Abstract

Topical consumer interest in natural, healthier, safer and nutritional juice, has inspired the search for innovative technologies that can minimize product degradation. In this regard, thermosonication has been proposed as a potential processing technology that can preserve and produce “fresh” products. Watermelon (Citrullus lanatus) juice is a nutrient-rich fruit juice that is desired by consumers due to its appealing color, pleasant odor, sweet taste and low-calorie content. This fruit juice is, however, highly perishable and prone to microorganisms, because of its neutral pH value and high amount of water activity. In addition, it is thermo-sensitive and therefore degrades quickly under thermal processing. This study aimed to identify the optimal thermosonication processing conditions for retaining the critical quality parameters (lycopene, β-carotene, ascorbic acid and total polyphenolic content) of watermelon juice. Response surface methodology, employing a central composite design, was used to determine the effects of temperature (18–52 °C), processing time (2–13 min) and amplitude level (24–73 μm) at a constant frequency of 25 kHz. The highest quality parameters were obtained at 25 °C, 2 min, and 24 µm at a constant frequency of 25 kHz, which resulted in lycopene of 8.10 mg/100 g, β-carotene of 0.19 mg/100 g, ascorbic acid of 3.11 mg/100 g and total polyphenolic content of 23.96 mg/GAE/g with a desirability of 0.81. The proposed model was adequate (p < 0.0001), with a satisfactory determination coefficient (R2) of less than 0.8 for all phytochemicals. Thermosonicated watermelon juice samples showed minimal changes in their phytochemical properties, when compared to fresh juices; the lycopene content showed a significant increase after thermosonication, and a significant retention of β-carotene, ascorbic acid and total polyphenolic acid was observed. According to the findings, thermosonication could be a viable method for preserving watermelon juice, with minimal quality loss and improved functional attributes.

Similar content being viewed by others

Introduction

There has been an upsurge in interest in the consumption of natural fruit juices to substitute traditional caffeine-containing beverages such as coffee, tea or carbonated soft drinks1. This trend by health-conscious consumers has prompted the need to expand the supply of fruit juices2. Fruits are ideal ingredients for functional beverages. Considering their nutritional value, fruit juices can have functional properties such as antioxidant, antimicrobial, anti-inflammatory, and anti-cancer properties which are beneficial to human health3. Native to tropical Africa, the watermelon fruit (Citrullus lanatus) is a member of the Cucurbitaceae family4, preferred by consumers for its sweet, edible flesh and juice and its refreshing characteristics5. Its biomass is categorized into three components: flesh, seeds, and rind6. The flesh contributes to approximately 68% of the total weight, the rind approximately 30%, and the seeds about 2%7. Watermelon is considered the second most cultivated fruit in the world4, with a global production of almost 103 million tons in 20187. In 2018/2019, the preliminary production volume of watermelons in South Africa amounted to 91.4 thousand metric tons, but in 2023 that market reduced slightly8.

Watermelon is traditionally consumed in its fresh form but in recent years several cuisines employ its pulp for the preparation of juices, jellies, ice cream and sweets in general9. Due to its high-water content, watermelon is mostly processed in to fruit juice to tame the summer thirst10,11. This nutritional fruit juice has a desirable color, pleasant odor and sweet taste, and can be a constituent of a healthy diet due to its nutritional content, low cholesterol, low saturated fat and low sodium levels12. It is rich in minerals, specific amino acids and phytochemicals, such as total polyphenolic content (TPC), β-carotene, ascorbic acid (AA) and lycopene5. Of all the fruits, watermelon contains the highest bioavailable lycopene, containing 60% more than heat-processed tomato juice13. Watermelon juice also contains phytochemicals which have antioxidant and anti-inflammatory properties10. Antioxidants prevent and repair the damage caused by free radicals to the human body, and reduce the risk of various diseases including hypertension, inflammatory illnesses, cancers, diabetes, and arthritis14,15. In addition, antioxidants combat oxidative stress and prevent the occurrence of cardiovascular disorders, ageing as well as neurodegenerative diseases1. Watermelon juice has been classified as a functional food due to its significant amounts of amino acid L-citrulline and electrolytes; as a result, it is recommended as a functional beverage aiding muscle recovery during exercise10,16. Therefore, inclusion of watermelon juice in a diet could help reducing degenerative human diseases; also reduce their negative side effects.

