Abstract

Ni-based superalloys offer a unique combination of mechanical properties, corrosion resistance and high temperature performance. Near ambient pressure X-ray photoelectron spectroscopy was used to study in operando the initial steps of oxidation for Ni-5Cr, Ni-15Cr, Ni-30Cr and Ni-15Cr-6W at 500 °C, p(O2)=10−6 mbar. The comparison of oxide evolution for these alloys quantifies the outsized impact of W in promoting chromia formation. For the binary alloys an increase in chromia due to Cr-surface enrichment is followed by NiO nucleation and growth thus seeding a dual-layer structure. The addition of W (Ni-15Cr-6W) shifts the reaction pathways towards chromia thus enhancing oxide quality. Density functional theory calculations confirm that W atoms adjacent to Cr create highly favorable oxygen adsorption sites. The addition of W supercharges the reactivity of Cr with oxygen essentially funneling oxygen atoms into Cr sites. The experimental results are discussed in the context of surface composition, chemistry, reactant fluxes, and microstructure.

Similar content being viewed by others

Introduction

Ni-based superalloys, steels, and Ni-Al alloys are often designed with mechanical, or thermal properties in mind, but in contrast to these design intentions, their use and lifetime is frequently limited by the ability of the alloy to withstand adverse conditions such as immersion in saltwater, high atmospheric concentrations of sulfur, acidic solutions, and radiation-induced defects1,2,3,4,5,6,7,8,9,10. The load imparted by environmental stressors is significant and of particular concern for alloys integrated in energy applications such as batteries and fuel cells11,12,13. Ni-Cr alloys are multipotent materials that are not only used as structural materials but also find applications as catalysts and interconnects in fuel cells14,15,16. The challenge to mitigate degradation can be met by using alloys that foster the formation of stable and resilient passive layers, usually a dense oxide such as alumina or chromia.

Building a comprehensive understanding of the oxidation process is of great importance and extends from high temperature performance to intermediate temperatures where thermodynamic equilibrium is not achieved1,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35. Over many years of alloy and oxidation research, it has been demonstrated that the addition of minor alloying elements, MAE, (<10 at%) and even trace elements (<1 at%) can have an outsized impact on the formation of the preferred oxide and consequently the reliability of the protective oxide layer. The impact of adding Mo or W to the alloy is well-documented for dry and aqueous corrosion where it is uniquely powerful in limiting pitting events2,4,5,30,36,37,38,39. The majority of models describing the impact of MAEs to date relate performance nearly exclusively to processes within the Mo/W-containing oxide layer based on “sequestration” of defects and stabilization or local passivation of pits40,41,42,43,44. In contrast to the wealth of studies in this field the detailed mechanisms which impart this “gain of function” are not well understood, thus limiting systematic predictions of materials performance. Advancing the mechanistic understanding of the alloy surface reactions is critical to fully integrate the oxidation reaction, and corrosion protection in the pertinent alloy design space.

A critical aspect of the oxide formation are the initial reaction steps leading from the alloy surface to a closed oxide film where growth kinetics can then be described following the Cabrera-Mott model. The post-growth analysis of oxide films forms the rich basis for our current knowledge on oxidation. Relatively new techniques such as ambient pressure X-ray photoelectron spectroscopy (NAP-XPS), and in-situ transmission electron microscopy25,26,30,45,46,47,48,49 have opened a window to in operando studies, which offer unique and detailed information about the oxidation process. Our work presented here uses NAP-XPS to compare the oxidation between Ni-Cr alloys and Ni-Cr-W alloys and the exposure time equals 25 μs at atmospheric pressure (~5000 s of oxidation at 10−6 mbar). This is a short time with respect to oxide scale growth but the events during this initial growth step are thought to influence the subsequent growth progression and performance. The comparison of “exposure time” does not take into account the variations in oxide surface defects or (possibly) pressure dependent surface reconstructions, which is often referred to as the “pressure gap” and subject to future work. One example where surface reactions play out on these short timescales, is the creation and subsequent oxidation of bare alloy surfaces formed at the crack tip during crack initiation and propagation. It is evident from several recent studies that reactions at the alloy surfaces can not be inferred by comparing the reactions of pure element surfaces17,25,26,45,50.

Results

Pristine alloy – core level analysis

The result section is partitioned as following: (i) composition of the pristine alloy surface immediately prior to the start of oxidation, (ii) oxidation of the binary alloys Ni-5Cr, Ni-15Cr, and Ni-30Cr and evolution of the oxide layer, (iii) oxidation of the ternary Ni-15Cr-6W alloy and comparison with the binary alloys. Figure 1 shows the Ni 2p3/2 and Cr 2p3/2 core levels for the binary Ni-15Cr and ternary Ni-15Cr-6W alloys prior to oxygen exposure. They are positioned at 852.6 and 574.2 eV, respectively, in agreement with the literature51,52,53,54. The characteristic asymmetry caused by the metallicity of the material is readily apparent on the high binding energy side, and the Ni-satellite is positioned at 858.6 eV (see Supplementary Fig. 2). Peak positions are constant, but the FWHM (full width at half maximum) for the Cr 2p peak is reduced from 2.2 eV (Ni-5Cr, Ni-15Cr) to 1.8 eV (Ni-30Cr) and 1.4 eV (Ni-15Cr-6W), while the FWHM (full width at half maximum) for Ni 2p remains constant with 1.2 eV. The instrumental resolution is 0.1 to 0.2 eV and thus smaller than the widths of the core levels. The reduction in peak width can be associated with an increase in the core hole lifetime, whereas a long core hole lifetime is associated with a narrow Lorentzian contribution to the peak width via the Heisenberg uncertainty principle. The disorder within the binary and ternary alloys, respectively the local variation in nearest neighbor configurations, can also lead to the observed modulation of the peak shape through the change in average local potential around the core hole. A modulation of the short range order (SRO) might explain the difference in the FWHM between Ni-15Cr and N-15Cr-6W55.

Ni 2p3/2 and Cr 2p3/2 core level spectra including experimental data (symbols) and fit results for a binary and ternary alloy with the same Ni/Cr ratio. The fit envelope and fit peaks with a Doniach-Sunic lineshape are marked as a full line, the Shirley background is the broken line. The Ni 2p3/2 peak includes the satellite peak.

