Abstract

The development of strategies to overcome the shortage of forage due to persistently low rainfall is becoming a central task for animal nutrition in research and practice. In this study, it was investigated how the treatment of straw with NaOH or feed urea in a practicable procedure for modern farms affects rumen fermentation (gas production and greenhouse gas concentration) as well as the digestibility of feed energy and nutrients. For this purpose, the treatments were tested individually and in different proportions in a total mixed ration (TMR) in ruminal batch cultures in vitro and in a digestibility trial with sheep. In order to explain the observed effects at the molecular level, descriptive data from 13C solid state nuclear magnetic resonance (NMR) and Fourier-transform infrared (FTIR) spectroscopy were obtained. NaOH treatment of straw increased crude ash (CA), non-fibrous carbohydrates, digestible energy (DE), and metabolizable energy (ME) concentration, whereas the proportion of neutral detergent fibre (aNDFom) and hemicellulose decreased. In urea treated straw, NH3–N and crude protein increased, whereas acid detergent lignin (ADL), DE, and ME decreased. The physically effective fibre (peNDF8) concentration increased in TMR containing 18% of NaOH or urea treated straw (p < 0.01). The application of straw treatments as pure substrates (not as part of a TMR) increased gas production and decelerated ruminal fermentation (p < 0.05). In vitro organic matter digestibility (IVOMD) of the straw (0.31) increased after NaOH (0.51; p < 0.05) and urea treatment (0.41; p > 0.05). As part of a TMR, straw treatments had no distinct effect on gas production or IVOMD. Concentrations of CH4 and CO2 were likewise not affected. Apparent total tract digestibility of aNDFom, acid detergent fibre (ADFom), hemicellulose, and cellulose increased in the TMR by approximately 10% points following NaOH treatment (p < 0.05). The inclusion of urea treated straw did not affect apparent digestibility. Calculated true digestibility of aNDFom was 0.68, 0.74, and 0.79, of ADFom 0.58, 0.57, and 0.65, and of ADL 0.02, 0.13, and 0.08 in TMR including untreated, NaOH treated, and urea treated straw, respectively. 13C NMR and FTIR analyses consistently revealed that the global structure and crystallinity of the carbohydrates (cellulose and hemicellulose) was not altered by treatment and the concentration of lignin was likewise not affected. Depolymerisation of lignin did not occur. However, NMR signals assigned to acetyl groups were significantly altered indicating that straw treatments disrupted linkages between hemicelluloses and lignin. Moreover, the acetates signal was affected. This signal can be assigned to linkages between ferulic acids and hemicelluloses (arabinoxylans). FTIR spectra of straw treatments mainly differed at a wavelength of 1730 cm−1 and 1240 cm−1. Disappearance of the 1730 cm−1 peak suggests removal of hemicelluloses or lignin related compounds by treatment. The disappearance of the lignin peak at 1240 cm−1 could be due to conjugated ketone (phenyl-carbonyl) removal or the removal of ferulic and p-coumaric acid acetyl groups. Both treatments are supposed to release fermentable cell wall components (hemicelluloses) from lignin-associated bonds and as a result, straw fibre can be better fermented in the rumen. This contributes to energy supply and increased fibre digestibility at least in the TMR that contained NaOH treated straw. The alkaline straw treatments probably induced a release of phenolics such as ferulic acid and p-coumaric acid, which can be metabolised in the gut and the liver and metabolites might be excreted with the urine. This could notably contribute to metabolic energy losses.

Similar content being viewed by others

Introduction

In the course of an ongoing climate change, regions with significant agricultural production such as Central Europe and Central North America will likely experience a long-term increase of drought frequency and persistence in spring and summer with lasting extraordinary high temperatures and at the same time an increase of events of heavy precipitation1,2,3,4. This will deeply impair food and feed production due to crop and pasture shortfalls1. Such forecasts and actual experiences with forage shortages in the years 2018–2020 in Europe have led to the reactivation of the search for alternative forage resources.

Ruminants are proficient to utilise feeds rich in fibre due to their symbiosis with rumen microbial populations and this is why by-products from the agro-industry and food production, grassland, or woodland can be applied with expected good success5. This is also one reason why ruminants will play an essential role in future global land use and food production systems if sustainability goals are to be achieved under the influence of ongoing climate change6.

Despite forage shortage, cereal straws remain available to a large extent and throughout the year. In 2020, 60% of barley, 60% of oats, 86% of rye, 34% of wheat, and 94% of triticale produced worldwide came from Europe and this resulted in a total of around 321 million tonnes of straw residue7,8. However, straws are poorly digestible, which is due to a concentration of lignin up to 17% of dry matter (DM)9,10,11,12,13. Lignin is a major cell wall component that is involved in providing rigidity, internal transport of water and nutrients, and protection12. The lignin polymer consists of phenylpropane units, whose precursors are the monolignols p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol12. Those are building a complex amorphous polymer via β-O-4, α-O-4, β-5, β-1, 5–5, 4-O-5, and β-β linkages, which is further forming complexes with other polymers such as cellulose and hemicellulose12.

Aside from physical and biological treatments of straw, chemicals can be used to break up the interpolymer bonds in the cell wall in order to release carbohydrates (e.g., hemicelluloses) that rumen microorganisms do readily ferment14. The application of alkalis such as NaOH, KOH, Ca(OH)2, or urea is associated mainly with improved digestibility13,15 and may improve low-quality feeds’ value. Especially NaOH and urea treatments were intensively studied and their effects are well documented13,15,16,17,18,19. The degrading effect of alkalis is usually higher the stronger the caustic solution or its degree of dissociation20. This makes NaOH more effective and cheaper than KOH or Ca(OH)220. The sodagrain method for NaOH application developed by Ørskov et al.21 is well established in agricultural practice, which is why we decided to build upon this experience. Although urea is less effective than NaOH20, it was chosen as it is easy and safe to handle and may improve straws’ feed value by adding nitrogen. In general, application protocols need to be revised against the background of current regulations of the European Union on environmental protection to avoid water and air pollution.

The objectives of this study were to examine effects of NaOH or urea treatment of barley straw on carbohydrate fermentation and in vitro organic matter digestibility (IVOMD) in the rumen and total tract digestibility of energy, crude nutrients, and detergent fibres.

Methods

Ethical and policy notes

The animals used in the experiments presented in this report were kept and cared for by the Research Centre for Agricultural and Nutritional Sciences, Martin Luther University Halle-Wittenberg, Wettin/Löbejün, Saxony-Anhalt (Germany). The sheep were used for experimental purposes with the approval of the Saxony-Anhalt Federal Administration Authority (approval no. 42505-3-813 and 2-1524 MLU).

Sampling of plant materials did not involve threatened or wild flora species in terms of the IUCN Policy Statement on Research Involving Species at Risk of Extinction.

All methods described in the following were performed according to the relevant guidelines and regulations as cited.

Use of experimental animals was reported in accordance with the ARRIVE guidelines.

Barley straw treatments and composition of total mixed rations (TMR)

Untreated winter barley straw served as the control. The same batch of straw was used for the treatments. For NaOH treatment, caustic soda microbeads of technical grade (WHC GmbH, Hilgertshausen, Germany) were dissolved in tap water following the procedure described by Ørskov et al.21. Then, 60 g NaOH/kg DM of chopped straw (2–5 cm particle size) were applied and mixed for 5 min. Safety measures as recommended by the manufacturer were considered. For the urea treatment, feed grade urea (90%) (SALVANA TIERNAHRUNG GmbH, Kl. O.-Sparrieshoop, Germany) was applied with 40 g/kg DM of the chopped straw and mixed for 5 min. With both treatments, the straw was remoistened to 600 g DM/kg. The treated straw was stored 14 days at ambient temperature in January 2021 (0.8 °C on monthly average) (NaOH treatment) and 25 °C (urea treatment) and then frozen to − 20 °C until analysis. The treatment of the straw, including remoistening, and mixing of the TMR, was carried out in a feed mixer wagon. Untreated straw was also run through the feed mixer and then mixed into the TMR.

