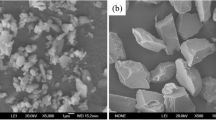

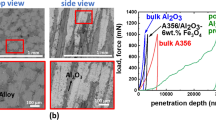

Al2O3 based porous ceramic (APC) is prepared successfully by a polymer sponge replica method.1 The main raw material used is white fuzed corundum powder. The effect of zirconium dioxide content (0 – 12 wt.%), sintering temperature (1450 – 1550°C), and holding duration (2 – 6 h) on APC phase composition, macrostructure, microstructure, and properties after sintering, ultimate strength in compression and thermal shock resistance, are studied. Porous ceramic based on Al2O3, exhibiting an ultrafine microstructure, may be prepared by adding ZrO2. It has been detected that APC properties depend to a considerable extent on production process parameters. APC exhibiting considerable porosity (88.9%), good ultimate strength in compression (0.52 MPa), and good thermal shock resistance (19 thermal cycles) may be obtained by firing a specimen containing 8 wt.% ZrO2 at 1500°C and holding for 2 h.

Similar content being viewed by others

References

A. R. Studart, U. T. Gonzenbach, E. Tervoort, and L. J. Gauckler, “Processing routes to macroporous ceramics: a review”, J. Am. Ceram. Soc., 89(6), 1771 – 1789 (2006).

Y. S Han, J. B. Li, B. Chi, and Z. H. Wen, “The effect of sintering temperature on porous silica composite strength”, J. Porous Mater., 10(1), 41 – 45 (2003).

X. W. Zhu, D. L. Jiang, and S. H. Tan, “Reaction bonding of open cell SiC–Al2O3 composites”, Mater. Res. Bull., 36(11), 2003 – 2015 (2001).

W. Wei, X. M. Cao, C. Tian, and J. S. Zhang, “The influence of Si distribution and content on the thermoelectric properties of SiC foam ceramics”, Micropor. Mesopor. Mat., 112(1 – 3), 521 – 525 (2008).

S. Akpinar, I. A. Altun, and K. Onel, “Effects of SiC addition on the structure and properties of reticulated porous mullite ceramics”, J. Eur. Ceram. Soc., 30(13), 2727 – 2734 (2010).

S. Deville, E. Saiz, and A. P. Tomsia, “Ice-templated porous alumina structures”, Acta Mater., 55, No. 6, 1965 – 1974 (2007).

Y. Zhang, K. C. Zhou, Y. X. Bao, and D. Zhang, “Effects of rheological properties on ice-templated porous hydroxyapatite ceramics”, Mater. Sci. Eng. C, 33(1), 340 – 346 (2013).

F. Z. Zhang, T. Kato, M. Fuji, and M. Takahashi, “Gelcasting fabrication of porous ceramics using a continuous process”, J. Eur. Ceram. Soc., 26(4 – 5), 667 – 671 (2006).

F. K Yang, C. W. Li, Y. M. Lin, and C. A. Wang, “Effects of sintering temperature on properties of porous mullite/corundum ceramics”, Mater. Lett., 73, 36 – 39 (2012).

D. Y. Li and M. S. Li, “Porous Y2SiO5 ceramic with low thermal conductivity ”, J. Mater. Sci. Technol., 28(9), 799 – 802 (2012).

A. Preiss, B. Sua, S. Collins, and D. Simpson, “Tailored graded pore structure in zirconia toughened alumina ceramics using double-side cooling freeze casting”, J. Eur. Ceram. Soc., 32(8), 1575 – 1583 (2012).

J. K. Efavi, L. Damoah, D. Y. Bensah, D. D. Arhin, and D. Tetteh, “Development of porous ceramic bodies from kaolin deposits for industrial applications”, Appl. Clay Sci., 65 – 66, 31 – 36 (2012).

J. G. Bai, X. H Yang, Y. G. Shi, S. C. Xu, and J. F. Yang, “Fabrication of directional SiC porous ceramics using Fe2O3 as pore-forming agent”, Mater. Lett., 78, 192 – 194 (2012).

