Abstract

The objective of this work was to investigate the sorption behavior of gases, namely CO2, CH4, and N2, by molecules of coal sampled from Linglu mine under different water inclusion rates. To this end, the adsorption, diffusion, adsorption heat, and potential energy distribution characteristics of the gases in the coal pores at different water inclusion rates were analyzed using molecular dynamics and grand canonical ensemble Monte Carlo methods. The results showed that the adsorption relationship of the coal molecules on CO2, CH4, and N2 exhibited a downtrend followed by an uptrend when the water content was increased from 0 to 3.6%. The adsorption amount of CO2 was approximately twice as much as those of CH4 and N2, indicating that the competitive adsorption advantage of CO2 compared with those of CH4 and N2 was unaffected by the water content. The trend in the average heat of adsorption was generally consistent with the trend in the density of coal molecules under different moisture contents. Under the same conditions, the diffusion coefficient within a coal molecule was negatively related to the water content in the system. The layer spacing of the water molecules (2.875 Å) was greater than the liquid–water layer spacing, indicating the formation of a water molecule layer at this point, which inhibited gas adsorption. This study lays a theoretical foundation for further investigating the microscopic mechanism of coal–water interaction.

Similar content being viewed by others

Introduction

The adsorption process of water molecules by coal is relatively complex and is a combined result of intermolecular electrostatic forces and hydrogen bonding1,2. Several studies have reported that the adsorption of CO2, CH4, and N2 by coal macromolecules decreases with the increase in the number of water molecules3,4,5. However, there is literature confirming the role of water molecules in facilitating the adsorption of methane6.

In an attempt to study the sorption characteristics and thermodynamic properties of CO2, CH4, and N2 on coal under different water contents, scholars at home and abroad have conducted a series of experiments7,8,9 and simulations10,11. Li et al.12,13,14 simulated the sorption properties of coal on CO2 and CH4 at various water inclusion rates and pore sizes using the grand canonical ensemble Monte Carlo (GCMC) method and verified that the sorption of CH4 and CO2 by coal molecules is negatively correlated with the water inclusion rate. Zhang et al.15,16,17 analyzed the effects of the temperature and content of moisture on the isotherms and thermodynamic properties of CH4 adsorption through simulations. Gao et al.18,19 verified that the greater the amount of water injection, the lower the desorption of the gas. Thus, water injection can decrease the risk of coal and gas protrusion. Wang et al.20,21 quantitatively characterized the effects of adsorbed water and water vapor on coal gas sorption by nuclear magnetic resonance (NMR) spectroscopy. The results showed that water vapor preferred to adsorb in the coal micropores, while liquid water filled the extensive network of pores and cracks. Xing et al.22 verified that water competes with CH4 for specific sorption sites, resulting in a reduced CH4 sorption capacity for shales containing water. Environmental factors, such as the pressure, temperature, and other external factors, can also vary the water distribution and endowment in shale, thus affecting the CH4 sorption capacity of shale to a certain extent23. Zhang et al.24 used a combination of X-ray photoelectron spectroscopy (XPS), mercury intrusion porosimetry (MIP), and high-pressure volumetric method to quantitatively analyze the adsorption behavior of CH4 in tectonic coals under the influence of moisture. They further verified that the sorption capacity of CH4 decreases with an increase in the water content. Guo et al.25 tested coal samples with different water contents by developing a new type of device for water injection gas adsorption. Some foreign scholars have studied the adsorption characteristics and thermodynamic analysis of coal containing different amounts of water. Chattaraj et al.26 discussed the adsorption behavior of coalbed methane and showed that the adsorption process can be better explained in terms of thermodynamics and its molecular dynamics (MD). Men’shchikov et al.27 studied the porous structure, phases, and chemical properties of activated carbon through experimental methods such as nitrogen adsorption, X-ray diffraction, and scanning electron microscopy. The sorption of CH4 and the thermodynamic properties of the sorption system were analyzed. Gensterblum et al.28 measured the sorption isotherms of CH4 and CO2 for coal samples of various coal grades at dry and moisture equilibriums and investigated the variation in the sorption capacities of CH4 and CO2 by coals of different grades, as well as the effect of water on the sorption characteristics. Muangthong-On et al.29 measured the heat of sorption/desorption of water on coal using thermogravimetric analysis and differential scanning calorimetry (TG-DSC) at temperatures exceeding 100 ℃. They demonstrated that the adsorption of water vapor plays an important role in the self-heating of coal. These studies have provided a basis to study the sorption/desorption characteristics of coal on gas under different water contents.