A series of experiments was conducted. Initially, an in vitro batch culture experiment was performed to assess treatment effects on gas production as a measure of carbohydrate fermentation in the rumen and IVOMD using untreated barley straw, NaOH, and urea straw treatments. Additionally, a basal TMR consisting of 90 mg barley, 4 mg soybean meal, and 106 mg lucerne chaff proportionately to 200 mg on a DM basis of total substrate was fed in the in vitro fermenters, and six TMR variants in which straw treatments replaced lucerne chaff by 10.6 mg (10%) or 21.2 mg (20%), respectively (Experiment 1). A second batch culture experiment was conducted using practical TMR, which were made of 250 g of the untreated straw or one of the treated straws, 600 g maize silage, 200 g rapeseed meal, 250 g barley, and 200 g water on as fed basis. The straw treatments accounted for approximately 18% in the TMR on DM basis (Experiment 2). These TMR variants were then used to determine total tract digestibility of energy, crude nutrients, and detergent fibres in a digestibility trial with sheep (Experiment 3).

Nutrient composition of the straw treatments used in Experiment 1 and the TMR variants used in Experiment 2 and Experiment 3 is given in Table 1. The barley straw treated with NaOH had 0.6 mmol NH3/L extract (50 g straw/400 mL distilled water, 24 h incubation), which is 1.1 g NH3–N/kg total nitrogen, and a pH of 10.0. Urea treated straw had 27.6 mmol NH3/L, 310 g NH3–N/kg total nitrogen, and a pH of 9.1.

Analysis of particle size distribution and physically effective neutral detergent fibre (peNDF8)

For the analysis of particle size distribution of the practical TMR variants, we used a GORR device with a 19- and an 8-mm sieve (GORR GmbH, Eschwege, Germany) similar to the 2-sieve model of the Penn State Particle Separator22. We followed the instructions provided by the Penn State University23 and performed this analysis twice, first using the original “wet” material with five repetitions for each TMR variant, and secondly, using material dried at 60 °C for 24 h with three, three, and two repetitions for the untreated TMR, NaOH treated TMR, and urea treated TMR, respectively. The physical effectiveness factor (pef) of each of the TMR variants was calculated according to Li et al.24 as the proportion of DM retained on the 19- and 8-mm sieves of the separator (pef8). Then, peNDF8 was calculated as pef8 × neutral detergent fibre (aNDFom) content24.

In vitro incubations

Ruminal carbohydrate fermentation was analysed using gas production in an in vitro model based on microbial batch cultures, which were sampled from ruminal fluid. For the batch culture experiments, ruminal fluid was obtained from four rumen-cannulated adult German Blackheaded Mutton wethers. The sheep had free access to tap water. Meadow hay was offered ad libitum and each animal received daily 200 g of a 3 mm-pelleted concentrate (IBEKA PANTO Schäferstolz, HL Hamburger Leistungsfutter GmbH, Hamburg, Germany) and 10 g of a mineral feed preparation (basu-kraft® Top-Mineral; BASU Heimtierspezialitäten GmbH, Bad Sulza, Germany). The sheep had the possibility to ingest straw from the bedding. Dry matter and crude nutrient concentrations of hay and the concentrate are given in Table 2. As declared by the manufacturer, the mineral feed was composed of calcium carbonate, sodium chloride, calcium-sodium phosphate, wheat semolina bran, monocalcium phosphate, and sugar beet molasses and contained 190 g calcium, 40 g phosphor, 110 g sodium, and 35 g magnesium/kg on as fed basis. Additives per kg mineral feed were: 3000 mg zinc (2000 mg zinc oxide 3b603 and 1000 mg zinc sulphate, monohydrate 3b605), 820 mg manganese (700 mg manganese(II) oxide 3b502 and 120 mg manganese(II) sulphate, monohydrate 3b503), 250 mg copper (copper(II) sulphate, pentahydrate 3b405), 50 mg iodine (calcium iodate, water-free 3b202), 25 mg selenium (sodium selenite 3b801), and 10 mg cobalt (coated cobalt(II) carbonate granulate 3b304).

In vitro incubations were carried out using the ANKOM RF Gas Production System (ANKOM Technology, Macedon, NY, USA). Experiment 1 was conducted in May 2021 and Experiment 2 in November 2021. Each experiment comprised four consecutive runs (i.e., four biological replicates). In Experiment 1, the substrates (i.e., pure straw treatments or TMR) were incubated in duplicate and four blanks that contained only ruminal fluid and buffer solution were considered in each run; in Experiment 2, substrates were incubated in triplicate and four blanks were considered (i.e., two or three technical replicates per run; four in case of blanks). The batch culture experiments were carried out in accordance with the protocol of the Association of German Agricultural Analytic and Research Institutes (VDLUFA)25 using method no. 25.1. Ruminal fluid was collected from two of the four wethers immediately before feeding and about 1 h prior to the start of a run. The animals were randomly selected for taking ruminal fluid. The mixed fluid was filtered through a one-layered cheesecloth and stored in a thermos bottle during transport to the laboratory. The buffer solution was adjusted to prolonged incubation times, which means that 2 g NH4HCO3 were added and 2 g NaHCO3/L were reduced compared to the original recipe26. In Experiment 1, the ruminal fluid had a pH of 6.6 ± 0.068, a redox potential of − 264 ± 11.7 mV, and a temperature of 36 ± 0.96 °C when arriving the laboratory. In Experiment 2, the ruminal fluid had a pH of 6.7 ± 0.090, a redox potential of − 264 ± 15.4 mV, and a temperature of 33 ± 2.3 °C. The inoculum was prepared of two parts of the buffer (nutrient solution) and one part of ruminal fluid under stirring and continuous CO2 flush. In Experiment 1, the inoculum had a pH of 6.8 ± 0.031 and a redox potential of − 239 ± 8.63 mV. In Experiment 2, the inoculum had a pH of 6.7 ± 0.055 and a redox potential of − 209 ± 12.7 mV. A quantity of 0.2 g of substrate, pulverised using a ball mill (Retsch MM 400, Retsch GmbH, Haan, Germany), was weighed into the fermenters and 30 mL of inoculum was added using an automated pump. We used glass bottles with an actual volume capacity of 136 ± 2.68 mL, which is approximately a 106 mL headspace volume. The fermenters were capped with gas pressure measuring modules and placed into water baths at 80 r/min agitation and a constant temperature of 39 °C. To purge out oxygen, the fermenters were vented with argon through the modules’ Luer port until the inner pressure exceeded 55 kPa, whereupon the entire gas was automatically released. Gas production was measured using the following settings: at least 5 min recording interval, a 10 kPa threshold for the automatic release of accumulated gas in order to prevent supersaturation in the medium, and a valve open time of 150 ms. The cumulative gas pressures were automatically recorded in real-time and afterwards corrected for blank fermentation and converted first to moles of gas produced using the Ideal Gas Law and then to mL of gas using Avogadro's Law.

