus, this study did not capture the impact of socioeconomic changes in China post 2017. With China’s focus on clean energy, central and western cities rich in wind and solar resources are emerging as clean energy suppliers. This dynamic is compounded by the growing demand for electricity from eastern high-tech cities due to the rise of the digital economy, which can lead to a situation where cities benefit from other cities’ clean energy efforts without making a commensurate contribution. Future works with more recent data on city-level emissions and economic activity can examine outsourced carbon mitigation behavior in this new context. In addition, given the significant changes in consumer lifestyles and preferences, future research will aim to incorporate these demand-side factors into our assessment of outsourced carbon mitigation efforts, thereby creating a more comprehensive assessment framework.

Methods

Carbon footprint accounting

This study developed an environmentally extended input–output model to estimate carbon footprint of Chinese cities. This model can trace spillover effects through regionally dispersed supply chains and, therefore, yields comprehensive estimates of the environmental impacts, such as greenhouse gases37,38, air pollution39, water sources40,41, energy consumption42,43, forest landscape44 and land use45,46. In this study, we utilized the MRIO table data for the years 2012 and 2017 to estimate the carbon footprint of cities in China.

This study used the Leontief inverse model to calculate the carbon footprint caused by final demand47. Mathematically,

where X is the vector of total output, I is the identity matrix and (I − A)−1 is the Leontief inverse matrix, A is the technical coefficient matrix and Y is the final demand matrix. On the basis of the carbon intensity E (that is, CO2 emissions per unit of output), the carbon footprint is calculated as:

where CF is a vector of carbon footprint, referring total CO2 emissions in goods and services used for final demand.

CO2 emission inventory construction

Equations (3) and (4) are used to calculate the fossil fuel-related and process-related emissions, respectively, as:

where CEij is the CO2 emissions caused by the sector j using the fossil fuel i; ADij refers to activity data (that is, consumption of corresponding fossil fuel types and sectors); NCVi (net calorific value of fossil fuel), CCi (carbon content of fossil fuel) and \({\mathrm{O}}_{{ij}}\) (oxygenation efficiency of fossil fuel) are emission factors for fuel. CEt is CO2 emissions induced in the industrial processes t, ADt is the production amount of processes t and EFt is emission factor of processes t.

Structural decomposition analysis

To understand the socioeconomic driving forces, we employed structural decomposition analysis to decompose carbon footprint into carbon intensity (E), production structure (\(L={\left({{I}}-{{A}}\right)}^{-1}\)), final demand (F) in equation (2). We used the average of two polar decompositions48 to solve numerical values as follows:

where 0 refers to base year (2012 year), and 1 refers to target year (2017 year). ∆ represents the change in a factor.

Mitigation efforts on technological progress

The total impact of change in production-side factors (that is, carbon intensity per output and production structure) reflects the technology progress as follows:

where ∆CT represents the change in emissions due to technological progress. However, ∆CT cannot truly reflect the real mitigation efforts of technological progress in different cities due to different final demand benchmarks. With the same magnitude of mitigation efforts on technological progress, cities with higher demand benchmarks will have a greater contribution to emission reduction. Therefore, we calculated units to remove the effect of this amplifier:

where TP represents the change in emissions per final demand caused by mitigation efforts.

Data source

According to our previous study30, we constructed a Chinese MRIO table consisting of 313 regions and 42 socioeconomic sectors for the years 2012 and 2017, by using a feasible nonsurvey methodology49. We collected economic statistics for 309 cities, including output, value-added, GDP and trade data from city statistics books and the China customs database. Using calibrated city-level output and trade data, we estimated supply and demand by sector for cities in each province. The maximum entropy model was applied to disaggregate estimated demand and supply into self-supplied and externally supplied categories. We then used the cross-entropy model to estimate single regional input–output (SRIO) tables for each city based on these estimates and the provincial SRIO table. Using the maximum entropy model again, we estimated intercity trade flows by sector, linking all city-level SRIO tables and trade flows to create a city-level MRIO table for each province. These city-level MRIO tables were then nested into the China provincial MRIO table, excluding data for Hong Kong, Macau and Taiwan due to data unavailability. The 313 regions covered include 309 cities and Tibet, Yunnan, Qinghai and Hainan provinces, treated at the same level as cities due to missing data. Both the 2012 and 2017 MRIO tables were compiled using current year prices, with 2012 as the benchmark year, and 2017 prices were converted to 2012 prices using deflators.

