Abstract

The special report of the Intergovernmental Panel on Climate Change’s (IPCC) on global warming of 1.5 °C marks a critical point in climate negotiations, which emphasizes the importance to control the CO2 level in the atmosphere. The current technology cluster of CO2 capture is still energy-intensive which results in a substantial increase in costs, thus the efficient conversion among various forms of energy is the major topic of research. Considering that most of the existing research are primarily based on the viewpoint of energy conservation on a specific case study, the results thus could not be efficiently generalized as a condensed mechanism of energy dissipation. In this work, the entropy generation evaluation of a 4-step temperature swing adsorption (TSA) process was presented as a sample. The values and contribution distributions of various entropy generation in the thermodynamic cycle were calculated to evaluate the major energy dissipation. The results on contribution distribution of entropy generation and heat required were compared, the entropy generation distribution contributed by heat transfer decreases from 63.27% to 53.72% with internal heat recovery (IHR) method integrated. Thus the entropy generation saving potential of IHR method could be proved.

Similar content being viewed by others

Introduction

The Special Report on Global Warming of 1.5 °C has been released by the Intergovernmental Panel on Climate Change (IPCC) on 8th October 2018, which has modeling that the Global net human-caused emissions of CO2 would need to fall by about 45 percent from 2010 levels by 2030, reaching net zero around 20501. It is obvious that the development of carbon capture technology would be needed to control the CO2 level in the atmosphere. Carbon capture could be executed with the application of three methods: a. Pre-Combustion Carbon Capture, b. Oxy-Combustion Carbon Capture and c. Post-Combustion Carbon Capture2, in which the Post-Combustion Carbon Capture has caught a lot of attention for that could be integrated with existing power plants.

A series of post-combustion technologies have been researched which include absorption, adsorption, membrane separation and so on, in which the absorption of CO2 by mature aqueous monoethanolamine (MEA) has been widely applied in demonstration project. But even for MEA absorption technology, the commercial utilization of which is still restricted by high energy consumption. Thus the concept of the thermodynamic cycle has been applied in MEA absorption research, which primarily focuses on the energy efficiency to confront with the energy-consumption problem3. And classic thermodynamic concepts such as COP and energy conversion efficiency have also been applied in the thermodynamic research on absorption technology4, compared the results of which with that in the ref.5, it could be found out that the energy consumption of absorption and adsorption are in the same level. This kind of method has also been applied in adsorption technology, Zhang6 has researched on the thermal energy required for regeneration of CO2-rich adsorbents, and concluded that the energy required can be greatly reduced by replacing the MEA technology with amine-based solid adsorbents capturing systems, due to the much lower heat capacity of solid adsorbents comparing to aqueous MEA and also the avoidance of evaporating a large amount of water in the regenerator. Thus the adsorption technology for carbon capture could be treated with energy-saving potential7. The thermodynamic carbon pump cycle has been proposed by Jiang8 to research on the energy-consumption of adsorption carbon capture technology, in which the minimum separation work and second law efficiency have been applied to evaluate the effect of operating parameters.

With the application of thermodynamic cycle concept in adsorption carbon capture technology, the energy required for adsorbents regeneration could be clarified. Zhao9 has researched on the comparative study of vacuum-pressure swing adsorption (VPSA) and pressure-temperature swing adsorption (PTSA) process based on the thermodynamic carbon pump theory, the effect of operating parameters on energy-efficiency was studied with the establishment of VPSA and PTSA thermodynamic cycle. Jiang8 has researched the 4-step temperature swing adsorption (TSA) process integrated with internal heat recovery (IHR) method, which primarily focuses on the improvement of exergy efficiency of the system. As effective performance improvement method of adsorption technology, the heat recovery method has been widely applied to reduce the energy consumption. Pan10 has researched three kinds of heat recovery methods which have been applied in recent adsorption refrigerators and contribution distribution of recovered heat but no entropy generation has been analyzed. Lu11 has proposed a heat pipe type adsorption refrigerator system, the COP of the system were evaluated with the combined recovery process in the view of the first law of thermodynamics. Zhang6 has researched the effect of the heat recover fractions on the degree of heat integration and the sensitivity analysis of cyclic parameters has been conducted to get the influential factors. It could be concluded that the current researches primarily focus on the amount of heat required in a thermodynamic cycle, while the essence of energy dissipation in the heat and mass transfer processes is still unclear, especially in the field of improvement method development.