Y. Kim, K. Min, J. Shim, and D. J. Kim, “Formation of porous SiC ceramics via recrystallization”, J. Eur. Ceram. Soc., 32(13), 3611 – 3615 (2012).

K. Sehwrtzalder and A. V. Somers, US Patent 3090094, Method of manufacturing porous ceramic (1963).

M. R. Nangrejo, X. J. Bao, and M. J. Edirisinghe, “Preparation of silicon carbide – silicon nitride composite foams from preceramic polymers”, J. Eur. Ceram. Soc., 20(11), 1777 – 1785 (2000).

X. M. Yao, Y. Yang, X. J. Liu, and Z. R. Huang, “Effect of recoating slurry compositions on the microstructure and properties of SiC reticulated porous ceramics”, J. Eur. Ceram. Soc., 33(15 – 16), 2909 – 2914 (2013).

M. Chen, J. K. Yu, and N. Wang, Refractories and Fuel Combustion [in Chinese] Metallurgical Industry Press, Beijing (2005).

Z. Y. Chen, Chemical Thermodynamics of Refractories [in Chinese] Metallurgical Industry Press, Beijing (2005).

W. H. Tuan, R. Z. Chen, T. C. Wang, C. H. Cheng, and P. S. Kuo, “Mechanical properties of Al2O3 / ZrO2 composites,” J. Eur. Ceram. Soc., 22(16), 2827 – 2833 (2002).

E. Geuzens, S. Mullens, J. Cooymans, J. Luyten, F. Lemoisson, K. Y. Sastry, L. Froyen, J. D’Haen, M. K. Van Bael, H. Van den Rul, and J. Mullens, “Synthesis and mechanical and tribological characterization of alumina-yttria stabilized zirconia (YSZ) nanocomposites with YSZ synthesized by means of an aqueous solution-gel method or a hydrothermal route”, Ceram. Inter., 34(5), 1315 – 1325 (2008).

J. Y. Yu, X. D. Sun, Q. Li, and X. D. Li, “Preparation of Al2O3 and Al2O3 – ZrO2 ceramic foams with adjustable cell structure by centrifugal slip casting”, Mater. Sci. Eng. A, 476(1 – 2), 274 – 280 (2008).

C. X. Wang, Y. X. Zhang, and Q. Yu, ZrO 2 Composite Refractories [in Chinese] Metallurgical Industry Press, Beijing (2005).

Z. H. Zhou, Z. H. Wang, Y. Yi, J. S. Lan, S. Q Jiang, and G. Wang, “Experimental study on impact resistance and mechanical characteristics of low-temperature sintered Al2O3–ZrO2 composites with anti-sandwich structure”, Powder Technol., 256, 239 – 243 (2014).

W. Pabst, E. Gregorová, and I. Sedlárová, “Preparation and characterization of porous alumina – zirconia composite ceramics”, J. Eur. Ceram. Soc., 31(14), 2721 – 2731 (2011).

J. K. Han, F. Saitob, and B. T. Lee, Microstructures of porous Al2O3 – 50 wt. % ZrO2 composites using in-situ synthesized Al2O3 – ZrO2 composite powders,” Mater. Lett., 58(16), 2181 – 2185 (2004).

This work was supported by the Fundamental Research Funds for the Central Universities (grant No. N120402006), the Educational Commission of Liaoning Province of China (grant No. L2012079), the National Natural Science Foundation of China (grant No. 51274057) and the National High-Tech R&D Program (863 Program) of China (grant No. 2013AA030902).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Novye Ogneupory, No. 12, pp. 43 – 50, December, 2014.

1Polymer sponge is impregnated with ceramic slurry, dried, and sintered at a specific temperature.

Rights and permissions

About this article

Cite this article

Ma, B., Li, Y., Liu, G. et al. Effect of Production Process Parameters on Manufacture and Properties of Porous Ceramic Based on Al2O3 . Refract Ind Ceram 55, 573–580 (2015). https://doi.org/10.1007/s11148-015-9768-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9768-6