Abstract

LiCoO2 is a historic lithium-ion battery cathode that continues to be used today because of its high energy density. However, the practical capacity of LiCoO2 is limited owing to the harmful phase transition at high voltages, which prevents the realization of its theoretical capacity. Here, we treat LiCoO2 particles with a molten salt of MgF2–LiF as a reaction accelerator to facilitate the diffusion and doping of magnesium into bulk LiCoO2 and to form a stable coating layer on the particle surface. Ex situ X-ray diffraction analysis confirms the inhibition of the harmful phase transition and the emergence of a different phase as the modified LiCoO2 was charged up to 4.7 V. The modified LiCoO2 shows high electrochemical performance during high-voltage operation. This technology provides a guideline for the suppressing fundamental degradation associated with phase transition and achieving ultra-high energy density LiCoO2 cathodes.

Similar content being viewed by others

Introduction

The emergence of portable electronic devices, such as smartphones or tablets, has significantly transformed various aspects of human life. The demand for high-capacity batteries demonstrates continuous growth with the continuous integration and enhancement of device features. Owing to its superior energy density1,2, LiCoO2 (LCO) remains the most promising candidate for high-capacity lithium-ion batteries, widely adopted in mobile devices. LCO has a high theoretical capacity of 274 mAh g−1; however, its highly delithiated state (high cut-off voltage) degrades the battery performance, forcing recent LCO-based products to be used at 4.47 V for full cells, corresponding to a potential of ~4.55 V versus Li+/Li and a discharge capacity of 200 mAh g−1. Factors, such as side reactions on LCO surface2,3, Co dissolution2,4, oxygen release2,5,6, crystal structure change1,2,6, and crack formation2,7, contribute to the degradation in capacity during cycling. To mitigate the degradations at high cut-off voltage, various techniques have been applied to LCO by elemental doping8,9,10,11,12,13,14,15, surface coating16,17,18,19,20,21,22,23,24, and improvement of electrolyte25,26,27.

LiCoO2 exhibits an α-NaFeO2 (layered rock salt) structure in the \(R\bar{3}m\) space group, and it belongs to the O3 phase, which is characterized by an ABCABC oxygen stacking sequence28,29,30,31,32,33,34. When lithium is extracted at a high voltage, LCO undergoes a phase transition from O3 to H1-3 and then to O1 (where O1 represents ABAB oxygen stacking and H1-3 is a hybrid of O1 and O3 with ABABCACABCBC oxygen stacking). This transition involves a structural change, which is equivalent to gliding of the CoO2 slabs, generating stress in the crystal. This structural change may induce crack formation and crystallinity degradation, thereby compromising the performance of LCO batteries. Hence, effectively preventing the phase transition from O3 to H1-3 is crucial, particularly for achieving stable cycling when the cut-off voltage exceeds 4.55 V versus Li+/Li1,2,13,14. Generally, the phase transition and volume change caused by electrochemical insertion/extraction of cations are common issues that result in the degradation of electrochemical properties. Therefore, effective mitigation of these phenomena is not only critical for LCO but also for the development of other cathode materials35,36,37.

Magnesium doping and coating can improve the electrochemical performance of LCO at a high voltage8,9,15,16,21. Recent research has shown that doping of Mg2+ ions in the Li sites of LCO can improve its electrochemical performance by serving as pillars between adjacent CoO2 slabs15,16,21,23. However, studies have failed to achieve satisfactory electrochemical reversibility of Li insertion/extraction during high-voltage charging.

In this study, we propose a method for the effective integration of Mg into LCO through treatment with molten fluoride salt as an additive, as shown in Fig. 1. Furthermore, the incorporation of Ni and Al increases the electrochemical stability. An Mg-enriched rock salt structure emerges on the surface of LCO after synthesis, forming a coherent bond with the bulk material. Ex situ X-ray diffraction (XRD) analysis proves that the modified LCO experiences a phase transition to a compressed O3 phase (referred to as “O3’ phase”) at 4.7 V without undergoing a transformation to the H1-3 phase. The modified LCO materials achieved remarkable capacity retention of 96.4% and 72.7% after 100 cycles at cut-off voltages of 4.6 and 4.7 V, respectively.

Schematic of the synthesis process of MFNA-LCO and its surface; the coherent bonding structure was drawn by VESTA50.

Results

Synthesis of Mg, Ni, and Al-modified-LCO using a molten fluoride salt

The effects of adding Mg, Ni, and Al were investigated using commercially available LCO powder. The modified sample (denoted as MFNA-LCO) was fabricated using fluorides, which act as the reaction accelerator38, as schematically shown in Fig. 1. Supplementary Fig. 1 shows the MFNA-LCO synthesis flowchart. MgF2 and LiF were added to the preheated LCO (LCO:MgF2:LiF = 1:0.01:0.003 molar ratio), followed by heating the mixture to 900 °C. Subsequently, Ni(OH)2 and Al(OH)3 were added (LCO:Ni(OH)2:Al(OH)3 = 1:0.005:0.005 molar ratio), and the resulting mixture was heated to 850 °C. For comparison, M-LCO, MF-LCO, FN-LCO, FA-LCO, FNA-LCO, F-LCO, NA-LCO, MFN-LCO, and MFA-LCO were synthesized using a similar procedure by adding only Mg(OH)2, MgF2–LiF, LiF–Ni(OH)2, LiF–Al(OH)3, LiF–Ni(OH)2–Al(OH)3, LiF, Ni(OH)2–Al(OH)3, MgF2–LiF–Ni(OH)2, and MgF2–LiF–Al(OH)3, respectively. Heated LCO with no added elements was also fabricated following the same first and second heating processes. It should be noted that pristine LCO was not subject to the heating process.

