Abstract

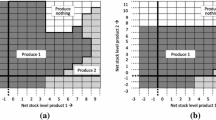

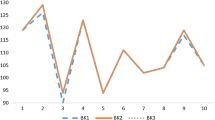

This paper studies the scheduling problem for two products on a single production facility. The objective is to specify a production and setup policy that minimizes the average inventory, backlog, and setup costs. Assuming that the production rate can be adjusted during the production runs, we provide a close form for an optimal production and setup schedule. Dynamic programming and Hamilton–Jacobi–Bellman equation is used to verify the optimality of the obtained policy.

Similar content being viewed by others

References

J.A. Buzacott and I.A. Ozkarahan, One-and two-stage scheduling of two products with distributed inserted idle time: The benefits of a controllable production rate, Naval Research Logistics Quarterly 30 (1983) 675–696.

F. Cheng, H. Yan and J. Yang, Production scheduling of continuous flow lines with setup times and costs, Production and Operations Management 7(4) (1998) 387–401.

S.E. Elmaghraby, The Economic Lot Scheduling Problem (ELSP): Review and extension, Management Science 24(6) (1978) 587–598.

M.E. Hafsi and S.X. Bai, The common cycle economic lot scheduling problem with backorders: Benefits of controllable production rates, Department of Industrial and Systems Engineering, Univ. of Florida, Research Report 95–01 (1994).

M.E. Hafsi and S.X. Bai, Optimal production control of a dynamic two-product manufacturing system with setup cost and setup times, Department of Industrial and Systems Engineering, Univ. of Florida, Research Report 95–01 (1995).

I. Moon, G. Gellego and D. Simchi-Levi, Controllable production rates in a family production context, International Journal of Production Research 29 (1991) 2459–2470.

S.P. Sethi and X.Y. Zhou, Optimal Feedback controls in deterministic dynamic two-machine flowshops, Operations Research Letters 19 (1996) 225–235.

E.A. Silver, Deliberately slowing down output in a family production context, International Journal of Production Research 28 (1990) 17–27.

J. Yang, Deterministic production and setup policies in continuous manafacturing systems, Ph.D. thesis, The Chinese University of Hong Kong (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yang, J., Yan, H. & Taksar, M. Optimal Production and Setup Scheduling: A One-Machine, Two-Product System. Annals of Operations Research 98, 291–311 (2000). https://doi.org/10.1023/A:1019268710146

Issue Date:

DOI: https://doi.org/10.1023/A:1019268710146