Abstract

Greenhouse gas (GHG) emissions from beef production in the United States are unevenly distributed across the supply chain and production regions, complicating where and how to reduce emissions most effectively. Using spatially explicit life cycle assessment methods, we quantify the baseline GHG emissions and mitigation opportunities of 42 practices spanning the supply chain from crop and livestock production to processing. We find that the potential to reduce GHGs across the beef sector ranges up to 30% (20 million tonnes CO2e reduced and 58 million tonnes CO2 sequestered each year relative to the baseline) under ubiquitous adoption assumptions, largely driven by opportunities in the grazing stage. Opportunities to reduce GHGs in the feed, grazing and feedlot stages vary across regions, yet large-scale adoption across the entire beef supply chain is important. These findings reveal promising locations and practices to invest in to advance mitigation goals and an upper-end theoretical potential for mitigation in the beef industry.

Similar content being viewed by others

Main

The United States is the world’s largest beef producer and fourth largest exporter, processing ~33 million head of cattle to produce over 12.3 million tonnes (Mt) of beef each year1,2. While providing an important source of food and supporting the livelihoods of millions, it results in 201 Mt of greenhouse gas (GHG) emissions each year, or 3.3% of total US emissions3,4. The industry has made meaningful gains in efficiency over the past 50 years5 in the United States, and beef supply chain actors, including producers, feedlot operators, processors and retailers, are increasingly committed to further reducing GHG emissions6,7,8,9 in response to the growing urgency and direct, material impacts of the climate and biodiversity crises. However, identifying where and which intervention strategies to prioritize remains a substantial challenge and barrier to progress due, in part, to the fact that emissions vary spatially and by production context, influencing where mitigation strategies are likely to be more or less effective (or even detrimental) for reducing production emissions10,11,12,13,14.

The US beef supply chain is one of the most complex food production systems in the world15,16, and like many agricultural supply chains, lacks transparency, which prevents processors, food companies and other key downstream decision-makers from identifying where and how to most effectively target efforts to reduce and mitigate GHG emissions12,13. Because the movement of cattle and feed through the various stages of production (Fig. 1) is currently not traceable in the United States17, models are needed to estimate subnational commodity flows and corresponding impacts unique to different regions18,19,20. Existing life cycle assessment (LCA) models aggregate impacts by commodity categories and do not connect these subnational flows to spatially explicit environmental impacts. Consequently, they do not estimate the reduction potential of regionally specific production practices nor the unique relationships that result in spatially variable impacts in downstream stages of the supply chain3,11,21,22,23. Characterizing such differences across production stages and regions is critical to prioritizing and deploying interventions.

Here we present a spatially explicit, fine-scale ‘cradle-to-gate’ assessment of GHG impacts and mitigation opportunities (Table 1) of the US beef supply chain. We identify emission hotspots and quantify individual and combined reduction potentials from applying different interventions across locations and stages of the supply chain. This is accomplished by linking the spatially determined impacts of production across the entire beef supply chain with a transport cost-minimization model that connects subnational agricultural commodity flows (feed and cattle) and individual beef processing facility demand (Fig. 1 and Supplementary Figs. 1–4). This approach bridges a critical gap in information necessary for decision-makers to prioritize the deployment of emission mitigation strategies in the US production system, propelling the industry to meet climate action targets. While we present a prospective, theoretical potential for different strategies to mitigate emissions considering existing practices and key biophysical constraints, other feasibility constraints related to economic, social or other factors are important to examine in future research. As such, our results are presented as a high-end estimate of what could be reached under ubiquitous adoption assumptions, assuming typical economic, social or other feasibility constraints can be overcome through market and regulatory incentives and technical improvements. It is also important to note that the selected list of strategies examined here spans those that may reduce emission sources directly and those that may increase the carbon sequestration potential of working lands (Tables 2 and 3); it does not represent an exhaustive list of opportunities, but rather those that have been touted in the industry as possible routes to meet climate action targets and those that can be examined within this study’s current analytical approach. Other strategies, such as changes in feed diets and productivity improvements, are outside the scope of our study but are also important opportunities to be examined in future research (see section 2.4 of Supplementary Information for additional discussion).