Watermelon juice is highly perishable, which makes it susceptible to microbial activity, because of its neutral pH value and high amount of water activity13. Santos et al.17 reported that, its shelf-life is approximately four days under room temperature. Low acidity and high-water content are what make the perishability of watermelon juice18. The perishable nature of watermelon juice creates a need for processing to increase its shelf-life and utilization16. Initially, the shelf life of watermelon juice was extended through the application of thermal pasteurization aimed at reducing the microbial and enzymatic load, but that deteriorated the quality of the juice18. This resulted in severe adverse effects in chemical reactions that led to a loss of color, the formation of novel compounds by the Maillard reaction, a reduction in nutrients, unpleasant sensory attributes and the degradation of phytochemicals in the beverage10,19. Because the watermelon fruit is thermo-sensitive13, watermelon-based products consequently tend to be limited in the market6. This state of affairs prompted researchers to search for alternative novel technology which can process watermelon juice without degrading its quality and health-promoting properties20. In line with this, thermosonication treatment, also known as ultrasonic-assisted heat treatment, is considered to be a smart and excellent innovative technological alternative to overcoming the thermal treatment limitations in processing fruit juices4. This innovative technique combines acoustic energy with moderate heat treatments to inactivate enzymes, pathogenic and spoilage microorganisms21,22. Thermosonication is an innovative approach which extends the shelf-life of foods and beverages, while retaining their nutritional, phytochemical compounds and enhancing their sensory qualities 23. The effectiveness of thermosonication is attributed to cell disruption caused by acoustic cavitation, which is determined by the frequency, power intensity and processing time21,24. Thermosonication induces the oxidative stress on fruits by utilizing the ultrasound to generate cavitation bubbles that release a massive amount of energy upon collapse, which effectively disintegrates water molecules into highly reactive ·OH radicals4. Yıkmıs et al.25, observed that thermosonication retained the bioactive compounds and minerals of black grape juice. Additionally, Zhang et al.4 reported that, thermosonication has induced oxidative stress of phenolics, leading to an increase in antioxidant capacity of fruit juice. Moreover, Kalsi et al.22 reported that thermosonication not only retained high content of ascorbic acid but also enhanced the levels of total phenols, flavonoids and antioxidant activity in guava juice. Additionally, thermosonication has proven to be effective in retaining the quality parameters of kutkura juice 26, apple juice27, and blueberry nectar28. The application of thermosonication thus has the potential to enable the processing of watermelon juice, with a high retention of desirable quality attributes. The desired quality attributes and increased shelf-life of watermelon juice may be achieved by optimizing its processing conditions using response surface methodology (RSM)—a model which employs mathematical and statistical techniques to analyse interactions between factors that influence experimental response values, it determines precise and optimal parameter combinations29. The model shows the influence of different independent variables and their interactions with the dependent variables under investigation, by creating a set of numerical models and producing a predictive equation, relating the values of the coefficients30. This study therefore aimed to determine the optimum thermosonication processing conditions for the preservation of selected phytochemicals in watermelon juice, using RSM.

Materials and methods

Sample collection and thermosonication

Three unbruised watermelons (Sugar baby cv) fruits per row were manually and randomly picked at the ripe stage from Valley Farms, South Africa. Their maturity was evident from the browning and drying of tendrils nearest the fruit, the loss of surface gloss, yellowing of the ground spot, and a dull instead of metallic sound produced when the fruit was thumped with the knuckles15. The watermelons weighed between 7.43 and 7.48 kg each. Two watermelon fruits per row were cut to ensure the validity of the methodology just before harvest. The fruits were transported to the Food Science laboratory at the Florida campus of the University of South Africa for processing. To remove soil residues, the watermelons were thoroughly washed under running tap water and kept overnight at about room temperature to simulate grocery store/retail conditions. The juice of each watermelon was extracted the following day. The watermelons were cut into 8–9 cm cubes, and the rind and seeds were separated from the flesh using a knife. The flesh was put in the table juice extractor (Russell Hobbs Juice Sensation Model no: RHJM01. 220–240 V–700 W, UK) to extract the juice. Next, the watermelon juice was thermosonicated using a combination of an ultrasound bath (Water bath, ST 30, Turkey) and a Sonicator probe (QSonica, Model Q700, USA). The juice was processed according to the generated independent variables at a constant frequency of 25 kHz (Table 1). Sixteen samples of treated fruit juice were placed in 50 ml polyethylene bottles and stored at − 20 °C for 72 h before analysis13. All reagents were supplied by Merck Chemical Suppliers.

Experimental design

The experiment was done using RSM. Central composite design (CCD) was employed to study the combined effect of three independent variables—time, temperature, and amplitude29. Design Expert (statistical software version 6, Stat-ease Inc., Minneapolis MN, USA) was used. The CCD with a quadratic model was employed to produce the experimental designs, statistical analysis and regression model30. Amplitude (µm), temperature (°C) and processing time (min) were used as independent variables (Table 1). A total of 16 different combinations were generated, according to the CCD (Table 1). The dependent variables measured from the juice were lycopene, β-carotene, AA and TPC. Response surface plots which showed the values of the dependent variables were plotted using CCD.