For the CO2 emission inventory of Chinese cities, we adopted the methods developed by Shan50,51. This inventory includes scope 1 emissions from 17 types of fossil fuels and industrial processes as defined by the Intergovernmental Panel on Climate Change52. The emissions inventory is organized using 47 socioeconomic sectors, aligned with China’s national and provincial emission accounts. To estimate city-level emissions, we applied a systematic approach that downscaled provincial energy balances and sectoral energy consumption to the city level, using auxiliary socioeconomic data such as industrial output, population and GDP. To address inconsistencies in the statistical calibration of energy consumption in China, the sum of city-level energy consumption was constrained to match the sum of provincial energy consumption statistics.

We segregated cities into five distinct industry dominated type: agriculture cities, light-industry city, heavy-industry city, energy city and high-tech city (Supplementary Table 2). This classification was based on the percentage of each city’s GDP contributed by these sectors. Initially, we condensed 42 different economic sectors into the five mentioned categories and computed the proportion of value added by each sector. Subsequently, we utilized the K-means algorithm with the Euclidean distance measure, taking into account the value-added percentages of the GDP attributable to each of the five sectoral groups in the year 2017.

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The city-level MRIO table for the 313 regions and the city-level carbon inventory are available in the CEADs database via https://www.ceads.net/.

Code availability

Code to calculate the carbon footprint and associated decomposition analysis is available at https://github.com/ChengqiXia/Outsourced-Carbon-Mitigation-for-Chinese-Cities-from-2012-to-2017.

References

Shahbaz, M., Chaudhary, A. R. & Ozturk, I. Does urbanization cause increasing energy demand in Pakistan? Empirical evidence from STIRPAT model. Energy 122, 83–93 (2017).

Wright, L. A., Coello, J., Kemp, S. & Williams, I. Carbon footprinting for climate change management in cities. Carbon Manage. 2, 49–60 (2011).

Glaeser, E. L. & Kahn, M. E. The greenness of cities: carbon dioxide emissions and urban development. J. Urban Econ. 67, 404–418 (2010).

Shan, Y. et al. City-level climate change mitigation in China. Sci. Adv. 4, eaaq0390 (2018).

Zhang, Y., Tian, K., Li, X., Jiang, X. & Yang, C. From globalization to regionalization? Assessing its potential environmentaland economic effects. Appl. Energ. 310, 118642 (2022).

Qi, Y., Ma, X., Xie, Y., Wang, W. & Wang, J. Uncovering the key mechanisms of differentiated carbon neutrality policy on cross-regional transfer of high-carbon industries in China. J. Clean. Prod. 418, 137918 (2023).

Zhu, B. & Zhang, T. The impact of cross-region industrial structure optimization on economy, carbon emissions and energy consumption: a case of the Yangtze River Delta. Sci. Total Environ. 778, 146089 (2021).

Long, Y. & Yoshida, Y. Quantifying city-scale emission responsibility based on input-output analysis—insight from Tokyo, Japan. Appl. Energ. 218, 349–360 (2018).

Grimm, N. B. et al. Global change and the ecology of cities. Science 319, 756–760 (2008).

Wang, Y. et al. Carbon peak and carbon neutrality in China: goals, implementation path, and prospects. China Geol. 4, 1–27 (2021).

Mi, Z. et al. Economic development and converging household carbon footprints in China. Nat. Sustain. 3, 529–537 (2020).

Liu, Z. et al. Challenges and opportunities for carbon neutrality in China. Nat. Rev. Earth Environ. 3, 141–155 (2021).