Aggregate US beef industry baseline emissions

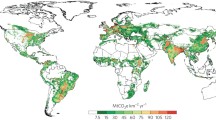

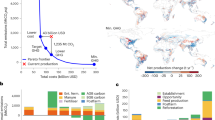

We find that the US beef industry currently emits 257.5 Mt CO2e yr−1 in total (Fig. 2), with 15% attributed to feed production, 64% to grazing, 19% to confinement and 3% to processing. Across all processing facilities, fed-beef generates an average of 32.6 kgCO2e kg−1 boneless beef, culled beef generates approximately 30.0 kgCO2e kg−1 boneless beef and culled dairy cows generate 14.5 kgCO2e kg−1 boneless beef owing to much of the impacts allocated to dairy products. These estimates are comparable to others published that are based on national average inventories3,22. Unlike previously published methods for estimating the US beef industry emissions, this model also enables the assessment of subregional patterns and identification of hotspots of mitigation opportunities for different actors along the supply chain. Generally, findings indicate absolute emissions from feed production associated with beef sourcing, and confinement (primarily feedlots) is concentrated in the Great Plains and Midwest regions, whereas emissions from grazing tend to be more evenly distributed across the western United States (Fig. 3). Emissions associated with the processing stage are localized around processing facilities; the highest densities of these facilities occur in close proximity to confinement operations (that is, in the Great Plains), but there are also emission hotspots associated with processing occurring in the northeastern and southwestern regions (Fig. 3).

Practices are grouped and colour coded by production stage (that is, feed, grazing, feedlot, dairy and processing) and correspond to the selected scenario combinations highlighted in Fig. 4. Individual practices and the associated reduction potentials are indicated in Supplementary Table 33 (see Tables 1 and 2 for mitigation scenario details). ‘Feedlot’ and ‘Dairy’ are combined as ‘Confinement’ in Figs. 3 and 4. Negative values represent carbon sequestration potential.

Spatial distribution of beef emissions and emission intensity

Our model shows that emissions from feed, grazing, confinement and processing vary across the country, including at the county scale (Fig. 3). The grazing stage generates the majority of emissions (64%) owing firstly to the duration of this phase in cattle life cycles (for example, beef cows spend upwards of 2,400 days on pastureland, with calves and stockers spending around 450 days grazing, compared with about 145 days spent in feedlots) and secondly to the differences in feed efficiency between the average diet of cattle in the grazing stage compared with confined feeding operations. That is, cattle fed concentrates (for example, corn, dried distiller grain with solubles (DDGS) and wheat-based feed products) in feedlots emit fewer GHGs per unit of feed compared with cattle consuming grass and other forage because of the higher digestible energy content of concentrates. These findings are similar to those of other studies comparing GHG impacts of grain-finished and grass-finished cattle systems24 for US beef production3,22, which also indicate that a majority of baseline emissions can be attributed to enteric fermentation and manure generated while cattle are grazing. Total emissions for a given county are thus a result of the number of cattle produced in each county and the associated emission intensity, with counties specializing in grazing operations often having higher emissions than those specializing in confinement operations, with the exception of a few large confinement operations in the central United States and parts of California that support substantial cattle populations. Production of feed concentrates and consumption of feed in confinement generates 34% of total emissions. Our model estimates that a large proportion of emissions generated from feed production occurs in Great Plains states such as Nebraska and Kansas, which represent key sourcing regions for feedlots.