LCO is susceptible to thermal decomposition in air above 950 °C39. However, MgO is extraordinarily thermally stable, with a melting point of 2852 °C. When LCO and MgO powders are heated below the decomposition temperatures of LCO, the solid-state reactions within the conventional mixing and baking processes tend to be inhomogeneous and slow. Therefore, the introduction of Mg into LCO is difficult when using conventional doping and coating techniques. Thus, we propose the use of molten fluoride salts to facilitate the diffusion and doping of Mg into the LCO bulk. This method involves coating the LCO particle surface with excess Mg at the same time as the doping. By using a differential scanning calorimeter (DSC), the eutectic point of MgF2–LiF40 was determined as 731.4 °C, as shown in Supplementary Fig. 2. Consequently, when subjected to the proposed temperature (900 °C) in this technique, these compounds undergo a transition from solid to liquid phase and convert into molten salt. In addition, DSC results of the molten fluoride salt containing Mg and LCO (MgF2–LiF–LCO) revealed an endothermic peak at 814.5 °C (Supplementary Fig. 3). This suggests that the LCO particle surface reacts with the Mg-containing fluoride liquid immediately below the decomposition temperature of LCO. Furthermore, SEM-EDX shows that heating melted the added MgF2–LiF nanoparticles, which were spread wet on the surface of the LCO particle (Supplementary Fig. 4e–j).

Morphological and structural analyses

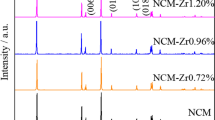

The powder XRD patterns of the pristine LCO and MFNA-LCO powders indicated the presence of O3 phase and \(R\bar{3}m\) space group; no other phases were observed (Supplementary Fig. 5 and Supplementary Table 1). Furthermore, scanning electron microscopy (SEM) revealed that the MFNA-LCO surface was smoother than that of pristine LCO (Fig. 2a–d, Supplementary Fig. 4). Energy dispersive X-ray (EDX) elemental mapping analysis of MFNA-LCO particle shows that Mg, Ni, and Al are uniformly distributed. However, nanoparticles composed mainly of these added elements were not observed (Supplementary Fig. 4n–p). This could be attributed to the partial melting of the LCO particle surface and the molten fluoride salt during the heating process.

a, b SEM images of pristine LCO. c, d SEM images of MFNA-LCO. e HAADF-STEM image of pristine LCO particle surface. f Enlarged view of region enclosed by red dotted rectangle in (e), the vicinity of the surface suffers cation mixing slightly. g NBED patterns of marked areas 1 and 2 in (e). h HAADF-STEM image of MFNA-LCO particle surface. i Enlarged view of region enclosed by red dotted rectangle in (h), with the yellow dashed line as a guide to the eye, suggesting the coherent bonding between the layered rock salt (Region I) and the rock salt (Region II) structures. j NBED patterns of marked areas 3 and 4 in (h). As shown, the inner part of MFNA-LCO has a layered rock salt structure with a visible contrast between the Co and Li layers in the HAADF-STEM image. The STEM image of the outermost surface shows cation mixing of ~1-nm-thick layer, and the diffraction patterns include spots indicating a rock salt structure (orange circles), as well as a spot indicating a layered rock salt structure (green circle). Scale bars, 10 µm (a, c), 2 µm (b, d), and 3 nm (e, f, h, i).

In the synthesis of MFNA-LCO, the elemental ratio is Co:Mg:F = 1:0.01:0.023. By the quantitative analysis of the added elements by using inductively coupled plasma mass spectrometry (ICP-MS), the elemental ratio of Co:Mg in the MFNA-LCO particles was confirmed as 1:0.0093 (Supplementary Table 2). An electron probe microanalyzer (EPMA) also revealed a Co:Mg = 1:0.009 in an MFNA-LCO particle cross-section (Supplementary Table 3). However, X-ray photoelectron spectroscopy (XPS) (Supplementary Table 4 and Supplementary Fig. 6) showed that the ratios of Mg and F to Co (Co:Mg:F = 1:0.93:0.53 atomic ratio) in MFNA-LCO were significantly higher than those of Mg and F added during synthesis to Co included in pristine LCO. This indicates that Mg and F were abundantly distributed on the outermost surface of the MFNA-LCO particles. The F 1s binding energy of MFNA-LCO was different from that of MgF2, which was used as an added material (Supplementary Fig. 6b). Furthermore, the Mg 1s binding energy of MFNA-LCO implies the presence of oxyfluoride41 (Supplementary Fig. 6c).

High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images and nanobeam electron diffraction (NBED) patterns revealed a layered rock salt structure near the surface of the pristine LCO particles, which is similar to its interior structure, as presented in Fig. 2e–g. In MFNA-LCO, a layered rock salt structure is observed in the bulk region. However, a rock salt structure, as indicated by the electron diffraction spots enclosed by orange circles, is mainly observed at the outermost surface region with a thickness of ~1 nm. Within this region, a small number of layered rock salt structures are also observed, as shown by the electron diffraction spot enclosed by the green circle (Fig. 2h–j). Notably, the continuity of the alignment of atomic columns between Region I and Region II indicates that the rock salt shell (Region II) is coherently bonded to the layered rock salt core (Region I) (Fig. 2i). Since this rock salt shell contains similar amounts of Li as Co and Mg as seen in the XPS results (Supplementary Table 4), Li ions are expected to pass through the shell. STEM-EDX elemental mapping analysis of MFNA-LCO (Fig. 3, Supplementary Fig. 7) revealed a uniform distribution of F, Mg, and Ni across the outermost surface, whereas their presence in the bulk was negligible in this measurement. Al is observed over a broad region from the particle surface. Near the surface of MFNA-LCO, distinct gradients of added elements were visible22,42. These observations suggest a topotactic phase transition of the layered rock salt to the rock salt structure during synthesis, which is attributed to the migration of added elements into the structure of LCO.

The distribution of added elements on the surface of the MFNA-LCO particle could be explained as follows. First, the solubility of Mg2+ in LCO is ~0.5%43, while Al3+ can form a solid solution with LCO, represented as LiAlxCo1−xO211,12. Second, MgO, CoO, and NiO form solid solutions with a rock salt structure44. Hence, the Mg2+ and Ni2+ ions may supplant Co2+ ions of the CoO region in LCO particle surface, which was formed by reducing the surface region during high-temperature heating. Therefore, the rock salt layer on the surface of LCO contains significant quantities of Mg and Ni. On the other hand, the c-axis elongation observed by XRD and the EPMA analyses suggest that most of the added Mg formed a solid solution in the LCO particles10. The distribution of the added elements is achieved using molten salts of LiF and MgF2, combined with the appropriate heating steps. Supplementary Note 1 describes the detailed characterizations of the samples for each step of the MFNA-LCO synthesis process.