The fermenters’ headspace gas was sampled at four periods throughout incubation (between 2 and 3 h, 4 and 5 h, 24 and 25 h, and 48 and 49 h) via the modules’ vent valve using an adapter connected to a 2.5 mL gas-proof syringe (SGE Analytical Science, Trajan Scientific and Medical, Ringwood, Australia). In the syringe, vacuum was created, the module was activated manually, and gas flowed into the syringe. At least 2 mL gas was collected per sample and immediately injected into a Shimadzu GC 2010 Plus (Shimadzu Corp., Kyoto, Japan) fitted with a 250 μL upstream gas loop, a Shin Carbon micro-packed column (Restek Corp., Bellefonte, PA, USA; 2 m × 0.53 mm inner diameter, 80/100 mesh size), and a Barrier Discharge Ionization detector (BID-2010 Plus). Helium was the carrier gas. The following settings were applied: 150 °C injection temperature, split mode with a split ratio of 2, 250 kPa pressure, 45.6 mL/min total flow, 14.2 mL/min column flow, 129.8 cm/s linear velocity, 3 mL/min purge flow, oven temperature programme: 35 °C hold for 2.5 min, 20 °C/min to 180 °C, hold for 0.5 min, 280 °C detector temperature, 50 mL/min discharged flow, and a sampling rate of 40 ms. Peak areas of CO2, CH4, and H2 were corrected for corresponding gas peaks that appeared in the blank fermenters. This was only applicable until the second sampling period.

The IVOMD coefficients were calculated on the basis of gas production measured in the batch cultures and crude nutrient analyses as proposed by Menke and Steingass27 using equation no. 43f., where IVOMD (%) = 14.88 + 0.8893 gas production (mL/200 mg DM) + 0.0448 crude protein (CP) (g/kg DM) + 0.0651 crude ash (CA) (g/kg DM). Note, gas production was measured using the ANKOM RF Gas Production System and not the Hohenheim Gas Test as proposed by Menke and Steingass27. This could have led to small differences in IVOMD estimates.

In vivo determination of energy and nutrient digestibility

Total tract digestibility of TMR including the straw treatments was determined in a digestibility trial. Twelve adult Pomeranian Coarsewool wethers served as model animals. All animals were clinically healthy and under regular veterinary supervision. The digestibility trial was performed following the guidelines of the Society of Nutrition Physiology (GfE)28. The experiment consisted of 14 d adaptation to the diet followed by 6 d of total collection of faeces. Four wethers each received one of the three TMR variants. The animals were randomly assigned to the TMR variants. No inclusion or exclusion criteria were set. Feed bulk samples were collected immediately before the start of the experiment during the weighing of the rations. The sheep additionally received 10 g/day of a mineral feed preparation (basu-kraft® Top-Mineral; BASU Heimtierspezialitäten GmbH, Bad Sulza, Germany) and tap water was offered ad libitum. The actual feeding level of the sheep was 0.80 ± 0.081 times the energy maintenance level (0.43 MJ metabolizable energy, ME/kg body weight0.75/day)28,29. The feeding level was chosen in deviation from the GfE recommendations in order to ensure that the animals leave as little food as possible, which has proven itself in previous trials. The recommended feed protein content for digestibility determination in sheep is a minimum of 120 g CP/kg diet DM28. This was widely achieved in this experiment. The diets were offered in two equal meals per day. During the total collection period, the sheep were individually housed in metabolic cages and were fitted with harnesses to ensure complete faeces collection. The harnesses were emptied each morning prior to the first meal of the day. Daily defecation was quantified and an aliquot of 20% was taken. The quantity of feed residuals was recorded each morning. Feed residuals were minimal 0.13% and maximal 1.9% of the feed quantity that was offered and were considered for digestibility calculations. The faecal samples of each collection day were combined to bulk samples per animal and collection period. Feed and faecal samples were stored dry or were frozen to -20 °C, respectively. The animals were weighed immediately before adaptation, before the collection period, and at the end of the experiment. The initial body weight of the sheep was 64 ± 9.2 kg and remained constant during the experiment (body weight was 61 ± 9.5 kg after adaptation and 62 ± 9.2 kg after the collection period). Digestibility coefficients of DM, organic matter (OM), GE, crude nutrients, and detergent fibres were calculated as (intake—faecal output)/intake over the 6 days of faeces collection for each individual. The determined digestibility coefficients were used to predict digestible energy (DE), and ME and net energy lactation (NEL) concentration of the TMR variants according to GfE29, where ME (MJ/kg DM) = 0.0312 digestible acid ether extract (AEE) + 0.0136 digestible crude fibre (CF) + 0.0147 (digestible OM−digestible AEE−digestible CF) + 0.00234 CP. The concentration of NEL was then calculated as follows: NEL (MJ/kg DM) = 0.6 (1 + 0.004 (q − 57)) ME, where q = (ME/gross energy, GE) × 100. Digestibility coefficients of the detergent fibres were additionally determined using linear regression between intake of indigestible detergent fibre and intake of total detergent fibre and calculated as 1 − b, where b is the slope of the regression line when the function is y = a + bx (x is the explanatory variable, y is the dependent variable, and a is the intercept).

13C solid state NMR and FTIR analysis

13C solid state NMR analysis was performed using a Bruker Avance III HD 300 MHz spectrometer (Bruker Corp., Billerica, MA, USA). A classic (Bruker CP) cross polarization sequence was used at magic angle spinning. The samples were spun in 4-mm zirconia rotors, closed with KeI-F caps, at 12.5 kHz spinning frequency on 4-mm MAS Bruker probe operating. Cross polarization from 1H to 13C was performed using the Bruker CP method, where the contact time was set at 2 ms, the number of scans was 2048, and D1 was 5 s. Spinal-64 heteronuclear decoupling was applied during the 15-ms acquisition time. The decoupling pulse was optimised on a 13C-labelled histidine standard sample and set to 6.4 μs. The NMR data were processed (phase and baseline) by top spin Bruker 4.1.4 software and the spectra are displayed with a line broadening value of 10.

Fourier-transform infrared spectroscopy was acquired using a FTIR ATR Bruker Alpha P spectrometer (Bruker Optics GmbH & Co. KG, Ettlingen, Germany) in the range of 400 to 4000 cm−1. The ATR spectra were collected with a 4 cm−1 resolution and the results were averaged on 64 scans with manual baseline correction and normalisation.

Additional chemical analyses

Feed and faeces samples were freeze-dried and ground to pass a 1 mm sieve of a standard laboratory sample mill. Dry matter, CA, CP, AEE, CF, and detergent fibres were analysed using VDLUFA methods no. 3.1, 4.1.1, 5.1.1 B, 6.1.1, 6.5.1, 6.5.2, 6.5.3, and 8.125. Neutral detergent fibre was pre-treated with heat-stable amylase added to the neutral detergent solution. Neutral detergent fibre and acid detergent fibre (ADFom) were expressed exclusive of residual ash. The concentration of GE was determined by bomb calorimetry using a C7000 Oxygen Bomb Calorimeter (IKA Werke, Staufen, Germany). The proportion of nitrogen-free extract (NFE) was calculated as NFE = 1000−CA−CP−AEE−CF. Hemicellulose, cellulose, and non-fibrous carbohydrates (NFC) concentrations were calculated as follows: Hemicellulose = aNDFom−ADFom, cellulose = ADFom−acid detergent lignin (ADL), and NFC = 1000−(CP + aNDFom + AEE + CA). The pH and redox potentials were measured using a Mettler Toledo Seven Excellence unit with InLab® Expert Pro and InLab® Redox electrodes (Mettler Toledo GmbH, Greifensee, Switzerland). The concentration of NH3 in feed extracts (50 g straw, 400 mL water, and 24 h incubation time) was determined using the method of Conway and Byrne30.