Determination of lycopene and β-carotene in watermelon juice

Lycopene and β-carotene were analyzed according to method by Olives-Barba et al.31 with some modification. In brief, aapproximately 3 g of watermelon juice was placed in a vessel. The watermelon juice was mixed with 100 ml of extraction solvent (methanol/Tetrahydrofuran (THF) (50:50 v/v) and hexane/acetone/ethanol (50:25:25 v/v/v) separately. The mixture was stirred for 30 min. The sample was then centrifuged at 1890 rpm for 15 min at 4 °C. The methanol/THF (50:50 v/v) extract was diluted to a concentration of THF lower than 10%; for the hexane/acetone/ethanol extract 15 ml of distilled water was added; the upper layer was placed in a round-bottom flask and an aliquot of 10 ml of the extract was evaporated to dryness under nitrogen flow under vacuum. The residues were dissolved to a final volume of 10 ml. The final solution was filtered through 0.45 µm membrane filters and 100 µL was injected for analysis using HPLC with a detector at absorbance 450 nm for β-carotene and 475 nm for lycopene. The mobile phase was a mixture of methanol and acetone (90/10 v/v) at a flow rate of 0.9 ml/ min. The column temperature was 30 °C. The sample was assayed by mobile phase of methanol/ACN + TEA 9 µM, the mobile phase was filtered through a 0.45 µm membrane and degassed ultrasonically prior to use. The absorbance was read at 450 nm for β-carotene and 475 nm for lycopene31.

Determination of AA in watermelon juice

The ascorbic acid (AA) was determined by HPLC (Model RD-20A, Japan) using the method of Soliva-Fortuny et al.32. Approximately 25 ml of watermelon fruit juice was homogenised with 10 ml of extraction solution (10% metaphosphoric acid + 0.5% 2, 3 dimercapto-1-propanol, BAL, a thiol-reducing reagent). The homogenised mixture was centrifuged at 1890 rpm for 15 min at 4 °C. The supernatant was vacuum-filtered through Whatman No. 1 paper and diluted to 50 ml with distilled water. Then, samples were passed through a 0.45 µm membrane filter. An aliquot of 20 µl was injected into the HPLC system using an NH2 Spherisorb S5 column (250 4.6 mm, 5 µm). Detection was performed with a 486-absorbance detector at 254 nm.

Determination of TPC in watermelon juice

TPC (expressed as gallic acid equivalent) was determined according to the method of Soliva-Fortuny et al.32 with slight modifications described by Shi et al.11. In brief, aapproximately 1.0 ml of watermelon juice was mixed with 1.0 ml of Na2CO3 solution (2 g/100 ml H2O) and kept at room temperature for 3 min. After the addition of 0.2 ml Folin-Ciocalteu reagent (twofold diluted with H2O), the reaction was kept for 30 min in the dark room, followed by centrifugation (Model 5702, RH, Japan) at 13.400 rpm for 5 min. The absorbance of supernatant was measured at 765 nm by using a UV-2600 UV/vis spectrophotometer (Shimadzu, Japan).

Statistical analysis

The data analysis was performed using Design Expert statistical software version 6 (Stat-ease Inc., Minneapolis MN, USA)30. The analysis of variance (ANOVA) and regression coefficients of individual phytochemicals in terms of actual factors, were determined. The significances of all terms in the polynomial were statistically analyzed, at a probability level (p) of 0.0001, while the regression coefficient of determination (R2) was used to determine the adequacy of each model. The linear models were used to predict the responses. These values were related to the coded variables by a second-degree polynomial using the equations and plots.

Results and discussion

Effects of thermosonication on the lycopene content of the watermelon juice

Lycopene is a fat-soluble red-coloured phytochemical that has attracted significant interest since it is deemed to play a vital role in preventing chronic diseases such as cancer and diabetes33,34. The fresh watermelon juice recorded a lycopene content of 6.19 mg/100 g (Table 2) which was less than the 12.20 mg/100 g reported by Oberoi and Sogi35. The difference in these values may be due to agricultural practices and climate factors14.

The lycopene content of thermosonicated watermelon juice was dependent on processing variables (Table 2). A significant increase in lycopene was observed at lower processing variables (25 °C, 2 min and 24 µm); these processing parameters recorded a lycopene content of 8.10 mg/100 g compared to the 6.19 mg/100 g observed in the fresh sample. Rawson et al.36 observed a similar pattern during the thermosonication of watermelon juice. The increase in lycopene content at lower processing variables was probably due to the growth, formation and violent collapse of small bubbles in the liquid during sonication, resulting from the fluctuation in pressure—a phenomenon known as acoustic cavitation35. In addition, at lower processing variables there are not enough violent cavitation bubbles due to low viscosity, and there are no dampening effects on collapse by high vapor pressure due to low temperature37,38.

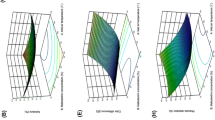

The analysis of variance showed a linear model and a significant lack of fit (p < 0.0001), indicating that the model was adequate (Table 3). The relation between independent variables and lycopene content was exhibited with a high correlation coefficient (R2 = 0.8378). A correlation coefficient close to 1 indicates the effectiveness of the correlation between predicted values and actual ones31. The adjusted determination coefficients (Adj R2) were also close to 1 (0.7973), which indicated that the experimental values could be significantly predicted by the model. The increase of lycopene in the thermosonicated samples, which was dependent on experimental conditions, decreased as processing variables increased. The response surface plots (Fig. 1a) showed a continuous decrease in lycopene content as processing variables increased.