Electrochemical performance

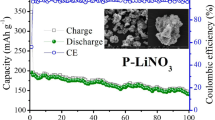

Figure 4a, b show the cycling performance of pristine LCO and MFNA-LCO cathodes in half cells. With the commonly used electrolyte, MFNA-LCO demonstrated considerably higher capacity retentions than those of pristine LCO. Specifically, the capacity retention of MFNA-LCO was 96.4% (205.2 mAh g−1) at 2.5–4.6 V (versus Li+/Li) and 72.7% (160.9 mAh g−1) at 2.5–4.7 V (versus Li+/Li) after 100 cycles, which are much higher compared with those of pristine LCO. The high Coulombic efficiency observed during cycling with MFNA-LCO implies that the oxydative electrolyte decomposition was effectively suppressed by the surface coating layer. The charge/discharge curves (Fig. 4c) show that the average discharge voltage of MFNA-LCO remained high even after 100 cycles. Conversely, the average discharge voltage of pristine LCO decreased with an increase in the voltage polarization6,22. In addition, at each discharge rate, MFNA-LCO demonstrated a superior rate performance relative to that of pristine LCO (Fig. 4d). MFNA-LCO underwent charging/discharging even with a high mass loading at a practical level (20 mg cm−2) (Supplementary Fig. 8).

Cycling performance of coin-type half cells with pristine LCO and MFNA-LCO cathodes in the voltage range of 2.5–4.6 V (a) and 2.5–4.7 V (b) (versus Li+/Li) at 25 °C. c Charge/discharge curves of pristine LCO and MFNA-LCO in the voltage range of 2.5–4.7 V (versus Li+/Li) at different cycles under the condition shown in (b). d Rate performance of pristine LCO and MFNA-LCO in the voltage range of 2.5–4.7 V (versus Li+/Li). Defining 1 C = 200 mA g−1, the current values of 40, 100, 200, 400, 600, 1000, and 2000 mA g−1 used in the rate test correspond to 0.2, 0.5, 1, 2, 3, 5, and 10 C, respectively.

The first charge/discharge cycles of MFNA-LCO demonstrated a decrease in cell resistance and an increase in the discharge capacity. This phenomenon is attributed to the formation of a solid electrolyte interphase (SEI) on the surface of LCO45,46 and the diffusion of Mg into the LCO structure23. To optimize the performance, a modified fluorinated electrolyte25 was applied instead of a commonly used electrolyte. To mitigate the impact of electrolyte decomposition, the cycling performance was evaluated with a high charge/discharge rate and a low mass-loading electrode. This approach led to high-capacity retention of 88.5% (191.5 mAh g−1) at a voltage range of 2.5–4.7 V (versus Li+/Li) after 100 cycles (Supplementary Fig. 9). For practical use, pouch-type full cells with the same configuration as a commercial product were fabricated using an MFNA-LCO cathode and a commercial graphite anode. Each full cell’s energy density retention after 500 cycles was 90.3% (656.8 Wh kg−1) and 75.8% (593.4 Wh kg−1) in the voltage range of 3.0–4.5 V and 3.0–4.6 V (versus graphite), respectively (Fig. 5). The full cells using MFNA-LCO show significantly more stable cycling performance in consideration of the previous studies on doping and coating for LCO at high voltage14,19,24.

Analysis of pristine LCO and MFNA-LCO after cycling tests

The ex situ XRD patterns (Supplementary Fig. 10) of pristine LCO in a discharged state after 100 cycles showed broad XRD peaks, indicating low crystallinity, while MFNA-LCO displayed sharp peaks, indicating that its high crystallinity was maintained after 100 cycles. Supplementary Fig. 11 shows SEM images of pristine LCO and MFNA-LCO in a discharge state after cycling. After 5 cycles, pristine LCO exhibited a small number of cracks, which were observed clearly around grain boundaries. After 50 cycles, cracks increased and became larger. In MFNA-LCO, no crack was observed after 5 cycles, and a very few small cracks were observed after 50 cycles. The HAADF-STEM image (Fig. 6a) and NBED patterns (Fig. 6b) of pristine LCO in a fully discharged state after 50 cycles demonstrate the formation of a ~ 3 nm thick spinel and rock salt phases on its surface5. Importantly, even after 50 cycles, the outermost surface of MFNA-LCO maintained its ~1 nm thick, rock salt structure (Fig. 6c, d). The formation of spinel and then rock salt phases on the degraded surface of the pristine LCO is attributed to the release of oxygen from the LCO surface5,6. However, due to the high concentrations of Mg, Ni, and Al on the surface layer of MFNA-LCO, the release of oxygen from the LCO surface is inhibited under highly delithiated conditions; thus, the formation of the spinel region is impeded. Also, F is present in high concentrations on the surface layer of MFNA-LCO, protecting the particle surface from HF attack47 caused by electrolyte decomposition during the cycling and preserving the interface for insertion/extraction of Li ions.

Discussion

To unveil the mechanism of improvement, we discuss structural analysis during the high-voltage cycles. Typically, LCO undergoes a phase transition from O3 to H1-3 upon charging up to 4.55 V (x < 0.3 in LixCoO2)1,2,30,32,34. This structural change reduces the capacity retention of LCO at high voltages6. Considering that the excellent electrochemical performances of MFNA-LCO at high voltage could be strongly correlated to the inhibition of this phase transition, we performed ex situ XRD measurements on the charged cathodes extracted from half cells.

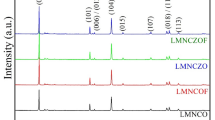

Figure 7 shows the ex situ XRD results for pristine LCO and MFNA-LCO cathodes at different cycles. When the first charging of pristine LCO at 4.7 V resulted in a charge capacity of 239.4 mAh g−1 and Li concentration (LixCoO2) of x = 0.13, the H1-3 phase formation was confirmed through ex situ XRD (Fig. 7a–c). Even when the first charging was up to 4.6 V, resulting in a lower charge capacity of 224.6 mAh g−1 (x = 0.18), the H1-3 phase was formed (Supplementary Fig. 12a–c). These results are consistent with those of previous reports1,2,30,32,34. In the fifth charged sample at 4.7 V, the surface of pristine LCO was likely to be damaged by exposing to the high voltage, and the damaged surface made Li diffusion difficult, resulting in the charge capacity of 145.6 mAh g−1 (x = 0.47). Because pristine LCO severely suffers from degradation of reversibility, the phase transitions from O3 to H1-3 at x < 0.3 were not observed.