Emission intensity, defined here as kg of CO2e emissions per kg of boneless beef at the processing gate, is also distributed and varies across counties, driven in part by downstream assumptions of processing yields associated with particular cattle types and sourcing regions (for example, culled cows versus stockers), as well as differences in primary productivity (for example, crop yields, net primary productivity of forage). The influence of these variables can cause noticeable differences in the location of hotspots for emission intensity of a particular stage compared with the same stage’s total emission. For example, in some feed production regions outside the Midwest, such as in the northeastern United States, high-emission-intensity hotspots (Fig. 3b) due to lower-than-average yields in these regions (as well as other differences in production20) are conversely associated with relatively low total emissions (Fig. 3a) because of the smaller quantities of feed sourced from these areas. Identifying regions that have both high emission intensity and high total emissions, such as the Nebraska and Kansas feed production regions, helps highlight the key areas for prioritizing investments to efficiently reduce emissions within the sector. Emissions from grazing are primarily caused by enteric fermentation in beef cows, which are mostly reared on the rangelands of the western United States and attributed in part to offspring that are then supplied to confinement operations. These rangelands are characterized by lower-quality forage, as measured by total digestible energy. This results in reduced digestive efficiency in cows, leading to increased methane emissions due to the higher fibre content of their diet. Emission intensities in the northeast United States and southern California are lower than those of other production areas owing to the influence of culled dairy cows and calf-fed dairy cattle in the supply chain. In addition to inherent efficiencies within the calf-fed dairy cattle production system, such as the steer’s overall shorter lifespan (Supplementary Table 8) in regions practicing lightweighting and reduced time spent grazing, the attribution of the majority of the emissions from dairy cow production to milk products25 reduces the emission intensity of beef sourced from culled dairy cattle compared with other systems (Supplementary Figs. 3 and 4).

Potential for GHG mitigation in the beef supply chain

Across the US beef industry, we find that 30% of the baseline GHG emissions could be mitigated through full implementation of alternative practices (summarized in Tables 1 and 3) in the feed production (8%), grazing (19%), confinement (3%) and processing (1%) stages, equivalent to 20 Mt CO2e reduced and 58 Mt CO2 sequestered each year relative to the baseline (Fig. 2). The majority of the emission mitigation potential exists in the grazing stage, which is also the most emission-intensive part of the supply chain (Fig. 2). These grazing management strategies are, however, based on relatively short-term carbon sequestration assumptions, with carbon storage potential neutralized after 10 years (given the underlying assumptions of this study). While total magnitudes of soil carbon gains are uncertain, if the sequestration rates used in this study can be realized (see section 3.1 of Supplementary Information and Supplementary Table 34 for specific assumptions), these carbon storage strategies can lead to substantial mitigation potential in the beef supply chain (47.7 Mt CO2), making them an important pathway for addressing the urgency of climate change alongside strategies that reduce actual emission sources (for example, enteric fermentation) that are also necessary to address climate action needs. We estimate that strategies that reduce emissions in the beef supply chain can mitigate 8% of the emission intensity of beef production. Other strategies that were outside the scope of this analysis, such as opportunities in selective breeding, precision feeding, diet reformulation and other technologies targeting direct reduction of enteric methane production not considered (for example, feed additives with various modes of action, vaccines and so on), may have additional potential reduction benefits26. Within each stage of the beef supply chain, we find that stacking mitigation opportunities in feed production could reduce feed emissions by 54% (20.6 Mt CO2e), which may have co-benefits for reducing emissions for other feed sourcing industries. Implementing a feed additive in the feedlot could reduce feedlot emissions by 12% (4.7 Mt CO2e), as enteric fermentation represents about half of the stage’s emissions (Fig. 4). Furthermore, a combination of interventions in dairy production, such as manure management, potentially reduces in-stage emissions by 42% (3.5 Mt CO2e) and the emissions associated with the processing stage could be reduced by 26% (1.8 Mt CO2e) through energy management strategies (Fig. 4). Notably, the use of silvopasture applied across all eligible land in the grazing stage reduces total cradle-to-gate emissions (from feed production through beef processing) by 13% through carbon sequestration in additional tree biomass (20% within the grazing stage alone), representing the largest single opportunity for mitigating emissions in the beef supply chain in the short to medium term (see Methods, section 3.1.7 of Supplementary Information, and Supplementary Tables 33 and 34 for details on estimation). By contrast, applying nutrient management strategies and cover crops to all applicable feed production lands (that is, the practices with the greatest mitigation potential in the stage; Fig. 4) results in just 4% emission reduction from the overall total baseline (and 27% reduction within the feed stage alone).

Scenario combinations are shown in Mt CO2e and are selected based on maximizing the reduction potential for the industry. 4Rs, a nutrient management strategy encompassing right placement, right timing, right type and right amount of fertilizers; AD, anaerobic digestion; AMP, adaptive multi-paddock grazing; LUC, land use change; NGP, Northern Great Plains.