Most studies on the effect of water addition on coal sorption/desorption characteristics have focused on macroscopic phenomena, while studies on microscopic mechanisms are fewer and less in-depth. Therefore, in this work, the adsorption/desorption characteristics and thermodynamic properties of CO2, CH4, and N2 by molecules in the Linglu mine coal with different water contents were quantitatively analyzed by simulating the injection of different amounts of water molecules into the coal seam, which is crucial for the suppression of coal–gas protrusion.

Methodology

Coal model building and optimization

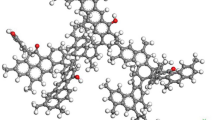

The adsorption of coal on gas can be categorized as a physical adsorption process30,31. In response to this paper, based on the test results of coal samples from Linglu coal mine, the molecular structure model of coal (C216H169O12N4) was established to study the adsorption characteristics of CO2, CH4, and N2 on coal with different moisture contents taken from the Linglu mine. The established 2D model was imported into the Materials Studio software, and the structure was subjected to geometric optimization, energy optimization, and simulated annealing with a minimum value of annealed energy. The simulation parameters are shown in Table 1. Table 2 presents the optimized energy parameters. Figure 1 shows the optimized molecular models of the Linglu mine coal, where 10, 20, and 30 molecules of water are added to the computational cell using the amorphous cell module. Figure 2 shows the ultracrystalline cell model of this coal constructed under different water content conditions.

Parameter settings for adsorption kinetics simulation

The adsorption laws and influencing characteristics of CO2, CH4, and N2 adsorption by the molecules of the Linglu mine coal at different temperatures (273.15, 283.15, 293.15, 303.15, and 313.15 K) and water contents were analyzed based on the GCMC simulation method. A geometry optimization of the coal molecular fragments was performed using the Forcite module with the simulation parameters listed in Table 3. The MD method was then applied to analyze the diffusion and flow ability of the water molecules, and the NVT system with a constant number of molecules (N), constant volume (V), and constant temperature (T) was selected to run the MD simulations. The temperature was fixed using the Berendsen thermostat. In the MD operation, the simulation step size was 1 fs, and the total simulation time was 500 ps, of which the first 60 ps were used to bring the system to equilibrium and the middle 60–100 ps to determine its diffusion properties.

Results and discussion

Influence of water content on CO2, CH4, and N2 sorption and adsorption heat trends

Adsorption capacity

The sorption of CO2, CH4, and N2 using the structural model of the Linglu mine coal was calculated at different temperatures (273.15, 283.15, 293.15, 303.15, and 313.15 K), pressures (0.1–10 MPa), and moisture contents (0%, 1.2%, 2.4%, and 3.6%), as shown in Fig. 1. The coal molecules were modeled with 0, 10, 20, and 30 water molecules.

The formula for calculating the water content32 is as follows:

where MH2O is the molecular weight of water, g/mol; Mcoal is the molecular weight of coal, g/mol; and W is the water content, %.