With the thermodynamic carbon pump model proposed by Zhao11, the concept of entropy can be applied to research on the energy dissipation in the necessary step of a cycle, by which the guideline for the development of energy-saving method could be obtained. Myat12 has researched on performance analysis of adsorption cooling system using a thermodynamic framework with an entropy generation analysis, which research on the minimization of entropy generation in the system to lead to the maximization of the coefficient of performance, but the energy dissipation in each step is not mentioned. The concept of entropy generation has also been applied in the refs13,14, in which the dynamic performance of system was evaluated with such indicator.

In conclusion, the effect of heat recovery method on entropy generation is still not researched comprehensively as shown in the Table 1, the energy-saving potential of IHR method is primarily researched in the view of the first law of thermodynamics, the energy dissipation in each step of an adsorption thermodynamic cycle should be clarified. Thus in this conclusion, the entropy generation saving potential of such method was evaluated in the view of the second law of thermodynamics.

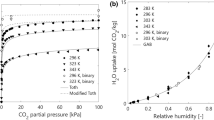

4-step TSA technology was researched in this work as a base case, the thermodynamic cycle established in the CO2 adsorption isotherms diagram was shown in the Fig. 1-a. This cycle could also be illustrated in the Clapeyron diagram, and two possible types of which as shown in the Fig. 1-b was researched in this work.

The schematic diagram of 4-step TSA process (a) and thermodynamic cycle established (b). The Clapeyron diagram has been widely applied in research on physical adsorption technology, such as adsorption refrigeration cycle27, which is also suitable for research on adsorption carbon capture technology like the 4-step TSA technology. As shown in the (a,b), step 1–2 is the pre-cooling process, in which the temperature of the adsorption reactor decreases from T1 (Tad) to T2 with no adsorbed amount changed. Step 2–3 is the adsorption process, the adsorbed amount increases with the CO2 partial pressure is Pad in the atmosphere condition, and the adsorption heat is taken away by cooling fluid (such as cold water in Tad). Step 3–4 is the pre-heating process, in which the reactor bed is heated from T3 (Tad) to T4 with no adsorbed amount changed. And step 4-1 is the desorption process, the adsorbed amount decreases in this process with the CO2 partial pressure is Pde in the atmosphere condition, and the adsorption reactor is heated by heating fluid (such as hot steam in Tde) continuously to T1(Tde), then a new cycle starts. With characteristics of different adsorbents, the temperature in the end of pre-cooling process might be higher or lower than that in the end of pre-heating process as shown in the Fig. 2-b. The assumptions of the cycles researched are unrolled as follows: 1. The adsorbed CO2 is treated as looping fluid in this cycle. 2. The adsorbed amount of N2 is much lower than that of CO2 in the adsorbent, which can be neglected. 3. The temperature of adsorbent-adsorbate pair in the adsorption column is assumed as uniform. 4. The adsorption capacity of the adsorbent can be fully utilized in the whole thermodynamic cycle. e. The specific heat capacity of adsorbate is neglected for that is small enough as researched in refs28,29.

Considering that the heat and mass transfer exist in the steps 2–3 and 4-1 at the same time, the decoupling method could be applied to research on thermodynamic analysis more fluently. The decoupling of these two types of cycle was shown in the Fig. 2-a.

In the step 2–3, CO2 is adsorbed by adsorbent while the temperature decreases to Tad, the sensible heat of temperature variation and isosteric heat of adsorption are absorbed by the cooling fluid together. With the decoupling method, this step can be divided into two new isobaric steps: step 2-2′ and 2′-3. Thus the step 1-2-2′ is an isosteric step in all, in which the temperature decreases from Tde directly to Tad and the step 2′-3 is an isothermal step, in which the amount of adsorbed CO2 increases in Tad.