Statistical analysis

Statistical analysis was performed using SAS 9.4 analytical software (SAS Institute Inc., Cary, NY, USA). The gas production data set was scaled down to a 0.5 h resolution and non-linear regression analysis was performed using the MODEL procedure and Gompertz function31. Significant differences in estimated parameters of gas production kinetics among the substrates or treatments were assessed using likelihood ratio 95% confidence intervals. The concentration of peNDF8 as well as the concentrations of CO2, CH4, and H2 were compared among the three TMR variants using the Kruskal–Wallis test with the NPAR1WAY procedure. In the gas components data set, outliers were identified using boxplots and removed. Outliers were defined as observations further than 3 times of the interquartile range. The peNDF8 contents were compared between “wet” and “dry” sieving, and IVOMD and total tract digestibility coefficients were compared among the straw treatments and/or TMR variants using the Wilcoxon Rank Sum test with NPAR1WAY. Differences with p < 0.05 were considered to be significant.

Results and discussion

Energy and nutrient concentrations

The nutrient concentrations of the pure straw treatments and the TMR variants are given in Table 1 and calculated energy concentrations are given in Table 3. Energy and nutrient concentrations are provided as descriptive information and were not subjected to statistical evaluation. However, there were some noticeable changes as a result of straw treatments and trends, which are described in the following. In NaOH treated straw, the concentration of CA increased by 6% points, concentrations of aNDFom and hemicellulose decreased by 13 and 11% points, respectively, the concentration of NFC increased by 6% points, and as a result, DE and ME concentration of the TMR increased by 0.2 MJ/kg DM. An increased CA concentration (here from 72 to 135 g/kg DM) usually reduces OM concentration and the energy density of the straw. The addition of 60 g NaOH/kg straw DM corresponds to a sodium concentration of about 30 g/kg DM32,33, which is a significant increase compared to untreated straw (0.2 g/kg DM)33. After aerobic storage of the straw, a part of sodium is present as NaHCO3, which remains as part of the inorganic residue during incineration and is recorded as CA. Rogers et al.34 and Masters et al.35 reported feed intake depression and declined digestibility as a result of high sodium levels in the rumen and increased osmolality of the ruminal fluid. As part of the practical TMR formulations used in this study (18.2% inclusion on DM basis), NaOH treated straw did not induce a distinct CA increase (just a plus of 1.2% points) and thus, it had no detrimental effect on DE or ME concentration of the diet or on digestibility. In urea treated straw, the CP concentration was higher than in untreated straw (3% points; total nitrogen contained 31% NH3–N). This TMR with 18.2% urea treated straw with 40 g urea/kg straw (i.e., 18.4 g nitrogen/kg straw with 46% nitrogen in the urea) and 141 g CP/kg DM (i.e., 22.6 g nitrogen), contained 14.8% nitrogen from urea, measured against the total nitrogen in the ration. Thus, this TMR was in a range where the supplemental nitrogen source may have had a positive effect on microbial growth in the rumen and microbial protein and fatty acid synthesis, as well as on the digestibility of DM, OM, detergent fibres, and CP36,37,38. However, urea concentrations significantly higher than this would burden the liver metabolism, through which excess NH3 has to be detoxified, and lead to increased nitrogen excretion via the urine39. Urea treatment of the straw did also decrease ADL concentration of the TMR by 10% points and the DE and ME concentration by 0.5 and 0.1 MJ/kg DM, respectively. The results are consistent with previous reports40,41.

Particle size distribution and peNDF8

Particle size distribution of the as fed TMR variants is illustrated in Fig. 1. In the TMR containing untreated straw, 2 ± 0.5% of particles were retained on the upper sieve of the separator (19 mm), 31 ± 1.4% on the middle sieve (8 mm), and 67 ± 1.8% were smaller than 8 mm and found on the bottom pan, in the TMR containing NaOH treated straw, 8 ± 5% of particles were larger than 19 mm, 31 ± 2.4% were between 19 and 8 mm, and 61 ± 2.9% were smaller than 8 mm, and in the TMR containing urea treated straw, 17 ± 5.0% were retained on the upper sieve, 22 ± 3.5% on the middle sieve, and 61 ± 1.9% of particles laid on the bottom pan. Then, pef8 and peNDF8 were 0.33 ± 0.018 and 124 ± 6.66 g/kg DM in the TMR with untreated straw, 0.39 ± 0.029 and 153 ± 11.4 g/kg DM in the TMR with NaOH treated straw, and 0.39 ± 0.019 and 156 ± 7.47 g/kg DM in the TMR with urea treated straw, respectively. The peNDF8 of TMR significantly increased in the variants containing NaOH or urea treated straw (p < 0.01). The 19- and 8-mm sieves retain particles from the diet which are buoyant in the rumen, form the forage mat, substantially support rumination and pH regulation (prevention of acidosis), and promote fibre digestion23,42. On that basis, the diet’s peNDF8 concentration is a key factor maintaining physiological ruminal function42. In dairy cows, peNDF8 should have a proportion of 15–18% in the diet on a DM basis, when starch is between 20 and 25% and NFC are between 35 and 40%43. The higher content of peNDF8 in the TMR with treated straws was mainly due to an accumulation of large particles retained by the 19-mm sieve. To clear up if this could be a result of remoistening during processing in the feed mixer, we performed the analysis a second time using dried materials (dried at 60 °C for 24 h; 967 ± 29.0 g DM, 995 ± 0.509 g DM, and 978 ± 29.9 g DM/kg in untreated, NaOH treated, and urea treated straw TMR, respectively). In the dried TMR, peNDF8 was 95 ± 3.9 g/kg (untreated), 130 ± 25.9 g/kg (NaOH treated), and 113 ± 14.6 g/kg (urea treated). This was consistently lower than with “wet” sieving (p < 0.05 for the untreated TMR, p > 0.05 for the treatments). Among the dried TMR variants, peNDF8 contents did not significantly differ, but showed a clear trend to an increase after treatment. There was no indication of a relevant remoistening effect, but alkaline treatment in the feed mixer could have led to swelling of fibre structures (e.g., cellulose)44 and particle agglomeration, which was not reversed after drying.

Illustration of particle size distribution of as fed “wet” TMR composed of 33.5% maize silage, 21.6% rapeseed meal, 26.7% barley grains, and 18.2% of untreated, NaOH treated, or urea treated barley straw on dry matter basis using the method described by Lammers et al.22 and Heinrichs and Jones23. TMR, total mixed ration.