The mathematical equation in terms of coded factors showing effects on lycopene is shown in Eq. (1), where A is temperature, B is time and C is amplitude.

Shi and Maguer39 observed a similar trend during the thermosonication of tomato juice, with their study reporting that the lycopene content decreased with the combination of higher time–temperature conditions on tomato juice. This is because at high temperatures, the intensity of bubble collapse is weakened by the higher vapor pressure 38. Moreover, isomerization of trans-lycopene to the cis form, induced by heat and ultrasound during sonication treatment, leads to an undesirable decrease in lycopene content4,26. In addition, Khongthaw et al.40 reported that, the loss or decrease of lycopene is intensified during processing because lycopene can simply oxidize and rearrange into a cis isomer. The decrease may also be influenced by an oxidative injury occurring during thermosonication41. Moreover, the decrease in lycopene might be due to exposure to light during the experiment, since lycopene is an unstable phytochemical which isomerizes under light irradiation, high-temperature treatments and oxidation42.

Effects of thermosonication on the β-carotene content of the watermelon juice

β-carotene is a phytochemical that has received considerable attention for being a precursor of vitamin A and shows strong biological activity as an antioxidant43. Fresh watermelon juice recorded 0.23 mg/100 g of β-carotene. The values of β-carotene content in the thermosonicated juice varied between 0.01 and 0.19 mg/100 g (Table 2). This study observed a decrease in β-carotene as processing variables were intensified, however, the amount of β-carotene was retained at lower processing variables (25 °C, 2 min and 24 µm), rather than at higher processing variables (Table 2). A similar trend was observed by other researchers who investigated the effects of thermosonication on fruit juices. Urango et al.24 reported that high temperatures during thermosonication were associated with an alteration of the food quality, and nutritional and sensory properties. In addition, the decrease in β-carotene content could be due to the cell disruption occurring during thermosonication processing44. During sonication, bubbles are released in the liquid medium, leading to an increase in enzyme activity which results in the formation of free radicals45. The rate of bubbles released at lower processing variables was found to be slower than those released at higher processing variables, while longer processing variables released bubbles at a faster rate and caused more cell disruption, which resulted in a gradual decrease of β-carotene39. The ANOVA results for β-carotene are shown in Table 3. The p-values less than 0.001 specify that the model was significant (Table 3). The values of determination coefficients (R2 = 0.7540) and adjusted determination coefficients (Adj. R2) were close to 1, which indicates a high degree of correlation between the experimental and predicted values. Each output variable in RSM has a mathematical relationship with the experimental variables by a linear equation. The equation for β-carotene can be expressed as follows: high temperatures can affect nutritional and sensory properties altering food quality.

The generated response surface plot corresponding to each response showed the interactive effects of the variables (Fig. 1b). The loss of β-carotene was associated with high processing variables—as processing variables accelerated, the loss was intensified. Fonteles et al.45 reported that, under high processing variables the bubbles can disrupt the propagation of ultrasound waves, resulting in the loss of vital compounds such as β-carotene. Furthermore, Oberoi and Sogi18 reported that β-carotene content was decreased by acoustic cavitation (i.e., repeated cycles of compression and decompression produced during sonication). The acoustic cavitation may collapse less violently, which accelerates the decrease of β-carotene39. Acoustic cavitation leads to damage to the cellular structure of compounds, therefore natural liquid layers close the phase boundaries and consequently accelerate the process of mass transfer45. The development of free radicals and peroxide compounds produced during ultrasound at higher processing variables leads to a decrease in β-carotene46. Fonteles et al.45 further reported that the quantity of β-carotene was decreased by the free radicals which degraded the hydroxyl (–OH). This was due to the opening of the rings and the development of chalcone, which was caused by the temperature increase occurring during sonication47. High pressure and heat treatment were found to accelerate the isomerization of β-carotene48.