Surface composition of alloys

The surface composition of the alloys immediately prior to the start of the oxidation at T = 500 °C and after the reduction of the native oxide layer is summarized in Table 1; oxygen was <0.5 at% for any of the surfaces. Surprisingly all alloys are surface enriched in Cr and this effect is especially strong for the ternary alloys. This observation is counter to the calculations by Ruban et al.56 who predicted anti-segregation in dilute Ni-Cr with Ni as a host and Cr as the solute on the FCC(111) surface. The IMFP (inelastic mean free path) of a photoexcited Cr 2p core electron excited at a photon energy of hν = 1120 eV barely exceeds 2 nm, and the Cr-enrichment is confined to the top few surface layers as shown in Supplementary Fig. 3. The complete dataset for Cr-segregation is included in the Supplementary Fig. 3. Possible reactions leading to the surface enrichment after annealing and reduction include (i) the reduction of the native oxide leaves behind a Cr-enriched surface with limited dissolution of surface Cr into the bulk, (ii) Cr surface accumulation through rapid Cr diffusion along grain boundaries but limited dissolution into the bulk within the experimental timeframe, or (iii) segregation of Cr at the surface on non-(111) surfaces counter to the predictions by Ruban et al. for (111) surfaces56. It is worth noting that for alloys with much larger grains as discussed in Supplementary Note 3 and Supplementary Fig. 9, the Cr surface enrichment is at most 2.5% pointing to a decisive role of alloy microstructure in controlling surface composition. The mechanism of surface enrichment in Cr is subject to additional experimentation.

Oxide evolution of Ni-15Cr

A complete set of spectra acquired in the oxidation of Ni-15Cr is summarized in Fig. 2. The cumulative oxidation time is 4,200 s, and metal and oxide contributions are marked. As the oxidation progresses the information depth of the photoemission signal moves gradually from the alloy into the oxide, hence the attenuation of the alloy signal can be used to deduce additional kinetic information. The transformation of Ni to NiO is gradual and the broad peak on the high binding energy side, which corresponds to the complex multiplet structure of Ni-oxides, gains in intensity as the oxidation progresses. On the other hand, Cr(0) is rapidly and completely transformed into chromia leaving behind a Cr-depleted alloy sub-surface region.

a Schematic illustration of the experiment progression. The information depth window for XPS moves away from the alloy-oxide interface over time. Signal attenuation of the alloy is therefore a signature of oxide growth and growth mode. b Ni 2p3/2, and (c) Cr 2p3/2 core levels as a function of oxidation time – the spectrum in blue is the pristine alloy immediately before start of the oxidation experiment.

Figure 3 summarizes representative results of the Ni 2p core level fit for the binary alloys. The Ni 2p and Cr 2p core level fitting process is discussed in the Supplementary Figs. 2, 4 and 5, and Supplementary Note 1. The constrained fit described in the method section and Supplementary Information deliver the relative contributions of oxide and metal for each oxidation step. Examples for early and late stages of oxidation are summarized in Fig. 3a–c.

Example of Ni2p3/2 peak fit for all binary alloys towards the end of the oxidation experiment: red line/symbols – experimental data, black line – fit envelope, broken line – Shirley background – green lines: Ni(II) multiplet from NiO reference spectra, yellow line: assigned tentatively to Ni3+ [alternative assignments are discussed in the text], blue line – Ni(0) in alloy. a Ni-30Cr, b Ni-15Cr, c Ni-5Cr. The oxide contribution to the Ni-5Cr peak is clearly visible but its intensity is insufficient to fit the oxide contributions; the fit for the alloy peak is included in the graph. a, b include the fit following the assignments established by Payne et al. (d) summarizes the Ni3+ contributions for Ni-15Cr and Ni-30Cr as a function of oxidation time. The error bar in Fig. 3(d) in the contribution of the Ni3+/defect peak to Ni2p core level is ±5%. The error bar on the time axis is smaller than the size of the marker.

A single additional peak beyond the NiO reference multiplet structure is introduced to achieve a high quality fit, and this contribution is tentatively assigned to Ni3+.57,58, The spectra do not support the presence of spinel (NiCr2O4) which is concluded from the comparison with a set of synthetic spectra with variable NiO and spinel components shown in Supplementary Fig. 5. Payne et al.58, in their study of the oxidation of polycrystalline Ni, observed Ni 2p peak shapes near identical to those in our work and suggested that the additional contribution is due to Ni3+ from defect states – an interpretation which is reflected in several other publications59,60,61. This assignment is tentative54,60 but offers a possible interpretation of bonding states not native to perfect NiO. We henceforth label this defect population as Ni3+ but significant compositional and defect complexity can hide beneath this label.

The defect concentration, respectively the Ni3+ peak intensity, is near constant throughout the oxide growth (Fig. 3d). This excludes the interpretation of this state as being solely due to alloy-oxide interface defects, and strongly suggests that a stable population of defects is retained throughout the growth process. Small contributions of radiation damage cannot be entirely excluded62,63. The Ni3+ contribution of about 20% seems relatively large, but the small thickness of the oxide layers of only a few nm, and the fine grained microstructure can contribute to an overall high defect concentration.

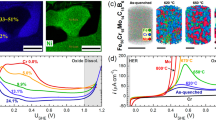

Oxide evolution: Binary and ternary alloys

The evolution of oxide and its composition over time is illustrated in Figs. 4 and 5. Figure 4 summarizes the attenuation of the alloy signal (Ni+Cr) in Fig. 4a, and the increase in oxide signal throughout the growth process in Fig. 4b. All intensities are normalized to the signal intensity at t=0 for the respective experiment and the sample is stationary for the entire time of each oxidation experiment. The Cr concentration in the near-interface region of the alloy as shown in Fig. 4, decreases rapidly to less than 1 at% for all alloys with the exception of the ternary alloy Ni-15Cr-6W at 400 °C where a constant near-interface concentration for Cr of about 5% is retained. For the ternary alloy held at 500 °C the oxidation process is so rapid that no alloy signal is observed any more after 1,000 s (Fig. 4b). The attenuation of the alloy signal is directly correlated with the overall oxide growth mode and growth kinetics and shows significant variations as a function of alloy composition.

a, b Decomposition of the Ni 2p3/2, and Cr 2p3/2 core levels into alloy and oxide contributions for 4 alloys at 500 °C, and Ni-15Cr-6W at 400 °C, respectively. The sum of (alloy+oxide) signal is normalized to 1 to allow for direct comparison between all datasets. The relative contributions of alloy and oxide are determined from the fit for each oxidation step, and all alloys studied. For all experiments at 500 °C no Cr is detected except for small contributions far below the bulk alloy levels in the first two oxidation steps. c Alloy composition for Ni-15-6W oxidized at 400° C, which is the only alloy where Cr and W can still be detected in the vicinity of the alloy-oxide interface.