Ex situ XRD patterns of pristine LCO cathodes in the 1st and 5th charged states up to 4.7 V (a), and enlarged views in the 2θ range of 18°–21° (b), and 42°–48 (c). Ex situ XRD patterns of MFNA-LCO cathodes in the 1st, 2nd, 5th, and 50th charged states up to 4.7 V (d), and enlarged views in the 2θ range of 18°–21° (e) and 42°–48° (f). The reference XRD patterns of Li0.35CoO2 O3 phase (ICSD collection code 17291247), Li0.12CoO2 H1-3 phase32, and O3’ phase (determined in this work) are also shown for comparison. (◇) Conventional delithiated O3 phase, (△) H1-3 phase, (●) O3’ phase.

Figure 7d–f show the ex situ XRD results of the MFNA-LCO cathode during the first charging up to 4.7 V, which corresponds to a charge capacity of 220.1 mAh g−1 (x = 0.20). The ex situ XRD results of MFNA-LCO, charged to 4.7 V, show a superposition of diffraction patterns from two O3 phases, while the diffraction pattern corresponding to the H1-3 phase is absent. The diffraction pattern of the first O3 phase exhibits peaks at 2θ = 19.0° and 45.3° on the lower-angle side (the peaks marked with ◇), while the diffraction pattern of the second O3 phase shows peaks at 2θ = 19.2° and 45.5° on the higher-angle side (the peaks marked with ●). The first O3 phase corresponds to the conventional delithiated O3 phase28,30,32,34,48,49. This classification is based on the continuous shift of diffraction peaks from 4.5 to 4.7 V in the charged state (Supplementary Fig. 12d–f). The second O3 phase is considered a different phase with a smaller unit cell volume and identical symmetry to the O3 phase. In this paper, we refer to this different structure of LCO as “O3’ phase.”

The charge capacity of the second charging was 215.4 mAh g−1 (x = 0.21) (Fig.7d–f), which was slightly smaller than that of the first charging. In the second charging, the area intensity ratio of the diffraction peaks associated with the O3’ phase increased and peak positions shifted upward. The upward shift of peaks indicates a reduction in the unit cell volume, suggesting a decrease in the Li concentration in LCO. This is inconsistent with the Li concentrations in the first and second charging estimated from the electrochemically observed capacities (1st: x = 0.20, 2nd: x = 0.21). Notably, during the first charging, the charge may be consumed not only by Li extraction but also by electrolyte decomposition accompanied with SEI formation which can be confirmed from Coulombic efficiency. Therefore, in the first charging, the actual Li concentration is considered to be higher than the Li concentration estimated from the capacity (x = 0.20), and probably higher than the actual Li concentration of the second charging. After conducting the fifth charging with a capacity of 225.3 mAh g−1 (x = 0.18), the O3’ phase emerged as the single phase, and the diffraction peaks shifted to higher angles, as the charge capacity increased from the second charging. The O3’ phase remained after the 50th charging with a capacity of 214.5 mAh g−1 (x = 0.22), although weak diffraction peaks, associated with the H1-3 phase, were detected. The dQ dV−1 curves of MFNA-LCO in Supplementary Fig. 13 display reversible peaks at voltages above 4.5 V during the 5th and 50th charge/discharge, indicating the sustained reversibility of the phase transition from O3 to O3’ phase. The lattice parameters of the O3’ phase were determined using the Rietveld refinement of the XRD pattern from the 1st and 5th charging cycles, as detailed in Supplementary Table 5. Compared to the reported values in previous studies for highly delithiated O3 phases48,49, the c lattice parameter is significantly smaller.

The hypothesis in the current study postulates that the pillar effect13,15,16,21,23 of Mg in MFNA-LCO inhibits the gliding of CoO2 slabs. To validate this hypothesis, we evaluated the cycling performance of the M-LCO, MF-LCO, FN-LCO, FA-LCO, FNA-LCO, and MFNA-LCO cathodes in combination with the ex situ XRD measurements for highly charged states (Supplementary Figs. 14 and 15). As a result, only MF-LCO and MFNA-LCO exhibited high cycling performance and did not show the H1-3 phase. The formation of the O3’ phase hence results from the introduction of Mg through treatment with molten fluoride salts. In a highly delithiated state, the presence of Mg substituted in the Li layer provides structural support, preventing the gliding of the CoO2 slabs and the phase transition from O3 to H1-3 (Fig. 8). Furthermore, gliding is probably initiated at the surface of LCO and hence could be suppressed by the presence of the Mg-rich rock salt region at the surface of MFNA-LCO. Due to inhibited gliding, the MFNA-LCO surface was less likely to deteriorate after cycling, as shown in the SEM images (Supplementary Fig. 11) and STEM image (Fig. 6). Consequently, Li diffusion was not inhibited in MFNA-LCO, allowing it to potentially exhibit excellent rate and cycling performances.

The schematic structure was drawn by VESTA50.

The cycling performances of heated LCO, F-LCO, FNA-LCO, and NA-LCO were measured to examine the effect of LiF only. The addition of LiF, without MgF2, did not lead to drastic improvement in cycling performances (Supplementary Fig. 16). Therefore, the main effect of LiF is to accelerate the reaction for Mg coating and doping, not to compensate for Li volatilization. Supplementary Fig. 17 shows the cycling performances of MFN-LCO and MFA-LCO, which enables the verification of the effects of Ni and Al. MFN-LCO or MFA-LCO were synthesized by adding Ni or Al to MF-LCO before the second heating process. Compared with MFN-LCO and MFA-LCO, MFNA-LCO exhibited the highest capacity retention. This is attributed to the fact that MFNA-LCO exhibits very high Coulomb efficiencies (e.g., 99.79%, 99.48%, and 99.34% for MFNA-LCO, MFN-LCO, and MFA-LCO, respectively, when compared in the third cycle with a cut-off voltage of 4.7 V).

