Abstract

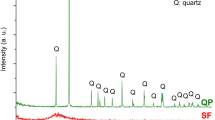

The effect of high temperature on the residual properties of plain and polypropylene fiber reinforced Portland cement paste was investigated. Plain Portland cement paste having water/cement ratio of 0.32 was exposed to the temperatures of 20, 50, 75, 100, 120, 150, 200, 300, 400, 440, 520, 600, 700, 800, and 1000°C. Paste with polypropylene fibers was exposed to the temperature of 20, 120, 150, 200, 300, 440, 520, and 700°C. Residual compressive and flexural strengths were measured and pore structure of the pastes was determined by mercury porosimetry. The total porosity of the pastes more than doubled when exposure temperature was increased from 20°C to 1000°C. The gradual heating coarsened the pore structure. The most notable coarsening of pore structure—together with strength loss—took place at exposure temperatures exceeding 600°C. At 600°C, the residual compressive capacity (fc600°C/fc20°C) was still over 50% of the original. Strength loss due to the increase of temperature was not linear. Polypropylene fibers produced a finer residual capillary pore structure, decreased compressive strengths, and improved residual flexural strengths at low temperatures. According to the tests, it seems that exposure temperatures from 50°C to 120°C can be as dangerous as exposure temperatures 400–500°C to the residual strength of cement paste produced by a low water cement ratio.

Similar content being viewed by others

References

J. Piasta, “Heat Deformations of Cement Paste Phases and the Microstructure of Cement Paste,” Materials and Structures: Research and Testing, vol. 17,no. 102, 1984, pp. 415–420.

U-M. Jumppanen, U. Dieterichs, and K. Hinrichsmeyer, “Material Properties of F-Concrete at High Temperatures,” Research Reports 452, Technical Research Centre of Finland, Espoo, 1986.

F.S. Rostásy, R. Weiss, and G. Wiedemann, “Changes of Pore Structure of Cement Mortars Due to Temperature,” Cement and Concrete Research, vol. 10,no. 2, 1980, pp. 157–164.

R. Sarshar and G.A. Khoury, “Material and Environmental Factors Influencing the Compressive Strength of Unsealed Cement Paste and Concrete at High Temperatures,” Magazine of Concrete Research, vol. 45,no. 162, 1993, pp. 51–61.

R. Sarshar, “Effect of Elevated Temperatures on the Strength of Different Cement Pastes and Concretes,” Ph.D. Thesis, University of London, 1989.

W.P.S. Dias, G.A. Khoury, and P.J.E. Sullivan, “Mechanical Properties of Hardened Cement Paste Exposed to Temperatures up to 700°C (1292°F),” ACI Materials Journal, vol. 87,no. 2, 1990, pp. 160–166.

G.A. Khoury, “Compressive Strength of Concrete at High Temperatures: A Reassessment,” Magazine of Concrete Research, vol. 44,no. 161, 1992, pp. 291–309.

U. Diederichs, U-M. Jumppanen, and V. Penttala, “Behavior of High Strength Concrete at High Temperatures,” Report 92, Helsinki University of Technology, Faculty of Civil Engineering and Surveying, Concrete Technology, Espoo, 1989.

A.M. Alhozaimy, P. Soroushian, and F. Mirza, “Mechanical Properties of Polypropylene Fiber Reinforced Concrete and the Effects of Pozzolanic Materials,” Cement and Concrete Composites, vol. 18,no. 2, 1996, pp. 85–92.

G.D. Manolis, P.J. Gareis, A.D. Tsonos, and J.A. Neal, “Dynamic Properties of Polypropylene Fiber-Reinforced Concrete Slabs,” Cement and Concrete Composites, vol. 19,no. 4, 1997, pp. 341–349.

N. Banthia and A. Dubey, “Measurement of Flexural Toughness of Fiber-Reinforced Concrete Using Novel Technique—Part 2: Performance of Various Composites,” ACI Materials Journals, vol. 97,no. 1, 2000, pp. 3–11.

M.L. Allan and L.E. Kukacka, “Strength and Durability of Polypropylene Fiber Reinforced Grouts,” Cement and Concrete Research, vol. 25,no. 3, 1995, pp. 511–521.

A. Nishida, N. Yamazaki, H. Inoue, U. Schneider, and U. Diederichs, “Study on the Properties of High Strength Concrete with Short Polypropylene Fiber for Spalling Resistance,” in Proceedings of the International Conference on Concrete under Severe Conditions, CONSEC '95, Sapporo, Japan, 1995, pp. 511–521.

T.A. Hammer, Spalling Reduction through Material Design, Trondheim, Norway, SINTEF, Report STF70 A95024, 1995, 32 pp.

L. Zhang and F.P. Glasser, “Critical Examination of Drying Damage to Cement Pastes,” Advances in Cement Research, vol. 12,no. 2, 2000, pp. 79–88.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Komonen, J., Penttala, V. Effects of High Temperature on the Pore Structure and Strength of Plain and Polypropylene Fiber Reinforced Cement Pastes. Fire Technology 39, 23–34 (2003). https://doi.org/10.1023/A:1021723126005

Issue Date:

DOI: https://doi.org/10.1023/A:1021723126005