Abstract

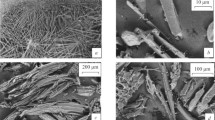

It is demonstrated that pastes obtained from cordierite milled jointly with a surfactant are suitable for extruding porous ceramics of a complex profile. The suspensions consisting of the components for the synthesis of cordierite have unsatisfactory molding properties. The processes of high-temperature calcination of molded cordierite ceramics are studied.

Similar content being viewed by others

REFERENCES

E. G. Avvakumov and A. A. Gusev, Cordierite As a Promising Ceramic Material[in Russian], Izd-vo SO RAN, Novosibirsk (1999).

E. G. Avvakumov, E. T. Devyatkina, N. V. Kosova, et al., “A new mechanochemical method for preparing cordierite and cordierite-based carrier,” Kinetika Kataliz, 39(5), 722 - 725 (1998).

V. Yu. Prokof'ev, A. V. Kunin, A. P. Il'in, et al., The use of mechanochemical methods for the synthesis of cordierite catalyst carriers," Zh. Prikl. Khim., 70, Issue 10, 1655 - 1659 (1997).

A. F. Bessonov and E. V. Bessonova, “Kinetics and mechanism of phase formation in heating a mixture of MgO, Al2O3, and SiO2,” Izv. Akad. Nauk SSSR, Ser. Neorg. Mater., 20(1), 92 - 96 (1984).

V. E. Morozkova, G. R. Karagedov, and A. S. Berger, “The effect of mechanical activation on the synthesis and sintering of cordierite,” Sib. Khim. Zh., Issue 1, 115 - 118 (1993).

V. Yu. Prokof'ev, A. P. Il'in, Yu. G. Shirokov, and É. N. Yurchenko, “The selection of optimum properties of molding mixtures for extrusion of block carriers and catalysts with a cellular structure,” Zh. Prikl. Khim., 68, Issue 4, 613 - 618 (1995).

V. Yu. Prokof'ev, A. P. Il'in, Yu. G. Shirokov, et al., “The impact of relaxation effects on the process of extrusion of carriers and catalysts,” Zh. Prikl. Khim., 69, Issue 10, 1685 - 1690 (1996).

V. Yu. Prokof'ev and A. P. Il'in, “Structure formation and con-trolling properties of molding mixtures for extrusion,” Izv. Vuzov, Ser. Khimiya Khim. Tekhnol., 44, Issue 2, 72 - 77 (2001).

É. N. Yurchenko, V. Yu. Prokof'ev, A. P. Il'in, and Yu. G. Shirokov, “Control of structural-mechanical and flow properties of molding mixtures based on titanium dioxide,” Zh. Prikl. Khim., 68, Issue 4, 607 - 612 (1995).

N. N. Kruglitskii, Principles of Physicochemical Mechanics, Part 1[in Russian], Kiev, Vishcha Shkola (1975).

E. D. Shchukin, A. I. Bessonov, and S. A. Paranskii, Mechanical Tests of Catalysts and Sorbents[in Russian], Nauka, Moscow (1971).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Prokof'ev, V.Y., Kunin, A.V. & Il'in, A.P. Molding Cordierite-Based Porous Ceramic of a Complex Profile. Glass and Ceramics 61, 291–294 (2004). https://doi.org/10.1023/B:GLAC.0000048693.72675.d3

Issue Date:

DOI: https://doi.org/10.1023/B:GLAC.0000048693.72675.d3