Abstract

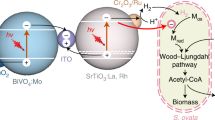

Semiconductor biohybrids integrating the merits of living cells and semiconductor materials have the potential to shift the current energy-intensive chemical production system to a more sustainable one by offering efficient solar-to-chemical conversion. However, cost-competitive and environmentally friendly scaling-up approaches are still urgently needed. To tackle this challenge, we propose a strategy that co-utilizes pollutants in wastewater to produce semiconductor biohybrids in-situ for scalable solar-to-chemical conversion. Specifically, we introduce an aerobic sulfate reduction pathway into Vibrio natriegens to enable the direct utilization of heavy metal ions (that is, Cd2+), sulfate and organics in wastewater to biosynthesize functional semiconductor nanoparticles in living V. natriegens to assemble semiconductor biohybrids. Meanwhile, a designated biosynthetic pathway is introduced into the biohybrids to enable the production of 2,3-butanediol, a valuable bulk chemical with wide applications, from organics in wastewater. Using the obtained biohybrids, the production of 2,3-butanediol reaches 13.09 g l−1 in a 5-l illuminated fermenter using wastewater as the feedstock, revealing its scalability. Life-cycle assessment shows that this specific biohybrid route has substantial sustainability gain compared with conventional 2,3-butanediol production routes. This work can bring solar-driven biomanufacturing and waste-to-wealth conversion one step forward and pave the way to cleaner production and circular economy.

Similar content being viewed by others

Data availability

All data presented in this manuscript are available in the paper and its Supplementary Information. Figures 1–5 and Supplementary Figs. 1–14, 16, 18 and 20 are available on Figshare at https://doi.org/10.6084/m9.figshare.24115851. Source data are provided with this paper.

References

Scown, C. D. & Keasling, J. D. Sustainable manufacturing with synthetic biology. Nat. Biotechnol. 40, 304–307 (2022).

Liew, F. E. et al. Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nat. Biotechnol. 40, 335–344 (2022).

Liu, Y. Z. et al. Biofuels for a sustainable future. Cell 184, 1636–1647 (2021).

Jones, S. W. et al. CO2 fixation by anaerobic non-photosynthetic mixotrophy for improved carbon conversion. Nat. Commun. 7, 12800 (2016).

Sakimoto, K. K., Wong, A. B. & Yang, P. D. Self-photosensitization of nonphotosynthetic bacteria for solar-to-chemical production. Science 351, 74–77 (2016).

Guo, J. L. et al. Light-driven fine chemical production in yeast biohybrids. Science 362, 813–816 (2018).

Cestellos-Blanco, S., Zhang, H., Kim, J. M., Shen, Y. X. & Yang, P. D. Photosynthetic semiconductor biohybrids for solar-driven biocatalysis. Nat. Catal. 3, 245–255 (2020).

Kornienko, N., Zhang, J. Z., Sakimoto, K. K., Yang, P. D. & Reisner, E. Interfacing nature’s catalytic machinery with synthetic materials for semi-artificial photosynthesis. Nat. Nanotechnol. 13, 890–899 (2018).

Cestellos-Blanco, S., Kim, J. M., Watanabe, N. G., Chan, R. R. & Yang, P. D. Molecular insights and future frontiers in cell photosensitization for solar-driven CO2 conversion. iScience 24, 102952 (2021).

Kang, S. H., Bozhilov, K. N., Myung, N. V., Mulchandani, A. & Chen, W. Microbial synthesis of CdS nanocrystals in genetically engineered E. coli. Angew. Chem. Int. Ed. 47, 5186–5189 (2008).

Kornienko, N. et al. Spectroscopic elucidation of energy transfer in hybrid inorganic-biological organisms for solar-to-chemical production. Proc. Natl Acad. Sci. USA 113, 11750–11755 (2016).

Wang, B., Jiang, Z. F., Yu, J. C., Wang, J. F. & Wong, P. K. Enhanced CO2 reduction and valuable C2+ chemical production by a CdS-photosynthetic hybrid system. Nanoscale 11, 9296–9301 (2019).