In vitro carbohydrate fermentation—gas production and composition

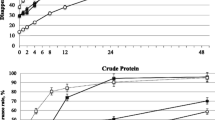

Estimated parameters of gas production kinetics and goodness of fit indicators are summarized in Table 4 and the curves are illustrated in Fig. 2a–c. In Experiment 1, the asymptote of gas production from fermentation of untreated barley straw was at 105 mL/g DM and it lasted about 17 h to achieve one-third and 33 h to achieve two-third of the maximal gas production. This is within the range of gas production profiles obtained from incubations of barley straw during a ring test45. Gas production was significantly increased in NaOH and urea treatments (p < 0.05) and fermentation was decelerated (p < 0.05). This was more distinct in NaOH than in urea treated straw (p < 0.05). Previous studies have shown that alkaline treatments of straw are able to break down hemicellulose-lignin and lignocellulose bonds, hydrolyse uronic and acetic acid esters, and disrupt cellulose crystallinity, leading to improved degradation of hemicelluloses and cellulose13,14,46,47 and this is reflected by increased gas production as a direct measure of microbial activity48. In the TMR that contained untreated straw by 10% of lucerne chaff, gas production profiles did not differ from that of the basal TMR. Addition of straw by 20% of lucerne chaff increased the gas production asymptote (p < 0.05). In the TMR that contained NaOH treated straw by 10% of lucerne chaff, gas production increased compared to the TMR with untreated straw at the 10% level (p < 0.05). With a 20% replacement, however, gas production did not differ. The duration of TMR fermentation was barely affected with the NaOH straw treatment. Replacement of lucerne chaff by 10% urea treated straw distinctly increased gas production and hastened fermentation (p < 0.05). A further 10% point plus of urea treated straw, however, decreased gas production and deferred fermentation of the TMR (p < 0.05). This could have been the result of an asynchronous supply of nitrogen and energy at the beginning of the fermentation period due to excess nitrogen in the system. However, the microorganisms in the batch culture actually recover quickly—within approximately 12 h49. In vitro incubation of practical TMR revealed that inclusion of NaOH treated straw increased the gas production asymptote compared to TMR with an untreated straw component (p < 0.05; Table 4, Fig. 2c). Gas production decreased by inclusion of urea treated straw (p < 0.05; Table 4, Fig. 2c). With both treatments, gas production was decelerated (p < 0.05; Table 4). However, on the TMR level, these changes are not relevant from a practical point of view.

Gas production profiles from incubation of pure straw treatments (a), a model TMR composed of 45% barley grains, 2% soybean meal, and 53% lucerne chaff and model TMR including the straw treatments with 10 or 20% of the proportion of lucerne chaff (Experiment 1) (b), and practical TMR composed of 33.5% maize silage, 21.6% rapeseed meal, 26.7% barley grains, and 18.2% of one of the straw treatments on DM basis in the in vitro batch culture system (Experiment 2) (c). Linear relationship between digestible OM and digestible aNDFom concentration of the practical TMR (Experiment 3) (d). Linear regression between intake, by sheep, of indigestible detergent fibre and intake of total detergent fibre from the practical TMR (Experiment 3) (e). Legend: (a, c)  untreated straw,

untreated straw,  NaOH treated straw,

NaOH treated straw,  urea treated straw; (b)

urea treated straw; (b)  basal TMR,

basal TMR,  untreated straw (10%),

untreated straw (10%),  untreated straw (20%),

untreated straw (20%),  NaOH treated straw (10%),

NaOH treated straw (10%),  NaOH treated straw (20%),

NaOH treated straw (20%),  urea treated straw (10%),

urea treated straw (10%),  urea treated straw (20%). The straw treatments and conducted experiments are specified in the text. ADFom, acid detergent fibre expressed exclusive of residual ash, ADL, acid detergent lignin; aNDFom, amylase-treated neutral detergent fibre expressed exclusive of residual ash; DM, dry matter; OM, organic matter; TMR, total mixed ration.

urea treated straw (20%). The straw treatments and conducted experiments are specified in the text. ADFom, acid detergent fibre expressed exclusive of residual ash, ADL, acid detergent lignin; aNDFom, amylase-treated neutral detergent fibre expressed exclusive of residual ash; DM, dry matter; OM, organic matter; TMR, total mixed ration.

Concentrations of CH4 and CO2 increased with incubation time. In the TMR including untreated straw, 0.6 ± 0.02% CH4 and 0.9 ± 0.07% CO2 were found in the headspace gas after around 2 h, 1.1 ± 0.67% CH4 and 1.7 ± 1.2% CO2 were found after 4 h, 3.0 ± 2.1% CH4 and 12.5 ± 8.27% CO2 were found after 24 h, and 5.3 ± 0.52% CH4 and 16.5 ± 0.347% CO2 were found after 48 h of incubation. The concentration of gaseous H2 was consistently lower than 0.01%. We have no information about the concomitant concentration of H2 dissolved in the inoculum, but it could have been many times higher, because in in vitro systems, gaseous and dissolved H2 are not necessarily in equilibrium50. No differences in gas composition were detected between the incubated TMR including NaOH or urea treated straw, or in comparison to the untreated variant.

Energy and nutrient digestibility

The IVOMD coefficients provided in Table 5 indicate the theoretical digestibility after feed passage through the rumen and are calculated on the basis of gas production and crude nutrient analyses27. In the pure straws (Experiment 1), NaOH and urea treatments increased IVOMD by 20% points (p < 0.05) and 10% points (p > 0.05), respectively. As part of the TMR (Experiment 2), however, treated straw did not affect IVOMD.

Total tract DM, OM, energy, crude nutrient, and detergent fibre digestibility coefficients are shown in Table 6 and were widely within the range reported by previous studies using different kinds of straws and different levels of inclusion into a TMR51,52,53,54. Total tract digestibility was generally highest in the TMR containing NaOH treated straw. The digestibility of aNDFom, ADFom, and hemicellulose of the TMR containing NaOH treated straw increased by approximately 10% points compared to the untreated straw TMR variant (p < 0.05). A 9% points plus in digestibility was found for cellulose (p = 0.057). The increase in OM digestibility was less pronounced than the increase in fibre digestibility, although there was no reduction in digestibility of any other crude nutrient. Nevertheless, a clear linear relationship between the proportion of digestible OM and the proportion of digestible aNDFom (as an example digestible fibre fraction) was confirmed (Fig. 2d). The release and degradation of hemicelluloses and cellulose following NaOH treatment led to improved energy, OM, and fibre digestibility also in previous studies16,17,20,47,54,55. The inclusion of urea treated straw did not notably affect digestibility of energy, ash, OM, nutrients, or fibres in the TMR (Table 6) and this confirms reports that urea is not as much effective as NaOH can be32,54. The level of inclusion of treated straw into the diet is crucial for successful application, because more than 30% of alkaline treated straw in a TMR on DM basis may lead to intake depression and body weight decline56.

Linear regression analysis was performed between intake of indigestible detergent fibre and intake of total detergent fibre (Fig. 2e). Then, digestibility, calculated as 1 − b, of aNDFom was 0.68, 0.74, and 0.79, digestibility of ADFom was 0.58, 0.57, and 0.65, and digestibility of ADL was 0.02, 0.13, and 0.08 in TMR composed with untreated straw, NaOH treated straw, and urea treated straw, respectively. The results of this regression analysis can be interpreted as the true digestibility coefficients of the fibre fractions57. They may differ from the apparent digestibility coefficients we obtained from the digestibility trial, however, notable endogenous losses of fibrous carbohydrates are not to expect. The number of available data points, their distribution, and range are decisive for the reliability of the regression approach and must be critically examined in the present case.

13C NMR and FTIR spectra

To clear up the observed effects of NaOH or urea treatment of straws on ruminal carbohydrate fermentation and on digestibility of fibres, samples of the straw treatments were subjected to 13C solid state NMR and FTIR spectroscopy. 13C NMR and FTIR analyses were performed using representative bulk samples of the TMR variants. The results of these analyses clearly indicate how the treatment of straw with NaOH or urea works at the molecular level, but are descriptive and do not yet allow statistically reliable statements.