In conclusion, this study achieved the diffusion and doping of Mg from the surface of LCO particles using molten fluoride salt as a reaction accelerator. In addition, the excess Mg covered the surface of MFNA-LCO particles. This technique effectively prevented the harmful phase transition to H1-3, particularly at a charge voltage of 4.7 V. Additionally, the ex situ XRD analysis of MFNA-LCO at 4.7 V revealed the formation of a different O3 phase (O3’ phase). The inhibition of phase transition to the H1-3 phase by this surface treatment and Mg doping suppressed crystallinity degradation and cracking after cycling with a cut-off voltage of 4.7 V. The Ragone plot presented in Supplementary Fig. 18 demonstrates that MFNA-LCO has the highest energy density among practical cathode materials. Therefore, MFNA-LCO has the potential to significantly impact the field of high-energy density batteries, thereby contributing to the advancement of mobile electronics. This study also provides valuable insight into the basic mechanism of phase transition by cation insertion/extraction. Our findings could be also applied to other cathode materials whose degradation is caused by phase transition.

Methods

Materials synthesis

To synthesize MFNA-LCO, MgF2 (99.9%, Kojundo Chemical Lab. Co., Ltd.), LiF (99%, Kojundo Chemical Lab. Co., Ltd.), Ni(OH)2 (99.9%, Kojundo Chemical Lab. Co., Ltd.), Al(OH)3 (99.99%, Kojundo Chemical Lab. Co., Ltd.) and LiCoO2 (99%, CELLSEED® C-10N, Nippon Chemical Industrial Co., Ltd.) were used. The C-10N without any processing was also used as pristine LCO.

MFNA-LCO was synthesized by following the flowchart presented in Supplementary Fig. 1. The muffle furnace was used for all the heating processes, and the samples were placed inside an alumina crucible. Pristine LCO (D50 of 12.5 μm) was preheated at 850 °C for 2 h in an oxygen atmosphere without the addition of any elements. In the first addition process, a 1:0.01:0.003 molar ratio of preheated LCO, MgF2, and LiF, respectively, was prepared. This mixture was subjected to heating at 900 °C in an oxygen atmosphere for 20 h. In the second addition process, the LCO obtained in the first addition process, Ni(OH)2, and Al(OH)3 were mixed in a molar ratio of 1:0.005:0.005, respectively. The mixture was subjected to heating at 850 °C for 10 h in an oxygen atmosphere.

For comparative purposes, M-LCO, MF-LCO, FN-LCO, FA-LCO, FNA-LCO, F-LCO, NA-LCO, MFN-LCO, MFA-LCO, were synthesized, and heated LCO was also prepared. All the samples were subjected to similar synthesis procedures as MFNA-LCO. To synthesize M-LCO, the preheated LCO was mixed with Mg(OH)2 in a 1:0.01 molar ratio, and then subjected to heating, similar to the first addition process described earlier. To synthesize MF-LCO, the preheated LCO, MgF2, and LiF were mixed in a molar ratio of 1:0.01:0.003, respectively, and then subjected to heating, similar to the first addition process. These products were finally subjected to heating, similar to the second addition process without any added elements. To synthesize FN-LCO, FA-LCO, FNA-LCO, and F-LCO, the preheated LCO and LiF were mixed in a 1:0.023 molar ratio and then subjected to heating, similar to the first addition process. The obtained LCO was mixed with Ni(OH)2 or Al(OH)3 in the molar ratio of 1:0.005, or with Ni(OH)2 and Al(OH)3 in a molar ratio of 1:0.005:0.005 and then subjected to the heating process, similar to the second addition process. To synthesize NA-LCO, no element was added to the preheated LCO before the first heating. The LCO subjected to the first heating was mixed with Ni(OH)2 and Al(OH)3 in a molar ratio of 1:0.005:0.005 and then subjected to the second heating process. To synthesize MFN-LCO and MFA-LCO, the preheated LCO, MgF2, and LiF were mixed in a molar ratio of 1:0.01:0.003 and then subjected to the first heating process. The obtained LCO was mixed with Ni(OH)2 or Al(OH)3 in the molar ratio of 1:0.005 and then subjected to the second heating process. The heated LCO without any added elements was also fabricated through the same first and second heating processes.

Half cell fabrications

The LCO cathode was fabricated by mixing 95 wt% active material, 3 wt% carbon black (DENKA BLACK, Denka Co., Ltd.) as a conductive additive, and 2 wt% polyvinylidene fluoride (Solef®5130, Solbay Co., Ltd.) as a binder. The weighed powders were mixed in N-methyl-1,2-pyrrolidone (NMP) to produce a homogeneous slurry. The slurry was coated onto an Al foil current collector by using a doctor blade. The NMP solvent was dried at 80 °C for 0.5 h in a forced convection drying oven. The mass loading of the active material was controlled to ~7 mg cm−2, while the mass loading for Supplementary Figs. 8 and 9 was controlled to ~20 mg cm−2 and ~3 mg cm−2, respectively. The coin-type half cells (CR2032) were assembled in an Ar-filled glove box using the prepared cathode, the Li metal foil (thickness of 0.6 mm, purity of 99.9%, Honjo Metal Co., Ltd.) as a counter electrode, polypropylene (PP, Celgard 2400, Celgard, LLC) as a separator, and an electrolyte. Two types of electrolytes were used for the half cells: a commonly used electrolyte containing 1 M LiPF6 dissolved in ethylene carbonate/diethyl carbonate (EC/DEC = 3:7 in volume ratio) with 2 wt% vinylene carbonate (VC), and a fluorinated electrolyte containing 1 M LiPF6 dissolved in fluoroethylene carbonate/methyl 3,3,3-trifluoropropionate (FEC/MTFP, 2:8 in volume ratio) with 5 wt% 1,3-propanesultone (PS). We employed the commonly used electrolyte unless otherwise noted.