The step 4-1 can be treated with a similar method, CO2 is desorbed from adsorbent while the temperature increases to Tde, the sensible heat of temperature variation and isosteric heat of desorption comes from the heating fluid together. With the decoupling method, this step can also be divided into two new isobaric steps: step 4-4′ and 4′-1. Thus the step 3-4-4′ is an isosteric step, in which the temperature increases Tad directly to Tde and the step 4′-1 is an isothermal step, in which the amount of adsorbed CO2 decreases in Tde.

With internal heat recovery (IHR) method integrated, the thermodynamic cycle could be more complex, which could also be researched with the decoupling method. The IHR method has been widely applied in fluidized bed adsorption system15, which is also suitable for fixed bed adsorption system described in this paper to reduce the energy consumption. With the establishment of the thermodynamic cycle, the temperature variation of the adsorbent-adsorbate pair can be easily clarified to conduct the design of IHR method, which supply insight into the energy-saving potential.

The results in the ref.6 show that the sensible heat of adsorbent-adsorbate pair accounts for the primary part of energy consumption because of the vast temperature variation, thus the heat recovery method is suitable to be applied, and the IHR of sensible heat can reach 75% through special techniques6, which is researched in this paper. The application of IHR method can be unrolled in the decoupled schematic diagram of the 4-step TSA cycle with a simple case as shown in the Fig. 2-b. Two adsorption beds are applied to provide carbon capture capacity continuingly, thus a part of sensible heat of one adsorption bed in the pre-cooling step can be applied to supply the energy required of the other adsorption bed in the pre-heating step, which means that the sensible heat dissipated while the temperature of one bed decreases from Tde to T6 is recovered to supply the energy required to heat the other bed from Tad to T5.

By circulating the working fluid in the circuit between the above two adsorption beds, sensible heat can be transported from the bed in the pre-cooling step to the other bed in the pre-heating step16 as shown in the Fig. 2. Considering that the heat transfer temperature difference is needed in the heat recovery exchanger, the minimum temperature difference between the working fluid in these two bed could be defined as the minimum temperature approach Tm17. With the minimum temperature approach Tm defined, the T5 and T6 can be expressed as Eqs 1 and 2.

An ideal 4-step TSA thermodynamic cycle with IHR method could be researched when Tm is assumed as 0 K. Thus the value of T5 and T6 is equal in this ideal cycle, which can be expressed as shown in the Eq. 3:

Thus with the decoupling method described, the entropy generation of heat and mass transfer could be calculated respectively in the 4-step TSA technology integrated with IHR improvement method.

Results and Discussion

Entropy generation analysis

Heat required analysis has been described in the ref.8, the numerical value and contribution distribution of entropy generation and heat required in the 4-step TSA technology were compared as shown in the Fig. 3. With the operating parameters listed in the Table 2 and the minimum temperature approach was assumed as 0 K, the entropy generation per kilograms captured CO2 of four steps mentioned above was calculated as illustrated.

The adsorption capacity of adsorbent is primarily affected by temperature in a TSA cycle, thus the energy required in the pre-cooling and pre-heating steps account for the major part, which both contribute to 43.79%, the similar trend is also obtained in the ref.17. Thus such cycle can be integrated with IHR method for the potential of sensible heat recovery, which would be researched in this work as well. As for the heat required in the adsorption and desorption steps, which is needed to push the mass transfer, only account to a small part in the view of the first law of thermodynamics. But in the view of the second law of thermodynamics, the contribution of the desorption step is quite different as shown in the Fig. 3. The major irreversibility of the 4 steps can be obtained in this section, which contributed by heat transfer accounts to a dominant distribution though, the mass transfer irreversibility in the desorption step cannot be ignored.