Zheng, H. et al. Leveraging opportunity of low carbon transition by super-emitter cities in China. Sci. Bull 68, S2095927323005340 (2023).

Bai, X. et al. Defining and advancing a systems approach for sustainable cities. Curr. Opin. Env. Sust. 23, 69–78 (2016).

Kim, O. & Walker, M. The free rider problem: experimental evidence. Public Choice 43, 3–24 (1984).

Vanderheiden, S. Climate change and free riding. J. Moral Philos. 13, 1–27 (2016).

Zhang, Z. Decoupling China’s carbon emissions increase from economic growth: an economic analysis and policy implications. World Dev. 28, 739–752 (2000).

Yang, Y., Tang, D. & Zhang, P. Effects of fiscal decentralization on carbon emissions in China. Int. J. Energy Sect. Ma. 14, 213–228 (2020).

Sykes, M. & Axsen, J. No free ride to zero-emissions: simulating a region’s need to implement its own zero-emissions vehicle (ZEV) mandate to achieve 2050 GHG targets. Energy Policy 110, 447–460 (2017).

Lessmann, K., Marschinski, R., Finus, M., Kornek, U. & Edenhofer, O. Emissions trading with non‐signatories in a climate agreement—an analysis of coalition stability. Manch. Sch. 82, 82–109 (2014).

Gui, H., Xue, J., Li, Y. & Chen, L. Research on carbon emissions reduction strategy considering government subsidy and free riding behavior. Environ. Eng. Sci. 39, 329–341 (2022).

Chuang, J., Lien, H.-L., Den, W., Iskandar, L. & Liao, P.-H. The relationship between electricity emission factor and renewable energy certificate: the free rider and outsider effect. Sustain. Environ. Res. 28, 422–429 (2018).

Nagpure, A. S., Tong, K. & Ramaswami, A. Socially-differentiated urban metabolism methodology informs equity in coupled carbon-air pollution mitigation strategies: insights from three Indian cities. Environ. Res. Lett. 17, 094025 (2022).

Qian, Y. et al. Large inter-city inequality in consumption-based CO2 emissions for China’s Pearl River Basin cities. Resour. Conserv. Recycl. 176, 105923 (2022).

Mi, Z. et al. Consumption-based emission accounting for Chinese cities. Appl. Energ. 184, 1073–1081 (2016).

Chen, G., Wiedmann, T., Hadjikakou, M. & Rowley, H. City carbon footprint networks. Energies 9, 602 (2016).

Long, Y. et al. Monthly direct and indirect greenhouse gases emissions from household consumption in the major Japanese cities. Sci. Data 8, 301 (2021).

Bai, Y., Zheng, H., Meng, J. & Li, Y. Jing-Jin-Ji urban agglomeration over China’s economic transition. Earth’s Future 9, e2021EF002132 (2021).

Mi, Z. et al. Carbon emissions of cities from a consumption-based perspective. Appl. Energ. 235, 509–518 (2019).

Xia, C. et al. The evolution of carbon footprint in the Yangtze River Delta city cluster during economic transition 2012–2015. Resour. Conserv. Recy. 181, 106266 (2022).

Liu, Y., Lu, F., Xian, C. & Ouyang, Z. Urban development and resource endowments shape natural resource utilization efficiency in Chinese cities. J. Environ. Sci. 126, 806–816 (2023).

Mi, Z. et al. China’s energy consumption in the new normal. Earth’s Future 6, 1007–1016 (2018).

Tong, D. et al. Committed emissions from existing energy infrastructure jeopardize 1.5 °C climate target. Nature 572, 373–377 (2019).

Issa Zadeh, S. B. & Garay-Rondero, C. L. Enhancing urban sustainability: unravelling carbon footprint reduction in smart cities through modern supply-chain measures. Smart Cities 6, 3225–3250 (2023).

Tian, K., Zhang, Y. & Li, Y. et al. Regional trade agreement burdens global carbon emissions mitigation. Nat. Commun. 13, 408 (2022).

Tian, K. et al. Economic exposure to regional value chain disruptions: evidence from Wuhan’s lockdown in China. Reg. Stud. 57, 525–536 (2022).

