Abstract

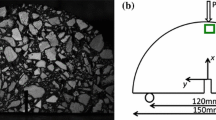

Digital image correlation (DIC) and the strain gage method are both widely used in characterizing the fracture mechanisms of materials. However, the quantitative comparisons of rock fracture parameters between the two methods have been studied insufficiently. In this paper, dynamic three-point bending impact tests were performed on white marble specimens using DIC and the strain gage method simultaneously. The complete cracking process was recorded by two high-speed cameras situated on either side of the specimen. The crack propagation velocities were obtained and the dynamic stress intensity factors (DSIFs) were calculated by both methods for analysis and comparison. The experimental results show that the crack propagation velocities almost remain constant during the cracking process, and the evolutions of strain values recorded by gages are consistent with the modified strain variations obtained theoretically. DSIFs calculated by DIC show good agreement with the results obtained from strain gages #1 to #4, while the size effect and the multiple stress waves interfere with the strain signals sensed in strain gage #5, causing a relatively larger deviation in the DSIF. In addition, the complete fracture process (including the variations in successive displacement and strain fields) can be obtained by the DIC method, while a rough changing trend in the DSIF can be given by the strain gage method with a limited number of strain gages.

Similar content being viewed by others

Abbreviations

- \(\left( {x,y} \right)\) :

-

Coordinate of the testing strain gage

- \(\mu\) :

-

Shear modulus

- \(\varepsilon_{\text{g}}\) :

-

Strain values recorded by gages

- \(\varepsilon_{\text{max} }\) :

-

Maximum value of modified strain curve

- \(A_{0} ,A_{1} ,B_{0}\) :

-

Constant parameters in three-parameter model

- \(c\) :

-

Crack propagation velocity

- \(\bar{c}\) :

-

Average crack propagation velocity

- \(c_{1} ,c_{2}\) :

-

Longitudinal and shear wave velocities, respectively

- \(\nu\) :

-

Poisson’s ratio

- \(\alpha\) :

-

Orientation of strain gage

- \(E_{\text{d}}\) :

-

Dynamic Young’s modulus

- \(\rho\) :

-

Density of the specimen

- \(y_{\text{g}}\) :

-

Perpendicular distance between gage and cracking path

- \(u,v\) :

-

Displacement components

- \(\Delta x,\Delta y\) :

-

Distances between point O and point P

- \(\frac{\partial u}{\partial x},\frac{\partial u}{\partial y},\frac{\partial v}{\partial x},\frac{\partial v}{\partial y}\) :

-

Gradients of displacement components

- \(f\left( {x,y} \right),g\left( {x,y} \right)\) :

-

Gray-level values for reference and deformed image

- \(\bar{f},\bar{g}\) :

-

Average gray-level value of subimage

- \(T_{x} ,T_{y} ,R\) :

-

Rigid-body translation and rotation

- \(K_{\text{I}}^{\text{d}}\) :

-

Dynamic mode I stress intensity factor

- DIC:

-

Digital image correlation

- DSIF:

-

Dynamic stress intensity factor

- PMMA:

-

Polymethyl methacrylate

- NSCB:

-

Notched semicircular bend

- ROI:

-

Region of interest

- AESP:

-

Acoustic emission signal parameter

References

Arakawa K, Mada T, Takahashi K (2000) Experimental analysis of dynamic effects in brittle fracture of PMMA. Key Eng Mater 183:265–270

Cheon DS, Jung YB, Park ES, Song WK, Jang HI (2011) Evaluation of damage level for rock slopes using acoustic emission technique with waveguides. Eng Geol 121(1–2):75–88

Corr D, Accardi M, Graham-Brady L, Shah S (2007) Digital image correlation analysis of interfacial debonding properties and fracture behavior in concrete. Eng Fract Mech 74(1–2):109–121

Dally JW, Sanford RJ (1987) Strain-gage methods for measuring the opening-mode stress-intensity factor K I. Exp Mech 27(4):381–388

Dally JW, Sanford RJ (1990) Measuring the stress intensity factor for propagating cracks with strain gages. J Test Eval 18(4):240–249

Durif E, Fregonese M, Réthoré J, Combescure A (2010) Development of a digital image correlation controlled fatigue crack propagation experiment. EPJ Web Conf 6:31012

Etheridge JM, Dally JW (1978) A three-parameter method for determining stress intensity factors from isochromatic fringe loops. J Strain Anal Eng Des 13(2):91–94

Gao G, Huang S, Xia K, Li Z (2015) Application of digital image correlation (DIC) in dynamic notched semi-circular bend (NSCB) tests. Exp Mech 55(1):95–104

Irwin GR (1957) Analysis of stresses and strains near the end of a crack traversing a plate. J Appl Mech 24:361–364

Joudon V, Portemont G, Lauro F, Bennani B (2014) Experimental procedure to characterize the mode I dynamic fracture toughness of advanced epoxy resins. Eng Fract Mech 126:166–177

Kim JS, Lee KS, Cho WJ, Choi HJ, Cho GC (2015) A comparative evaluation of stress–strain and acoustic emission methods for quantitative damage assessments of brittle rock. Rock Mech Rock Eng 48(2):495–508

Kirugulige MS, Tippur HV (2009) Measurement of fracture parameters for a mixed-mode crack driven by stress waves using image correlation technique and high-speed digital photography. Strain 45(2):108–122