Effects of thermosonication on the AA content of the watermelon juice

AA is an easily oxidized strong antioxidant compound which is naturally occurring and mostly found in plants species and their by-products49. It plays an important role in collagen tissue synthesis and the development of the immune system, and in reducing the risk of cardiovascular diseases and nervous disorders50. It is considered an indicator of quality in fruit juices51. For these reasons, it is crucial to keep AA stable and retain it during juice processing. The fresh watermelon juice recorded 3.47 mg/100 ml of AA (Table 2). This study observed a decrease in AA as processing variables were intensified, however, thermosonication retained about 3.11 mg/100 g of AA at lower processing variables (25 °C, 2 min and 24 µm). There was a constant decrease in AA with increasing temperature, time and amplitude (Table 2). According to Abdullah and Chin51, AA is not a stable compound therefore it is easily oxidised under extreme heat treatment. Moreover, Anaya-Esparza et al.50 reported that AA degradation is dependent on amplitude, acoustic energy density, temperature, and treatment time during thermosonication. Tiwari et al.52 reported 5% decrease in AA in orange juice during thermosonication; while Adekunte et al.53 observed a 32% decrease in tomato juice during thermosonication. The decrease in AA at higher processing variables might be attributed to severe physical conditions occurring as a result of the cavitation collapse of bubbles during sonication treatment28. In addition, the decrease in the AA content may be attributed to cavities (formed by sonication) which may be filled with water vapor and gases dissolved in the juice, such as O2 and N245. Therefore, moderate processing temperature is needed to ensure higher retention of ascorbic acid as it is a highly heat sensitive compound. The analysis of variance showed a significant linear model and a non-significant lack of fit (Table 3). The Predicted R2 (0.81) was in reasonable agreement with the Adjusted R2 (0.76). The regression equation of the model is presented in Eq. (3), where A is temperature, B is time and C is amplitude.

The plot shown in Fig. 1c illustrates the combined effects of temperature, time and amplitude on AA. The decrease was observed to be intensified at high processing variables (Table 2). Rawson et al.36 reported that AA is an unstable compound which degrades easily at higher processing variables. The decrease may also be due to the presence of oxygen and the breaking down of molecules during sonication53. Rawson et al.36 reported that the formation of hydroxyl radicals by water during sonication, which may occur at the gas–liquid interface causing oxidation and several sonochemical reactions to occur simultaneously, may lead to a decrease in AA. Tiwari et al.52 reported that AA content decreased due to a decrease in other compounds, since it has a protective effect on other compounds such as phenols. Sonication can result in enhanced free radicals, which leads to the oxidation of AA content, even though it induces degassing by cavitation of air-saturated systems44. A decrease in AA is associated with a decrease in color and pH, since it acts as a valid criterion for natural pigments and aromatic substances42. Thermosonication was found to retain the AA even at high processing variables. Therefore, thermosonication is a recommended processing method for retaining the considerable content of AA.

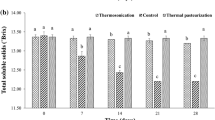

Effects of thermosonication on the TPC of the watermelon juice

TPC have protective effects on human health due to their strong antioxidant properties which combat free radicals in the body50. The results revealed a TPC of 25.95 mg GAE/g (Table 2) in fresh watermelon juice, while the TPC of thermosonicated watermelon juice varied between 7.88 and 23.96 mg GAE/g (Table 2). A decrease in TPC was observed in thermosonicated watermelon juice, which was more significant with increasing thermosonication intensity. Thermosonication retained about 23.96 mg/GAE/g at lower processing variables (25 °C, 2 min and 24 µm). However, TPC was retained even at the highest processing variables (Table 2). These observations align with those reported by Rawson et al.36 [whose study found that thermosonication retained the TPC in watermelon juice]. The decrease in TPC content could be due to high-energy cavitation bubbles containing solvent vapor44. These bubbles implode near cell walls, causing very high local temperatures, pressure increase and cell wall destruction, which ease mass transfer from cell to solvent, and enhance the loss of important phytochemicals42. The bubbles accelerate chemical reactions, increase diffusion rates, disperse aggregates, or inactivate enzymes and microorganisms41,48. Cavitational bubbles filled with water vapor and O2 gas dissolved in the juice during thermosonication, resulting in decreased TPC28,36. TPC is highly sensitive to heat, therefore a temperature increase accelerated the decrease of TPC54. Linear effects (temperature, time and amplitude) and their interaction were found to be significant, showing a 95% confidence interval (R2 = 0.8477) from a low p-value (p < 0.0001) and a high F-value (Table 3). The F-value of 22.27 implies that the model was significant (Table 3). Notably, there is only a 0.01% chance that an F-value this large could occur due to noise. The TPC of fresh juice was decreased by increasing the thermosonication variables (Fig. 1d). However, the decrease in TPC was not severe at lower processing variables (Fig. 1d).

Equation (4) illustrates the relationship between temperature, time and amplitude:

There was an increase in viscosity and a weak intensity of bubble collapse at high heat and vapor pressure, which resulted in a polyphenol decrease53. The collapse of the bubbles during sonication caused shock waves to pass through the solvent, enhancing the mass transfer within the system42, which led to the destruction of phytochemicals.

Numerical optimization and model fitting of experimental conditions

Optimization was carried out to determine the precise and optimal parameter combinations which retained the quality of parameters of the watermelon juice29. Temperature, time and amplitude were independent variables while lycopene, β-carotene, AA and the TPC of the watermelon juice were dependent variables. The ANOVA showed that the resultant linear models adequately represented the experimental data for the phytochemicals under investigation. The predicted values were closely correlated with the experimental data, as demonstrated by the R2. The p-values and f-values of the model were < 0.0001 for lycopene, β-carotene, AA, and TPC, which confirmed the goodness of fit of the model (Table 3). The optimum processing variables that retained the quality parameters were 25 °C for 2 min at an amplitude of 24 µm at a constant frequency of 25 kHz. These conditions resulted in lycopene of 8.10 mg/100 g, β-carotene of 0.19 mg/100 g, AA of 3.11 mg/100 g and TPC of 23.96 mg/GAE/g with a desirability of 0.81.

