Abstract

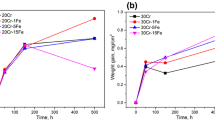

Electrodeposited Ni-La2O3composite films with nanometer-sizeLa2O3 oxide inclusions werefabricated by the codeposition of nickel withLa2O3 particles. The comparativeoxidation behavior in air at 900 and 1000°C of nickel coated with theNi-La2O3 composite and films withand without nickel-plating was studied by TGA, AE,SEM/EDX, EPMA, and TEM/EDX. In general, theNi-La2O3 composite-coated nickelhad the slowest rate and the best resistance tothermal cycling. AE tests revealed that cracking eventsin NiO scales on Ni-La2O3composite-coated nickel was significantly reduced incomparison to that of the scale on nickel-coated nickel during thermalcycling at 900°C. SEM investigation showed that theLa2O3-free NiO scale was composedof outer coarse columnar grains and inner equiaxed ones.By contrast, the scale on the Ni-La2O3composite-coated nickel consisted of only fine equiaxedNiO grains. The scale on theLa2O3-free samples wascharacterized by cracks that originated at thescale-substrate interface and spanned the scale thickness. By contrast,no scale cracks formed at theLa2O3-doped NiO scale-substrateinterface, but small voids were created at the triplepoints of the grain boundaries of NiO. In the La2O3-doped NiOscale, segregation of La ions to the NiO grainboundaries near the scale-surface was observed by EDXmicroanalyses in the TEM. It is believed that the Laions segregated at the grain boundaries of NiO led to an increase in thecohesion between nickel oxides and in a reduction of thescaling rate and the formation of scale with fineequiaxed crystal structure by blocking the outward and lateral growth of scale. The latter was dueto the predominant outward diffusion of nickel along NiOgrain boundaries being inhibited effectively by thesegregated La ions. The mechanism of the effect of the added La2O3particles on the nickel electrodeposits is discussed indetail.

Similar content being viewed by others

REFERENCES

D. P. Whittle and J. Stringer, Phil. Trans. R. Soc. London A295, 309 (1980).

D. P. Moon, Mater. Sci. Technol. A120, 754 (1989).

B. Pieraggi and R. A. Rapp, J. Electrochem. Soc. 140, 2844 (1993).

A. Strawbridge and R. A. Rapp, J. Electrochem. Soc. 141, 1905 (1994).

B. A. Pint, Oxid. Met. 45, 1 (1996).

A. Atkinson and R. I. Taylor, and P. D. Goode, Oxid. Met. 13, 519 (1979).

A. Atkinson, R. I. Taylor, and A. E. Hughes, Phil. Mag. A45, 823 (1982).

A. Atkinson and D. J. Smart, J. Electrochem. Soc. 135, 2286 (1988).

A. Atkinson, Oxid. Met. 28, 353 (1987).

F. N. Rhines and R. G. Connell, Jr., J. Electrochem. Soc. 124, 1122 (1977).

S. Mrowec, Corros. Soc. 7, 563 (1967).

A. G. Evans, D. Rajdev, and D. L. Douglass, Oxid. Met. 4, 151 (1972).

P. Kofstad, Oxid. Met. 24, 265 (1985).

A. A. Moosa, S. J. Rothman, and L. J. Nowicki, Oxid. Met. 24, 115 (1985).

D. P. Moon, Oxid. Met. 32, 47 (1989).

P. J. George, M. J. Bennett, H. E. Bishop, and G. Dearnaley, Mater. Sci. Eng. A116, 111 (1989).

F. Czerwinski and W. W. Smeltzer, J. Electrochem. Soc. 140, 2606 (1993).

F. Czerwinski and W. W. Smeltzer, Oxid. Met. 43, 25 (1995).

F. K. Sauter, J. Electrochem. Soc. 110, 557 (1963).

E. C. Kedward, Metallurgia 79, 225 (1969).

J. Foster, Trans. Inst. Met. Finish. 50, 207 (1972).

N. Guglielmi, Trans. Inst. Met. Finish. 119, 1009 (1972).

D. W. Snaith and P. D. Groves, Trans. Inst. Met. Finish. 55, 136 (1977).

A. S. Khanna, B. B. Jha, and B. Raj, Oxid. Met. 23, 159 (1985).

A. S. Khanna, B. B. Jha, and B. Raj, Oxid. Met. 27, 95 (1986).

Y. Zhang and D. Zhu, and D. A. Shores, Acta. Metallur. Mater. 43, 4015 (1995).

X. Peng, Z. Tang, T. Li, and W. Wu, Oxid. Met. submitted for publication.

X. Peng, Ph.D. thesis, Institute of Corrosion and Protection of Metals, Chinese Academy of Sciences, 1995.

J. K. Dennis and T. E. Such, Nickel and Chromium Plating, 2nd edn. (Butterworths, London, 1986).

P. W. Tasker and D. M. Duffy, Phil. Mag. A47, L45 (1983).

D. M. Duffy and P. W. Tasker, Phil. Mag. A54, 759 (1986).

C. Haanappel, T. Fransen, B. Geerdink, P. J. Gellings, and M. F. Stroosnijder, Oxid. Met. 35, 405 (1991).

R. J. Hussey, P. Paiacovou, J. Sehen, D. F. Mitchell, and M. J. Graham, Mater. Sci. Eng. A120, 147 (1989).

Handbook of Chemistry and Physics, R. C. Weast, ed. (CRC Press, Boca Raton, FL, 1979), p. B102.

Rights and permissions

About this article

Cite this article

Peng, X. Effect of La2O3 Particles on the Oxidation of Electrodeposited Nickel Films. Oxidation of Metals 51, 291–315 (1999). https://doi.org/10.1023/A:1018874707526

Issue Date:

DOI: https://doi.org/10.1023/A:1018874707526