Unequal spatial distribution of mitigation opportunities

Mitigation opportunities are also unequally distributed across the United States. We find that the Northern Great Plains and southeastern regions of the United States are hotspots for potential emission reductions (Figs. 5 and 6) because of the carbon sequestration capacity of specific practices within these areas. In the southeastern United States, the addition of trees to pasturelands (that is, silvopasture) is an important opportunity for storing more carbon in grazing systems, while in the Northern Great Plains, repairing degraded wetland areas can be a critical intervention. Hotspots for mitigating emissions in feed production coincide with the primary regions where concentrate feed is sourced, namely, the central part of the United States. Increasing the adoption of cover crops and nutrient management practices that reduce fertilizer needs, as well as increasing farm energy use efficiency, especially in pumping for irrigation, can reduce both direct and indirect emissions from feed production. Reducing annual land use change for feed production, that is, the conversion of lands to cropland for the production of feed ingredients, was also highlighted through our analysis and may be particularly relevant in regions experiencing declines in crop or pasture productivity due to soil degradation. Spatial distribution of mitigation opportunities within the confinement stage is limited by the location of feedlots and exhibits less variation between regions than other stages of the beef supply chain. This pattern is driven by two primary factors: (1) manure management systems in beef feedlots are highly similar across locations and (2) we assume a uniform scalar for the reduction potential of feed additives on enteric fermentation (see Supplementary Information section 3.3.1).

The results presented here show that the potential for mitigating emissions is meaningful but varies substantially across crop production and grazing regions owing to the differences in existing production practices, climate and soil conditions. The added detail made possible by this spatially explicit LCA modelling approach shows its importance for identifying key leverage points across regions and supply chain stages. While local ecological, operation and site conditions are critical to inform what practices are most appropriate for a given context, this information provides supply chain actors a critical starting place to be able to identify where and how to deploy resources for mitigation more effectively to advance climate action and more rapidly achieve targets and commitments. Our analysis provides an upper-end estimate of reduction potential assuming broadscale adoption of mitigation practices while incorporating some key conservation-related considerations, for example, limiting silvopasture to areas with historic forests and excluding this practice in native grasslands. There are certainly limits in the feasibility of adoption owing to economic and/or socio-cultural constraints across the country27,28; however, showing this full potential highlights what could be possible if those constraints were reduced. Furthermore, there are potential additional benefits29 or tradeoffs with other environmental, social and economic outcomes13 that would be critical to consider in any given context in addition to climate change mitigation benefits. As such, decision-makers should leverage evidence- and context-based approaches to facilitate adoption30 of opportunities across all sectors, especially as some opportunities in some sectors are likely to be more easily implemented than others29, and may also have co-benefits for reducing emissions in other sectors (for example, reducing the emission intensity of feed concentrates fed to other livestock sectors), which remains an area for future research.

