Abstract

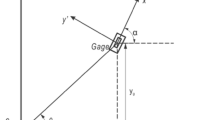

The fracture surface of a Charpy specimen contains information that can enrich the outcome of the test which at present is only the total energy absorbed. An automatic digital image processing technique based on the Horowitz and Pavlidis (1976) split-and-merge algorithm is proposed for partitioning Charpy fracture surface into regions with clear physical and mechanical meaning. Initial ductile fracture region, brittle zone and post-cleavage ductile shear region can be identified based on their relative brightness. Various geometrical properties of each region can then be easily calculated. The technique has been tested on a group of 773 broken Charpy samples made of TMCR and ship steels. The percentage of crystallinity calculated with the proposed technique agrees reasonably well with that obtained with visual inspection. Finally the potential of the technique and the ambiguity of the partition criterion based on surface light reflectivity are discussed.

Similar content being viewed by others

References

ASTM E 23 (1998). Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. Philadelphia: American Society for Testing and Materials.

Chen, S.Y., Lin, W.C. and Chen, C.T. (1991). Split-and-merge image segmentation based on localization feature analysis and statistical tests. CVGIP: Graphical Models and Image Processing 53(5), 457–475.

François, D. and Pineau, A. (eds.) (2002). From Charpy to present impact testing, papers selected from those presented at the Charpy Centenary Conference, 2-5 October 2001, Poitiers, France, Vol. 30 of Elsevier ESIS Series. Elsevier.

Gokhale, A.M. and Underwood, E.E. (1990). A general method for estimation of fracture surface roughness: Part I. Theoretical Aspects. Metallurgical Transactions A21(5), 1193–1199.

Haušild, P., Nedbal, I., Berdin, C. and Prioul, C. (2002). The influence of ductile tearing on fracture energy in the ductile-to-brittle transition temperature range. Materials Science and Engineering A335(1-2), 164–174.

Horowitz, S.L. and Pavlidis, T. (1976). Picture segmentation by a tree traversal algorithm. Journal of the Association for Computing Machinery 23(2), 368–388.

Hsiung, J.C. and Chou, Y.T. (1998). Fractal characterization of the fracture surface of a high-strength low-alloy steel. Journal of Materials Science 33(11), 2949–2953.

ISO 14556 (2000). International Standard. Steel-Charpy V-notch Pendulum Impact Test-Instrumented Test Method. International Organization for Standardization.

Mandelbrot, B.B. (1983). The Fractal Geometry of Nature. W.H. Freeman and Company, New York.

Russ, J.C. (2002). The Image Processing Handbook. CRC Press, 4 ed., Boca Raton, Florida, USA.

Su, Y. and Lei, W.S. (2000). Relationship between fracture toughness and fractal dimension of fracture surface of steel. International Journal of Fracture 106(3), L41–L46.

Thompson, A.W. and Knott, J.F. (1993). Micromechanics of brittle fracture. Metallurgical Transactions A 24(3), 523–534.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shterenlikht, A., Howard, I.C. Partition of Charpy fracture surface with digital image processing. International Journal of Fracture 129, 39–50 (2004). https://doi.org/10.1023/B:FRAC.0000038898.56538.d6

Issue Date:

DOI: https://doi.org/10.1023/B:FRAC.0000038898.56538.d6