As can be seen from Fig. 3, when the pressure in the system is from 0.1 to 1 MPa, the rising trend of the adsorption amount of CO2, CH4 and N2 rises rapidly with the increase of pressure, and the rising trend of the adsorption amount of the three kinds of gases is gradually smooth when the pressure is from 1 to 10 MPa, which indicates that the adsorption rate of the gases is more rapid in the low-pressure stage. The adsorption of the three gases decreases rapidly with increasing temperature. Clearly, increasing the pressure and decreasing the temperature were favorable to the adsorption of these gases. As shown in Fig. 3, the rise and fall trends of CO2, CH4, and N2 adsorption by coal with different water contents were investigated at a pressure of 10 MPa and a temperature of 293.15 K as an example. A comparison of Fig. 3a–d shows that CO2 adsorption decreases from 6.87 to 6.57 mmol/g, from 6.57 to 7.88 mmol/g, and from 7.88 to 4.23 mmol/g, respectively, when the water content in the system is increased from 0 to 1.2%, 2.4%, and 3.6%. Similarly, a comparison between Fig. 3e–l shows that the rise and fall trends of CH4 and N2 adsorption are the same as that of CO2 adsorption. As shown in Fig. 4, the rise and fall trends of CO2, CH4, and N2 adsorption in the system appears to be decreasing, then increasing, and finally decreasing. The reason for this phenomenon may be that the adsorption of coal on water molecules belongs to multilayer adsorption33, and initially the water molecules are easy to form hydrogen bonding with the oxygen-containing functional groups in the coal molecules34,35, but the hydrogen bonding belongs to the weak intermolecular interactions, and the interaction energies of the water molecules adsorbed on hydroxyl groups are much larger than the interaction energies adsorbed on the other reactive groups36. With the increase in the number of water molecules in coal, the oxygen-containing functional groups in the system will promote the competition between water molecules and CO2, CH4, and N2 adsorption, resulting in a regional increase in the adsorption of the three gases, CO2, CH4, and N237. Finally, after all the oxygenated functional groups in the coal were occupied, the excess water molecules began to adsorb on the pore surface of the coal in the form of free water, and they continuously condensed, eventually forming a water condensation film on the pore surface, which inhibited the sorption of CO2, CH4, and N2 by the coal. Ultimately, the adsorption amount reduced.

Adsorption heat

Adsorption heat is one of the important parameters to characterize thermodynamics in order to respond to the thermic effect generated by the sorption process of water molecules on CO2, CH4, and N2. During the sorption process, the gas molecules move to the surface of the coal, where the speed of molecular motion is significantly reduced, thus releasing a large amount of heat. Table 4 shows the average sorption heat of CO2, CH4, and N2 adsorbed by coal molecules of various water contents at various temperatures and pressure ranging from 0.1 to 10 MPa.

As shown in Fig. 5, at a temperature of 273.15 K, as the water content in the system is increased from 0 to 1.2%, the average sorption heats of CO2, CH4, and N2 decrease, respectively, from 7.70 to 7.48 kcal/mol, from 4.55 to 4.39 kcal/mol, and from 3.75 to 3.69 kcal/mol. When the water content in the system is increased from 1.2 to 2.4%, the average sorption heats of CO2, CH4, and N2 increase from 7.48 to 7.54 kcal/mol, from 4.39 to 4.40 kcal/mol, and from 3.69 to 3.74 kcal/mol, respectively. When the water content is increased from 2.4 to 3.6%, the average sorption heats of CO2, CH4, and N2 increase from 7.54 to 7.81 kcal/mol, from 4.40 to 4.82 kcal/mol, and from 3.74 to 4.04 kcal/mol, respectively.

Clearly, the average sorption heats of CO2, CH4, and N2 showed a decreasing trend with increasing temperature. However, the average heat of adsorption showed an increasing trend with an increase in the water content in the system from 1.2 to 3.6%. From a thermodynamic viewpoint, this phenomenon can be attributed to increase in the density of the water molecules in the system, and their values gradually stabilized as the optimization process approached 500 ps, as shown in Fig. 6, in which the densities converged to 0.855, 0.873, and 0.948 g/cm3, respectively, for water contents of 1.2%, 2.4%, and 3.6%. Therefore, the trend in the average sorption heat was consistent with the trend in the density of the H2O molecules in the system, indicating that the average sorption heat of the molecules in the Linglu mine coal with different water contents increases with the increase in the density of the system.

Radial distribution function (RDF) and diffusive behavior (MSD)

Radial distribution function

The RDF is a physical quantity that characterizes the microstructural features of particles, and its physical meaning is the probability that other particles would appear at a distance r around an arbitrarily specified central particle, which can be interpreted as the ratio of the local density of the system to its mean bulk density. The radial distribution function g(r) is given by Eq.38:

where dN corresponds to the range r to r + dr:

where ρ is the density of the particle.