While this study examines the spatial mitigation potential of 42 strategies (Supplementary Tables 33 and 34) available to the US beef sector, many more potential opportunities to reduce emissions exist that warrant further examination. Current and emerging technologies to mitigate enteric fermentation emissions have low or no adoption, but trials and other studies indicate substantial potential31 and new pathways for the regulation of these technologies are currently being explored. By contrast, there are additional restoration and land-based practices that could have soil carbon storage potential in certain grazing land locations that do not yet have a broad evidence base and need further investigation before they can be properly incorporated into spatially explicit mitigation planning, for example, additional riparian restoration approaches32,33. There is also potential to modify feed rations, which will have dynamic, complex effects on feed supply chains, enteric fermentation and manure emissions, and livestock growth and performance. Such complexity requires simulation models such as those deployed in this study, to identify the net outcomes and potential for reducing emissions across the industry to avoid potential leakage and rebound effects. Importantly, we find that under current supply chain conditions, the beef industry has the theoretical potential to mitigate emissions by 30% (8% from emission reductions and 22% from carbon sequestration and storage) through implementation of practices that primarily increase the carbon storage of working lands. Our study identifies which lands within the beef supply chain have the greatest potential opportunity to increase the carbon storage potential through adoption of alternative management practices, providing state and county officials, beef and crop processors, and producers with a road map to mitigate emissions in the industry. This methodological approach serves as an example for other agricultural industries and countries of production to follow for identifying effective and efficient pathways for climate action, as well as for other impact categories of interest like water scarcity and land use. While this study considers the warming potential of emissions over 100 years (that is, GWP100) based on the IPCC Fifth Assessment Report (AR5), which was the latest report available at the time of this study’s analysis, new metrics and assumptions such as those presented in the IPCC Sixth Assessment Report (AR6) are available that can be further considered in future analyses34,35. For example, GWP100 impacts from methane and nitrous oxides are reduced in AR6 compared with those of AR5, although considering shorter time frames such as the GWP20 or linking more directly to the changes in global temperatures such as through the global temperature potential or GWP* metric would further highlight the substantial impacts of short-lived emission sources such as methane on global temperature increase34,36. Including these and other metrics may probably have implications on the relative reduction potential of different strategies and remains an area for future research. While uncertainty and data limitations exist throughout this analysis (see section 2.4 of Supplementary Information), which can be refined as better data become available, the ability to provide geospatial indicators of relative environmental impacts and mitigation opportunities across the beef supply chain is a crucial step towards managing and achieving climate commitments.

Methods

Spatialization of the US beef supply chain

In the United States, commercial beef is produced from a variety of sources, the most common (80%; Supplementary Table 1 (ref. 2)) being from feedlot sources where beef cattle are fattened on high-grain diets. Before cattle enter feedlots, they often graze on roughages from pasture and rangeland. These beef cattle grazing systems maintain cow and calf populations, replacement heifers and stocker cattle. Of the total cattle supplied to feedlots, approximately 41% are supplied by stocker cattle, which typically spend 75% of their lifetime in grazing systems before entering feedlots; 27% are supplied by calves from cow–calf systems at around 310 days of age for a wean weight of 515 lb (these calves are known as calf-feds) and 32% of fed-cattle are supplied by male dairy steers that enter feedlots between an estimated 45 and 263 days of age depending on the region, which correspond to a weaning weight of 150 and 450 lb, respectively. In addition to fed-beef, dairy and beef cows are culled for beef at the end of their economically productive life, making up 9% and 10% of US cattle processed2,16. See Supplementary Tables 8 and 9 for further details. Because of the complexity of the multiple stages of production, diversity of sources of inputs and extensive movement of feed and cattle throughout the beef life cycle, GHG accounting methods that incorporate this detailed context are critical.

To model the beef supply chain, we built on the approach of the Food System Supply-Chain Sustainability Model (FoodS3)20,37,38 that combines a supply chain optimization model of subnational commodity flows with county-level spatially explicit environmental impacts. The supply chain model uses linear programming to minimize the total impedance of the system, considering county- and facility-scale feed and animal supplies and demand across all sectors of demand. Previous FoodS3 models20,37,38 focused on estimating the subnational transfers of corn, DDGS, soybean, wheat and middling feed commodity supplies to various sectors of demand and considered only the ‘cradle-to-crop gate’ environmental impacts. In this study, we focused on capturing the complexity of the beef supply chain, with pasture and rangelands and dairy operations supplying fed-calf and stockers to feedlots, and feedlots, grazing and dairy operations supplying fed-beef and culled cows to processing facilities. We used the USDA 2017 census to estimate livestock supplies and demand at the county level, and scaled the inventory populations to total commercially slaughtered beef quantities2. See section 1 of Supplementary Information for a detailed calculation methodology.