Yan, N., Zhou, K., Tong, Y. W., Leong, D. T. & Dickieson, M. P. Pathways to food from CO2 via ‘green chemical farming’. Nat. Sustain. 5, 907–909 (2022).

Li, W. W., Yu, H. Q. & Rittmann, B. E. Chemistry: reuse water pollutants. Nature 528, 29–31 (2015).

Sullivan, K. P. et al. Mixed plastics waste valorization through tandem chemical oxidation and biological funneling. Science 378, 207–211 (2022).

Atelge, M. R. et al. Biogas production from organic waste: recent progress and perspectives. Waste Biomass Valor. 11, 1019–1040 (2020).

Sun, G. L., Reynolds, E. E. & Belcher, A. M. Using yeast to sustainably remediate and extract heavy metals from waste waters. Nat. Sustain. 3, 303–311 (2020).

Oh, S. & Logan, B. E. Hydrogen and electricity production from a food processing wastewater using fermentation and microbial fuel cell technologies. Water Res. 39, 4673–4682 (2005).

Nam, J. Y., Yates, M. D., Zaybak, Z. & Logan, B. E. Examination of protein degradation in continuous flow, microbial electrolysis cells treating fermentation wastewater. Bioresour. Technol. 171, 182–186 (2014).

Kieu, H. T., Muller, E. & Horn, H. Heavy metal removal in anaerobic semi-continuous stirred tank reactors by a consortium of sulfate-reducing bacteria. Water Res. 45, 3863–3870 (2011).

Javanbakht, V., Alavi, S. A. & Zilouei, H. Mechanisms of heavy metal removal using microorganisms as biosorbent. Water Sci. Technol. 69, 1775–1787 (2014).

De Vrieze, J., Coma, M., Debeuckelaere, M., Van der Meeren, P. & Rabaey, K. High salinity in molasses wastewaters shifts anaerobic digestion to carboxylate production. Water Res. 98, 293–301 (2016).

Jassby, D., Cath, T. Y. & Buisson, H. The role of nanotechnology in industrial water treatment. Nat. Nanotechnol. 13, 670–672 (2018).

Wang, C. L., Maratukulam, P. D., Lum, A. M., Clark, D. S. & Keasling, J. D. Metabolic engineering of an aerobic sulfate reduction pathway and its application to precipitation of cadmium on the cell surface. Appl. Environ. Microbiol. 66, 4497–4502 (2000).

Zeng, Q., Hao, T. W., Mackey, H. R., van Loosdrecht, M. C. M. & Chen, G. H. Recent advances in dissimilatory sulfate reduction: from metabolic study to application. Water Res. 150, 162–181 (2019).

Xu, J. Q., Yang, S. & Yang, L. R. Vibrio natriegens as a host for rapid biotechnology. Trends Biotechnol. 40, 381–384 (2022).

Tait, S., Clarke, W. P., Keller, J. & Batstone, D. J. Removal of sulfate from high-strength wastewater by crystallisation. Water Res. 43, 762–772 (2009).

Riahi, S. & Rowley, C. N. Why can hydrogen sulfide permeate cell membranes? J. Am. Chem. Soc. 136, 15111–15113 (2014).

Sakpirom, J., Kantachote, D., Siripattanakul-Ratpukdi, S., McEvoy, J. & Khan, E. Simultaneous bioprecipitation of cadmium to cadmium sulfide nanoparticles and nitrogen fixation by Rhodopseudomonas palustris TN110. Chemosphere 223, 455–464 (2019).

Wang, B. et al. Biohybrid photoheterotrophic metabolism for significant enhancement of biological nitrogen fixation in pure microbial cultures. Energy Environ. Sci. 12, 2185–2191 (2019).

Xu, R. et al. New double network hydrogel adsorbent: highly efficient removal of Cd(II) and Mn(II) ions in aqueous solution. Chem. Eng. J. 275, 179–188 (2015).