Chemically distinct contributions to the oxide signal for all alloys and both oxidation temperatures. The color coding of the sum over all oxide contributions follows the scheme set up in Fig. 4. a–c Binary alloys with Ni-oxide and Cr-oxide contributions. d, e Oxide composition of the ternary alloys, whereas oxidation at 500 °C only yields Cr-oxide. And (f) shows a fit of the Cr 2p3/2 core level observed in (e) after the first few oxidation steps. The fit uses the multiplet peaks as described by Payne et al. for a chromia reference sample.

It is tempting to use these data to derive oxidation kinetics. However, this poses a significant challenge, which is directly related to the functional form of the signal attenuation for the alloy (or increase for the oxide) during oxide growth. For a layer-by-layer growth this can be captured with the Lambert-Beer equation or the Strohmeier formula64, but this is not the case for island growth modes. None of our observations strictly follow the layer-by-layer description which is captured with an exponential function. While modified equations exist for various island growth modes, the complexity of the oxide layer with mixed contributions from two different oxides prohibits a reliable quantitative interpretation. It is nonetheless of interest to illustrate an analysis which leads from the data presented in Fig. 5 to an assessment of equivalent film thickness deqiv (assuming a layer-by-layer growth mode) and then derives the respective growth rates R from d(dequiv)/dt. This process is described in the Supplementary Note 2, and Supplementary Figs. 6 and 7.

Development of oxide composition over time

Figure 5 addresses the composition of the oxide layer as a function of alloy composition and oxidation time. The XPS data support the assignment of Ni-oxide and Cr-oxide to Ni(II)O and Cr(III)2O3 through comparison with reference samples51,52,60,65,66. The work by Luo et al. performed close to our experimental conditions with in-situ transmission electron microscopy (TEM), agrees with our observations of NiO, and Cr2O326. In all binary alloys, the oxidation starts with an initial and rapid appearance of Cr2O3 which is followed by the growth of NiO. For Ni-5Cr and Ni-15Cr the chromia signal is reduced over time, and only NiO contributions continue to increase which is commensurate with NiO overgrowing the chromia layer. In Ni-30Cr and the ternary alloys, chromia rapidly forms and NiO remains the smaller component. The protective function of chromia can only be realized by forming a continuous seed layer, even if it is very thin, at the alloy-oxide interface. This continuity will not be realized for Cr-poor alloys.

The following sequence emerges: the thermodynamic preference for the formation of chromia plays out in the very early stages of oxidation leading to the nucleation of chromia islands which are subsequently buried beneath NiO. The kinetic preference for NiO nucleation, generally attributed to its epitaxial relation to the alloy17,38,50, is not sufficient to suppress chromia formation. In addition, chromia formation is supported by the Cr-enrichment of the alloys surfaces as summarized in Table 1 and is addressed in more detail in the discussion section. The formation of NiO in the ternary alloy is nearly completely suppressed as summarized in Fig. 4 – more so for the oxidation at 500 °C than at 400 °C. The fit of the Cr 2p multiplet for the chromia layer on the ternary alloy agrees very well with the chromia reference sample (Fig. 5f). The fit included in Fig. 5f is in agreement with51,66 and the recent work by Vasconcelos Borges Pinho et al. which includes a calculation of the multiplet splitting67.

Tungsten integration in oxide layer

The W 4f core levels for 400 °C and 500 °C oxidation of the ternary alloys are shown in Fig. 6a, b. The core levels are normalized to unit height and both panels include the fit of the W 4f peak including W metal and oxide: W(0) and W(VI)-oxide (WO3) W 4f7/2 contributions are positioned at 31.5 eV, and 35.2 eV binding energy, respectively, and included in the fit. For 500 °C the oxide contribution is minute, and the W(0) signal for the alloy (Ni+Cr+W=100at%) is 5.1at% at t=0, and 8at% at t=1995 s. Longer oxidation times show only Cr-oxide, and the alloy signal is attenuated correspondingly (Figs. 4 and 5). In contrast, for the 400 °C oxidation process W(0) and W(VI) oxide contributions are detected throughout the experiment. This leads us to propose that tungsten is enriched at the NiO-chromia interface, which is commensurate with current models on the role of W in the repair of pitting sites in aqueous corrosion5,38.

W4f core level recorded during the oxidation of Ni-15Cr-6W at (a) 500 °C, and (b) 400 °C. The experimental spectra are marked with a red line-symbol, and the fit envelope is a black line. The W metal (blue line) and oxide signals (green line) are separated with a fit. The respective time since start of oxidation is given on the right hand side of each graph, and (b) includes the metal/oxide ratio. The oxide contributions in (a) is below 10%.

The O 1s peak is unfortunately less informative since it includes a multitude of superimposed contributions, which are only distinguished by relatively small chemical shifts: chemisorbed oxygen on the alloy surface, chemi- and physisorbed oxygen68 on the oxide surfaces and at defects, and oxygen bound in the oxide layer. For all samples, the oxygen concentration exceeds the stoichiometric contributions expected from the oxides during the NAP-XPS experiment by 20–40% which confirms oxide termination with oxygen atoms, or even dissolution of some oxygen within the surface layers of the alloy69. Select examples of the O 1s core level are included in the Supplementary Fig. 8.

Discussion

This work was designed to shed light on the initial steps in the oxidation process integrating with earlier studies observing the oxidation at the nanoscale with scanning tunneling microscopy (STM)17,50. The oxidation conditions here are chosen specifically to observe the competition between Ni and Cr oxidation, and the cross-comparison between four alloys – three binary and one ternary - leads to insight about the role of W as a minor alloying element. The operando mode in NAP-XPS informs about the transition from clean alloy surface to the first few nanometers of oxide where the process moves into the much better studied Cabrera Mott regime. The sequence of oxidation, the contributions of Ni-defects and Ni3+, and the integration of W-oxide at grain boundaries are addressed in the result section and supported by information included in the Supplementary Information. One of the most dramatic results is the impact of W on the progression of the oxidation reaction whose interpretation is supported by the introduction of surface chemical models to fully capture this observation. We propose that the interplay between several mechanisms – surface chemistry, variation in surface composition and segregation, and modulation of bulk and grain boundary diffusivity – drives the significant shift in oxide composition following the addition of W to the alloy.