Conclusion

The perishability and non-thermal nature of watermelon juice called for the application of non-thermal innovative technologies to extend the shelf-life thereof and expand its utilization. In this study, thermosonication was applied to process the watermelon juice, with a view to retaining its critical quality parameters (lycopene, β-carotene, AA and TPC) using the RSM. The highest quality parameters were retained at 25 °C, 2 min, 24 µm and a constant frequency of 25 kHz. This study observed an increase in lycopene at lower processing variables and a decrease as processing variables intensified. A decrease in β-carotene, AA and TPC was also observed as processing variables intensified, however, it was proven that thermosonication retained all the quality parameters which were investigated. Temperature and time were key factors in determining the decrease in quality parameters. All dependent variables were highly significant (p < 0.0001) to the independent variables studied, apart from the β-carotene which was non-significant (p > 0.05). The ANOVA results showed that the proposed model was adequate (p < 0.0001), significant, and fit all quality parameters. The R2 for predicted quality parameters showed a good correlation with the experimental data at a confidence level of 95%. The results revealed the advantages of thermosonication for watermelon juice processing. At low processing variables, thermosonication enhanced and retained the phytochemicals of the watermelon juice. Although the application of thermosonication in beverage-processing industries is still not common, the findings indicate that such processing could be a worthwhile potential technique to produce watermelon juice with enhanced overall quality. The exploration into its effect on microbial activity to better the shelf-life extension as well as on consumer preferences could enhance the market to the diversification of the beverage industry.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request, request from the corresponding author at maotomossa@gmail.com.

References

Theba, T., Nayi, P. & Ravani, A. Beetroot-based blended juice: Process development, physico-chemical analysis and optimization of novel health drink. Food Chem. Adv. 4, 100607 (2024).

Hashemi, S. M. B., Roohi, R. & Abedi, E. Thermodynamics, kinetics, and computational fluid dynamics modeling of Escherichia coli and Salmonella Typhi inactivation during the thermosonication process of celery juice. Ultrason. Sonochem. 104, 106820 (2024).

Silva, J. M. et al. Optimization of foam mat drying using central composite design to produce mixed juice powder: A process and characterization study. Food Bioprod. Process. 146, 58–68 (2024).

Zheng, Y. Global characteristics and trends of researches on watermelon: Based on bibliometric and visualized analysis. Heliyon. 10, 26824 (2024).

Candido da Silva, M. C. et al. Impact of sulfite use and acidification on chemical quality components in thermally processed watermelon juices. Food Res. Int. 180, 114088 (2024).

Zia, S., Khan, M. R., Shabbir, M. A. & Aadil, R. M. An update on functional, nutraceutical and industrial applications of watermelon by-products: A comprehensive review. Trends Food Sci. Technol. 114, 275–291 (2021).

Rezagholizade-Shirvan, A., Shokri, S., Dadpour, S. M. & Amiryousefi, M. R. Evaluation of physicochemical, antioxidant, antibacterial activity, and sensory properties of watermelon rind candy. Heliyon. 9(6), 17300 (2023).

Cowling, N. (2023). Production of melons in South Africa from 2000 to 2019(in metric tons). South Africa: production of melons 2000–2019 | Statista (accessed 10 October 2023).

Elboughdiri, N. et al. Application of statistical physical, DFT computation and molecular dynamics simulation for enhanced removal of crystal violet and basic fuchsin dyes utilizing biosorbent derived from residual watermelon seeds (Citrullus lanatus). Process Saf. Environ. Prot. 186, 995–1010 (2024).

Bhattacharjee, C., Saxena, V. K. & Dutta, S. Novel thermal and non-thermal processing of watermelon juice. Trends Food Sci. Technol. 93, 234–243 (2019).

Shi, F., Wang, L. & Li, S. Enhancement in the physicochemical properties, antioxidant activity, volatile compounds, and non-volatile compounds of watermelon juices through Lactobacillus plantarum JHT78 fermentation. Food Chem. 420, 136146 (2023).

Mendoza-Enano, M. L., Stanley, R. & Frank, D. Linking consumer sensory acceptability to volatile composition for improved shelf-life: A case study of fresh-cut watermelon (Citrullus lanatus). Postharvest Biol. Technol. 154, 137–147 (2019).

Oberoi, D. P. S. & Sogi, D. S. Drying kinetics, moisture diffusivity and lycopene retention of watermelon pomace in different dryers. J. Food Sci. Technol. 52, 7377–7384 (2015).