Luo, X. B., Xi, Y., Yu, H. Y., Yin, X. C. & Luo, S. L. Capturing cadmium(II) ion from wastewater containing solid particles and floccules using ion-imprinted polymers with broom effect. Ind. Eng. Chem. Res. 56, 2350–2358 (2017).

Liu, T. Y., Yang, X., Wang, Z. L. & Yan, X. X. Enhanced chitosan beads-supported Fe0-nanoparticles for removal of heavy metals from electroplating wastewater in permeable reactive barriers. Water Res. 47, 6691–6700 (2013).

Suzuki, Y., Kametani, T. & Maruyama, T. Removal of heavy metals from aqueous solution by nonliving Ulva seaweed as biosorbent. Water Res. 39, 1803–1808 (2005).

Goncalves, M. M. M., da Costa, A. C. A., Leite, S. G. F. & Sant′Anna, G. L. Jr Heavy metal removal from synthetic wastewaters in an anaerobic bioreactor using stillage from ethanol distilleries as a carbon source. Chemosphere 69, 1815–1820 (2007).

D’Angelo, S. C., Dall’Ara, A., Mondelli, C., Pérez-Ramírez, J. & Papadokonstantakis, S. Techno-economic analysis of a glycerol biorefinery. ACS Sustain. Chem. Eng. 6, 16563–16572 (2018).

Quispe, C. A. G., Coronado, C. J. R. & Carvalho, J. A. Jr. Glycerol: production, consumption, prices, characterization and new trends in combustion. Renew. Sustain. Energy Rev. 27, 475–493 (2013).

Ye, J. et al. Light-driven carbon dioxide reduction to methane by Methanosarcina barkeri-CdS biohybrid. Appl. Catal. B 257, 117916 (2019).

Ji, X. J., Huang, H. & Ouyang, P. K. Microbial 2,3-butanediol production: a state-of-the-art review. Biotechnol. Adv. 29, 351–364 (2011).

Celinska, E. & Grajek, W. Biotechnological production of 2,3-butanediol-current state and prospects. Biotechnol. Adv. 27, 715–725 (2009).

Xu, Y. Q. et al. Systematic metabolic engineering of Escherichia coli for high-yield production of fuel bio-chemical 2,3-butanediol. Metab. Eng. 23, 22–33 (2014).

Zhang, H. et al. Bacteria photosensitized by intracellular gold nanoclusters for solar fuel production. Nat. Nanotechnol. 13, 900–905 (2018).

Wei, W. et al. A surface-display biohybrid approach to light-driven hydrogen production in air. Sci. Adv. 4, eaap9253 (2018).

Ding, Y. C. et al. Nanorg microbial factories: light-driven renewable biochemical synthesis using quantum dot-bacteria nanobiohybrids. J. Am. Chem. Soc. 141, 10272–10282 (2019).

Wang, M., Chen, B. Q., Fang, Y. M. & Tan, T. W. Cofactor engineering for more efficient production of chemicals and biofuels. Biotechnol. Adv. 35, 1032–1039 (2017).

Zhang, R. T. et al. Proteomic and metabolic elucidation of solar-powered biomanufacturing by bio-abiotic hybrid system. Chem 6, 234–249 (2020).

Bo, T. T. et al. Photocatalytic H2 evolution on CdS modified with partially crystallized MoS2 under visible light irradiation. Chem. Phys. Lett. 746, 137305 (2020).

Jin, S. et al. Acetogenic bacteria utilize light-driven electrons as an energy source for autotrophic growth. Proc. Natl. Acad. Sci. USA 118, e2020552118 (2021).

Guan, X. et al. Maximizing light-driven CO2 and N2 fixation efficiency in quantum dot-bacteria hybrids. Nat. Catal. 5, 1019–1029 (2022).

Hu, W. Q., Tian, J. P., Zang, N., Gao, Y. & Chen, L. J. Study of the development and performance of centralized wastewater treatment plants in Chinese industrial parks. J. Clean. Prod. 214, 939–951 (2019).

Weinstock, M. T., Hesek, E. D., Wilson, C. M. & Gibson, D. G. Vibrio natriegens as a fast-growing host for molecular biology. Nat. Methods 13, 849–851 (2016).