As shown in Fig. 7, with the addition of different amounts of water (1.2%, 2.4%, and 3.6%) to the system, the H2O molecules showed the first peak at 0.975 Å, with the peaks being 1200.31, 638.13, and 371.65, respectively. A second peak occurred at 1.525 Å with peaks of 132.94, 73.45, and 41.78, respectively. From these two peaks, it can be seen that the H2O molecules exhibited the highest peak when the water content in the system was 1.2%, followed by that when the water contents were 2.4% and 3.6%. The difference in the peaks indicates that, the fewer the H2O molecules added to the molecular model of the Linglu mine coal (10–30 molecules), the tighter the arrangement of the H2O molecules in the pores. The H2O molecules showed a third peak at 2.875 Å with peaks of 10.07, 18.35, and 7.71, marking the formation of a layer of H2O molecules with a layer spacing greater than the liquid–water layer spacing at 2.86 Å39. When the water contents in the system were 1.2%, 2.4%, and 3.6%, the H2O molecules competed for adsorption with CO2, CH4, and N2 in the preliminary stage due to the lack of formation of the water molecule layer, resulting in an elevated adsorption of the three gases in the system. The sorption of CO2, CH4, and N2 by the Linglu mine coal reduced in the later stage due to the formation of the H2O molecular layer. This conclusion is consistent with that arrived at in Sect “Adsorption capacity”.

Diffusion coefficients

The diffusion behavior of a substance in a pore is proportional to the mean-square displacement of the center of mass of its molecules, and the corresponding diffusion coefficient is the rate of change in the mean-square displacement of all the molecules of the substance over a long duration40, and the MSD is calculated using the equation:

where N is the number of molecules; \({r}_{i}(0)\) is the initial site vector of the molecule; and \({r}_{i}(t)\) is the molecular site vector at time t.

The diffusion coefficient of a gas, Eq.41, is given below:

where D is the diffusion coefficient of the gas; \({k}_{MSD}\) is the slope of the MSD curve.

Diffusion coefficient is a physical quantity that describes the process of diffusion of a substance in space, and is the amount of substance per unit time, per unit area, that diffuses in the direction of lower concentration. Figure 8 shows the MSD versus time curves for CO2, CH4, and N2 after water injection. It can be seen that the diffusion coefficient of N2 in the system is obviously larger than that of CH4 and CO2, and the increase of water content did not inhibit the diffusion rate of N2. The trend of the curves shows that water content has a more significant effect on the diffusion capacity of N2, followed by CH4 and CO2.

The diffusion coefficients of CO2, CH4, and N2 in coal molecules under the conditions of different water content are shown in Table 5. When the water content is 1.2%, the diffusion coefficients of CO2, CH4, and N2 are 6.38 × 10−7, 2.26 × 10−6, and 7.47 × 10−6 cm2·s−1, respectively; when the water content is 3.6%, the diffusion coefficients of CO2, CH4, and N2 were 2.77 × 10−7, 3.83 × 10−7, and 3.53 × 10−6 cm2·s−1, respectively. This is because with the increase of water content, the collision efficiency between the molecules increases, and the interaction force between them is strengthened, resulting in the inhibition of the diffusion of CO2, CH4, and N2 in the pores, leading to a low diffusion coefficient.

Potential energy distribution

The potential energy distribution of CO2, CH4, and N2 adsorbed by the coal molecules in the Linglu mine was simulated at a temperature of 293.15 K and a pressure of 10 MPa, as shown in Fig. 9. The effect of the water content in the coal molecules on the preferential adsorption potential of CO2, CH4, and N2 was analyzed.

Figure 9 shows that the absolute value of the potential energy peak exhibits a trend of increasing and then decreasing in systems with water contents of 1.2%, 2.4%, and 3.6%. This is mainly because of the formation of ionic and covalent bonds between the adsorbed particles and atoms during the adsorption process, forming an ordered covering layer on the surface of molecules42,43. When an adsorbed particle is close to the surface, it is subjected to an adsorption potential, and the adsorbed particle releases energy and adsorbs at the position where the potential energy of the molecule’s surface has a minimum value. Interactions between its adsorbed atoms change the potential energy distribution on the surface. This is the main reason why the potential energy distribution graph shows a rise and then a fall. With the increase in the water content, the peak potential energies of the optimal adsorption sites of CO2, CH4, and N2 in the system were compared, and the peak potential energies of CO2 were − 8.15, − 8.95, and − 8.05 kcal/mol, respectively, under the different water contents. The peak potential energies of CH4 were − 3.95, − 4.45, and − 4.25 kcal/mol, respectively. The peak potential energies of N2 were − 2.75, − 2.85, and − 2.35 kcal/mol, respectively. The sorption advantage of CO2 was significantly greater than those of CH4 and N2. Therefore, it can be concluded that the presence of water does not inhibit the CO2 adsorption advantage.