Figure 7 summarizes the relation between chromia content in the oxide, alloy bulk and surface compositions. The oxide layer compositions are calculated from the XPS results, and also presented in Figs. 4, 5, Table 1, Supplementary Note 3 and Supplementary Fig. 9 (for the large grain sample). For the chromia content in the oxide the largest value observed within each oxidation sequence is used. The Cr content at binary alloy surfaces scales linearly with the bulk composition with the exception of the Ni-15Cr large grain sample (Supplementary Fig. 9) whose surface enrichment is only about 2%. We tentatively attribute this difference to the reduced Cr-transport along grain boundaries in the large grain sample. For the ternary alloy, Ni-15Cr-6W, the surface is strongly enriched in Cr and approaches the surface composition of Ni-30Cr. Again the large grain sample is an exception and surface enrichment is minimal at only a few percent. All ternary alloys, irrespective of degree of surface enrichment with Cr, show a strong propensity to form chromia rich oxide layers exceeding in all cases 85%. Large grain samples express the same preference for chromia formation despite their small Cr-surface enrichment. The comparison between strongly and weakly Cr enriched surfaces strengthens the view that surface composition, while important, cannot solely explain our observations, and surface chemistry has to be considered to fully capture the initial oxidation steps.

Comparison between chromia content in the oxide layer and the bulk and surface composition of the respective alloy. The compositions are calculated from the XPS results, and also included in Figs. 4, 5, Table 1, and Supplementary Information Fig. 9 for the large grain sample. For the chromia content in the oxide the largest value observed within each oxidation sequence is used. The error bar is ± 4% for the chromia contribution to the oxide (ordinate), and ± 2% for the Cr contribution in the alloy (abscissa).

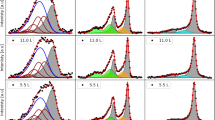

We therefore propose that an additional mechanism, related to the surface chemistry of the alloy, plays a significant role in defining the preference for chromia formation on the ternary alloy surfaces. Surface chemistry models might offer a pathway to predict the impact of minor alloying elements and aid in the design of new and improved alloys. We therefore performed a set of DFT calculations to assess the preferential adsorption sites for O atoms on different alloy surface configurations, Ni(100) with Cr or W surface substitution and Ni(100) with Cr and W surface substitution, as shown in Fig. 8. The different top, hollow and bridge sites were probed, and the lowest energy sites are included in the figure. Cr, and W atoms are substituted for a surface Ni in the Ni-layer to represent binary and ternary alloy configurations, in 1/9 or 2/9 surface concentrations as well as at higher surface concentrations 3/9 or 4/9. Figure 8 shows the most stable adsorption sites for each alloy configuration. Bader analysis for the surface shows that the alloying atom charges are about 0.1 |e| smaller on the W-Cr/Ni(100) surface than on the W/Ni(100) or Cr/Ni(100) surfaces. The Bader charge on W in W-Cr/Ni(100) is 0.50 |e|, compared to 0.61 |e| in W/Ni(100), and the Bader charge on Cr in W-Cr/Ni(100) is 0.58 |e|, compared to 0.68 |e| in Cr/Ni(100). The d-band center of the W-Cr/Ni(100) surface is closer to the Fermi level than the W/Ni(100) or Cr/Ni(100) surfaces, which is expected based on their relative position in the periodic table. The d-band center of W-Cr/Ni(100) is −0.85 eV, which is closer to the Fermi energy than the d-band center of W/Ni(100) at −1.05 eV and the d-band center of Cr/Ni(100) at −0.91 eV. This calculation considers the d-band center of the entire top layer but we can also look at the shift of just the W d-band.

Summary of the most stable adsorption sites for atomic oxygen on different surfaces as calculated with DFT for FCC surfaces with one to four non-Ni atoms. Labeled n/m where n is the number of non-Ni atoms and m = 9 as the number of surface atoms. The figures are arranged in order of O binding energy from the weakest (A) to the strongest binding energy (E) A at 1/9 Cr surface alloy and the lowest energy adsorption site is at the Ni-Cr 4-fold site; B at 1/9 W surface alloy the on-top O site is most stable; C a 3/9 Cr surface alloy and the Cr-Ni-Cr hollow site is most stable; D at 2/9 Cr/W surface alloy with the bridge site between W and Cr as the energetically favorable site; E at 4/9 Cr/W surface alloy a W-Cr-Cr hollow site is most stable. This is also the overall most stable configuration of the three structures.

At the lower alloy concentration on the W/Ni(100) surface, O binds on top of the W atom with a binding energy of −4.27 eV. On the Cr/Ni(100) surface, O binds at a hollow site adjacent to the Cr atom with a binding energy of −3.81 eV. The lowest energy adsorption site on the 3/9 surface is at a hollow site where the O interacts mostly with 2Cr and 1 Ni with binding energy of −4.36 V while at the 4/9 surface the O interacts mainly with 2 Cr and 1 W the lowest adsorption site with the adsorption energy of −5.0 eV. It is particularly notable that the lowest energy binding site of O on the W-Cr/Ni(100) surface is at the bridge site between the W and Cr atoms with a binding energy of −4.79 eV for the low surface concentration and between 1W and 2Cr at higher surface concentrations with a binding energy of −5.0 eV. O binds stronger to the W-Cr/Ni(100) surface than the W/Ni(100) or Cr/Ni(100) surface, which is expected due to the higher d-band center of W-Cr/Ni(100). These results are in agreement with Hammer and Nørskov’s d-band model70 that states that a surface with a higher d-band center binds the adsorbate more strongly. In short – a larger Cr content in the surface enhances reaction with oxygen, but the addition of W essentially supercharges the reactivity of Cr with oxygen.

The DFT calculations illustrate that the initial adsorption site for O at the W-Cr bridge position or at the W-Cr-Cr hollow site can serve as the primary nucleation site to initiate the formation of Cr-oxides over Ni-oxide. Essentially, W is feeding O to Cr, thus denying O to Ni, and a larger Cr concentration favors oxygen adsorption, but addition of W delivers an even stronger preference for adsorption for the same Cr-atom configuration. The strong local chemical potential gradient in response to the initial surface reaction is the driving force to continue rapid growth of Cr-oxide and suppresses at the same time the nucleation of NiO. W atoms act essentially as a catalyst that initiates the formation of the coveted chromia. Future simulations will take it a step further and include different surface orientations, and the transition from initial adsorption site to toxide nuclei.