Spatially explicit baseline beef LCA

To assess GHG mitigation pathways, we first constructed baseline life cycle inventories reflecting the material and energy inputs and emissions and intermediate product outputs for each stage of the beef supply chain. We did so by building on initial county-scale average (2007–2017) GHG estimates of feed concentrate ingredients, including corn feed, DDGS, soybean meal, wheat and wheat middlings20, and further updated these estimates to account for the current annual carbon sequestration of existing cropland conservation practices, including cover cropping, changing tillage regions to reduced or no till, and use of precision agriculture technologies. See section 2.1.1 of Supplementary Information for details on estimation. We further estimated the other feed-related emissions from feed milling and intensively managed pasture systems that use synthetic fertilizers, and include initial spatial GHG estimates of alfalfa, corn silage and alfalfa hay production, which are roughages used in relatively high proportions in dairy production systems (see section 2.1.2 of Supplementary Information and N. Springer et al. (manuscript in progress) for details on estimation). We connected the estimated emissions per unit of feed produced in each area with the downstream demand across feedlot and dairy production locations using the supply chain optimization model, resulting in unique county-scale feed footprints.

We further estimated the GHG emissions associated with on-farm livestock production, including enteric fermentation considering regionally defined diets and forages from the US EPA, manure management considering each type of operation and phase of growth (for example, cow–calf versus feedlot and dairy cow versus dairy heifers), and energy and other materials used on farms considering differences across regions and type of operations. See section 2.2 of Supplementary Information for further details on estimation. The emissions estimated for the grazing stage in the cattle production system were then aggregated based on the county-to-county sourcing information estimated from the supply chain models that detail, for a given feedlot location, the portion of cattle sourced from each category of supply (stockers, calf-feds, dairy steer calves), which was then used as the weights for estimating total grazing stage emissions from fed-cattle.

Finally, we estimated the emissions associated with the processing stage of the supply chain considering the fuel and electricity used, the respective Emission and Generation Resource Integrated Database (eGRID) operating region and the embedded emissions from upstream cattle production. As in the case of the fed-cattle supply, we similarly aggregated emissions for processors, in which direct and embedded emissions from livestock production are combined with supply chain estimates detailing the portion of fed-cattle versus culled beef and dairy cows supplied to each processing facility to meet annual demand.

GHG mitigation opportunities

We examined several GHG mitigation opportunities across each of the different stages of the beef supply chain. Where data were available, we considered the existing penetration of conservation management strategies, such as cover cropping and nutrient management, and examined the potential change in emissions if the remaining runway for adoption were implemented. We used county-level emission-reduction potential across stages and management options, largely relying on COMET-PLANNER39, which uses biogeochemical models such as DAYCENT to estimate sequestration potentials, for feed management opportunities and some grazing management opportunities. For some mitigation opportunities, we found COMET-PLANNER estimates of GHG mitigation to be vastly different from those reported in other literature (for example, silvopasture). In these cases, we used the more conservative estimate. Key assumptions are described in Table 2, and more details are available in Supplementary Tables 33 and 34, and sections 3.1 to 3.4 of Supplementary Information.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

This analysis uses all publicly available datasets, primarily from USDA (for example, censuses, surveys, WASDE, AgStar) and EPA (for example, national GHG inventories). Data sources, assumptions and approaches used for the supply chain analysis and life cycle analysis are described and detailed in Supplementary Information. Data for Figs. 2 and 5 are provided in Supplementary Data 1 and are also available via figshare at https://doi.org/10.6084/m9.figshare.26488249 (ref. 41).

Code availability

Data analysis was conducted in both Python v3.11.2 and Microsoft Excel v16.65. For specific inquiries regarding the analyses please contact the corresponding author.

References

FAO Crops and livestock products 2023. FAOSTAT https://www.fao.org/faostat/en/#data/QCL (2023).

USDA Livestock Slaughter Summary (USDA National Agricultural Statistics Service, 2022).

Rotz, A., Asem-Hiablie, S., Place, S. & Thoma, G. Environmental footprints of beef cattle production in the United States. Agric. Syst. 169, 1–13 (2019).

Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2021 (US EPA, 2022).

Since 1970 Increasing Cattle Weights Have Fueled Growth of US Beef Production as Cattle Used Have Decreased (USDA, 2019); https://www.ers.usda.gov/data-products/chart-gallery/gallery/chart-detail/?chartId=93225

Cattle industry commits to climate neutrality by 2040. NCBA (NCBA, 12 August 2021); https://www.ncba.org/ncba-news/news-releases/news/details/27404/cattle-industry-commits-to-climate-neutrality-by-2040

McDonald’s McDonald’s helps drive impact on climate action. https://corporate.mcdonalds.com/corpmcd/our-stories/article/net-zero-climate.html (2021).