Conclusions

-

(1)

With the increase in the water content from 0 to 3.6% in the system, with the adsorption amount of CO2 being approximately twice as much as those of CH4 and N2. This indicates that the presence of water had almost no effect on the sorption advantage of CO2.

-

(2)

The average sorption heat in the system was negatively correlated with the density of the water molecules, CO2 emitted more heat during adsorption, resulting in its average heat of adsorption being significantly greater than those of CH4 and N2.

-

(3)

The effect of water content on the diffusion ability of N2 is more significant, followed by CH4 and CO2. The diffusion coefficients of these three gases decreased gradually with the increase of water molecules. Based on the radial distribution function, the molecular layer spacing of the H2O molecules (2.875 Å) was greater than the liquid–water layer spacing of 2.86 Å. Therefore, the adsorption of CO2, CH4, and N2 was inhibited by the formation of the water molecule layer.

-

(4)

At the same temperature and pressure, and water contents of 1.2%, 2.4%, 3.6%, in terms of the sorption potential, the absolute values of the potential energy peaks of CO2, CH4, and N2 increased and then decreased, with the same trend as its adsorption amount.

Data availability

All data supporting the findings of this study are available from the corresponding author Jiaxing Lin upon request.

References

Busch, A. & Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 87, 49–71. https://doi.org/10.1016/j.coal.2011.04.011 (2011).

Gao, Z. & Yang, W. Adsorption mechanism of water molecule on different rank coals molecular surface. J. China Coal Soc. 42, 753–759. https://doi.org/10.13225/j.cnki.jccs.2016.0642 (2017).

Nie, B., He, X., Wang, E. & Zhang, L. Micro-mechanism of coal adsorbing water. J. China Univ. Min. Technol. 33, 17–21 (2004).

Sang, S., Zhu, Y., Zhang, J., Zhang, X. & Zhang, S. Experimental study on the effect of liquid water on methane adsorption by coal: A case study of coal reservoirs in the southern Qinshui Basin. Chin. Sci. Bull. 50, 79–85 (2005).

Zhang, S. & Sang, S. Influence mechanism of liquid water on methane absorption of coals with different ranks. Acta Geol. Sin. 82, 1350–1354 (2008).

Zhiguo, X. & Leiting, M. Experimental study on the inhibitory effect of the gas desorption in the coal seam water-infusion. J. Saf. Environ. 15, 55–59. https://doi.org/10.13637/j.issn.1009-6094.2015.02.012 (2015).

Feng, Y. & Dong, H. Estimation of coal seam gas pressure based on gas desorption characteristics of coal with different moisture contents. Saf. Coal Mines 54, 8–14. https://doi.org/10.13347/j.cnki.mkaq.2023.09.002 (2023).

Liu, X., Zhang, Y., Zhang, X., Wang, J. & Zhou, C. Study on the effect and mechanism of original moisture on coal spontaneous combustion. J. Taiyuan Univ. Technol. 52, 350–359 (2021).

Nie, B. et al. Sorption characteristics of methane among various rank coals: Impact of moisture. Adsorption 22, 315–325. https://doi.org/10.1007/s10450-016-9778-9 (2016).

Tang, X. Simulation of CO2 and O2 adsorption in bituminous coals with different moisture contents. Inn. Mong. Coal Econ. https://doi.org/10.13487/j.cnki.imce.024146 (2023).

Zhu, H. et al. Thermodynamic characteristics of methane adsorption about coking coal molecular with different sulfur components: Considering the influence of moisture contents. J. Nat. Gas Sci. Eng. https://doi.org/10.1016/j.jngse.2021.104053 (2021).

Kang, N., Chen, X., Yang, H., Zhao, S. & Qi, L. Effect of different placement sequences of water on the methane adsorption properties of coal. ACS Omega 8, 6689–6698. https://doi.org/10.1021/acsomega.2c07283 (2023).

Li, Y., Yang, Z. & Li, X. Molecular simulation study on the effect of coal rank and moisture on CO2/CH4 competitive adsorption. Energy Fuels 33, 9087–9098. https://doi.org/10.1021/acs.energyfuels.9b01805 (2019).