Zhang, Y. et al. Systems metabolic engineering of Vibrio natriegens for the production of 1,3-propanediol. Metab. Eng. 65, 52–65 (2021).

Gao, X. et al. Engineering the methylerythritol phosphate pathway in cyanobacteria for photosynthetic isoprene production from CO2. Energy Environ. Sci. 9, 1400–1411 (2016).

Wernet, G. et al. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230 (2016).

Lifecycle Analysis of Greenhouse Gas Emissions Under the Renewable Fuel Standard (US EPA, 2021).

Dunn, J. B. et al. Life-cycle Analysis of Bioproducts and their Conventional Counterparts in GREET Technical Report (US Department of Energy, 2015).

2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories (IPCC, 2019).

Jiang, H., Jin, Q., Cheng, P. P., Hua, M. & Ye, Z. How are typical urban sewage treatment technologies going in China: from the perspective of life cycle environmental and economic coupled assessment. Environ. Sci. Pollut. Res. 28, 45109–45120 (2021).

Pi, S. S. et al. Solar-driven waste-to-chemical conversion by wastewater-derived semiconductor biohybrids. Figshare https://doi.org/10.6084/m9.figshare.24115851 (2023).

Acknowledgements

We thank C. Zhong for valuable suggestions and discussion of this work and the Shenzhen Infrastructure for Synthetic Biology for instrument support and technical assistance. This work was supported by the National Natural Science Foundation of China (Grant No. 32230060, C.Y. and X.G.; Grant No. 22176046, L.L.; Grant No. 32171426, X.G.; Grant No. 52200090, S.P.), Shenzhen Science and Technology Program (Grant No. GXWD20220811173949005, KQTD20190929172630447 and JCYJ20210324124209025, L.L.; Grant No. JCYJ20220818101804010, RCYX20221008092901004, X.G.), the National Key R&D Program of China (Grant No. 2021YFA0910800, X.G.), State Key Laboratory of Urban Water Resource and Environment (Harbin Institute of Technology) (Grant No. 2021TS13, L.L.) and the Natural Science Foundation of Guangdong Province (Grant No. 2022A1515012016, L.L.).

Author information

Authors and Affiliations

Contributions

X.G., L.L., Y.L. and C.Y. supervised the research; X.G. and L.L. designed the experiments; S.P., W.Y. and W.F. contributed to the biohybrid production, and the structural and chemical characterizations; W. Cheng and S.P. performed the metabolic experiment, with the results verified by X.G.; S.P., R.Y. and W.Y. contributed to the wastewater-relevant experiments and fermenter data; L.C., Z.L., R.Y. and W. Chao performed the photoelectrochemical analysis; W. Chao, N.R., X.G. and L.L. contributed to the LCA data; S.P., X.G., Y.L., L.L., W.Y. and W. Chao wrote the manuscript and received comments from all the other authors.

Corresponding authors

Ethics declarations

Competing interests

L.L., X.G., R.Y., S.P. and W.Y. are co-inventors on filed China patents CN202310145122.9 and CN202210318999.9 related to the production of semiconductor nanoparticles and biohybrids directly from wastewater by engineered strains that incorporate discoveries included in this manuscript. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Shu Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods, LCA, Tables 1–15, Figs. 1–21 and References.

Supplementary Data 1

Source data for Supplementary Figs. 1–14, 16, 18 and 20.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data, EDS mapping data and photoelectrochemical data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Fermenter data.

Source Data Fig. 5

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pi, S., Yang, W., Feng, W. et al. Solar-driven waste-to-chemical conversion by wastewater-derived semiconductor biohybrids. Nat Sustain 6, 1673–1684 (2023). https://doi.org/10.1038/s41893-023-01233-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-023-01233-2

- Springer Nature Limited

This article is cited by

-

Research progress and prospect of low-carbon biological technology for nitrate removal in wastewater treatment

Frontiers of Environmental Science & Engineering (2024)

-

Boosting solar hydrogen production via electrostatic interaction mediated E. coli-TiO2−x biohybrid system

Nano Research (2024)