Bianchi, G., Rizzolo, A., Grassi, M., Provenzi, L. & Scalzo, R. L. External maturity indicators, carotenoid and sugar compositions and volatile patterns in ‘Cuoredolce’® and ‘Rugby’ mini-watermelon (Citrullus lanatus) varieties in relation of ripening degree at harvest. Postharvest Biol. Technol. 136, 1–11 (2018).

Kyriacou, M. C., Leskovar, D. I., Colla, G. & Rouphael, Y. Watermelon and melon fruit quality: The genotypic and agro-environmental factors implicated. Sci. Hortic. 30, 8–12 (2018).

Milczarek, R. R. & Sedej, I. Aroma profiling of forward-osmosis watermelon juice concentrate and comparison to fresh fruit and thermal concentrate. Food Sci. Technol. 151, 112147 (2021).

Santos, M. D. et al. Preservation of a highly perishable food, watermelon juice, at and above room temperature under mild pressure (hyperbaric storage) as an alternative to refrigeration. Food Sci. Technol. 62, 901–905 (2015).

Oberoi, D. P. S. & Sogi, D. S. Utilization of watermelon pulp for lycopene extraction by response surface methodology. Food Chem. 232, 316–321 (2017).

Yang, F. et al. Low-frequency ultrasonic treatment: A potential strategy to improve the flavour of fresh watermelon juice. Ultrason. Sonochem. 91, 106238 (2022).

Guo, W., Tang, X., Cui, S., Zhang, Q., Zhao, J., Mao, B., & Zhang, H. (2023). Recent advance in quality preservation of non-thermal preservation technology of fresh mushroom: a review. Critical Reviews in Food Science and Nutrition. 1 – 17.

Hu, Y., Cheng, L., Gilbert, E. P., Lee, S. J. & Yang, A. Impact of thermosonication at neutral pH on the structural characteristics of faba bean protein isolate dispersions and their physicochemical and techno-functional properties. Food Hydrocoll. 154, 110140 (2024).

Kalsi, B. S., Singh, S., Alam, M. S. & Bhatia, S. Application of thermosonication for guava juice processing: Impacts on bioactive, microbial, enzymatic and quality attributes. Ultrason. Sonochem. 99, 10659 (2023).

Moura, R. S. et al. Thermosonication as an effective substitution for fusion in Brazilian cheese spread (Requeijão Cremoso) manufacturing: The effect of ultrasonic power on technological properties. Ultrason. Sonochem. 105, 106867 (2024).

Urango, A. C. M., Strieder, M. M., Silva, E. K. & Meireles, M. A. Impact of thermosonication processing on food quality and safety: A review. Food Bioprocess Technol. 15, 1700–1728 (2022).

Yıkmıs, S., Demirok, N. T., Levent, O. & Apaydın, D. Impact of thermal pasteurization and thermosonication treatments on black grape juice (Vitis vinifera L): ICP-OES, GC–MS/MS and HPLC analyses. Heliyon. 9, 19314 (2023).

Kesavan, R. K., Gogoi, S. & Nayak, P. K. Influence of thermosonication and pasteurization on the quality attributes of kutkura (Meyna spinosa) juice. Appl. Food Res. 3, 100268 (2023).

Illera, A. E. et al. Effect of thermosonication batch treatment on enzyme inactivation kinetics and other quality parameters of cloudy apple juice. Innov. Food Sci. Emerg. Technol. 47, 71–80 (2018).

Jambrak, A. R., Šimunek, M., Zeko, A., Herceg, Z. & Vukušić, T. Antioxidant, quality and electronic tongue sensory parameters of thermosonicated blueberry nectar. Innov. Food Sci. Emerg. Technol. 44, 202–211 (2017).

Bhattacharya, R., Arora, S. & Ghosh, S. Bioprocess optimization for food-grade cellulolytic enzyme production from sorghum waste in a novel solid-state fermentation bioreactor for enhanced apple juice clarification. J. Environ. Manag. 358, 120781 (2024).

Fragasso, J., Moro, L., Lye, L. M. & Quinton, B. W. Characterization of resilient mounts for marine diesel engines: Prediction of static response via nonlinear analysis and response surface methodology. Ocean Eng. 171, 14–24 (2019).

Olives-Barba, A. I. et al. Application of a UV–VIS detection-HPLC method for a rapid determination of lycopene and β-carotene in vegetables. Food Chem. 95, 328–336 (2006).

Soliva-Fortuny, R. C., Elez-Martınez, P. & Martın-Belloso, O. Microbiological and biochemical stability of fresh-cut apples preserved by modified atmosphere packaging. Innov. Food Sci. Emerg. Technol. 5, 215–224 (2004).

Asaduzzaman, M. D., Hasan, N., Begum, K. & Hoque, S. M. Z. Degradation kinetics of lycopene from red amaranth & preparation of winter melon jelly using this lycopene and comparison with commercial jelly. Heliyon. 10, 31135 (2024).