Full cell fabrications

The preparation of the cathode was identical to the preparation of the half cells. The anode is composed of a mixture of materials comprising 96 wt% synthetic graphite (meso carbon micro beads (MCMB) graphite G10, Linyi Gelon Lib Co., Ltd.) as an active material, 1 wt% vapor-grown carbon nanofiber (VGCF-H, Showa Denko Co., Ltd.) as a conductive additive, 1 wt% sodium carboxymethyl cellulose (CMC, Kishida Chemical Co., Ltd.) as a thickener, and 2 wt% styrene–butadiene rubber (SBR, TRD2001, JSR Corporation) as a binder. The weighed powders were mixed with distilled water to produce a slurry, which was then coated onto a Cu-foil current collector. The cathode and anode mass loading were 10.6 and 7.6 mg cm−2, while their dimensions were 41 mm × 50 mm and 45 mm × 53 mm, respectively. The design of the cell was aimed at achieving a cathode-to-anode capacity ratio of ~80% and a total cell capacity of 40 mAh with cathode and anode capacities of 200 and 300 mAh g−1, respectively. The assembly of the pouch-type full cells was conducted in an Ar-filled glove box by using a stacking process. Single-side coated anode and cathode sheets, a polypropylene separator (PP, Celgard 2400, Celgard, LLC), and an electrolyte comprising 1 M LiPF6 in FEC/MTFP, (2:8 in volume ratio) were used in this process.

Electrochemical measurements

The charge and discharge measurements were performed using a TOSCAT-3100 (TOYO SYSTEM Co., Ltd.) battery testing system and a temperature-controlled chamber at 25 °C. The maximum discharge capacity obtained during cycling tests was used to determine the capacity retention.

For the coin-type half cells, the cycling performance tests (Fig. 4a–c, Supplementary Fig. 14d, e, Supplementary Fig. 15d, e, Supplementary Figs. 16 and 17) were conducted with constant current–constant voltage (CCCV) charging at 100 mA g−1 with a final current of 10 mA g−1 and constant current (CC) discharging at 100 mA g−1 in the voltage range of 2.5–4.6 V or 2.5–4.7 V (versus Li+/Li). A rest period of 10 min was allowed after each charging and discharging step. The discharge rate performance tests (Fig. 4d) were conducted with constant current–constant voltage (CCCV) charging at 100 mA g−1, using a final current of 10 mA g−1 and followed by CC discharging in the voltage range of 2.5–4.7 V (versus Li+/Li). The CC discharge current varied every five cycles as follows: 40, 100, 200, 400, 600, 1000, 2000, and 100 mA g−1. A rest period of 10 min was allowed after each charging and discharging step. For the experiment presented in Supplementary Fig. 8, discharge rate performance tests were conducted with constant current–constant voltage (CCCV) charging at 40 mA g−1, using a final current of 4 mA g−1 and followed by CC discharging in the voltage range of 2.5–4.7 V (versus Li+/Li). The CC discharge current varied every five cycles as follows: 40, 100, 200, 400, 600, 1000, and 40 mA g−1. A rest period of 10 min was allowed after each charging and discharging step. For the experiment presented in Supplementary Fig. 9, cycling performance tests using fluorinated electrolyte were conducted with CCCV charging at 200 mA g−1 with a final current of 40 mA g−1 and CC discharging at 200 mA g−1 in the voltage range of 2.5–4.7 V (versus Li+/Li). A rest period of 1 min was allowed after each charging and discharging step. The dQ dV−1 measurements (Supplementary Fig. 13) at the 1st, 5th, and 50th cycles were conducted with CC (10 mA g−1) for the charging and discharging in the voltage range of 2.5–4.7 V (versus Li+/Li). Before the 5th or 50th measurement, the cell was cycled 4 or 49 times in the voltage range of 2.5–4.7 V (versus Li+/Li) using CCCV charging (100 mA g−1, a final current of 10 mA g−1) and CC discharging (100 mA g−1). A rest period of 10 min was allowed after each charging and discharging step.

The cycling performance tests of the pouch-type full cells (Fig. 5) were conducted with CCCV charging (40 mA g−1, a final current of 4 mA g−1) and CC discharging (40 mA g−1) in the voltage range of 3.0–4.5 V or 3.0–4.6 V (versus graphite). A rest period of 1 min was allowed after each charging and discharging step.

Materials characterization

XRD measurements were conducted using a Bruker D8 ADVANCE diffractometer with Cu Kα (λ = 1.5406 Å). Powder samples were analyzed within the 15°–90° scan range (2θ) with a 0.005° step width and a scan speed of 0.1 s step−1. Rietveld refinement was performed using DIFFRAC TOPAS V6 software (Bruker). The SEM images were acquired using a Hitachi SU4800 or SU8030 field-emission SEM (FE-SEM) with a 5 kV accelerating voltage. SEM-EDX analysis was performed using the EMAX Evolution EX-370 (HORIBA) with a 15 kV accelerating voltage. ICP-MS analysis was performed using an agilent 8900. EPMA analysis was performed using a JXA-iHP200F (JEOL) with a 10 kV accelerating voltage. XPS measurements were recorded using a spectrometer with an Al X-ray source (1486.6 eV) (Quantera-SXM, ULVAC-PHI, Inc.). All binding energies were calibrated using the C 1 s peak at 284.8 eV. Cross-sectional HAADF-STEM observations and NBED measurements were performed using a JEM-ARM200F produced by JEOL spherical aberration-corrected STEM at 200 kV accelerating voltage. Cross-sectional STEM-EDX analysis was performed using the JED-2300T (JEOL). DSC measurements were conducted using Thermo Plus (EV02 DSC8271, Rigaku) at a heating rate of 20 °C min−1 from room temperature to 1000 °C. An alumina pan (ϕ 5 × 2.5 mm), and Al2O3 powder as a reference were used.