The effect of the IHR method

The IHR method has been unrolled above, and the effect of which on entropy generation was illustrated in the Fig. 4-a when the minimum temperature approach Tm is assumed as 0 K, the operating parameters are summarized in the Table 2. In the heat recovery step, the “cooling fluid” is applied to drop the temperature of one adsorption bed in the pre-cooling step, thus the “cooling fluid” is heated to a higher temperature and could be applied to increase the temperature of the other adsorption bed in the pre-heating step. Substitute the operating parameters into the Eq. 26, the entropy generation of the heat recovery step with per kilograms of adsorbate can be obtained. In results, the entropy generation decreases from 2.27 kJ/kg K to 0.62 kJ/kg K in the pre-cooling step, from 1.88 kJ/kg K to 0.42 kJ/kg K in the pre-heating step while that in the adsorption and desorption steps are constant. Thus the contribution distribution of entropy generation varies in the integrated technology, in which the heat and mass transfer account for 63.27% and 36.73% respectively without IHR method, 53.72% and 46.28% respectively with IHR method.

It can be concluded that the IHR method contributes an obvious distribution variation of entropy generation, the dominant role of entropy generation is still that caused by heat transfer though. Considering that the IHR method could be replaced by serial heat recovery or passive heat recovery method to further reduce the heat transfer irreversibility10, the method to reduce the mass transfer irreversibility should be considered such as pressure recovery method18.

Considering that the heat recovery time would vastly increases with minimum temperature approach Tm reduces, which would negatively influences the system performance. The effect of minimum temperature approach Tm on the entropy generation variation is also researched in this section, and the comparison of entropy generation in the whole cycle with Tm changes from 2 K to 8 K is illustrated in the Fig. 4-b. It can be concluded that the entropy generation of the whole system increases slightly with the Tm increases for the amount of heat recovered reduces. Considering that the minimum temperature approach cannot be eliminated in actual heat exchanger design, the effect of which on the irreversibility of the whole cycle should be learned.

The effect of mainly operating parameters

The effect of mainly operating parameters on system performances of TSA technology, which include the minimum separation work and second-law efficiency, has been researched before11. However, how these parameters affect the entropy generation distribution in the whole cycle is still not clear. It is obvious that the TSA technology with IHR method is vastly influenced by temperature, thus the influence of adsorption and desorption temperature were researched in this section when the minimum temperature approach Tm was assumed as 5 K as shown in the Fig. 5, in which the assumed Tm is the common heat transfer temperature difference.

For the effect of adsorption temperature variation on the adsorption capacity in the cycle is larger, the entropy generation per kilograms adsorbed CO2 changes more obvious in the Fig. 5-a.

As shown in the Fig. 5-a, the entropy generation increases with the adsorption temperature. With the adsorption temperature increases from 298 K to 318 K, the entropy generation per kilograms CO2 captured increases from 3.23 kJ/kg K to 5.81 kJ/kg K which has changed nearly 80% with 20 K temperature increases. And the entropy generation contributed by heat transfer increases from 67.45% to 78.00% and that contributed by mass transfer decreases from 32.55% to 22.00% in total.

As shown in the Fig. 5-b, the entropy generation decreases as the adsorption temperature increases, it is obvious that the variation of the adsorbed amount is slight enough which has a slight effect on the variation of entropy generation. With the desorption temperature increases from 378 K to 398 K, the entropy generation per kilograms CO2 captured decreases from 3.36 kJ/kg K to 3.20 kJ/kg K. And the entropy generation contributed by heat transfer decreases from 68.06% to 67.44% and that contributed by mass transfer increases from 31.93% to 32.56% in total.

It can be concluded that though the temperature of adsorption and desorption directly influence the entropy generation caused by heat transfer, the entropy generation per kilograms adsorbed CO2 is primarily influenced by the amount of CO2 captured in the whole cycle. Thus the development of adsorbents to improve the adsorption capacity is still necessary to reduce the entropy generation in the 4-step TSA technology.