Meng, J. et al. The rise of South–South trade and its effect on global CO2 emissions. Nat. Commun. 9, 1871 (2018).

Zhang, Z. et al. Production globalization makes China’s exports cleaner. One Earth 2, 468–478 (2020).

Ou, J. et al. Role of export industries on ozone pollution and its precursors in China. Nat. Commun. 11, 5492 (2020).

Zheng, H. et al. Mapping carbon and water networks in the North China urban agglomeration. One Earth 1, 126–137 (2019).

Zhao, D., Hubacek, K., Feng, K., Sun, L. & Liu, J. Explaining virtual water trade: a spatial–temporal analysis of the comparative advantage of land, labor and water in China. Water Res. 153, 304–314 (2019).

He, H., Reynolds, C. J., Li, L. & Boland, J. Assessing net energy consumption of Australian economy from 2004–05 to 2014–15: environmentally-extended input-output analysis, structural decomposition analysis, and linkage analysis. Appl. Energ. 240, 766–777 (2019).

Li, M., Gao, Y., Meng, B. & Meng, J. Tracing embodied energy use through global value chains: channel decomposition and analysis of influential factors. Ecol. Econ. 208, 107766 (2023).

Kan, S. et al. Risk of intact forest landscape loss goes beyond global agricultural supply chains. One Earth 6, 55–65 (2023).

Hong, C. et al. Land-use emissions embodied in international trade. Science 376, 597–603 (2022).

Weinzettel, J., Hertwich, E. G., Peters, G. P., Steen-Olsen, K. & Galli, A. Affluence drives the global displacement of land use. Global Environ. Chang. 23, 433–438 (2013).

Leontief, W. W. Environmental repercussions and the economic structure: an input-output approach. Rev. Econ. Stat. 52, 262–271 (1970).

Dietzenbacher, E. & Los, B. Structural decomposition techniques: sense and sensitivity. Econ. Syst. Res. 10, 307–324 (1998).

Zheng, H. et al. Entropy-based Chinese city-level MRIO table framework. Econ. Syst. Res. 34, 519–544 (2022).

Shan, Y. et al. China CO2 emission accounts 1997–2015. Sci. Data 5, 170201 (2018).

Shan, Y., Huang, Q., Guan, D. & Hubacek, K. China CO2 emission accounts 2016–2017. Sci. Data 7, 54 (2020).

IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006 IPCC Guidel. Natl Greenh. Gas Invent. 1–40 (2006).

Acknowledgements

P.D. acknowledges the financial support from Key Technology Research and Development Program of Yunnan Province (202203AC100001). Y.S. acknowledges the financial support from National Natural Science Foundation of China (72243004 and 72361137002), Nederlandse Organisatie voor Wetenschappelijk Onderzoek NOW (482.22.01), and the Royal Society International Exchanges (IEC\NSFC\223059).

Author information

Authors and Affiliations

Contributions

H.Z. and C.X. designed the research. C.X. performed the research and modeling. C.X. and H.Z. analyzed the data. C.X. wrote the paper with inputs from H.Z., J.M., Y.S., X.L., J.L., Z.Y., M.C., P.D. and C.W. C.X. produced the graphics.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Cities thanks Xue-Chao Wang, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1 and 2 and Tables 1 and 2.

Supplementary Data 1

Dominated industry driving carbon footprint change.

Supplementary Data 2

The share of outsourced final demand in 2012 and 2017.

Source data

Source Data Fig. 1

Carbon footprint of Chinese cities.

Source Data Fig. 2

Contributions of driving factors to the carbon footprint change.

Source Data Fig. 3

City roles in terms of outsourced carbon mitigation beneficiaries.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xia, C., Zheng, H., Meng, J. et al. Outsourced carbon mitigation efforts of Chinese cities from 2012 to 2017. Nat Cities 1, 480–488 (2024). https://doi.org/10.1038/s44284-024-00088-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44284-024-00088-8

- Springer Nature America, Inc.