Ex situ XRD measurements

To perform ex situ XRD measurements, the coin-type half cells with commonly used electrolytes were employed. For the ex situ XRD of the pristine LCO and MFNA-LCO cathodes in a discharged state after 100 cycles (Supplementary Fig. 10), the cells were cycled using CCCV charging (40 mA g−1, a final current of 10 mA g−1) and CC discharging (40 mA g−1) in the voltage range of 2.5–4.7 V (versus Li+/Li). For the pristine LCO and MFNA-LCO cathodes in Fig. 7, in the 1st, 2nd, 5th, or 50th charging, the cells were charged with CC (10 mA g−1) up to 4.7 V before ex situ XRD measurements. Before the 2nd, 5th, or 50th charging, the cells were cycled 1, 4, or 49 times using CCCV charging (100 mA g−1, a final current of 10 mA g−1), and CC discharging (100 mA g−1) in the voltage range of 2.5–4.7 V (versus Li+/Li). For the pristine LCO and MFNA-LCO cathodes in Supplementary Fig. 12, in the first charging, the cells were charged with CC (10 mA g−1) up to 4.5, 4.6, or 4.7 V before ex situ XRD measurements. For the M-LCO, MF-LCO, FN-LCO, FA-LCO, FNA-LCO, and MFNA-LCO (Supplementary Figs. 14a–c, 15a–c) cathodes, the cells were cycled once using CCCV charging (40 mA g−1, a final current of 10 mA g−1) and CC discharging (40 mA g−1) in the voltage range of 2.5–4.5 V (versus Li+/Li). The cells were charged with CC (4 mA g−1) up to 4.6 V before the ex situ XRD measurement.

In an Ar-filled glove box, the cathode sheets of the charged or discharged cells were extracted and prepared for ex situ XRD measurements. The cathode sheets were washed with dimethyl carbonate to remove the electrolyte, dried, and then fixed on a flat glass substrate with a double-sided tape. These samples were enclosed in an airtight specimen holder (Part No: A100B33) in the Ar glove box. XRD measurements were performed within the scan range 15°–75° (2θ) with a 0.01° step width and a scan speed of 1.0 s step−1.

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Zhang, J.-C. et al. High-voltage LiCoO2 cathodes for high-energy-density lithium-ion battery. Rare Metals 41, 3946–3956 (2022).

Zhang, S.-D. et al. Advancing to 4.6 V review and prospect in developing high-energy-density LiCoO2 cathode for lithium-ion batteries. Small Methods 6, 2200148 (2022).

Schulz, N., Hausbrand, R., Wittich, C., Dimesso, L. & Jaegermann, W. XPS-surface analysis of SEI layers on Li-ion cathodes: Part II. SEI-composition and formation inside composite electrodes. J. Electrochem. Soc. 165, A833–A846 (2018).

Amatucci, G. G., Tarascon, J. M. & Klein, L. C. Cobalt dissolution in LiCoO2-based non-aqueous rechargeable batteries. Solid State Ionics 83, 167–173 (1996).

Sharifi-Asl, S., Lu, J., Amine, K. & Shahbazian-Yassar, R. Oxygen release degradation in Li-ion battery cathode materials: mechanisms and mitigating approaches. Adv. Energy Mater. 9, 1900551 (2019).

Yano, A., Shikano, M., Ueda, A., Sakaebe, H. & Ogumi, Z. LiCoO2 degradation behavior in the high-voltage phase transition region and improved reversibility with surface coating. J. Electrochem. Soc. 164, A6116–A6122 (2017).

Jiang, Y. et al. Atomistic mechanism of cracking degradation at twin boundary of LiCoO2. Nano Energy 78, 105364 (2020).

Tukamoto, H. & West, A. R. Electronic conductivity of LiCoO2 and its enhancement by magnesium doping. J. Electrochem. Soc. 144, 3164–3168 (1997).

Bae, J. G. et al. Structural evolution of Mg-doped single-crystal LiCoO2 cathodes: importance of morphology and Mg-doping sites. ACS Appl. Mater. Interfaces 15, 7939–7948 (2023).

Mladenov, M., Stoyanova, R., Zhecheva, E. & Vassilev, S. Effect of Mg doping and MgO-surface modification on the cycling stability of LiCoO2 electrodes. Electrochem. Commun. 3, 410–416 (2001).

Jang, Y. I. et al. Synthesis and characterization of LiAlyCo1−yO2 and LiAlyNi1−yO2. J. Power Sources 81–82, 589–593 (1999).

Luo, W. & Dahn, J. R. Comparative study of Li[Co1−zAlz]O2 prepared by solid-state and co-precipitation methods. Electrochim. Acta 54, 4655–4661 (2009).

Liu, A., Li, J., Shunmugasundaram, R. & Dahn, J. R. Synthesis of Mg and Mn doped LiCoO2 and effects on high voltage cycling. J. Electrochem. Soc. 164, A1655–A1664 (2017).

Zhang, J. N. et al. Trace doping of multiple elements enables stable battery cycling of LiCoO2 at 4.6 V. Nat. Energy 4, 594–603 (2019).

Kong, W. et al. Unraveling the distinct roles of Mg occupation on Li or Co sites on high-voltage LiCoO2. J. Electrochem. Soc. 168, 030528 (2021).

Shim, J.-H., Lee, S. & Park, S. S. Effects of MgO coating on the structural and electrochemical characteristics of LiCoO2 as cathode materials for lithium ion battery. Chem. Mater. 26, 2537–2543 (2014).

Cho, J., Kim, Y. J. & Park, B. Novel LiCoO2 cathode material with Al2O3 coating for a Li-ion cell. Chem. Mater. 12, 3788–3791 (2000).

Lee, J. G., Kim, B., Cho, J., Kim, Y. W. & Park, B. Effect of AlPO4-nanoparticle coating concentration on high-cutoff-voltage electrochemical performances in LiCoO2. J. Electrochem. Soc. 151, A801–A805 (2004).

Qian, J. et al. Electrochemical surface passivation of LiCoO2 particles at ultrahigh voltage and its applications in lithium-based batteries. Nat. Commun. 9, 4918 (2018).

Moon, S. H. et al. TiO2-coated LiCoO2 electrodes fabricated by a sputtering deposition method for lithium-ion batteries with enhanced electrochemical performance. RSC Adv. 9, 7903–7907 (2019).

Taguchi, N., Akita, T., Tatsumi, K. & Sakaebe, H. Characterization of MgO-coated-LiCoO2 particles by analytical transmission electron microscopy. J. Power Sources 328, 161–166 (2016).

He, Y. et al. A bi-functional strategy involving surface coating and subsurface gradient co-doping for enhanced cycle stability of LiCoO2 at 4.6 V. J. Energy Chem. 77, 553–560 (2023).

Orikasa, Y. et al. Origin of surface coating effect for MgO on LiCoO2 to improve the interfacial reaction between electrode and electrolyte. Adv. Mater. Interfaces 1, 1400195 (2014).