The continued chromia growth in the presence of W nonetheless has to be supported by Cr-transport from bulk to surface otherwise chromia growth will cease. The latter is seen in the Ni-5Cr and Ni-15Cr experiments where chromia growth is slowed down considerably after the first 2000 s of oxygen exposure. The lattice diffusion is relatively sluggish for Cr with a Dv* value of 9.3 × 10−21 m2/s in Ni-22Cr at 540 °C71. The alloys need to be depleted of Cr to a depth of roughly ~15 ± 3 nm to build a chromia layer of a few nm as it is observed towards the end of our experiments. This value is derived from a mass balance consideration laid out in Supplementary Fig. 10 and agrees with the diffusion length d calculated using \({{{\mathrm{d}}}} = 2\sqrt {D_v^ \ast } t\) where t is the timescale of the experiment. A significantly longer diffusion length is necessary to supply the requisite Cr atoms and sustain chromia growth in the Ni-15Cr- W alloys at 500 °C and at 400 °C. Intuitively the required increase in the lattice diffusion following the addition of a small percentage of W appears unlikely, and grain boundary diffusion, and specifically an enhanced grain boundary diffusion related to the presence of W might be necessary72. Unfortunately, the diffusion constants for Cr in Ni-15Cr-6W are not available in the literature to the best of our knowledge, and our argument has to remain incomplete for the time being.

The operando study of Ni-Cr and Ni-Cr-W alloys offers insight in the initial stages of oxidation, the competition between Ni-oxide and Cr-oxide formation under oxidation conditions where thermodynamic and kinetic factors compete. The comparison of oxide evolution for four different alloys with variable Cr and W content quantifies the role of W as a minor alloying element. We propose that the interplay between several mechanisms controls the oxide composition: (i) surface chemistry, (ii) variation in surface composition, and (iii) modulation of bulk and grain boundary diffusivity and its relation to alloy microstructure. DFT calculations illustrate that W adjacent to a Cr site or Cr cluster in the surface increases its propensity to react with oxygen: the surface chemistry is manipulated by the minor alloying element during the initial reaction steps at the alloy surface. This preference is thought to lower the activation barrier to chromia formation, leading to a chromia richer oxide. The surface chemistry plays out in the context of Cr transport within the alloy bulk, and at alloy grain boundaries. Unfortunately, the lack of data for the ternary Ni-Cr-W alloy limits our ability to fully separate the role of surface chemistry and reactant fluxes. Comparisons between small and large grain alloys as described in the Supplementary Information support the dominance of grain boundary over lattice diffusion in its influence on the progression of the oxidation. With this work we demonstrate the relevance of surface chemical aspects in oxidation, and the rich datasets which can be accessed with operando experiments.

Methods

Experimental setup and materials

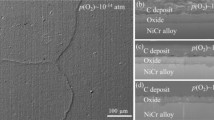

The NAP-XPS (near ambient pressure X-ray photoelectron spectroscopy) experiments were performed at Brookhaven National Laboratory (BNL) - National Synchrotron Light Source-II (NSLS-II) at the IOS (23-ID-2) beamline, which is an elliptically polarized undulator beamline with high brightness in the soft X-ray regime. The pressure regime used on our work is lower than true ambient conditions to slow down the reaction sufficiently for detailed observation, but nonetheless require a specialized setup which extends the pressure regime for electron spectroscopy where electron spectroscopy can be performed. The Ni-Cr alloys were cast into rectangular prisms, cold-worked to between 22 and 24% strain and then recrystallized at 900 °C for 1 h. The Ni-Cr-W alloy was recrystallized at 1300 °C. Alloy processing was done by J. Perepezko at the University of Wisconsin38. Sample homogeneity and composition was confirmed with Energy-Dispersive Spectroscopy (EDS), and the samples were then polished with a SiC grit and diamond solution to a mirror finish. An SEM (scanning electron microscope) micrograph of the Ni-15wt%Cr sample after oxidation is included in the Supplementary Fig. 1, which shows a representative grain size distribution. The alloy compositions were Ni 5wt%Cr, Ni 15wt%Cr, Ni 30wt%Cr, and one ternary alloy with Ni 15wt%Cr 6wt%W. All alloy compositions are given in wt% unless otherwise noted.

For NAP-XPS experiments, the sample was mounted on top of a ceramic button heater and a type-K thermocouple was placed between the sample and the heater. The alloys were annealed at T = 800 °C in the ultra-high vacuum (UHV) chamber (base pressure ~ p(O2) = 10−9 torr) to remove the native oxide layer. The cleanliness of the sample was confirmed with XPS and no oxygen was present within the detection limit of about 1.0%. The samples were cooled down to 500 °C and 400 °C, respectively, with the lower temperature used for one experiment with Ni-15Cr-6W, and the oxidation experiment started immediately. A complete set of core level spectra Ni 2p, Cr 2p, W 4f, and O 1s was recorded just prior to oxygen exposure. The photon energy was set to hν = 1120 eV which yields an inelastic mean free path (IMFP) of about 0.6 nm for Ni 2p, 1.0 nm for Cr 2p, 1.5 nm for W 4f, and 1.1 nm for O 1s using the respective kinetic energies of the photoelectron73. The p(O2) of high-purity (99.997%) molecular oxygen was adjusted at 10−6 torr which corresponds to 1 L (Langmuir) for an exposure of 1 s, and the Ni 2p, Cr 2p, W 4f, and O 1s core levels were recorded up to a maximum exposure time of 5000 s in operando. A single core level averaged over 3 scans takes about 200 s, and a set of Ni 2p, Cr 2p, (W 4f) core levels was recorded in this order for the entire exposure period, with O 1s spectra included every few cycles. The pass energy was set to 10 eV for all measurements, which yields an energy resolution of 0.2 eV. Step size of 0.1 eV was used for Ni 2p, and 0.05 eV for Cr 2p and W 4f. The samples were not moved during the in operando oxidation experiment and we therefore can directly compare signal intensities within an experiment over the entire oxidation time. Beam induced reduction can not be identified unambiguously and is therefore assumed to be smaller than the inherent experimental error and fluctuation between core level measurements. All measurements are recorded at the temperature of the oxidation experiment.

