Abstract

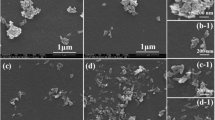

Porous hydroxyapatite (Hap) blocks were sintered at several temperatures and methyl methacrylate (MMA) grafted onto the surface in a 2-step heterogeneous system as a model example for surface modification. First, sintered porous Hap was modified with 2-methacryloyloxyethylene isocyanate (MOI) monomer in anhydrous dimethyl sulfoxide using di-n-butyltin (IV) dilaurate as a catalyst and hydroquinone as an inhibitor. Amount of the introduction of MOI monomer on porous Hap was 1.62 wt % at sintered temperature 800 °C, 0.68 wt % at it of 1000 °C, and 0.59 wt % at it of 1200 °C. Scanning electron microscopy (SEM) showed that porous Hap pore size and shape before and after MOI treatment were unchanged. Second, graft polymerization with MMA through the vinyl bond on porous Hap was conducted using α,α′-azobis isobutyronitrile (AIBN) as an initiator. Amount of Grafted PMMA on the MOI modified porous Hap was 2.84 wt % at sintered temperature of 800 °C, 6.97 wt % at it of 1000 °C, and 6.27 wt % at it of 1200 °C. MOI-modified and PMMA-grafted porous Hap were characterized using Fourier transform infrared (FT-IR) spectroscopy. The compressive strength of sintered porous Hap with grafted PMMA increased about 2.7–6.7 times compared to intact porous Hap. This 2-step surface modification on porous Hap is widely applicable to graft polymerization with vinyl polymer and conjugation with a protein or an oligopeptide, such as growth factor or an adhesion molecule, to improve Hap mechanical properties and functionality.

Similar content being viewed by others

References

I. Soten and G. A. Ozin, J. Mater. Chem. 9(3) (1999) 703.

L. C. Chow, J. Ceram. Soc. Japan. 99(10) (1991) 954.

M. Kikuchi, S. Itoh, S. Ichinose, K. Shinomiya and J. Tanaka, Biomaterials 22 (2001) 1705.

D. Walsh and S. Mann, in “Handbook of Biomimetics”, vol. S6, edited by Y. Osada (NTS Inc., Tokyo, Japan, 2000) 59, Chapter 1.

D. Walsh, T. Furuzono and J. Tanaka, Biomaterials 22 (2001) 1205.

P. Ylinen, M. Raekallio, T. Toivonen, K. Vihtonen and S. Vainonpaa, J. Oral Maxillofac. Surg. 49 (1991) 1191.

R. W. Bucholz, A. Carlto and R. Holmes, Clin. Orthop. 240 (1989) 53.

T. M. Chu, D. G. Orton, S. J. Hollister, S. E. Feinberg and J. W. Halloran, Biomaterials 23(5) (2002) 1283.

S. Joschek, B. Nies, R. Krotz and A. Goferich, ibid. 21(16) (2000) 1645.

W. J. Bigham, P. Stanley, J. M. Cahill Jr, R. W. Curran and A. C. Perry, Ophthal. Plast. Reconstr. Surg. 15(5) (1999) 317.

B. K. Vaughn, A. V. Lombardi Jr and T. H. Mallory, Semin. Arthoplasty. 2(4) (1991) 309.

G. Jiang and D. Shi, J. Biomed. Mater. Res. 43(1) (1998) 77.

A. M. P. Dupraz, J. R. De Wijn, S. A. T. Van Der Meer and K. De Groot, ibid. 30 (1996) 231.

K. Nishizawa, M. Toriyama, T. Suzuki, Y. Kawamoto, Y. Yokugawa and F. Nagata, Chem. Soc. Jpn. 1 (1995) 63.

J. C. Behiri, M. Braden, S. Khorasani, D. Wiwattanadate and W. Bonfield, in “Bioceramics”, vol. 4, edited by W. Bonfield, G. W. Hastings and K. E. Tanner (Elsevier Science, London, 1991) 301.

D. N. Misra, J. Dent. Res. 12 (1985) 1405.

Q. Liu, J. R. De Wijn, M. Van Toledo, D. Bakker and C. A. Van Blitterswijk, J. Mater. Sci.: Mater. Med. 7 (1996) 551.

V. Delpech and A. Lebugle, Clin. Mater. 5 (1990) 209.

J. Dandurand, V. Delpech, A. Lebugle, A. Lamure and C. Lacabanne, J. Biomed. Mater. Res. 24 (1990) 1377.

Q. Liu, J. R. De Wijn and C. A. Van Blitterswijk, ibid. 40(3) (1998) 490.

R. Labella, M. Braden and S. Deb, Biomaterials 15 (1994) 1197.

L. Yubao, C. P. A. T. Klein, J. De Wijn and S. Van De Meer, J. Mater. Sci.: Mater. Med. 5 (1994) 263.

M. R. Thomas, J. Coat. Technol. 55 (1983) 55.

A. Bayer, Ann. 245 (1888) 103.

H. Meyer, Ber. 28 (1895) 2965.

R. Meyer and E. Hartmann, ibid. 38 (1905) 3956.

T. Furuzono, K. Ishihara, N. Nakabayashi and Y. Tamada, Biomaterials. 21 (2000) 327.

G. T. Hermanson, “Bioconjugate Techniques” (Academic Press, Inc., New York, 1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matsuda, A., Furuzono, T., Walsh, D. et al. Surface modification of a porous hydroxyapatite to promote bonded polymer coatings. Journal of Materials Science: Materials in Medicine 14, 973–978 (2003). https://doi.org/10.1023/A:1026302700149

Issue Date:

DOI: https://doi.org/10.1023/A:1026302700149