USDA Partnerships for climate-smart commodities project summaries. https://www.usda.gov/climate-solutions/climate-smart-commodities/projects (2023).

JBS Our net-zero commitment https://jbsfoodsgroup.com/our-purpose/net-zero (2023).

Stackhouse-Lawson, K. & Thompson, L. 80 climate change and the beef industry: a rapid expansion. J. Anim. Sci. 100, 32–33 (2022).

Herrero, M. et al. Livestock and the environment: what have we learned in the past decade? Ann. R. Environ. Resour. 40, 177–202 (2015).

O’Rourke, D. The science of sustainable supply chains. Science 344, 1124–1127 (2014).

Castonguay, A. et al. Navigating sustainability trade-offs in global beef production. Nat. Sustain. 6, 284–294 (2023).

Poore, J. & Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 360, 987–992 (2018).

Suszkiw, J. Study clarifies U.S. beef's resource use and greenhouse gas emissions. (Agricultural Research Service, USDA, 11 March 2019); https://www.ars.usda.gov/news-events/news/research-news/2019/study-clarifies-us-beefs-resource-use-and-greenhouse-gas-emissions/

Drouillard, J. Current situation and future trends for beef production in the United States of America—a review. Asian–Australas. J. Anim. Sci. 31, 1007–1016 (2018).

Shear, H. & Pendell, D. Economic cost of traceability in US beef production. Front. Anim. Sci. 1, 552386 (2020).

Lin, X., Ruess, P., Marston, L. & Konar, M. Food flows between counties in the United States. Environ. Res. Lett. 14, 084011 (2019).

Karakoc, D., Wang, J. & Konar, M. Food flows between counties in the United States from 2007 to 2017. Environ. Res. Lett. 17, 3 (2022).

Pelton, R. et al. Land use leverage points to reduce GHG emissions in US agricultural supply chains. Environ. Res. Lett. 16, 11 (2021).

Putman, B., Rotz, C. & Thoma, G. A comprehensive environmental assessment of beef production and consumption in the United States. J. Clean. Prod. 402, 136766 (2023).

Asem-Hiablie, S., Battagliese, T., Stackhouse-Lawson, K. & Rotz, A. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 24, 441–455 (2019).

Eshel, G., Shepon, A., Makov, T. & Milo, R. Land, irrigation water, greenhouse gas, and reactive nitrogen burdens of meat, eggs, and dairy production in the United States. Proc. Natl Acad. Sci. USA 111, 11996–12001 (2014).

Clark, M. & Tilman, D. Comparative analysis of environmental impacts of agricultural production systems, agricultural input efficiency, and food choice. Environ. Res. Lett. 12, 6 (2017).

Thoma, G. E. A. Greenhouse gas emissions from milk production and consumption in the United States: a cradle-to-grave life cycle assessment circa 2008. Int. Dairy J. 31, S3–S14 (2013).

Beauchemin, K. et al. Invited review: Current enteric methane mitigation options. J. Dairy Sci. 105, 9297–9326 (2022).

Ranjan, P., Church, S., Floress, K. & Prokopy, L. Synthesizing conservation motivations and barriers: what have we learned from qualitative studies of farmers’ behaviors in the United States. Soc. Nat. Resour. 32, 1171–1199 (2019).

Prokopy, L. et al. Adoption of agricultural conservation practices in the United States: evidence from 35 years of quantitative liteature. J. Soil Water Conserv. 74, 520–534 (2019).

Fargione, J. et al. Natural climate solutions in the United States. Sci. Adv. 4, eaat1869 (2018).

Pineiro, V. et al. A scoping review on incentives for adoption of sustainable agricultural practices and their outcomes. Nat. Sustain. 3, 809–820 (2020).

Arndt, C., Hristov, A., Price, W. & Yu, Z. Full adoption of the most effective strategies to mitigate methane emissions by ruminants can help meet the 1.5 °C target by 2030 but not 2050. Proc. Natl Acad. Sci. USA 119, e2111294119 (2022).