Analysis of spectra

The spectra were analyzed with KolXPD, version 1.08, fitting software and fit with a Shirley background, a Doniach-Sunjic function convoluted with a Gaussian function for Ni, Cr and W metals peaks to account for their inherent asymmetry53, and all oxide peaks were fit using Voigt functions. The Shirley background is fixed at the flat sections of the spectra, for example at 870 eV and 847 eV on either side of the Ni 2p3/2 core level. The Au 4f7/2 peak was positioned at a binding energy of 84.0 eV for energy calibration and measured on a Au foil mounted on the sample holder. The peak parameters for the pristine alloy (Ni 2p, Cr 2p, and W 4f) are used to fit the Ni(0), Cr(0), and W(0) components of the core levels during oxidation, and compositions are calculated using the cross sections tabulated by Yeh et al. for the respective photon energy74. Contributions from the Ni 2p1/2 core level were not taken into account and this will slightly modulate the Shirley background shape compared to the fit of both components. We did not measure the Ni 2p1/2 core level in this experiment and favored a higher time resolution over measuring both spin-orbit components. The oxide contributions to the core levels include complex multiplets from the splitting of the final state energies caused by the partially occupied d-states. These multiplets are fit using the values tabulated for the reference materials by Biesinger et al. and Payne et al.52,65,66 for NiO, Cr2O3, and NiCr2O4. The peak parameters used for the oxide fit include relative peak positions (ΔE between multiplet components), intensity ratio between multiplet components, and FWHM (full width at half maximum) and are permitted to fluctuate only within narrow margins for a highly constrained fit. The overall intensity of oxide and alloy contributions are adjusted during the fit to determine relative contributions as a function of oxidation time. The large number of peaks within the multiplets necessitates this approach which is based on the knowledge of the signatures of the pure materials. The quality of every fit is judged by the residuals, and this fit method yields consistently high-quality results. The noise in the spectra is smaller than the fluctuations in the residuals owing to the excellent signal-to-noise-ratio. Residuals with near-random variations in intensity are used as the sign of a high-quality fit.

Density functional theory calculations

The details for the computational methods used to assess the energetic preference for O-bonding to select adsorption sites on the binary and ternary alloy surfaces were published previously75. In short, density functional theory calculations were performed using the Vienna Ab-initio Simulations Package76,77,78,79 (VASP) using the Perdew-Burke-Ernzerhof generalized gradient approximation80,81 (PBE-GGA) to describe the exchange correlations potential energy and the projector augmented wave82,83 (PAW) method for the core electrons. The calculations are spin polarized and include magnetization effects of Ni and Cr. The Brillouin zone was sampled using a 5 × 5 × 1 kpoints Monkhorst-Pack grid and the plane-wave cutoff kinetic energy was 400 eV. The surface slab was 7 layer thick, 3 × 3 cell, with a 20 Å vacuum separating the periodic images. The adsorbate and the top 4 layers were allowed to relax and the Ni-W-Cr surface was made by replacing two adjacent Ni atoms in the surface layer with W and Cr reflecting the random solid solution. The binding energy of O was also calculated at 3/9 (3Cr) and 4/9 (3Cr, 1W) surface concentrations for comparison. 5 different (3/9) and 11 different (4/9) configuration were minimized to determine the lowest energy surface configuration. O adsorption was only calculated for the lowest energy surface configuration. All oxygen binding energies are relative to 1/2 O2 in the gas phase.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Darolia, R. Development of strong, oxidation and corrosion resistant nickel-based superalloys: Critical review of challenges, progress and prospects. Int. Mater. Rev. 64, 355–380 (2018).

Ebrahimi, N., Biesinger, M. C., Shoesmith, D. W. & Noel, J. J. The influence of chromium and molybdenum on the repassivation of Nickel-Chromium-Molybdenum alloys in saline solutions. Surf. Interf. Anal. 49, 1359–1363 (2017).

Furrer, D. & Fecht, H. Ni-based superalloys for turbine discs. JOM 51, 14–17 (1999).

Lloyd, A. C., Noël, J. J., McIntyre, S. & Shoesmith, D. W. Cr, Mo and W alloying additions in Ni and their effect on passivity. Electrochim. Acta. 49, 3015–3027 (2004).

Lutton Cwalina, K., Demarest, C. R., Gerard, A. Y. & Scully, J. R. Revisiting the effects of molybdenum and tungsten alloying on corrosion behavior of nickel-chromium alloys in aqueous corrosion. Curr. Opin. Solid State Mater. Sci. 23, 129–141 (2019).

MacKay, R. A., Bagg, T. P., Smialek, J. L. & Nathal, M. V. A new approach of designing superalloys for low density. JOM 62, 48–54 (2010).

Qiu, Y., Thomas, S., Gibson, M. A., Fraser, H. L. & Birbilis, N. Corrosion of high entropy alloys. npj Mater. Degrad 1, 1–18 (2017).

Razumovskii, I. M. et al. New generation of Ni-based superalloys designed on the basis of first-principles calculations. Mat. Sci. Eng. A 497, 18–24 (2008).

Turchi, P. E. A., Kaufman, L. & Liu, Z.-K. Modeling of Ni–Cr–Mo based alloys: Part I—phase stability. Calphad 30, 70–87 (2006).

Turchi, P. E. A., Kaufman, L. & Liu, Z.-K. Modeling of Ni-Cr-Mo based alloys: Part II- Kinetics. Calphad 31, 237–248 (2006).

Hsu, C.-M., Yeh, A.-C., Shong, W.-J. & Liu, C.-K. Development of advanced metallic alloys for solid oxide fuel cell interconnector application. J. Alloy. Compd. 656, 903–911 (2016).

Jian, L., Jian, P., Jianzhong, X. & Xiaoliang, Q. Oxidation of Haynes 230 alloy in reduced temperature solid oxide fuel cell environments. J. Power Sources 139, 182–187 (2005).

Jian, L., Yuh, C. Y. & Faroque, M. Oxidation behavior of superalloys in oxidizing and reducing environments. Corros. Sci. 42, 1573–1585 (2000).

Klaus, S., Cai, Y., Louie, M. W., Trotochaud, L. & Bell, A. T. Effects of Fe electrolyte impurities on Ni(OH)2/NiOOH structure and oxygen evolution activity. J. Phys. Chem. C. 119, 7243–7254 (2015).

King, R. L. & Botte, G. G. Investigation of multi-metal catalysts for stable hydrogen production via urea electrolysis. J. Power Sources 196, 9579–9584 (2011).

Xu, W., Wu, Z. & Tao, S. Urea-based fuel cells and electrocatalysts for urea oxidation. Energy Technol. 4, 1329–1337 (2016).

Blades, W. H. & Reinke, P. From alloy to oxide: Capturing the early stages of oxidation on Ni-Cr(100) Alloys. ACS Appl. Mater. Interfaces 10, 43219–43229 (2018).

Calvarin, G., Molins, R. & Huntz, A. M. Oxidation mechanism of Ni–20Cr foils and its relation to the oxide-scale microstructure. Ox. Met. 53, 25–48 (1999).

Chattopadhyay, B. & Wood, G. C. The transient oxidation of alloys. Ox. Met. 2, 373–399 (1970).

Cornish, A. et al. Oxidation of polycrystalline Ni studied by spectromicroscopy: Phase separation in the early stages of crystallite growth. Phys. Rev. B 81, 085403 (2010).