Figure 3a shows the 13C NMR spectra for untreated barley straw in comparison to the treatments. The global structure of the carbohydrates (cellulose and hemicellulose) was not altered by treatment. There was no significant variation of the signals, which shows that no hydrolysis of these carbohydrates occurred. There was further no signal broadening observed for the carbohydrates showing that no variation in the ordered structure (crystallinity) had been induced. Variation in lignin structure was not clearly observed. This shows that no important depolymerisation of lignin occurred, which is especially related to ether β-O-4 linkages attributed to syringyl units (at 153 ppm). Signals of OCH3 regions at 56.2 ppm and aromatic components at 153–106 ppm did not show any significant variation indicating that also lignin content was not affected by treatment. The signal of methyl carbons at 20 ppm is attributed to methyl carbons in the acetyl groups of hemicelluloses and this signal was significantly modified by the treatments. Hydrolysis of the acetyl groups during treatment leads to the removal of acetic acid. This confirms Ternrud et al.47, who supposed removal of acetyl groups as one major effect of alkaline straw treatment. The acetates signal at 172 ppm was significantly affected as well (Fig. 3a). This signal could be assigned to linkages between ferulic acids and hemicelluloses (arabinoxylans) described as 8–5’ linkages between ferulic acid and guaiacyl58. Ferulates cross-link arabinoxylans and are an important factor in lignification of cell walls59. The removal of methyl and acetate groups by NaOH treatment is generally consistent with previous results60.

13C nuclear magnetic resonance (NMR) (a) and Fourier-transform infrared (FTIR) spectra (b) of untreated, NaOH treated, and urea treated barley straw. Straw treatments are specified in the text. The band assignments for FTIR spectra (peaks 1–14) are given in Table 7. FA, ferulic acid.

The FTIR spectra of the TMR including untreated barley straw, NaOH treated, or urea treated straw, respectively, are shown in Fig. 3b. The peak assignments are presented in Table 7. The frequencies corresponding to functional groups of lignin, hemicelluloses, and cellulose have been assigned. The position and shape of the OH group did not change significantly, which means that intermolecular interactions between functional group compounds remained intact61. The peaks at 2920 and 2840 cm−1 correspond to C–H stretching of methyl and methylene62. The peak at 1730 cm−1 was assigned to C=O stretching from unconjugated ketone, carbonyl, and ester groups of carbohydrate origin63. The peak at 1595 cm−1 is characteristic for aromatic rings and is the result of vibrations of the aromatic skeleton64. Wavenumbers between 800 and 1440 cm−1 were attributed to bonds present in multiple plant cell wall polymers65. In this region, absorption bands result from multiple bond type vibrations62,65,66, specified as follows: 1440 cm−1: O–H plane bending, 1420 cm−1: C–H plane deformation in lignin, 1370 cm−1: —C–H bending in wood, 1320 cm−1: C–O syringyl ring and CH2 wagging, 1240 cm−1: conjugated ketone (phenyl-carbonyl) in lignin, 1160 cm−1: C–O–C asymmetrical stretching in cellulose and hemicelluloses, 1030 cm−1: C–O, C=C, and C–C–O stretching in wood, and 890 cm−1: glycosidic linkage. The main differences between the three FTIR spectra were dedicated to peaks number 4 (1730 cm−1) and number 11 (1240 cm−1). Peak number 4 disappeared after treatment of straw suggesting that some hemicelluloses or lignin related compounds have been removed67. The disappearance of the lignin peak at 1240 cm−1 could be due to conjugated ketone (phenyl-carbonyl) removal (lignin that is wrapping the surface of cellulose fibres). Furthermore, this peak disappearance could be due to a ferulic and p-coumaric acid acetyl group removal67. This observation agreed with the results obtained from 13C solid state NMR analysis.

It is very likely that ferulic acid, p-coumaric acid, and possibly other hydroxycinnamic acids are then present in a free, dissolved form68,69. In the forestomach system of ruminants, hydroxycinnamic acids can be metabolised if they are still esterified or etherified (bound) in plant cell wall fragments70,71,72. However, if there is a larger proportion of dissolved phenolic conjugates after straw treatment, these are probably metabolised more quickly and with priority by rumen microorganisms. Ingested phenolics initially undergo rapid hydrogenation and dehydroxylation, resulting in 3-phenylpropionic acid70. This is absorbed and metabolised to benzoic acid by β-oxidation in the liver, or is metabolised via cinnamic acid to cinnamoylglycine and renally excreted in this form70,73. Benzoic acid is largely—to approximately 75–95%—excreted renally as hippuric acid70. Hippuric acid contributes significantly to the renal energy losses in ruminants (0.30 MJ/g renal nitrogen; for comparison: 0.023 MJ/g renal nitrogen from urea), which are 0.33–0.84 MJ/L and thus high per se74. A forced release of phenolic compounds through pre-digestion of the straw component in the diet could then have a detrimental effect on the energy balance of the animals.

Conclusions

Since cereal straws are available in sufficient quantities even when forage is scarce, they offer an important additional source of fibre and, if treated correctly, potentially also an additional source of energy for the nutrition of ruminants. Treatment of straw with NaOH or feed-grade urea can be practicably and safely carried out on farm. Both treatment methods probably led to a release of fermentable cell wall components (hemicelluloses, cellulose, and phenolic acids) from lignin-associated bonds. As a result, straw fibre seems to be fermented more effectively in the rumen and may contribute to the energy supply of the animal. However, the amount of straw in general and the amount of treated straw used in a TMR must be calculated in such a way that there is no decline in feed intake or digestibility. This has to be considered especially with NaOH treated straw, since sodium from added NaOH accumulates in the form of NaHCO3 and increases the CA content significantly. An increased CA content then reduces energy density. Digestibility of fibre fractions increased by 10% points in a TMR containing NaOH treated straw. The concentrations of DE, ME, and NEL increased by 0.2 MJ/kg DM. Urea treatment did not affect digestibility or NEL concentration of the TMR, but decreased the concentration of DE and ME by 0.5 and 0.1 MJ/kg DM, respectively. Another fact that needs to be considered is that metabolites from free phenolics such as ferulic acid and p-coumaric acid released by treatment could possibly increase metabolic energy losses when excreted with the urine.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Hänsel, S., Ustrnul, Z., Łupikasza, E. & Skalak, P. Assessing seasonal drought variations and trends over Central Europe. Adv. Water Res. 127, 53–75 (2019).

Lorenz, R., Stalhandske, Z. & Fischer, E. Detection of a climate change signal in extreme heat, heat stress, and cold in Europe from observations. Geophys. Res. Let. 46, 8363–8374 (2019).

Pfleiderer, P., Schleussner, C. F., Kornhuber, K. & Coumou, D. Summer weather becomes more persistent in a 2°C world. Nat. Climate Change 9, 666–671 (2019).

Zhao, C., Brissette, F., Chen, J. & Martel, J. L. Frequency change of future extreme summer meteorological and hydrological droughts over North America. J. Hydrol. 584, 124316. https://doi.org/10.1016/j.jhydrol.2019.124316 (2020).

Koike, S. & Kobayashi, Y. Fibrolytic rumen bacteria: Their ecology and functions. Asian Aust. J. Anim. Sci. 22, 131–138 (2009).

Schader, C. et al. Impacts of feeding less food-competing feedstuffs to livestock on global food system sustainability. J. R. Soc. Interface 12, 20150891. https://doi.org/10.1098/rsif.2015.0891 (2015).

Gauder, M., Graeff-Hönninger, S. & Claupein, W. Identifying the regional straw potential for energetic use on the basis of statistical information. Biomass Bioenergy 35, 1646–1654 (2011).

FAO. FAOSTAT Statistical database. https://www.fao.org/faostat/en/#data/QCL (2022).

Bagby, M., Nelson, G., Helman, E. & Clark, T. Determination of lignin in non-wood plant fiber sources. J. Technol. Assoc. Pulp Paper Ind. 54, 1876–1878 (1971).

Jung, H. G. Forage lignins and their effects on fiber digestibility. Agronomy J. 81, 33–38 (1989).