Conclusions

In summary, an abstract thermodynamic cycle was focused on in this work, by which the basic characteristics of the 4-step TSA process integrated with the IHR method would be clarified. With the equilibrium state points connected by ideal processes, a thermodynamic cycle could be obtained, and the details of energy dissipation in the cycle would be clarified in the view of thermodynamics. With the application of decoupling method and adsorption potential theory, the energy dissipation mechanism in adsorption carbon capture technologies could be clarified with the calculation of entropy generation contributed by heat transfer and mass transfer respectively. Such a method could also be applied to a series of adsorption technologies as a general analysis, which relies on the basic characteristics of different technologies but not parameters of specific devices. Through the analysis with the same set of standards, a horizontal comparison between different technologies could be achieved.

Methods

Modeling of adsorption isotherms

The activated carbon mentioned in the refs19,20 is applied in this work as the adsorbent, the adsorption capacity of which in equilibrium is expressed as a function of temperature and pressure called isotherm model. The experimentally measured data in ref.15 are fitted using the Langmuir model as shown in the Eq. 4 in the adsorption condition.

In which the qm and b are the parameters of the Langmuir model, more details of these could be found in the Table 3. And the Dubinin-Astakhov (D-A) model as shown in the Eq. 5 is applied to calculate the adsorbed amount in the desorption condition, the coefficients of which are also obtained from the ref.19.

In which the va is the specific volume of the liquid adsorbate and A is the adsorption potential as calculated in the ref.21. The adsorption isotherm coefficients and thermodynamic properties of adsorbent are shown in the Table 3.

The working capacity qw in the TSA cycle is defined in this paper, as shown in the Eq. 6, which unroll the amount of CO2 product obtained with per kilograms adsorbent in a cycle.

In which the qad and qde are calculated by Langmuir model and D-A model respectively, which represent the amount of adsorbed CO2 per kilograms adsorbent in the adsorption and desorption condition respectively.

Modeling of entropy generation

The concepts of entropy and entropy generation are applied in this section, the entropy generation of primary steps in a 4-step TSA process is calculated clarify the major irreversibility in a cycle. With the research on IHR method represented in the section 2.3, the improvement of system performance and the energy-saving potential of such method could be unrolled with entropy generation analysis in this section.

The concept of entropy is defined by the second law of thermodynamics which states that the entropy of a closed system increases or remains constant. The entropy balance of a closed system is shown in the Eq. 7 12:

In which the ∆Ssystem and ∆Ssurrounding represent the entropy variation of the system and surrounding respectively, and the system represents the adsorbate-adsorbent pair system and the surrounding represents the heating or cooling fluid in this work.

The pre-cooling and pre-heating steps

Based on the decoupling of 4-step TSA cycle process, the entropy generation of the re-organized pre-heating step 3-4′ and pre-cooling step 1-2′ could be calculated as follows:

In the preheating step, the adsorbent-adsorbate pair system is heated by the heating fluid, thus the adsorbent-adsorbate pair system and the heating fluid are the system and surrounding in the Eq. 8 respectively. With the assumption of the heat source is infinite, the temperature of the system increases from Tad to Tde and the temperature of the surrounding stays the same Tde.

Thus the entropy generation of the pre-heating step with per kilograms adsorbent can be calculated as shown in the Eq. 8, in which the PAT (process-average temperature) was defined in the ref.22 as shown in the Eq. 9, and the entropy generation of the closed system per kilograms captured CO2 is shown in the Eq. 10.

In which Cp is the specific heat capacity of the adsorbent, the value of which could be found in the ref.19 as shown in the Table 3.

Be conducted with the similar method, the entropy generation of the pre-cooling step with per kilograms adsorbent can be calculated as shown in the Eq. 11, in which the PAT was shown in the Eq. 12, and the entropy generation of the closed system per kilograms captured CO2 is shown in the Eq. 13.

The adsorption and desorption steps

Based on the decoupling of the 4-step TSA cycle, the mass transfer of CO2 between gas phase and adsorbed phase which in the adsorption and desorption steps are separated from heat transfer process, thus the entropy generation of the re-organized adsorption step 2′-3 and the re-organized desorption step 4′-1 can be calculated as follows:

With the assumption of these two steps react in the isothermal and isobaric condition, the energy conservation equation can be obtained based on the first law of thermodynamics as shown in the Eq. 14, in which no other work occurred besides volumetric work.

