Abstract

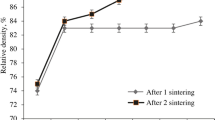

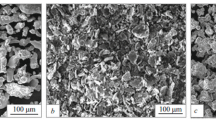

The effect of reduction annealing for powder obtained from cast iron shavings on powder specimen properties is studied. An approximate mechanism is suggested for the oxidation-reduction process during annealing of cast iron powder. An increase in annealing temperature leads to an increase in carbon gasification rate and change in absolute powder weight. Prior reduction annealing for cast iron powder improves its compactability, and increases the mechanical properties of sintered material. The best mechanical properties were obtained for specimen made from cast iron powder reduced at 1000°C. Alloying an iron-cast iron charge with 3 mass% of nickel-chromium alloy leads to a marked improvement in the mechanical properties of a sintered composite.

Similar content being viewed by others

REFERENCES

A. T. Mamedov, N. A. Aliev, and T. A. Bakhyshev, “Structure and properties of composite sintered material of the iron-cast iron type,” Poroshk. Metall., No. 1, 60–63 (1993).

A. T. Mamedov, N. A. Aliev, and A. A. Guliev, “Experience of processing cast iron waste shavings to powder,” Poroshk. Metall., No. 2, 94–98 (1993).

V. N. Androsev, A. T. Nikitin, V. P. Prikoptev, et al., “Use of engineering production waste in powder metallurgy,” “Practice of developing and introducing new advanced methods of powder metallurgy and coating applications,” (Chelyabinsk, May 22–23, 1986), Ural Sci.-Res. Pipe Inst., Chelyabinsk (1986).

T. G. Nikolaev, V. A. Kachanov, L. I. Armyanova, and S. B. Sorin, “Decarburizing of cast iron articles in a gas atmosphere,” Chernaya Metallurgiya, No. 3, 19–23 (1980).

A. T. Mamedov and A. A. Guliev, “Wear-resistant materials synthesized from a mixture of cast iron and steel waste shavings,” “Tribological problems of oil equipment,” (Baku, February 21–26, 1996), Baku (1996).

E. I. Androshek and D. P. Khudokormov, “Preparation of high-strength articles from cast iron powder,” in: Powder Metallurgy: Proc. VIII All-Union Conf. on Advanced Production Methods for Powder Articles, Minsk (1976).

A. T. Mamedov and A. A. Guliev, “Preparation of powder from cast iron shavings and features of manufacturing articles from them. II. Features of preparing powder articles, their structure and properties,” Poroshk. Metall., No. 9, 4–10 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mamedov, A.T. Reduction Annealing for Cast Iron Powder and Its Effect on Sintered Antifriction Material Properties. Powder Metallurgy and Metal Ceramics 42, 202–205 (2003). https://doi.org/10.1023/A:1024774218853

Issue Date:

DOI: https://doi.org/10.1023/A:1024774218853