Sun, J. X., Xu, F., Sun, X. F., Xiao, B. & Sun, R. C. Physico-chemical and thermal characterization of cellulose from barley straw. Polym. Degr. Stab. 88, 521–531 (2005).

Buranov, A. U. & Mazza, G. Lignin in straw of herbaceous crops. Ind. Crops Prod. 28, 237–259 (2008).

Adesogan, A. T. et al. Symposium review: technologies for improving fiber utilization. J. Dairy Sci. 102, 5726–5755 (2019).

Jung, H. G. & Deetz, D. A. Cell wall lignification and degradability. In Forage Cell Wall Structure and Digestibility (eds. Jung, H. G., Buxton, D. R., Hatfield, R. D. & Ralph, J.) 315–346 (ASA, CSSA, and SSSA Books, 1993).

Flachowsky, G. Physical, chemical and biological methods of straw treatment and options for practical use. Wiss. Zeits. Karl-Marx-Univ. Leipzig 36, 232–247 (1987).

Higgins, A. J. The effect of a sodium hydroxide spray treatment on digestibility of barley straw in sheep and goats. Agric. Wastes 3, 145–155 (1981).

Schneider, M., Richter, G. & Flachowsky, G. Feed value of wheat straw treated with NH3 gas. Wiss. Zeits. Karl-Marx-Univ. Leipzig 36, 248–253 (1987).

Ochrimenko, W. I., Flachowsky, G., Richter, G., Löhnert, H. J. & Hennig, A. Conservation of moist straw with urea and its use in feeding. Wiss. Zeits. Karl-Marx-Univ. Leipzig 36, 260–266 (1987).

Owen, E., Smith, T. & Makkar, H. Successes and failures with animal nutrition practices and technologies in developing countries: A synthesis of an FAO e-conference. Anim. Feed Sci. Technol. 174, 211–226 (2012).

Wanapat, M., Sundstøl, F. & Garmo, T. H. A comparison of alkali treatment methods to improve the nutritive value of straw, I: Digestibility and metabolizability. Anim. Feed Sci. Technol. 12, 295–309 (1985).

Ørskov, E. R., Stewart, C. S. & Greenhalgh, J. F. D. The effect of sodium hydroxide and urea on some storage properties of moist grain. J. Agric. Sci. 92, 185–188 (1979).

Lammers, B. P., Buckmaster, D. R. & Heinrichs, A. J. A simple method for the analysis of particle sizes of forage and total mixed rations. J. Dairy Sci. 79, 922–928 (1996).

Heinrichs, A. J. & Jones, C. M. Penn State Particle Separator. https://extension.psu.edu/penn-state-particle-separator (2016).

Li, C., Beauchemin, K. A. & Yang, W. Feeding diets varying in forage proportion and particle length to lactating dairy cows, I: Effects on ruminal pH and fermentation, microbial protein synthesis, digestibility, and milk production. J. Dairy Sci. 103, 4340–4354 (2020).

VDLUFA. Methodenbuch 3rd edn. (VDLUFA-Verlag, 2012).

Edmunds, B., Südekum, K. H., Spiekers, H., Schuster, M. & Schwarz, F. J. Estimating utilisable crude protein at the duodenum, a precursor to metabolisable crude protein for ruminants, from forages using a modified gas test. Anim. Feed Sci. Technol. 175, 106–113 (2012).

Menke, K. H. & Steingass, H. Estimation of the energetic feed value obtained from chemical analysis and in vitro gas production using rumen fluid. Anim. Res. Dev. 28, 7–55 (1988).

GfE. Leitlinien für die Bestimmung der Verdaulichkeit von Rohnährstoffen an Wiederkäuern. J. Anim. Physiol. Anim. Nutr. 65, 229–234 (1991).

GfE. Empfehlungen zur Energie- und Nährstoffversorgung der Milchkühe und Aufzuchtrinder (DLG-Verlag, 2001).

Conway, E. J. & Byrne, A. An absorption apparatus for the micro-determination of certain volatile substances: The micro-determination of ammonia. Biochem. J. 27, 419–429 (1933).

Dhanoa, M. et al. Estimating the extent of degradation of ruminant feeds from a description of their gas production profiles observed in vitro: Comparison of models. Br. J. Nutr. 83, 131–142 (2000).

Block, H. J. et al. Untersuchungen zum Feuchtstrohaufschluss von Stroh mit Natronlauge. 1. Mitteilung. Arch. Anim. Nutr. 35, 61–80 (1985).

Wildner, V. Untersuchungen zum Strohaufschluss für die Wiederkäuerernährung durch chemische und biologische Verfahren, Master Thesis (2020).

Rogers, J. A., Marks, B. C., Davis, C. L. & Clark, J. H. Alteration of rumen fermentation in steers by increasing rumen fluid dilution rate with mineral salts. J. Dairy Sci. 62, 1599–1605 (1979).

Masters, D. G., Rintoul, A. J., Dynes, R. A., Pearce, K. L. & Norman, H. C. Feed intake and production in sheep fed diets high in sodium and potassium. Aust. J. Agr. Res. 56, 427–434 (2005).

Wanapat, M. & Pimpa, O. Effect of ruminal NH3–N levels on ruminal fermentation, purine derivatives, digestibility and rice straw intake in swamp buffaloes. Asian Aust. J. Anim. Sci. 12, 904–907 (1999).

Satter, L. D. & Slyter, L. L. Effect of ammonia concentration on rumen microbial protein production in vitro. Br. J. Nutr. 32, 199–208 (1974).

Kanjanapruthipong, J. & Leng, R. A. The effects of dietary urea on microbial populations in the rumen of sheep. Asian Aus. J. Anim. Sci. 11, 661–672 (1998).

Getahun, D., Alemneh, T., Akeberegn, D., Getabalew, M. & Zewdie, D. Urea metabolism and recycling in ruminants. Biomed. J. Sci. Tech. Res. 20, 14790–14796 (2019).

Zaman, M. S. & Owen, E. The effect of calcium hydroxide and urea treatment of barley straw on chemical composition and digestibility in vitro. Anim. Feed Sci. Technol. 51, 165–171 (1995).

Madrid, J., Hernández, F., Pulgar, M. A. & Cid, J. M. In vivo digestibility of treated and untreated barley straw: Results of direct and by-difference digestibility trials. Anim. Feed Sci. Technol. 65, 129–138 (1997).

Zebeli, Q., Mansmann, D., Ametaj, B. N., Steingaß, H. & Drochner, W. A model to optimise the requirements of lactating dairy cows for physically effective neutral detergent fibre. Arch. Anim. Nutr. 64, 265–278 (2010).

Khorrami, B., Khiaosa-ard, R. & Zebeli, Q. Models to predict the risk of subacute ruminal acidosis in dairy cows based on dietary and cow factors: A meta-analysis. J. Dairy Sci. 104, 7761–7780 (2021).

Wang, Y., Zhao, Y. & Deng, Y. Effect of enzymatic treatment on cotton fiber dissolution in NaOH/urea solution at cold temperature. Carbohydr. Polym. 72, 178–184 (2008).

Cornou, C. et al. A ring test of a wireless in vitro gas production system. Anim. Prod. Sci. 53, 585–592 (2013).

Sun, R., Lawther, J. M. & Banks, W. B. Influence of alkaline pre-treatments on the cell wall components of wheat straw. Ind. Crops Prod. 4, 127–145 (1995).

Ternrud, I. E., Lindberg, J. E. & Theander, O. Continuous changes in straw carbohydrate digestion and composition along the gastrointestinal tract of ruminants. J. Sci. Food Agric. 41, 315–324 (1987).