Li, Z., Bai, Y., Yu, H., Hu, H. & Wang, Y. Molecular simulation of thermodynamic properties of CH4 and CO2 adsorption under different moisture content and pore size conditions. Fuel https://doi.org/10.1016/j.fuel.2023.127833 (2023).

Gao, D. & Xu, X. Molecular simulation on the influence of FeS2 on anthracite adsorption of CH4 and O2. J. Saudi Chem. Soc. https://doi.org/10.1016/j.jscs.2024.101823 (2024).

Hong, L., Lin, J., Gao, D. & Zheng, D. Molecular modeling of CO2 affecting competitive adsorption within anthracite coal. Sci. Rep. https://doi.org/10.1038/s41598-024-58483-z (2024).

Zhang, X. et al. Thermodynamic characteristics of methane adsorption on coals from China with selected metamorphism degrees: Considering the influence of temperature, moisture content, and in situ modification. Fuel https://doi.org/10.1016/j.fuel.2023.127771 (2023).

Gao, D. & Song, Z. Study on gas adsorption and desorption characteristics on water injection coal. J. Saudi Chem. Soc. https://doi.org/10.1016/j.jscs.2023.101645 (2023).

Zhang, G.-H., Liu, X.-X., Bi, Y.-W. & Pu, W.-L. Experimental study of water effects on gas desorption during high-pressure water injection. J. Coal Sci. Eng. 17, 408–413. https://doi.org/10.1007/s12404-011-0409-5 (2011).

Li, Y. et al. Characterizing water vapor adsorption on coal by nuclear magnetic resonance: Influence of coal pore structure and surface properties. Energy https://doi.org/10.1016/j.energy.2023.128420 (2023).

Wang, F., Yao, Y., Wen, Z., Sun, Q. & Yuan, X. Effect of water occurrences on methane adsorption capacity of coal: A comparison between bituminous coal and anthracite coal. Fuel https://doi.org/10.1016/j.fuel.2020.117102 (2020).

Xing, Y., Xiao, X., Zhou, Q., Liu, W. & Zhao, Y. Influence of water on the methane adsorption capacity of organic-rich shales and its controlling factors: A review. Energies https://doi.org/10.3390/en16083305 (2023).

Han, W., Li, A., Memon, A. & Ma, M. Synergetic effect of water, temperature, and pressure on methane adsorption in shale gas reservoirs. ACS Omega 6, 2215–2229. https://doi.org/10.1021/acsomega.0c05490 (2021).

Zhang, Q., Liu, X., Nie, B., Wu, W. & Wang, R. Methane sorption behavior on tectonic coal under the influence of moisture. Fuel https://doi.org/10.1016/j.fuel.2022.125150 (2022).

Guo, H., Cheng, Y., Wang, L., Lu, S. & Jin, K. Experimental study on the effect of moisture on low-rank coal adsorption characteristics. J. Nat. Gas Sci. Eng. 24, 245–251. https://doi.org/10.1016/j.jngse.2015.03.037 (2015).

Chattaraj, S., Mohanty, D., Kumar, T. & Halder, G. Thermodynamics, kinetics and modeling of sorption behaviour of coalbed methane—A review. J. Unconv. Oil Gas Resour. 16, 14–33. https://doi.org/10.1016/j.juogr.2016.09.001 (2016).

Men’shchikov, I. E., Shkolin, A. V., Fomkin, A. A. & Khozina, E. V. Thermodynamics of methane adsorption on carbon adsorbent prepared from mineral coal. Adsorption 27, 1095–1107 (2021).

Gensterblum, Y., Merkel, A., Busch, A. & Krooss, B. M. High-pressure CH4 and CO2 sorption isotherms as a function of coal maturity and the influence of moisture. Int. J. Coal Geol. 118, 45–57. https://doi.org/10.1016/j.coal.2013.07.024 (2013).

Muangthong-on, T., Wannapeera, J., Ohgaki, H. & Miura, K. TG-DSC study to measure heat of desorption of water during the thermal drying of coal and to examine the role of adsorption of water vapor for examining spontaneous heating of coal over 100 °C. Energy Fuels 31, 10691–10698. https://doi.org/10.1021/acs.energyfuels.7b01836 (2017).