With the assumption of the heat source in the surrounding is infinite, the entropy generation can be obtained as shown in the Eq. 15:

Substitute the Eq. 14 into the Eq. 15, the Eq. 16 can be obtained:

With the definition of enthalpy as shown in the Eq. 17, the Eq. 18 can be obtained:

Considering that the adsorption and desorption steps react in the isobaric condition, the Eq. 18 can be simplified into Eq. 19:

With the definition of Gibbs free energy as shown in the Eq. 20 and the isothermal hypothesis based on the decoupling cycle, the Eq. 21 can be obtained.

Substitute the Eqs 19 and 21 into 16, the entropy generation can be obtained as shown in the Eq. 22:

The adsorption potential theory was applied in the analysis on adsorption and desorption steps, which treated the adsorption process as the isothermal compression process. In the adsorption step, the integral Gibbs free energy ∆Gad change can be defined as the minimum isothermal work necessary to load the adsorbent to a given level, which can be calculated as shown in the Eq. 23 23,24,25, thus the entropy generation of the closed system per kilograms captured CO2 sge,ad is shown in the Eq. 24.

In the desorption step, the Gibbs free energy change ∆Gde can be calculated based on the adsorption potential theory26, which can be calculated as shown in the Eq. 25, thus the entropy generation of the closed system per kilograms captured CO2 sge,de is shown in the Eq. 26.

The IHR step

In the IHR step, a closed circuit of heat transfer fluid connecting two adsorption bed is formed, and the heat can be transported from a bed in the pre-cooling step to the other bed in the pre-heating step by circulating the heat transfer fluid. Thus in this step, temperature of the system in the pre-cooling step decreases from Tde to T6 and temperature of the system in the pre-heating step increases from Tad to T5, and the entropy generation per kilograms adsorbent can be calculated as shown in the Eq. 27, the entropy generation of the closed system per kilograms captured CO2 is shown in the Eq. 28.

References

Special Report on Global Warming of 1.5 °C. Incheon, South Korea: Intergovernmental Panel on Climate Change (IPCC). 7th October 2018.

Ben-Mansour, R. et al. Carbon capture by physical adsorption: Materials, experimental investigations and numerical modeling and simulation-A review. Appl Energ 161, 225–255 (2016).

Wang, J. et al. Thermodynamic considerations on MEA absorption: Whether thermodynamic cycle could be used as a tool for energy efficiency analysis. Energy 168, 380–392 (2018).

Xu, Y. et al. Application of the Thermodynamic Cycle to Assess the Energy Efficiency of Amine-Based Absorption of Carbon Capture. Energies 12, 2504 (2019).

Zhao, R. et al. A comprehensive performance evaluation of temperature swing adsorption for post-combustion carbon dioxide capture. Renew Sust Energ Rev 114, 109285 (2019).

Zhang, W. et al. Parametric study on the regeneration heat requirement of an amine-based solid adsorbent process for post-combustion carbon capture. Appl Energ 168, 394–405 (2016).

Li, S. J. et al. Mathematical modeling and numerical investigation of carbon capture by adsorption: Literature review and case study. Appl Energ 221, 437–449 (2018).

Jiang, L. et al. Performance exploration of temperature swing adsorption technology for carbon dioxide capture. Energ Convers Manage 165, 396–404 (2018).

Zhao, R. K. et al. A comparative study on CO2 capture performance of vacuum-pressure swing adsorption and pressure-temperature swing adsorption based on carbon pump cycle. Energy 137, 495–509 (2017).

Pan, Q. W. et al. Comparison of different kinds of heat recoveries applied in adsorption refrigeration system. Int J Refrig 55, 37–48 (2015).

Zhao, R. K. et al. Carbon pump: Fundamental theory and applications. Energy 119, 1131–1143 (2017).