Lautz, L., Kelleher, C. & Vidon, P. E. A. Restoring stream ecosystem function with beaver dam analogues: let's not make the same mistake twice. Hydrol. Process 33, 174–177 (2018).

Jordan, C. & Fairfax, E. Beaver: the North American freshwater climate action plan, WIREs Water 9, e1592 (2022).

IPCC Climate Change 2023: Synthesis Report (eds Core Writing Team, Lee, H. & Romero, J.) (IPCC, 2023).

IPCC Climate Change 2013: The Physical Science Basis (eds Stocker, T.F. et al.) (Cambridge Univ. Press, 2013).

Cain, M. et al. Improved calculation of warming-equivalent emissions for short-lived climate pollutants. NPJ Clim. Atmos. Sci. 2, 29 (2019).

Smith, T. et al. Subnational mobility and consumption-based environmental accounting of US corn in animal protein and ethanol supply chains. Proc. Natl Acad. Sci. USA 114, E7891–E7899 (2017).

Brauman, K. et al. Unique water scarcity footprints and water risks in US meat and ethanol supply chains identified via subnational commodity flows. Environ. Res. Lett. 15, 105018 (2020).

Swan, A. et al. COMET-Planner Carbon and Greenhouse Gas Evaluation for NRCS Conservation Practice Planning (USDA and Colorado State Univ., 2022).

NRCS Conservation practice standards information. https://www.nrcs.usda.gov/getting-assistance/conservation-practices#overview (2022).

Pelton, R. E. O. Supplementary data for greenhouse gas emissions in US beef production can be reduced by up to 30% with the adoption of selected mitigation measures in Nature Food. figshare https://doi.org/10.6084/m9.figshare.26488249 (2024).

Acknowledgements

We thank NSF (grant number 1805085), Foundation for Food and Agriculture Research (DSnew-0000000007), Walton Family Foundation (2019-232; received by R.E.O.P., N.S. and J.S.), The Nature Conservancy (received by C.E.K., S.K., K.A.R., S.G., E.Y., M.W. and K.J.), McDonald’s (received by R.E.O.P., N.S., J.S., C.E.K., S.K., K.A.R., M.W. and K.J) and WRI Land & Carbon Lab (grant number G3275; received by D.R.) for providing grant funding that collectively enabled the initiation of this study. We also want to acknowledge several current and former colleagues at The Nature Conservancy and the University of Minnesota who contributed to the development of this work, including D. Gross, A. Staggs, T. Kim, P. Hawthorne and M. Andrews, and A. Lyons for figure design support.

Author information

Authors and Affiliations

Contributions

R.E.O.P., K.J. and J.S. conceptualized the study. R.E.O.P., C.E.K., S.K., K.A.R., K.J. and J.S designed the study. R.E.O.P., D.R., N.S. and J.S. performed supply chain modelling and analysis. R.E.O.P., C.E.K., S.K., K.A.R., S.G., M.W. and E.Y. conducted mitigation opportunities analysis. R.E.O.P., C.E.K., S.K. and K.A.R. wrote the draft. All authors contributed to the review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare the following competing interests: this work was initiated with funding from McDonald’s and supported further by the Walton Family Foundation. Authors affiliated with The Nature Conservancy (C.E.K., S.K., K.A.R., S.G., E.Y., M.W. and K.J.) and the Institute on the Environment (R.E.O.P., N.S., D.R. and J.S.) work with various companies in the beef industry. R.E.O.P. is the principal and founder of LEIF LLC, an LCA consulting firm working with companies across food and agriculture. These relationships could be perceived as potential competing interests.

Peer review

Peer review information

Nature Food thanks Gidon Eshel, Ermias Kebreab and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–15, Tables 1–35 and Methods for the supply chain, baseline LCA and mitigation analysis.

Supplementary Data 1

Supplementary data for Figs. 2 and 5.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Pelton, R.E.O., Kazanski, C.E., Keerthi, S. et al. Greenhouse gas emissions in US beef production can be reduced by up to 30% with the adoption of selected mitigation measures. Nat Food 5, 787–797 (2024). https://doi.org/10.1038/s43016-024-01031-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s43016-024-01031-9

- Springer Nature Limited