Das, N. K. & Shoji., T. Early stage oxidation of Ni–Cr binary alloy (111), (110) and (100) surfaces: A combined density functional and quantum chemical molecular dynamics study. Corros. Sci. 73, 18–31 (2013).

Gulbransen, E. A. & Andrew, K. F. The kinetics of oxidation of high purity Nickel. J. Electrochem. Soc. 101, 128–140 (1954).

Hoflund, G. B. & Epling, W. S. Oxidation study of a Polycrystalline Ni/Cr Alloy II. Chem. Mater. 10, 50–58 (1998).

Kruska, K., Schreiber, D. K., Olszta, M. J., Riley, B. J. & Bruemmer, S. M. Temperature-dependent selective oxidation processes for Ni-5Cr and Ni-4Al. Corros. Sci. 139, 309–318 (2018).

Luo, L. et al. Atomic origins of water-vapour-promoted alloy oxidation. Nat. Mater. 17, 514–518 (2018).

Luo, L. et al. In-situ transmission electron microscopy study of surface oxidation for Ni–10Cr and Ni–20Cr alloys. Scr. Mater. 114, 129–132 (2016).

Pan, T. Quantum chemistry-based study of iron oxidation at the iron–water interface: An X-ray analysis aided study. Chem. Phys. Lett. 511, 7 (2011).

Reynolds, T. D. et al. Identifying heating rate dependent oxidation reactions on a nickel-base superalloy using synchrotron diffraction. Acta. Mat. 181, 570–583 (2019).

Sherman, Q. C., Voorhees, P. W. & Marks, L. D. Thermodynamics of solute capture during the oxidation of multicomponent metals. Acta. Mat. 181, 584–594 (2019).

Yu, X.-x et al. In Situ observations of early stage oxidation of Ni-Cr and Ni-Cr-Mo alloys. Corrosion 74, 939–946 (2018).

Atkinson, A. Transport processes during the growth of oxide films at elevated temperature. Rev. Mod. Phys. 57, 437–470 (1985).

Freund, H. J. & Pacchioni, G. Oxide ultra-thin films on metals: New materials for the design of supported metal catalysts. Chem. Soc. Rev. 37, 2224–2242 (2008).

Seyeux, A., Maurice, V. & Marcus, P. Oxide Film Growth Kinetics on Metals and Alloys I. Physical Model. J. Electrochem. Soc. 160, C189–C196 (2013).

Stellwag, B. Mechanisms of oxide film formation on austenitic stainless steels in high temperature water. Corros. Sci. 40, 337–370 (1998).

Yin, B., Yin, Y., Lei, Y., Dong, L. & Zhang, Y. Experimental and density functional studies on the corrosion behavior of the copper-nickel-tin alloy. Chem. Phys. Lett. 509, 192–197 (2011).

Espevik, S., Rapp, R. A., Daniel, P. L. & Hirth, J. P. Oxidation of Ni-Cr-W ternary alloys. Oxid. Met. 14, 85–108 (1978).

Hayes, J. R., Gray, J. J., Szmodis, A. W. & Orme, C. A. Influence of Cr and Mo on corrosion of Ni based alloys. Corrosion 62, 491–500 (2006).

Gusieva, K. et al. Repassivation behavior of individual grain facets on dilute Ni–Cr and Ni–Cr–Mo alloys in acidified chloride solution. J. Phys. Chem. C. 122, 19499–19513 (2018).

Maurice, V. & Marcus, P. Progress in corrosion science at atomic and nanometric scales. Prog. Mater. Sci. 95, 132–171 (2018).

Frankel, G. S., Li, T. & Scully, J. R. Localized corrosion: Passive film breakdown vs pit growth stability. J. Electrochem. Soc. 164, C180–C181 (2017).

Maurice, V. et al. Effects of molybdenum on the composition and nanoscale morphology of passivated austenitic stainless steel surfaces. Faraday Disc. 180, 151–170 (2015).

McCafferty. Oxide networks, graph theory, and the passivity of Ni-Cr-Mo ternary alloys. Corros. Sci. 42, 1993–2011 (2000).

Sprowl, L. H., Adam, B. M., Tucker, J. D. & Árnadóttir, L. First-principles study of the products of CO2 dissociation on nickel-based alloys: Trends in energetics with alloying element. Surf. Sci. 677, 219–231 (2018).

Samin, A. J. & Taylor, C. D. First-principles investigation of surface properties and adsorption of oxygen on Ni-22Cr and the role of molybdenum. Corros. Sci. 134, 103–111 (2018).

Luo, L. et al. In situ atomic scale visualization of surface kinetics driven dynamics of oxide growth on a Ni-Cr surface. Chem. Comm. 52, 3300–3303 (2016).

Larsson, A. et al. Thickness and composition of native oxides and near-surface regions of Ni superalloys. J. Alloys Compd. 895, 162657 (2022)

Oleksak, R. P. et al. Molecular-scale investigation of the oxidation behavior of chromia-forming alloys in high-temperature CO2. npj. Mater. Degrad. 5, 1–17 (2021).

Zhu, L. et al. Surface chemistry and diffusion of trace and alloying elements during in vacuum thermal deoxidation of stainless steel. Surf. Interface Anal. 54, 99–108 (2021).

Ma, L., Wiame, F., Maurice, V. & Marcus, P. New insight on early oxidation stages of austenitic stainless steel from in situ XPS analysis on single-crystalline Fe–18Cr–13Ni. Corros. Sci. 140, 205–216 (2018).

Blades, W. H., Barone, M. R. & Reinke, P. Initial atomic-scale oxidation pathways on a Ni–15Cr(100) alloy surface. npj. Mater Degrad. 5, 1–10 (2021).

Biesinger, M. C. et al. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 257, 2717–2730 (2011).

Biesinger, M. C., Payne, B. P., Lau, L. W. M., Gerson, A. & Smart, R. S. C. X-ray photoelectron spectroscopic chemical state quantification of mixed nickel metal, oxide and hydroxide systems. Surf. Interface Anal. 41, 324–332 (2009).

Doniach, S. & Sunjic, M. Many-electron singularity in X-ray photoemission and X-ray line spectra from metals. J. Phys. C: Solid State Phys. 3, 285–291 (1970).

Gupta, R. P. & Sen, S. K. Calculation of multiplet structure of corep-vacancy levels. Ii. Phys. Rev. B 12, 15–19 (1975).

Cole, R. J. & Weightman, P. Disorder broadening of core levels: Insights into alloy electronic structure. J. Electron Spectrosc. Relat. Phenom. 178-179, 112–122 (2010).