Myat, A. et al. An entropy generation and genetic algorithm optimization of two-bed adsorption cooling cycle. P I Mech Eng E-J Pro 226, 142–156 (2012).

Chua, H. T. et al. Entropy generation analysis of two-bed, silica gel-water, non-regenerative adsorption chillers. J Phys D Appl Phys 31, 1471 (1998).

Thu, K. et al. Entropy generation analysis of an adsorption cooling cycle. Int J Heat Mass Tran 60, 143–155 (2013).

Veneman, R. et al. Post-Combustion CO2 capture using supported amine sorbents: A process integration study. Energy Procedia 37, 2100–2108 (2013).

Determan, M. D. et al. Carbon Dioxide Capture Using Sorbent-Loaded Hollow-Fiber Modules with Integrated Heat Recovery. Ind Eng Chem Res 55, 2119–2127 (2016).

Jung, W. H. et al. Simulated moving bed adsorption process based on a polyethyleneimine-silica sorbent for CO2 capture with sensible heat recovery. Energy 150, 950–964 (2018).

Song, C. F. et al. Reducing energy consumption of advanced PTSA CO2 capture process-Experimental and numerical study. J Taiwan Inst Chem E 64, 69–78 (2016).

Singh, V. K. & Anil Kumar, E. Measurement and analysis of adsorption isotherms of CO2 on activated carbon. Appl Therm Eng 97, 77–86 (2016).

Singh, V. K. & Kumar, E. A. Experimental investigation and thermodynamic analysis of CO2 adsorption on activated carbons for cooling system. J CO2 Util 17, 290–304 (2017).

Singh, V. K. & Anil Kumar, E. Thermodynamic analysis of single-stage and single-effect two-stage adsorption cooling cycles using indigenous coconut shell based activated carbon-CO2 pair. Int J Refrig 84, 238–252 (2017).

Myers, A. L. Characterization of nanopores by standard enthalpy and entropy of adsorption of probe molecules. Colloid Surface A. 241, 9–14 (2004).

Gordon, J. M. & Ng, K. C. Cool thermodynamics-The engineering and physics of predictive, diagnostic and optimization methods for cooling systems. Cambridge International Science Publishing 1st edition, 79 (2001).

Deng, H. et al. Adsorption equilibrium for sulfur dioxide, nitric oxide, carbon dioxide, nitrogen on 13X and 5A zeolites. Chem Eng J 188, 77–85 (2012).

Gao, F. et al. Selective adsorption of CO on CuCl/Y adsorbent prepared using CuCl2 as precursor: Equilibrium and thermodynamics. Chem Eng J 290, 418–427 (2016).

Polanyi, M. The Potential Theory of Adsorption. Science 141, 1010–1013 (1963).

Wang, R. Z. et al. Theory and application of adsorption refrigeration. Beijing, Science Press (2007).

Zhao, R. K. et al. Performance analysis of temperature swing adsorption for CO2 capture using thermodynamic properties of adsorbed phase. Appl Therm Eng 123, 205–215 (2017).

Lu, Z. S. et al. Experimental analysis of an adsorption refrigerator with mass and heat-pipe heat recovery process. Energ Convers Manage 53, 291–297 (2012).

Acknowledgements

The authors are grateful for the support provided by China National Natural Science Funds under Grant No. 51876134, and Research Plan of Science and Technology of Tianjin City under Grant No. 18YDYGHZ00090, and Tianjin Talent Development Special Support Program for High-Level Innovation and Entrepreneurship team.

Author information

Authors and Affiliations

Contributions

Shuangjun Li and Weicong Xu contributed method development; Shuai Deng and Li Zhao contributed theoretical framework; Zhihao Guo and Zhenyu Du contributed data analysis; Xiangzhou Yuan contributed data of adsorbent material. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, S., Deng, S., Zhao, L. et al. Energy dissipation evaluation of temperature swing adsorption (TSA) cycle based on thermodynamic entropy insights. Sci Rep 9, 16599 (2019). https://doi.org/10.1038/s41598-019-53398-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-53398-6

- Springer Nature Limited