Zhou, Y., Fu, R., Yang, M., Liu, W. & Tong, Z. Lycopene suppresses gastric cancer cell growth without affecting normal gastric epithelial cells. J. Nutr. Biochem. 116, 109313 (2023).

Oberoi, D. P. S. & Sogi, D. S. Prediction of lycopene degradation during dehydration of watermelon pomace (cv Sugar Baby). J. Saudi Soc. Agric. Sci. 16, 97–103 (2017).

Rawson, A. et al. Effect of thermosonication on bioactive compounds in watermelon juice. Food Res. Int. 44, 1168–1173 (2011).

Lieu, L. N. & Le, V. V. M. Application of ultrasound in grape mash treatment in juice processing. Ultrason. Sonochem. 17, 273–279 (2010).

Sun, Y., Ma, G., Ye, X., Kakuda, Y. & Meng, R. Stability of all trans β-carotene under ultrasound treatment in a model system: Effects of different factors, kinetics and newly formed compounds. Ultrason. Sonochem. 17, 654–661 (2010).

Shi, J. & Maguer, M. L. Lycopene in tomato: Chemical and physical properties affected by food processing. Crit. Rev. Food Sci. Nutr. 40, 1–42 (2000).

Khongthaw, B., Chauhan, P. K., Dulta, K., Kumar, V. & Ighalo, J. O. Lycopene: Extraction, microencapsulation, and therapeutic properties. Bioresour. Technol. Rep. 25, 101787 (2024).

Aghajanzadeh, S., Ziaiifar, A. M. & Kashaninejad, M. Influence of thermal treatment, homogenization and xanthan gum on physicochemical properties of watermelon juice: a response surface approach. Food Sci. Technol. 85, 66–74 (2017).

Aguilar, K., Garvín, K., Ibarz, A. & Augusto, P. E. D. Ascorbic acid stability in fruit juices during thermosonication. Ultrason. Sonochem. 37, 375–381 (2017).

Kulczynski, B., Sidor, A., Brzozowska, A. & Gramza-Micha»owska, A. The role of carotenoids in bone health—a narrative review. Nutrition. 119, 112306 (2024).

Chen, J., Li, F., Li, Z., McClements, D. J. & Xiao, H. Encapsulation of carotenoids in emulsion-based delivery systems: Enhancement of b-carotene water-dispersibility and chemical stability. Food Hydrocoll. 69, 49–55 (2017).

Fonteles, T. V. et al. Power ultrasound processing of cantaloupe melon juice: Effects on quality parameters. Food Res. Int. 48, 41–48 (2012).

Dolatowski, Z. J., Stadnik, J. & Stasiak, D. Application of ultrasound in food technology. Acta Scientiarum Polonorum, Technologia Alimentaria. 6, 89–99 (2007).

Knockaert, G. et al. Lycopene degradation, isomerisation and in-vitro bioaccessibility in high-pressure homogenised tomato puree containing oil: Effect of additional thermal and high-pressure processing. Food Chem. 135, 1290–1297 (2012).

Singh, S. et al. Changes in lycopene, total carotenoid and anti-radical activity in teasel gourd (Momordica subangulata) fruit fractions at different stages of maturity. Ind. Crops Prod. 73, 154–163 (2015).

Asfaw, T. B. et al. Ultrasonic-assisted extraction and UHPLC determination of ascorbic acid, polyphenols, and half-maximum effective concentration in Citrus medica and Ziziphus spina-christi fruits using multivariate experimental design. Food Chem. 22, 101310 (2024).

Anaya-Esparza, L. M. et al. Thermosonication: An alternative processing for fruit and vegetable juices. Trends Food Sci. Technol. 61, 26–37 (2017).

Abdullah, N. & Chin, N. L. Application of thermosonication treatment in processing and production of high-quality and safe-to-drink fruit juices. Agric. Agric. Sci. Procedia. 2, 320–327 (2014).

Tiwari, B. K., O’Donnell, C. P. & Cullen, P. J. Effect of sonication on retention of anthocyanins in blackberry juice. J. Food Eng. 93, 166–171 (2009).

Adekunte, A. O., Tiwari, B. K., Cullen, P. J., Scannell, A. G. M. & O’Donnell, C. P. Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem. 12, 500–507 (2010).

Kim, S. et al. Antioxidant activity of a hydrothermal extract from watermelons. Food Sci. Technol. 59, 361–368 (2014).

Acknowledgements

The research leading to these results received funding from the National Research Foundation (NRF), South Africa. We thank Dr T Onipe and Dr L Mankga for proof reading and editing.

Author information

Authors and Affiliations

Contributions

Ms M.M.M. was the main researcher and Prof A.I.O.J. was the main supervisor, all Authors contributed equally to the complete of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Maoto, M.M., Jideani, A.I.O. Optimization of thermosonication conditions for critical quality parameters of watermelon juice using response surface methodology. Sci Rep 14, 13803 (2024). https://doi.org/10.1038/s41598-024-64066-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-64066-9

- Springer Nature Limited