Ruban, A. V., Skriver, J. L. & Nørskov, J. K. Surface Segregation energies in transition-metal alloys. Phys. Rev. B 59, 15990–15999 (1999).

Uhlenbrock, S., Scharfschwerdt, C., Neumann, M., Illing, G. & Freund, H.-J. The influence of defects on the Ni 2p and O 1s XPS of NiO. J. Phys.: Condens. Matter 4, 7973–7978 (1992).

Payne, B. P., Grosvenor, A. P., Biesinger, M. C., Kobe, B. A. & McIntyre, N. S. Structure and growth of oxides on polycrystalline nickel surfaces. Surf. Interface Anal. 39, 582–592 (2007).

A.F. Carley, S.D. Jackson, J.N. O’Shea, M. Roberts. The formation and characterisation of Ni3+ — an X-ray photoelectron spectroscopic investigation of potassium-doped Ni(110). O. Surf. Sci. 440, L868–L874.

Grosvenor, A. P., Biesinger, M. C., Smart, R. S. C. & McIntyre, N. S. New interpretations of XPS spectra of nickel metal and oxides. Surf. Sci. 600, 1771–1779 (2006).

Tyuliev, G. & Sokolova, M. Temperature dependence of Ni3+ quantity in surface layer of NiO. Appl. Surf. Sci. 52, 343–349 (1991).

Yu, X. X. et al. Nonequilibrium Solute Capture in Passivating Oxide Films. Phys. Rev. Lett. 121, 145701 (2018).

Unutulmazsoy, Y., Merkle, R., Fischer, D., Mannhart, J. & Maier, J. The oxidation kinetics of thin nickel films between 250 and 500 degrees C. Phys. Chem. Chem. Phys. 19, 9045–9052 (2017).

Strohmeier, B. R. An ESCA method for determining the oxide thickness on aluminum alloys. Surf. Interface Anal. 15, 51–56 (1990).

Biesinger, M. C., Brown, C., Mycroft, J. R., Davidson, R. D. & McIntyre, N. S. X-ray photoelectron spectroscopy studies of chromium compounds. Surf. Interface Anal. 36, 1550–1563 (2004).

Payne, B. P., Biesinger, M. C. & McIntyre, N. S. X-ray photoelectron spectroscopy studies of reactions on chromium metal and chromium oxide surfaces. J. Electron. Spec. Rel. Phenom. 184, 29–37 (2011).

Vasconcelos Borges Pinho, P., Chartier, A., Moussy, J.-B., Menut, D. & Miserque, F. Crystal field effects on the photoemission spectra in Cr2O3 thin films: From multiplet splitting features to the local structure. Materialia 12, 100753 (2020).

Kim, C. M., Jeong, H. S. & Kim, E. H. NEXAFS and XPS characterization of molecular oxygen adsorbed on Ni(100) at 80 K. Surf. Sci. 459, L457–L461 (2000).

Yu, X.-X., Han, J., Scully, J. R. & Marks, L. D. Oxygen injection during fast vs slow passivation in aqueous solution. Acta. Mat. 213, 116898 (2021).

Hammer, B. & Nørskov, J. K. Why Au is the noblest of all the metals. Nature 376, 238–241 (1995).

Gheno, F., Jomard, F., Desgranges, C. & Martinelli, L. Tracer diffusion of Cr in Ni and Ni-22Cr studied by SIMS. Materialia 3, 145–152 (2018).

Alexandrov, V., Sushko, M. L., Schreiber, D. K., Bruemmer, S. M. & Rosso, K. M. Ab Initio Modeling of Bulk and Intragranular Diffusion in Ni Alloys. J. Phys. Chem. Lett. 6, 1618–1623 (2015).

Tanuma, S., Powell, C. J. & Penn, D. R. Calculations of electron inelastic mean free paths. V. Data for 14 organic compounds over the 50–2000 eV range. Surf. Interface Anal. 21, 165–176 (1994).

Yeh, J. J. & Lindau, I. Atomic subshell photoionization cross sections and asymmetry parameters. Data Nucl. Data Tables 32, 1–155 (1985).

Sprowl, L. H., Adam, B. M., Tucker, J. D. & Arnadottir, L. First-principles study of the products of CO2 dissociation on nickel -based alloys: Trends in energetics with alloying element. Surf. Sci. 677, 219–231 (2018).

Kresse, G. & Hafner, J. Abinitio molecular-dynamics for liquid-metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Hafner, J. Ab-Initio molecular-dynamics simulation of the liquid-metal amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Erratum: Generalized gradient approximation made simple. Phys. Rev. Lett. 78, 1396 (1997).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Acknowledgements

C.V., V.A.A., and P.R. would like to thank the Office of Naval Research for supporting the MURI Program entitled “Corrosion in 4D,” Grant N00014-14-1-0675, under program manager Dr. David Shifler. The XPS instrument acquisition for large grain measurements shown in the Supplementary Information was supported by a DURIP award (Office of Navel Research) Grant N00014-16-1-2842, program manager Dr. David Shifler. Reinke acknowledges the support by NSF DMR Metals and Metallic Nanostructures award #2004326. This work (L.A.) used the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by the National Science Foundation grant number ACI-1548562. The XSEDE Comet cluster at the San Diego Supercomputer Center and Stampede at the Texas Advanced Computing Center (TACC) at the University of Texas at Austin were used through allocation TG-ENG170002 and TG-DMR160093. This research used resources of the 23-ID-2 (IOS) beamline of the National Synchrotron Light Source II, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under Contract No. DE-SC0012704. The support for V.A.A. to conduct this work by Prof. E. Opila (UVa) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

C.V., V.A.A., performed the experiment with the guidance of I.W. and A.H.; C.V., V.A.A., and P.R performed the analysis. L.A. performed the DFT calculations. The results were discussed, revised critically, and approved by all authors. P.R. wrote the manuscript which was proofread, and approved for submission by all authors. P.R conceived and lead the study.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Volders, C., Angelici, V.A., Waluyo, I. et al. Unraveling the role of tungsten as a minor alloying element in the oxidation NiCr alloys. npj Mater Degrad 6, 52 (2022). https://doi.org/10.1038/s41529-022-00265-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-022-00265-x

- Springer Nature Limited

This article is cited by

-

Dynamics of early-stage oxide formation on a Ni-Cr-Mo alloy

npj Materials Degradation (2024)

-

Elemental partitioning and corrosion resistance of Ni–Cr alloys revealed by accurate ab-initio thermodynamic and electrochemical calculations

npj Materials Degradation (2023)