Li BQ, Einstein HH (2017) Comparison of visual and acoustic emission observations in a four point bending experiment on Barre Granite. Rock Mech Rock Eng 50(9):2277–2296

Lin Q, Labuz JF (2013) Fracture of sandstone characterized by digital image correlation. Int J Rock Mech Min Sci 60:235–245

Liu W, Wang S, Yao X (2016) Experimental study on stress intensity factor for an axial crack in a PMMA cylindrical shell. Polym Test 56:36–44

Manogg P (1965) Schattenoptische Messung der spezifischen Bruchenergie wahrend des Bruchvorgangs bei Plexiglas. Phys Noncryst Solids 481–490

McNeill SR, Peters WH, Sutton MA (1987) Estimation of stress intensity factor by digital image correlation. Eng Fract Mech 28(1):101–112

Pan B, Wu D, Xia Y (2010a) High-temperature deformation field measurement by combining transient aerodynamic heating simulation system and reliability-guided digital image correlation. Opt Lasers Eng 48(9):841–848

Pan B, Lu Z, Xie H (2010b) Mean intensity gradient: an effective global parameter for quality assessment of the speckle patterns used in digital image correlation. Opt Lasers Eng 48(4):469–477

Rethore J, Gravouil A, Morestin F, Combescure A (2005) Estimation of mixed-mode stress intensity factors using digital image correlation and an interaction integral. Int J Fract 132(1):65–79

Sanford RJ (1989) Determining fracture parameters with full-field optical methods. Exp Mech 29(3):241–247

Sanford RJ (2003) Principles of fracture mechanics. Prentice Hall, Upper Saddle River

Sanford RJ, Dally JW (1979) A general method for determining mixed-mode stress intensity factors from isochromatic fringe patterns. Eng Fract Mech 11(4):621–633

Sanford RJ, Fourney WL, Chona R, Irwin GR (1981) Photoelastic study of the influence of non-singular stresses in fracture test specimens (no. NUREG/CR-2179; ORNL/Sub-7778/2). Oak Ridge National Lab, TN (USA)

Sarangi H, Murthy KSRK, Chakraborty D (2012) Optimum strain gage locations for accurate determination of the mixed mode stress intensity factors. Eng Fract Mech 88:63–78

Shukla A, Dally JW (2014) Experimental solid mechanics. College House Enterprises, LLC, Knoxville, pp 439–474

Shukla A, Agarwal BD, Bhushan B (1989) Determination of stress intensity factor in orthotropic composite materials using strain gages. Eng Fract Mech 32(3):469–477

Sutton MA, Orteu JJ, Schreier H (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer Science & Business Media, Berlin

Tippur HV (2010) Coherent gradient sensing (CGS) method for fracture mechanics: a review. Fatigue Fract Eng Mater Struct 33(12):832–858

Yao XF, Xu W (2011) Recent application of caustics on experimental dynamic fracture studies. Fatigue Fract Eng Mater Struct 34(6):448–459

Yao XF, Xu W, Xu MQ, Arakawa K, Mada T, Takahashi K (2003) Experimental study of dynamic fracture behavior of PMMA with overlapping offset-parallel cracks. Polym Test 22(6):663–670

Yao XF, Xu W, Bai SL, Yeh HY (2008) Caustics analysis of the crack initiation and propagation of graded materials. Compos Sci Technol 68(3–4):953–962

Yoneyama S, Morimoto Y, Takashi M (2006) Automatic evaluation of mixed-mode stress intensity factors utilizing digital image correlation. Strain 42(1):21–29

Yue Z, Song Y, Yang R, Yu Q (2017) Comparison of caustics and the strain gage method for measuring mode I stress intensity factor of PMMA material. Polym Test 59:10–19

Zhang R, He L (2012) Measurement of mixed-mode stress intensity factors using digital image correlation method. Opt Lasers Eng 50(7):1001–1007

Zhang QB, Zhao J (2014) A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech Rock Eng 47(4):1411–1478

Zhang J, Peng W, Liu F, Zhang H, Li Z (2016) Monitoring rock failure processes using the Hilbert–Huang transform of acoustic emission signals. Rock Mech Rock Eng 49(2):427–442

Zhang XP, Zhang Q, Wu S (2017) Acoustic emission characteristics of the rock-like material containing a single flaw under different compressive loading rates. Comput Geotech 83:83–97

Zhao Y, Zhang L, Wang W, Pu C, Wan W, Tang J (2016) Cracking and stress–strain behavior of rock-like material containing two flaws under uniaxial compression. Rock Mech Rock Eng 49(7):2665–2687

Zhao C, Zhou M, Zhao CF, Bao C (2018) Cracking processes and coalescence modes in rock-like specimens with two parallel pre-existing cracks. Rock Mech Rock Eng 2018:1–17

Acknowledgements

This research was supported by the National Key Research and Development Program (2016YFC060090X). The authors gratefully acknowledge the editorial staff of RMRE and the reviewers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yue, Z., Song, Y., Li, P. et al. Applications of Digital Image Correlation (DIC) and the Strain Gage Method for Measuring Dynamic Mode I Fracture Parameters of the White Marble Specimen. Rock Mech Rock Eng 52, 4203–4216 (2019). https://doi.org/10.1007/s00603-019-01830-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-01830-8