Tan, B. et al. Molecular simulation for physisorption characteristics of O2 in low-rank coals. Energy https://doi.org/10.1016/j.energy.2021.122538 (2022).

Wang, Z., Li, Y., Wang, Z. & Zhou, L. Factors influencing the methane adsorption capacity of coal and adsorption heat variations. Energy Fuels 37, 13080–13092. https://doi.org/10.1021/acs.energyfuels.3c02339 (2023).

Liwei, C., Dongjie, W., Le, B., Yuan, L. & Xiaohua, L. Study on the influence of coal seam water content on the effect of CO2 isobaric diffusion displacing CH4. Coal Sci. Technol. https://doi.org/10.12438/cst.2024-0061 (2024).

Wang, C. et al. Adsorption of water on carbon materials: The formation of “water bridge” and its effect on water adsorption. Colloids Surf. A Physicochem. Eng. Asp. https://doi.org/10.1016/j.colsurfa.2021.127719 (2021).

Zhiqiang, X., Xiangyang, L., Yanan, T., Dinghua, L. & Guanlin, R. Quantum chemical calculation of the interaction between lignite and water molecules. J. China Univ. Min. Technol. 51, 554–561. https://doi.org/10.13247/j.cnki.jcumt.001411 (2022).

Wu, J. et al. Moisture removal mechanism of low-rank coal by hydrothermal dewatering: Physicochemical property analysis and DFT calculation. Fuel 187, 242–249 (2017).

Zhengyang, G., Shaokun, L., Jinda, L., Pengfei, Y. & Chuanmin, C. Micro-mechanism of water molecule adsorption on lignite surfaces. J. Chin. Soc. Power Eng. 36, 258–264 (2016).

Jianhua, X. & Lei, L. Study on influence of coal surface functional groups on methane and carbon dioxide adsorption properties. Coal Sci. Technol. 49, 145–151. https://doi.org/10.13199/j.cnki.cst.2021.06.017 (2021).

Xu, W. et al. Molecular dynamic investigations on the adhesion behaviors of asphalt mastic-aggregate interface. Materials https://doi.org/10.3390/ma13225061 (2020).

Jianhua, X., Fangui, Z., Huzhen, L., Bin, L. & Xiaoxia, S. Molecular simulation of the CH4/CO2/H2O adsorption onto the molecular structure of coal. Sci. China Earth Sci. 44, 1418–1428 (2014).

You, X. et al. Molecular dynamics simulations and contact angle of surfactant at the coal–water interface. Mol. Simul. 44, 722–727. https://doi.org/10.1080/08927022.2018.1441530 (2018).

Xia, Y., Yang, Z., Zhang, R., Xing, Y. & Gui, X. Enhancement of the surface hydrophobicity of low-rank coal by adsorbing DTAB: An experimental and molecular dynamics simulation study. Fuel 239, 145–152. https://doi.org/10.1016/j.fuel.2018.10.156 (2019).

Yunfei, Z. & Yan, L. Study of graphene wear based on coupled interfacial bonding effects. J. At. Mol. Phys. https://doi.org/10.19855/j.1000-0364.2025.062003 (2025).

Shaohong, Z., Haikuan, Y., Kai, W., Jiamin, L. & Jide, L. Influence of diamine structural units on thermosetting polymer with dynamic covalent bonds. New Chem. Mat. https://doi.org/10.19817/j.cnki.issn1006-3536.2024.10.033 (2024).

Acknowledgements

The authors would like to thank all the reviewers who participated in the review, as well as MJEditor (www.mjeditor.com) for providing English editing services during the preparation of this manuscript.

Funding

This work is supported by the National Natural Science Foundation of China (Grant No.52074147), Liaoning Natural Science Foundation of China (Grant No. LJKQZ20222334) and Liaoning Province Education Administration (Grant No. LJ2017FBL001).

Author information

Authors and Affiliations

Contributions

The data were analyzed by H.L. and G. D., Z. D., W. W. analyzed the images, and L.J. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hong, L., Lin, J., Gao, D. et al. Molecular simulation of the effect of water content on CO2, CH4, and N2 adsorption characteristics of coal. Sci Rep 14, 18190 (2024). https://doi.org/10.1038/s41598-024-69113-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-69113-z

- Springer Nature Limited