Abstract

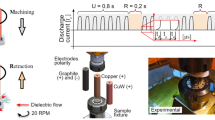

This paper presents a study of the EDM machining of H13 and D2 tool steels using electrodes of different diameters. Scanning electron microscopy is employed to analyze the machined surface, and the concept of a Crack Critical Line (CCL) is introduced to explore the influence of electrode size, EDM parameters and material thermal conductivity on surface cracking. The current results reveal that the surface crack distribution is influenced by the machining parameters, the electrode diameter and the material conductivity. It is noted that cracks tend not to appear when the machining is performed with a decreased pulse current and an increased pulse-on duration. Furthermore, it is observed that changing the electrode diameter causes a parallel shift of the CCL location within the crack distribution map. The intercept of the line depends on the electrode size. When small diameter electrodes are employed in the machining process, the location of the CCL shifts upwards. This causes the no-crack zone to enlarge, and therefore permits a wider choice of machining parameters to be adopted.

Similar content being viewed by others

References

O. A. Abu Zeid, J. Mater. Process. Technol. 68(1997) 27.

T. Masuzawa, K. Okajima, T. Taguchi and M. Fujino, CIRP Ann. 51(2002) 355.

D. M. Allen and A. Lecheheb, J. Mater. Process. Technol. 58(1996) 53.

B. H. Yan, A. C. Wang, C. Y. Huang and F. Y. Huang, Int. J. Mach. Tools Manuf. 42(2002) 1105.

L. C. Lee, L. C. Lim, V. Narayanan and V. C. Venkatesh, ibid. 28(1988) 359.

L. C. Lim, L. C. Lee, Y. S. Wong and H. H. Lu, Mater. Sci. Technol. 7(1991) 239.

P. F. Thomson, ibid. 5(1989) 1153.

Y. Fukuzawa, Y. Kojima, T, Tani, E. Sekiguti and N. Mohri, Mater. Manuf. Process. 10(1995) 195.

K. Schmidt and U. Busack, Der Stahlformenbauer 1(1994) 75.

K. Schmidt and U. Busack, Der Stahlformenbauer 3(1994) 36.

W.-I. Jutzler, in "Funkenerosives Senken-Verfahreneinflu-esse auf die break Oberflaechenbeschaffenheit und die Festigkeit des Werkstuecks" (Dissertation in RWTH Aachen, 1982) 35.

H. T. Lee, F. C. Hsu and T. Y. Tai, Mater. Sci. Eng. A Struct. Mater 364(2004) 346.

W. J. Tomlinson and J. R. Adkin, Surf. Eng. 8(1992) 283.

J. C. Rebelo, A. Morao Dias, D. Kremer and J. L. Lebrun, J. Mater. Process. Technol. 84(1998) 90.

H. T. Lee and T. Y. Tai, ibid. 142(2003) 676.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, H.T., Rehbach, W.P., Tai, T.Y. et al. Relationship between electrode size and surface cracking in the EDM machining process. Journal of Materials Science 39, 6981–6986 (2004). https://doi.org/10.1023/B:JMSC.0000047541.95138.17

Issue Date:

DOI: https://doi.org/10.1023/B:JMSC.0000047541.95138.17