Yang, X. et al. Pushing lithium cobalt oxides to 4.7 V by lattice-matched interfacial engineering. Adv. Energy Mater. 12, 2200197 (2022).

Holoubek, J. et al. An all-fluorinated ester electrolyte for stable high-voltage Li metal batteries capable of ultra-low-temperature operation. ACS Energy Lett. 5, 1438–1447 (2020).

Zhang, B. et al. Role of 1,3-propane sultone and vinylene carbonate in solid electrolyte interface formation and gas generation. J. Phys. Chem. C 119, 11337–11348 (2015).

Wu, Z. et al. The roles of sulfur-containing additives and their working mechanism on the temperature-dependent performances of Li-ion batteries. J. Electrochem. Soc. 165, A2792–A2800 (2018).

Reimers, J. N. & Dahn, J. R. Electrochemical and in situ X-ray diffraction studies of lithium intercalation in LixCoO2. J. Electrochem. Soc. 139, 2091–2097 (1992).

Ohzuku, T. & Ueda, A. Solid-state redox reactions of LiCoO2 (R3m) for 4 volt secondary lithium cells. J. Electrochem. Soc. 141, 2972–2977 (1994).

Amatucci, G. G., Tarascon, J. M. & Klein, L. C. CoO2, the end member of the LixCoO2 solid solution. J. Electrochem. Soc. 143, 1114–1123 (1996).

Ménétrier, M., Saadoune, I., Levasseur, S. & Delmas, C. The insulator-metal transition upon lithium deintercalation from LiCoO2: electronic properties and 7Li NMR study. J. Mater. Chem. 9, 1135–1140 (1999).

Chen, Z., Lu, Z. & Dahn, J. R. Staging phase transitions in LixCoO2. J. Electrochem. Soc. 149, A1604–A1609 (2002).

Okumura, T., Yamaguchi, Y., Shikano, M. & Kobayashi, H. Correlation of lithium ion distribution and X-ray absorption near-edge structure in O3- and O2-lithium cobalt oxides from first-principle calculation. J. Mater. Chem. 22, 17340–17348 (2012).

Van der Ven, A., Aydinol, M. K., Ceder, G., Kresse, G. & Hafner, J. First-principles investigation of phase stability in LixCoO2. Phys. Rev. B 58, 2975–2987 (1998).

Kubota, K. et al. Impact of Mg and Ti doping in O3 type NaNi1/2Mn1/2O2 on reversibility and phase transition during electrochemical Na intercalation. J. Mater. Chem. A 9, 12830–12844 (2021).

Kim, E. J. et al. Active material and interphase structures governing performance in sodium and potassium ion batteries. Chem. Sci. 13, 6121–6158 (2022).

Pandey, A. K., Campéon, B. D. L., Konuma, I. & Yabuuchi, N. P3-type layered K0.6Cr0.6Ti0.4O2 for potassium storage applications. Energy Adv. 2, 98–102 (2023).

Zhang, C. et al. Effect of LiF addition on sintering behavior and dielectric breakdown mechanism of MgO-based microwave dielectric ceramics. J. Materiomics 7, 478–487 (2021).

Antolini, E. & Ferretti, M. Synthesis and thermal stability of LiCoO2. J. Solid State Chem. 117, 1–7 (1995).

Counts, W. E., Roy, R. & Osborn, E. F. Fluoride model systems: II, The binary systems CaF2-BeF2, MgF2-BeF2, and LiF-MgF2. J. Am. Ceram. Soc. 36, 12–17 (1953).

Ju, L. et al. Significantly improved cyclability of conversion‐type transition metal oxyfluoride cathodes by homologous passivation layer reconstruction. Adv. Energy Mater. 10, 1903333 (2020).

Sun, Y.-K. et al. High-energy cathode material for long-life and safe lithium batteries. Nat. Mater. 8, 320–324 (2009).

Koyama, Y., Arai, H., Tanaka, I., Uchimoto, Y. & Ogumi, Z. First principles study of dopant solubility and defect chemistry in LiCoO2. J. Mater. Chem. A 2, 11235–11245 (2014).

Wartenberg, H. V. & Prophet, E. Schmelzdiagramme hochstfeuerfester oxyde. V. Systeme mit MgO. Z. Anorg. Allg. Chem. 208, 369–379 (1932).

Heine, J. et al. Fluoroethylene carbonate as electrolyte additive in tetraethylene glycol dimethyl ether based electrolytes for application in lithium ion and lithium metal batteries. J. Electrochem. Soc. 162, A1094–A1101 (2015).

Becking, J. et al. Lithium-metal foil surface modification: an effective method to improve the cycling performance of lithium-metal batteries. Adv. Mater. Interfaces 4, 1700166 (2017).

Sun, Y.-K., Yoon, C. S., Myung, S.-T., Belharouak, I. & Amine, K. Role of AlF3 coating on LiCoO2 particles during cycling to cutoff voltage above 4.5 V. J. Electrochem. Soc. 156, A1005–A1010 (2009).

Takahashi, Y. et al. Structure and electron density analysis of electrochemically and chemically delithiated LiCoO2 single crystals. J. Solid State Chem. 180, 313–321 (2007).

Kawasaki, S. et al. Measurement of electron correlations in LixCoO2 (x=0.0–0.35) using 59Co nuclear magnetic resonance and nuclear quadrupole resonance techniques. Phys. Rev. B 79, 220514 (2009).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011).

Author information

Authors and Affiliations

Contributions

M.M. and S.Y. conceived the project. M.M., M.T. and T.T. developed the theory. J.S., T.O. and Y.M. synthesized the materials and conducted the electrochemical measurements of half cells. J.S. conducted ex situ XRD measurements. K.K. assembled and conducted the electrochemical measurements of pouch-type full cells. K.Y. and T.T. prepared figures and tables. R.W. analyzed the data. G.K. and S.K. contributed to the interpretation of results and to reviewing drafts. All the authors co-wrote and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Hong Li and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Jet-Sing Lee.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mikami, M., Saito, J., Ochiai, T. et al. Controlling lithium cobalt oxide phase transition using molten fluoride salt for improved lithium-ion batteries. Commun Mater 5, 108 (2024). https://doi.org/10.1038/s43246-024-00543-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-024-00543-y

- Springer Nature Limited