Liu, J. X., Susenbeth, A. & Südekum, K. H. In vitro gas production measurements to evaluate interactions between untreated and chemically treated rice straws, grass hay, and mulberry leaves. J. Anim. Sci. 80, 517–524 (2002).

Newbold, J. R. & Rust, S. R. Effect of asynchronous nitrogen and energy supply on growth of ruminal bacteria in batch culture. J. Anim. Sci. 70, 538–546 (1992).

Wang, M., Sun, X. Z., Janssen, P. H., Tang, S. X. & Tan, Z. L. Responses of methane production and fermentation pathways to the increased dissolved hydrogen concentration generated by eight substrates in in vitro ruminal cultures. Anim. Feed Sci. Technol. 194, 1–11 (2014).

Mazzenga, A., Gianesella, M., Brscic, M. & Cozzi, G. Feeding behaviour, diet digestibility, rumen fluid and metabolic parameters of beef cattle fed total mixed rations with a stepped substitution of wheat straw with maize silage. Livest. Sci. 122, 16–23 (2009).

Jami, E. et al. Effects of including NaOH-treated corn straw as a substitute for wheat hay in the ration of lactating cows on performance, digestibility, and rumen microbial profile. J. Dairy Sci. 97, 1623–1633 (2014).

Eastridge, M. L. et al. Dairy cows fed equivalent concentrations of forage neutral detergent fiber from corn silage, alfalfa hay, wheat straw, and corn stover had similar milk yield and total tract digestibility. Anim. Feed Sci. Technol. 225, 81–86 (2017).

Stehr, K. R. et al. Effect of replacing barley silage with calcium oxide-treated barley straw on rumen fermentation, rumen microbiota, nutrient digestibility, and growth performance of finishing beef cattle. Can. J. Anim. Sci. 101, 493–506 (2021).

Haddad, S. G., Grant, R. J. & Klopfenstein, T. J. Digestibility of alkali-treated wheat straw measured in vitro or in vivo using Holstein heifers. J. Anim. Sci. 72, 3258–3265 (1994).

Haddad, S. G., Grant, R. J. & Kachman, S. D. Effect of wheat straw treated with alkali on ruminal function and lactational performance of dairy cows. J. Dairy Sci. 81, 1956–1965 (1998).

Mertens, D. R. Predicting intake and digestibility using mathematical models of ruminal function. J. Anim. Sci. 64, 1548–1558 (1987).

Ralph, J., Grabber, J. H. & Hatfield, R. D. Lignin-ferulate cross-links in grasses: active incorporation of ferulate polysaccharide esters into ryegrass lignins. Carbohyd. Res. 275, 167–178 (1995).

Hatfield, R. D., Rancour, D. M. & Marita, J. M. Grass cell walls: a story of cross-linking. Front. Plant Sci. https://doi.org/10.3389/fpls.2016.02056 (2017).

Do Espirito Santo, M. C. et al. When the order matters: impacts of lignin removal and xylan conformation on the physical structure and enzymatic hydrolysis of sugarcane bagasse. Ind. Crop. Prod. 180, 114708 (2022).

Mamilla, J. L. K., Novak, U., Grilc, M. & Likozar, B. Natural deep eutectic solvents (DES) for fractionation of waste lignocellulosic biomass and its cascade conversion to value-added bio-based chemicals. Biomass Bioenergy 120, 417–425 (2019).

Bahng, M. K., Donohoe, B. S. & Nimlos, M. R. Application of an Fourier transform-infrared imaging tool for measuring temperature or reaction profiles in pyrolyzed wood. Energy Fuels 25, 370–378 (2011).

Faix, O. Classification of lignins from different botanical origins by FT-IR spectroscopy. Holzforschung 45, 21–27 (1991).

Nada, A. A. M. A., El-Sakhawy, M. & Kamel, S. M. Infra-red spectroscopic study of lignins. Polymer Degr. Stab. 60, 247–251 (1998).

Sills, D. L. Enzymatic hydrolysis of alkaline pretreated biomasses: Assessment of commercial hemicellulase mixtures and the use of FTIR spectroscopy to predict saccharification. PhD Thesis, Cornell University (2011).

Xu, F., Yu, J., Tesso, T., Dowell, F. & Wang, D. Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: A mini-review. Appl. Eng. 104, 801–809 (2013).

Zaini, N. A. B. M., Chatzifragkou, A. & Charalampopoulos, D. Alkaline fractionation and enzymatic saccharification of wheat dried distillers’ grains with solubles (DDGS). Food Bioprod. Process. 118, 103–113 (2019).

Wang, Y., Spratling, B. M., ZoBell, D. R., Wiedmeier, R. D. & McAllister, T. A. Effect of alkali pretreatment of wheat straw on the efficacy of exogenous fibrolytic enzymes. J. Anim. Sci. 82, 198–208 (2004).

Linh, T. N., Fujita, H. & Sakoda, A. Release kinetics of esterified p-coumaric acid and ferulic acid from rice straw in mild alkaline solution. Biores. Technol. 232, 192–203 (2017).

Chesson, A. et al. Hydroxycinnamic acids in the digestive tract of livestock and humans. J. Sci. Food Agric. 79, 373–378 (1999).

Cao, B. B., Wang, R., Bo, Y. K., Bai, S. & Yang, H. J. In situ rumen digestibility of ester-linked ferulic and p-coumaric acids in crop stover or straws in comparison with alfalfa and Chinese wild ryegrass hays. Anim. Feed Sci. Technol. 212, 27–34 (2016).

Wang, Y. L., Wang, W. K., Wu, Q. C. & Yang, H. J. The release and catabolism of ferulic acid in plant cell wall by rumen microbes: A review. Anim. Nutr. 9, 335–344 (2022).

Lowry, J. B., Sumpter, E. A., McSweeney, C. S., Schlink, A. C. & Bowden, B. Phenolic acids in the fibre of some tropical grasses, effect on feed quality, and their metabolism by sheep. Aust. J. Agric. Res. 44, 1123–1133 (1993).

Nehring, K. Lehrbuch der Tierernährung und Futtermittelkunde 9th ed. (Neumann-Neudamm, 1972).

Barman, D. N. et al. Alkali pretreatment of wheat straw (Triticum aestivum) at boiling temperature for producing a bioethanol precursor. Biosci. Biotechnol. Biochem. 76, 2201–2207 (2012).

Acknowledgements

The authors would like to thank the State of Saxony for the financial support within the project “Ruminant Nutrition in Times of Feed Scarcity”.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

M.B., S.D.M., O.S., and A.Z. conceptualized the study. Main investigation and formal analysis were performed by M.B., Y.LeB., G.K., R.B., and S.D.M. O.S. and A.Z. were responsible for funding acquisition. Resources were provided by Y.LeB., G.K., and A.Z. Visualization and writing of the original manuscript draft were performed by M.B. and Y.LeB. Review and editing of the manuscript were performed by M.B., Y.LeB., G.K., S.D.M., O.S., and A.Z.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bachmann, M., Martens, S.D., Le Brech, Y. et al. Physicochemical characterisation of barley straw treated with sodium hydroxide or urea and its digestibility and in vitro fermentability in ruminants. Sci Rep 12, 20530 (2022). https://doi.org/10.1038/s41598-022-24738-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-24738-w

- Springer Nature Limited

This article is cited by

-

Study on the characteristics of H2 and CH4 production by bio-fermentation from sorghum straw pretreated with NaOH

Biomass Conversion and Biorefinery (2024)

-

Enzymatic valorization of alkali-treated chickpea straw and sunflower stalks as high fibrous agricultural wastes for sustainable ruminant nutrition

Biomass Conversion and Biorefinery (2023)